According to the provisions in the urban road management law of each district, no excavation shall be allowed within 5 years after the construction, reconstruction and expansion of the urban roads are put into use, and within 3 years after the completion of the major repair roads. If a new technology can be found to rapidly reinforce the road base without excavation, the grouting technology of ground polymer emerges as The Times require. Strengthening and reinforcing of the ground polymer applied to the base disease, “ Road doctor ” Overcome the limitations of previous studies, through their own testing power, material research, equipment research and development, to provide road managers with a rapid solution.

With the increase of road mileage and traffic volume year by year, the demand for road performance is higher and higher. In the actual use process, due to rain erosion and the effect of Vehicle load, the strength of the pavement base decreases, and even subsidence, cracking and other phenomena occur, which affect the service life of the road.

Traditional craft dig in filling way to rebuild the road surface structure, but the construction equipment, low working efficiency, long construction period, high cost, large traffic impact, in order to overcome these problems, the yingda independent research and development of trenchless type of polymer minimally invasive reinforcement reinforcement technology, can effectively restore pavement strength, become indispensable to reinforce subgrade and grass-roots good method.

concept

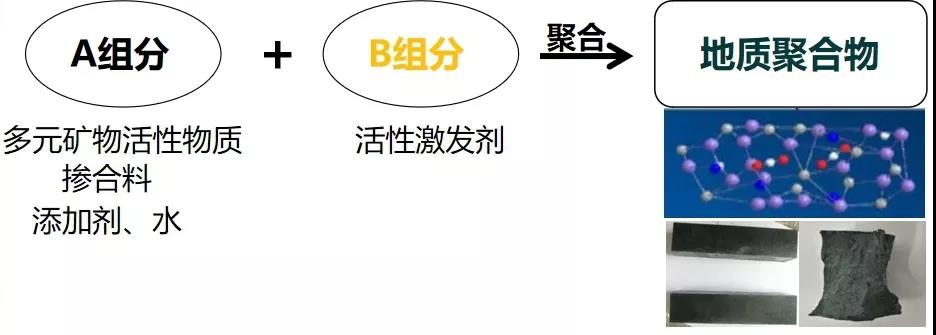

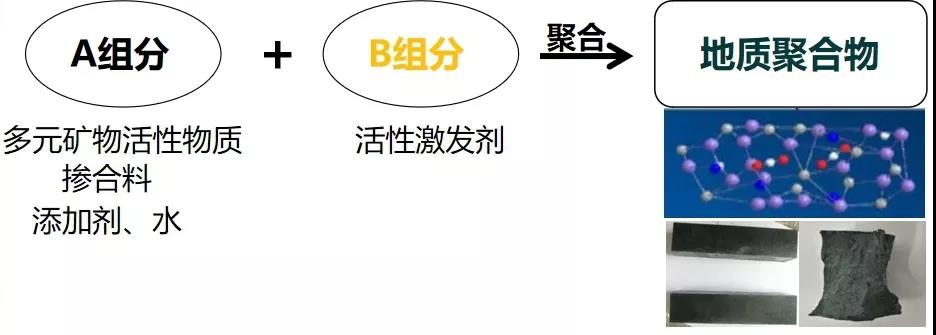

Polymer grouting technology, refers to the special equipment, drilling and grouting to geological polymer slurry injection pavement base and subgrade, the slurry in the role of pressure, through the splitting, compaction and filling, permeability and so on the many kinds of principle, squeeze out the water and air inside the pavement structure crack, again through chemical bond, ion exchange, and a variety of action such as inert packing to cementing loose body as a whole, form a high strength, waterproof performance and chemical stability good stone body, improve the bearing capacity of the road. Geopolymer grouting material, which plays A key role, is an alkali-activated cementitious material. The mixture reaction of the two components A and B in the figure below is used to produce inorganic materials with dense polymer network structure.

properties of geopolymer grouting material

The grouting material of ground polymer itself has good stability, great strength and good flow performance of slurry. Under pressure, it has strong permeability, which can improve the compactness and water stability of base and roadbed, increase the stability of roadbed and pavement, and extend the service life of pavement.

Schematic diagram of grouting process of geopolymer

Application scope of geopolymer grouting process:

(1) treatment of pavement base and roadbed diseases and reinforcement of pavement structure;

(2) building foundation reinforcement.

3 detection first

Inda geotechnical polymer reinforcement technology covers detection, materials, equipment, construction, not only in its outstanding advantages of geotechnical polymer materials, but also has advanced detection equipment and construction equipment, to provide targeted road structure reinforcement and reinforcement solutions.

(1) FWD test pavement bearing capacity

The structural strength of pavement was evaluated by FWD.

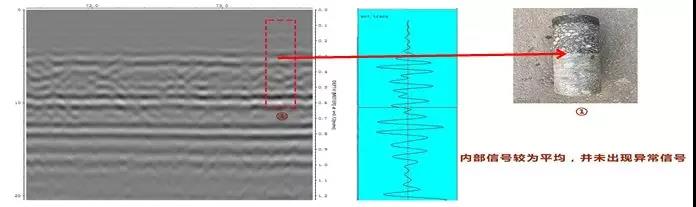

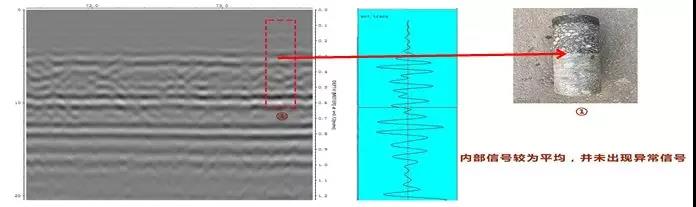

(2) detection of deep recessive diseases by GPR

The application of ground penetrating radar, combined with typical location coring, can accurately determine the type, range and depth of the disease, optimize the grouting process parameters, and improve the grouting effect.

4 grouting material

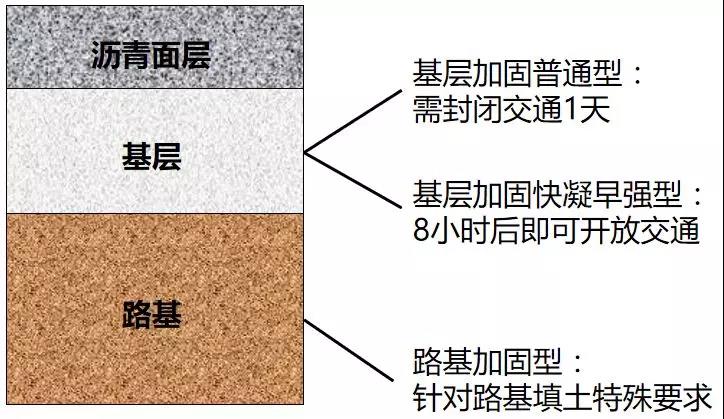

1. Different attenuation layers, different geopolymer materials

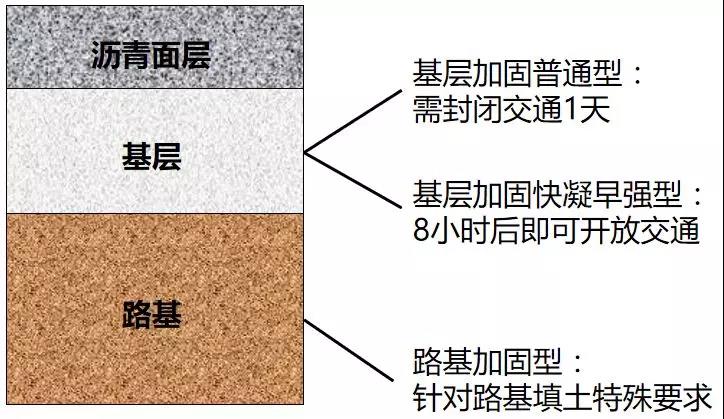

According to different grouting stratum and different demand of traffic opening time, “ Road doctor ” Different types of geopolymer grouting materials were developed, including ordinary type of base reinforcement, fast setting early strength type of base reinforcement and roadbed reinforcement type.

Multi-type grouting material

2. Yingda geotechnical polymer grouting material has prominent advantages

Different from other grouting processes, yingda geopolymer grouting has the following unique advantages:

(1) the grout is stable and no bleeding

Traditional cement grouting material is easy to be layered and has poor uniformity. Yingda geotechnical polymer grouting material is not stratified, not bleeding, slurry stability, uniformity is good.

(2) ultra-high liquidity, strong permeability

Slurry initial fluidity 11-12s, viscosity similar to edible oil; After standing for 30min, the fluidity still has 15s. Under low grouting pressure (less than 1MPa), it can be filled, infiltrated and squeezed into micro voids to improve the overall strength.

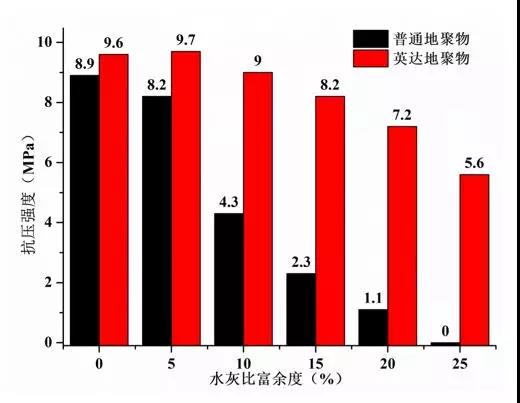

(3) strong water retention ability

Inda geopolymer material contains crystallization factor, which can ensure the mechanical property stability of grouting material and grouting reinforcement effect under the condition of over-wet condition.

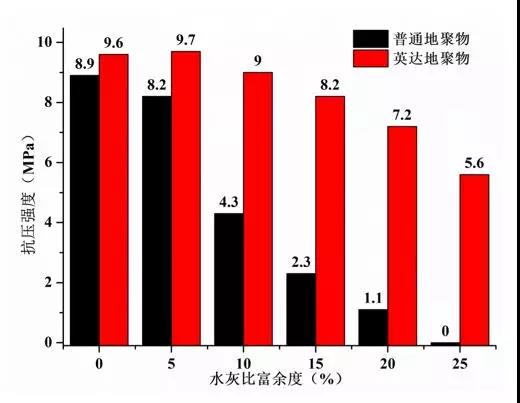

Comparison diagram of compressive strength of geopolymer materials under different water-cement ratio abundance

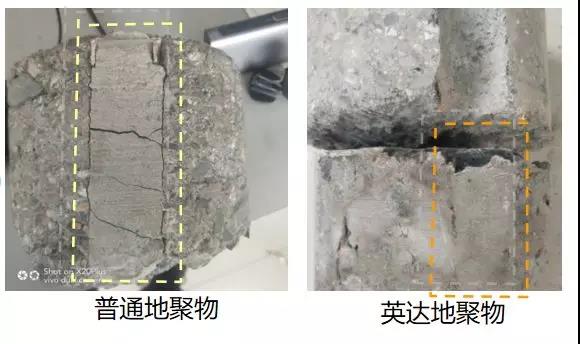

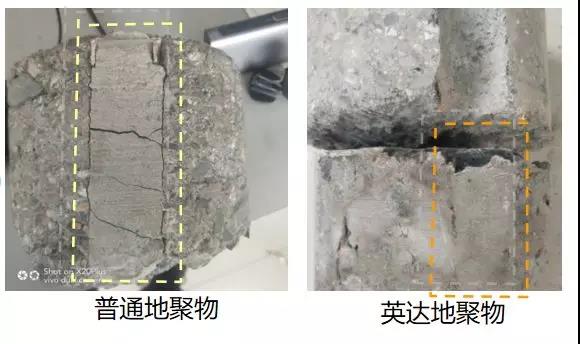

(4) excellent crack resistance under dry conditions

Common ground polymer materials have natural defects, easy to dehydrate and crack under natural environment or humidity less than 75%. Inda dipolymer materials add high polymer crack resistant fiber to ensure the crack resistance and strength of materials under dry conditions (low humidity). The core sample taken out of yingda geotechnical polymer grouting material can be placed in the air for 1 month without cracking.

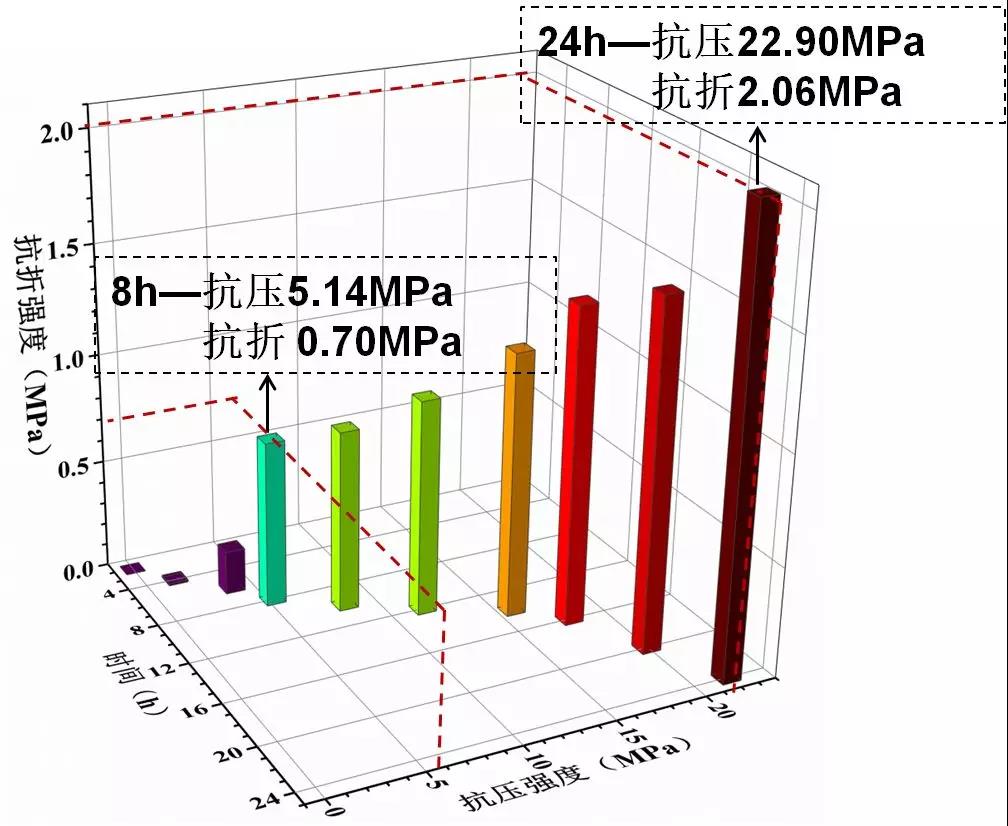

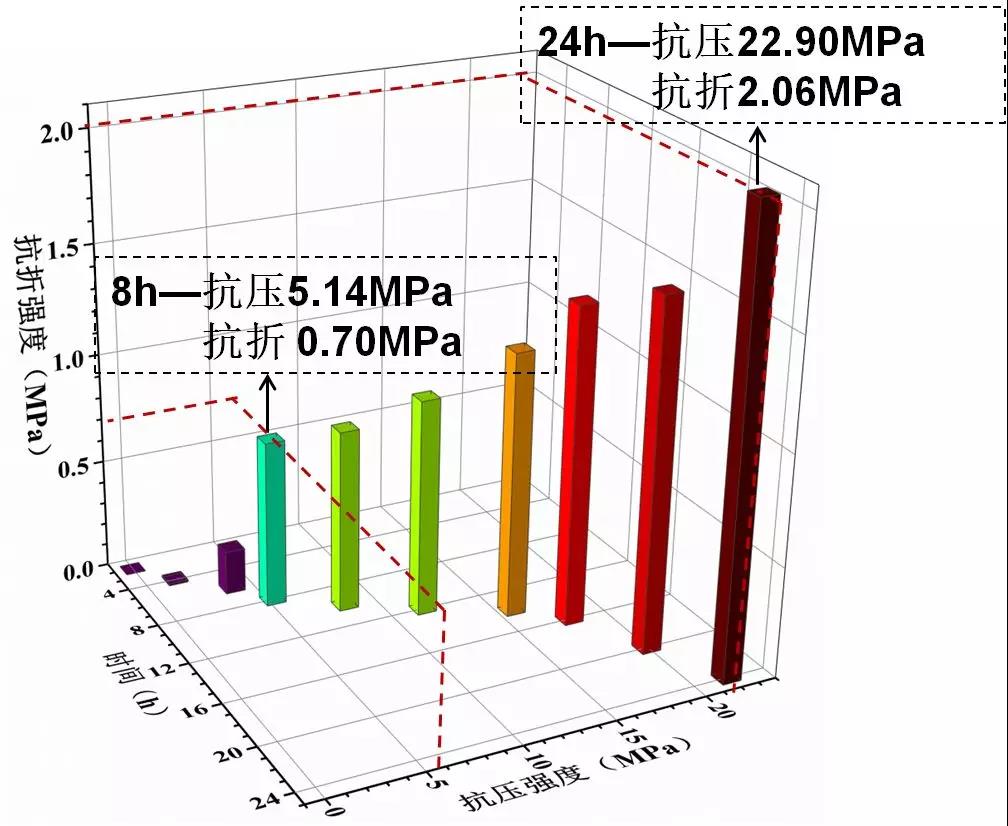

(5) quick coagulation early strong, short health time

The test data showed that the compressive strength of inda polymer material reached above 5MPa within 8 hours, above 20MPa within 24 hours, and above 2MPa at the same time. After grouting, the traffic can be opened quickly with little interference to the traffic.

Changes of flexural strength and compressive strength of inda geopolymer over time

(6) strong ability to consolidate loose bodies

Active activator in yingda geopolymer material can activate inert silicon and aluminum oxides in semi-rigid base or subgrade filling soil, react with mineral active substances in slurry, form stone body and improve road bearing capacity.

5 self-developed equipment

1. Dust-free minimally invasive punching machine

The intelligent dust-free minimally invasive punching machine is used to punch the pavement quickly, with fast punching speed and accurate depth control.

2. Integrated dual-liquid grouting machine

The equipment adopts double-liquid grouting, which is easy to operate and has high construction efficiency. Components A and B prepared in advance are mixed and stirred for 1-2min to produce the material for grouting. The construction speed is 3-5 times faster than conventional grouting.

6 application case

Jin tan in December, is in the severe winter, in the traffic busy huayang south road, jin tan district municipal management office introduced “ Road doctor ” The maintenance of huayang south road, only 5 days time, so that the old road with a new appearance, to the winter cold gold altar covered with a new coat.

Old road surface, mesh crack, repair

The new road is

Can in such a short period of time to huayang south road maintenance new, the highway doctor this time is what kind of superb technology?

After more than ten years of traffic operation, there are not only surface diseases such as hemp, crack, aging and repair, but also local root diseases such as net crack/subsidence and grouting.

For the treatment of local grass-roots diseases, the traditional treatment methods are digging and backfilling new materials, which will cause many troubles such as long construction period and great influence of traffic.

To this end, highway doctors to the case, write a new prescription, successfully solved the traditional grassroots treatment faced by the problem.

remedy

Overall plan: firstly, test the pavement, and then design different drilling depths according to the test data for the dominant net crack subsidence, grouting, vertical and horizontal cracks and recessive local sections with weak structural strength, grouting reinforcement after drilling, and finally geothermal regeneration for the asphalt pavement as a whole.

(1) base reinforcement: trenchless minimally invasive reinforcement technology of geopolymer

Surface regeneration: shaping and paving geothermal regeneration process.

Then how did the full-depth green road maintenance technology combining minimally invasive reinforcement with geothermal regeneration be implemented on huayang south road?

Base reinforcement: minimally invasive reinforcement of trenchless geopolymer

Hole distribution and drilling: delimit the treatment scope of the disease and control the hole spacing accurately. For the net crack subsidence, grouting, cracks and other areas that need grouting, adopt dust-free minimally invasive drilling machine for drilling, with fast drilling speed and controllable depth.

Custom dust-free drill is working

Grouting: the integrated dual-liquid grouting machine is used for minimally invasive reinforcement of road base and roadbed.

The self-developed double-fluid grouting machine is grouting

Sealing hole: after drawing out the grouting hole after filling the slurry, cork seal should be adopted in time to ensure that the hole is filled tightly.

Observation and hole sealing

After the construction of huayang south road is completed with the above minimally invasive reinforcement technology of ground polymer, the road will be cleaned and closed for 8 hours to open the traffic.

Before construction, the deflection value of the road surface at the grouting position exceeded 40 (0.01mm). After grouting, the deflection value of the road surface decreased by 20-30% on average, and the strength of the road structure was greatly improved.

Surface regeneration: geothermal regeneration

Through the above trenchless geopolymer reinforcement technology, after grouting reinforcement was carried out on the base of huayang south road, the asphalt surface layer was recycled by the environmentally friendly, energy-saving and efficient shaping and paving geothermal regeneration process.

Shaping and paving geothermal regeneration process: a very small amount of new asphalt mixture is directly spread on the hot reclaimed pavement by heating, adding regenerant, raking and recycling, and the new and old asphalt mixture is compacted and formed once to realize the old road “ Regeneration & throughout; , the utilization rate of the original pavement asphalt mixture is up to 100%, the circulation chain is the shortest, the quality is excellent, and there is no dust and no solid waste discharge during the whole construction process.

in the construction of geothermal regeneration

This combination of geothermal regeneration by yingda and minimally invasive reinforcement by yingda dimer not only achieves the recycling of asphalt surface layer, but also avoids a series of problems caused by road base excavation.

Asphalt surface and base materials are the original value of the original level of recycling and reuse, save resources, protect the environment;

(2) road base treatment and asphalt surface layer seamless connection, to achieve rapid maintenance, shorten the construction cycle of more than 1/2, greatly reduce the impact of road maintenance on traffic;

Reduced the cost of road maintenance, energy conservation and environmental protection, reduce the damage to the ecological environment due to road maintenance.