Made at the 20th National Congress of the CPC“Promote green development,Promote the harmonious coexistence of man and nature”A major deployment,It puts forward new and higher requirements for the construction of ecological civilization and the protection of ecological environment.。Huairou District of Beijing aims to improve the internal and external transportation network,Focus on building a perfect system、Efficient and practical、Smart Green、Safe and reliable modern basic transportation system,Comprehensively enhance the comprehensive carrying capacity of the city、Operational efficiency and functional quality。

Recently,Wirtgen based on synchronous paving W 380 CR The Cold Regeneration Team succeeded in Huairou District, Beijing.GCold In-place Recycling of Foamed Asphalt in Huairou Section of National Highway 335,It fully embodies low carbon.、Environmental protection、Demonstration effect of saving resources。

Project overview

GThe 335 Huairou section is part of National Highway 335.,The starting point is Baoshan Temple Village,The destination is Caishudian Village。Long traffic time of the original road surface,Cracks have appeared、Block cracks and other pavement diseases,It seriously affects driving comfort and safety.,AndThe longitudinal slope of Huairou section is as high as 6.75%,The road width is only 7 m,Proportion of heavy traffic(Including Vehicles of more than 100 tons)Over 70%,Minimum radius of circular curve 30 m,In the case of not being able to break off relations,How to ensure rapid maintenance,Quickly open to traffic,Ensure long-term road performance after opening to traffic,It is a key consideration.。

Go around the mountain、Construction section with many bends and steep slopes

In order to solve these problems simultaneously,,Relevant leaders and responsible persons of Huairou Highway Bureau have conducted sufficient research work.,And organized the relevant expert demonstration.,In order to better respond to the national and regional calls for low-carbon roads and circular economy.,But also for new materials.、Popularization and application of new processes and technologies,Finally, it was decided to adopt the foam asphalt cold in-place recycling technology based on synchronous paving by Wirtgen for pavement maintenance.。

Original pavement condition

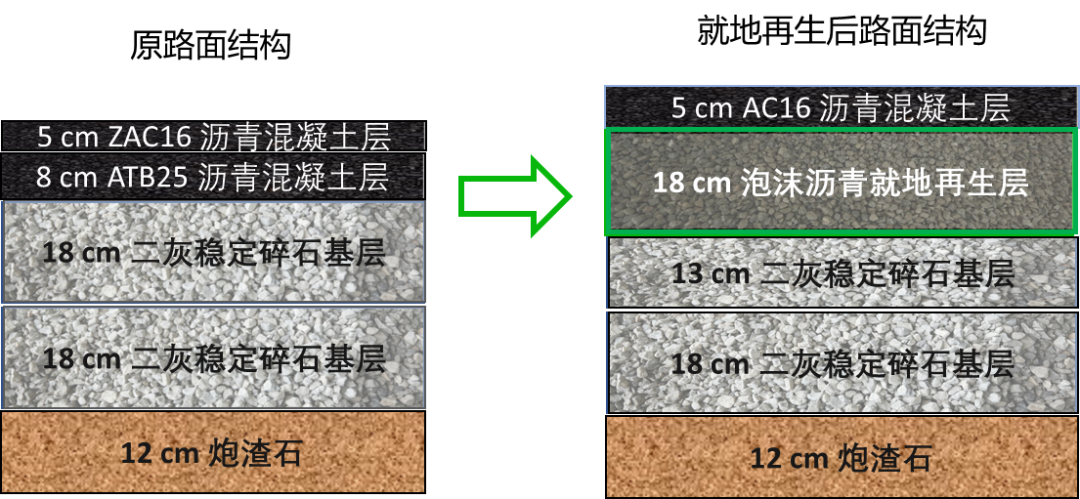

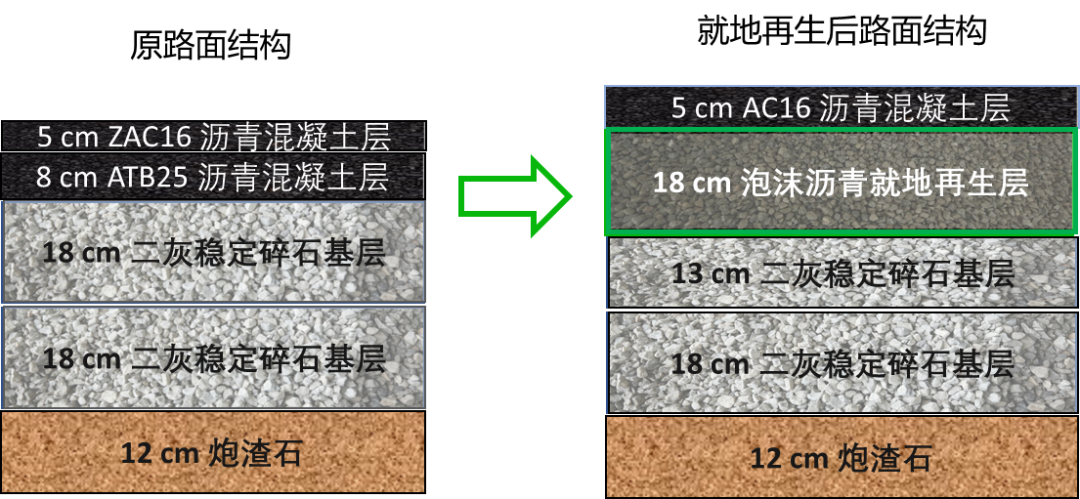

Before the implementation of the plan,The construction party has carried out a detailed road condition investigation on the original pavement.,Combined with the structure and diseases of the original pavement,Finally, the following regeneration scheme is selected to maintain the original pavement.:

Construction process

Use Wittgen first W 380 CR For the original pavement 18 cm Cold in-situ regeneration of foamed asphalt for structural layer,New foamed asphalt cold recycling layer is generated to be used as the lower surface layer.。

Cement pre-spreading

W 380 CR The cold Recycling Machine cuts and crushes the old pavement materials on the spot.,Add the foamed bitumen and water through a spray bar placed on the milling cover,And the cement pre-spread on the old road surface is stirred together,Because the milling and mixing rotor adopts a spiral structure,,The recycled material gathers towards the center,This ensures the uniformity of the recycled material in the transverse direction。

The cold recycled material is then conveyed by a conveyor belt to the following Vogler Paver hopper,Paving by Paver,Effective mixing of material from the reclaimer mill drum to the Paver screed length,This also ensures the dynamic uniformity of the recycled material in the longitudinal direction。

The whole construction process adopts flow operation.,One-time regeneration of half-width lane,The opposite lane is still passable,And half an hour after the end of the day's road regeneration,Tack coat oil is spread to prevent surface particles from falling off,Two hours later, the traffic was fully opened.。ForGLarge traffic flow of 335 logistics Truck,A narrow section of a national highway,It can minimize the impact on traffic.。

Open to traffic after cold in-place regeneration

High performance repair road has obvious economic and environmental benefits.

Under construction,Wittgen W 380 CR The advantages are obvious,Road surface capable of regenerating half width at one times,Construction efficiency is very high,The construction period is saved by about 50%,Traffic impacts during construction are greatly reduced。

At the same time,W 380 CR Undercut process is adopted during operation.,The grading uniformity of the milling material is improved,The material within the reclaimed width is remixed by the simultaneous spreading step,Cross-mixing is thus carried out in the lateral direction,Vertically, there are more than 25 m Dynamic mixing of,The discreteness of the pavement material is significantly eliminated。

The cold regeneration layer which has been opened to traffic has a certain bearing capacity,Flat and dense

Foam asphalt in-situ cold recycling layer core sampled

YesG335 This is a mountainous national highway with a long history.,Different maintenance history between different road sections,Materials between different sections、Moisture content、There is a large difference in the thickness of the structure.。The cold in-place recycling technology of foamed asphalt based on synchronous paving has high applicability,Not only can efficient construction,Quickly open to traffic,But also can well solve the crack reflection problem of the base layer.,Ensure the long-term stability of the pavement,So that that upgrade of the road in the aspects of strength and road performance can be realize more effectively,It provides a solution for the maintenance of heavy traffic sections in mountainous areas under the condition of non-disconnection.,It has a good reference value and significance.。

At the same time,This technology also shows many advantages in economy and energy saving and emission reduction.,Compared with the traditional technology,The construction period can be saved by 50 percent%Left and right,Realize the original asphalt concrete pavement old material 100%In-situ regeneration and recycling,Greatly reduce the use of new materials and the removal and disposal of road waste.。

Energy consumption can also be reduced by 60 percent%Above,Reducing CO2 emissions 80%Above,Realizing green environmental protection, energy conservation and high efficiency,Contribute to Green Sustainable Development and Double Carbon Goals。