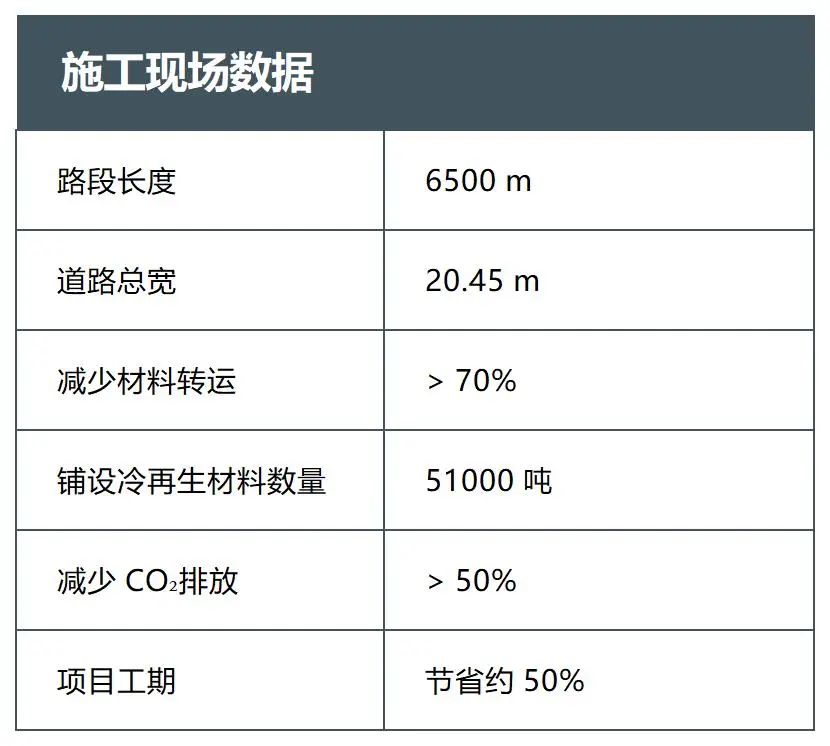

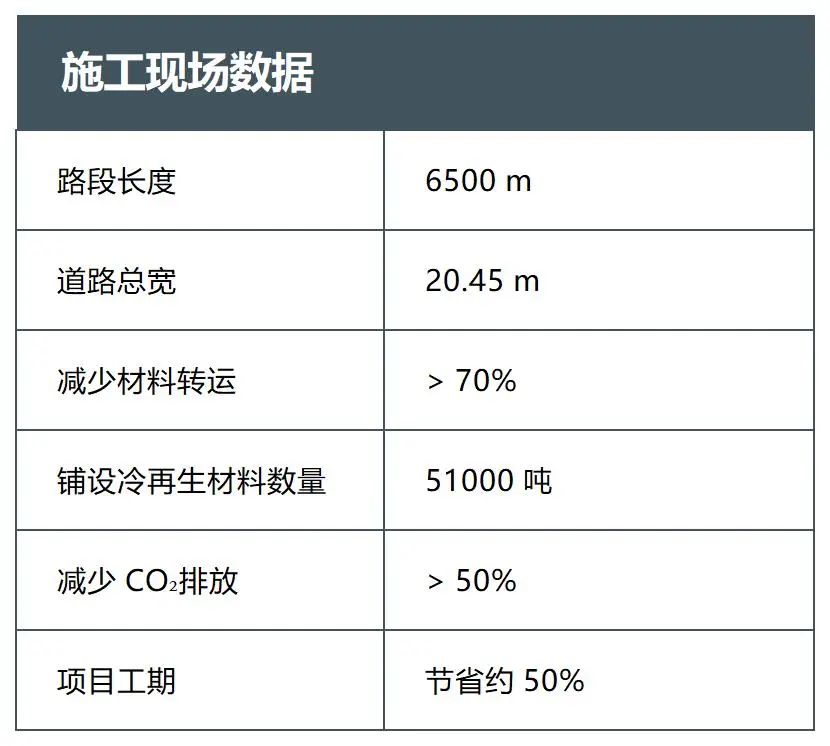

Near the famous Legoland in Denmark., One piece 6.5 kilometers(Four miles)Long E45 The road needs a complete overhaul in both directions.。The tender for the project specified a thickness of 20 cm(8 inches)Cold mix base course,The construction of this base requires the complete recycling of materials from the existing asphalt pavement。Besides KMA 240i Outside of mobile cold in-plant recycling equipment and Wittgen's large Milling Machine,The project also used Fogler Pavers and Hummer rollers.。

Economic and environmental protection

Cold recycling of pavement materials is a sustainable construction method in structural rehabilitation。A new base course is formed from a cold mix produced from foamed asphalt.,Ideal for roads of any traffic class,It is currently used all over the world.。

The deadline for the completion of the project is very tight.,Therefore, the smooth progress of the work related to the construction is very important.。“Responsible for the management of the project SR-Gruppen A/S Branch manager Morten Wold Express:"We use KMA 240i Up to 300 tons of cold mix per hour。

KMA 240i The mobile plant-mix cold recycling equipment can process 300 tons of cold recycling mixture per hour.

E Highway 45Milling width is 3.15 to 5.9 m,Milling depth of 28 cm,A large Wittgen Milling Machine was used.。The milled material is then transported to KMA 240i Mixing and processing at plant-mixed cold recycling site。The mobile plant-mix cold recycling equipment enables the conTractor to mill and pave the working surface of the asphalt nearby.,Shorten the distance of material transportation as much as possible,And significantly reduces overall CO2 emissions during the construction project。Before formal construction,The project party is responsible for the recycled asphalt mixture(RAP)The mix proportion design test is carried out.。The ideal ratio includes the addition of 2.2% Foamed asphalt、6% Lime and 0.8% Cement。

“For the grassroots,We need a cement and lime binder.。Ready-mixed materials of this type are not available in Denmark。There is a new KMA 240i,We can process the mixture ourselves during construction.,"SR-Gruppe Manager of Business Department Morten Wold Explain。

Precisely metered addition for ideal results

Coming up,Mixture passes through impact Crusher,Broken to 0-32 mm The granularity of,Feed by Wheel Loader KMA 240i Large capacity feed hopper,And then deliver toDouble-shaft continuous stirring pot。Two with double slot system and accurate weighingThe feeding auger is responsible for adding lime and cement binder respectively.。KMA 240i An additional feed auger is optional,And the field working capability of the equipment is improved.。Continuous weighing system ensures accurate metering of additives。Foamed bitumen is added through an integrated microcomputer-controlled batching system。

Incompletely enclosed construction site

The mixed asphalt cold recycling mixture is directly loaded into 36.A five-ton Truck.,And immediately transported to the construction site.。Motor Grader and Hummer rollers prepare and compact the frost protection layer under the asphalt pavement,Provide a stable surface for Pavers and Trucks in the next operation。Fogler's MT 3000-2i Mobile transfer Vehicle as material feeder,Ensure the smooth and seamless flow of materials at the construction site。MT 3000-2i A large amount of cold recycle mixture can be stacked。As complete road closure is not allowed during the project,Material transportation logistics is extremely challenging。MT 3000-2i Provides the necessary flexibility,Two lanes of the road can be completely repaired without completely closing the traffic.。

Vogler Super 1900-3i And MT 3000-3i The transfer Truck undertook the task of paving 20 cm thick cold recycled base.

Vogler Super 1900-3i PaverSet the paving material according to the vertical and horizontal slopes,Form 20 cm Cold recycling base course,Laid a new foundation for a busy road。Special attention is also required during the subsequent compaction process.。Hummer tandem rollers weighing more than 12 tons were operated for efficient compaction。Humvee GRW 280i Rubber-tyred rollers are responsible for the final surface preparation。

It took only two days.,They justLaid 8 cm The bonding layer and the surface layer。For this reason,They chose a polymer modified asphalt.,This asphalt concrete material meets the requirements of heavy Truck traffic in Truck lanes.,And is ideally complementary with that foam asphalt cold regeneration base course.。Of course,Vogler Super 1900-3i And MT 3000-2i Also collaborated to complete this work.。

Base course with Hummer roller、Compaction of surface course and binder course