Ergonomic and Efficient Compaction

Ammann APR Reversible Vibratory Plate Compactors deliver on the most demanding jobsites. The machines are ideally suited for compaction work in both soil and asphalt.

The plates can handle sensitive jobs, thanks to their exacting control, and also perform well in open spaces.

Hydrostatic controls make the plates manoeuvrable, accurate and fatigue-free to operate. Twin-shaft exciters take on any challenge.

What exactly makes Ammann hydrostatic controls stand out? Operators explain that it’s the difference between a run-of-the-mill implement and a tool that is precisely and perfectly suited for a job.

With hydrostatic controls, the working speed of the APR plates is infinitely variable in both forward and reverse. The control system responds quickly, enabling a rapid change of direction – even in tight places.

The variable adjustment range makes it possible for the plates to cover wide working areas. The range also allows operators to adjust to sensitive paving or soil compaction jobs. In particularly demanding ground conditions, the plates can also be switched to on-the-spot vibration, where the machines essentially hover in place to compact thoroughly.

Twin-shaft exciters in the vibratory plates operate efficiently and propel the machines over steep and uneven terrain. The exciter force is directed into the ground and into the materials to be compacted – and away from the operator.

The direction of the force, combined with the patented Z-buffer™, leads to the lowest hand-arm vibration (HAV) levels in the industry. The Z-buffer is a special damper that isolates the vibration and prevents it from being transmitted to the guide handle. HAV values of less than 2.5 m/sec2 reach the operator.

This value is so low that no documentation of the working hours is required, even in countries with strict regulations. Health risks from HAV have been eliminated on the APR series.

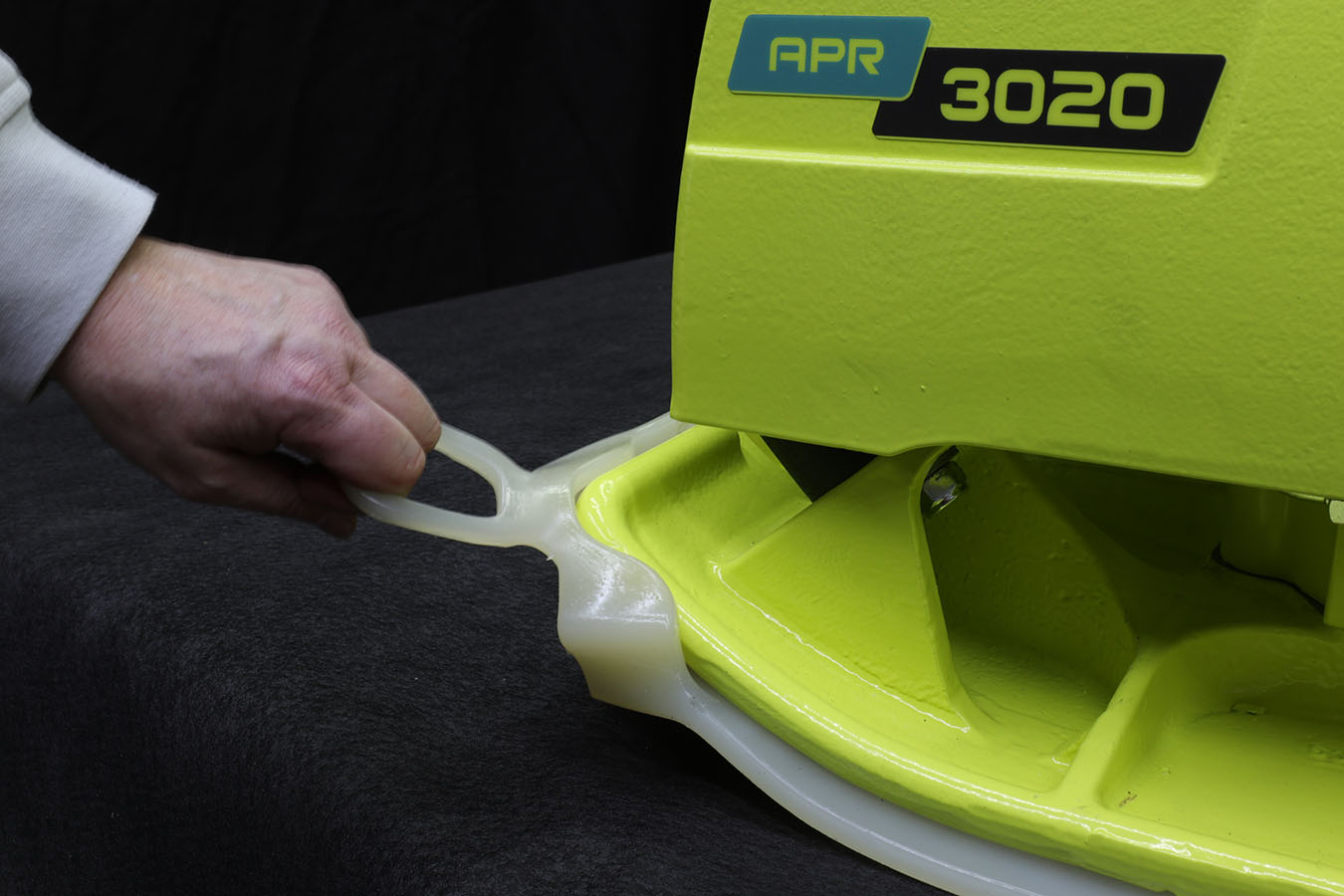

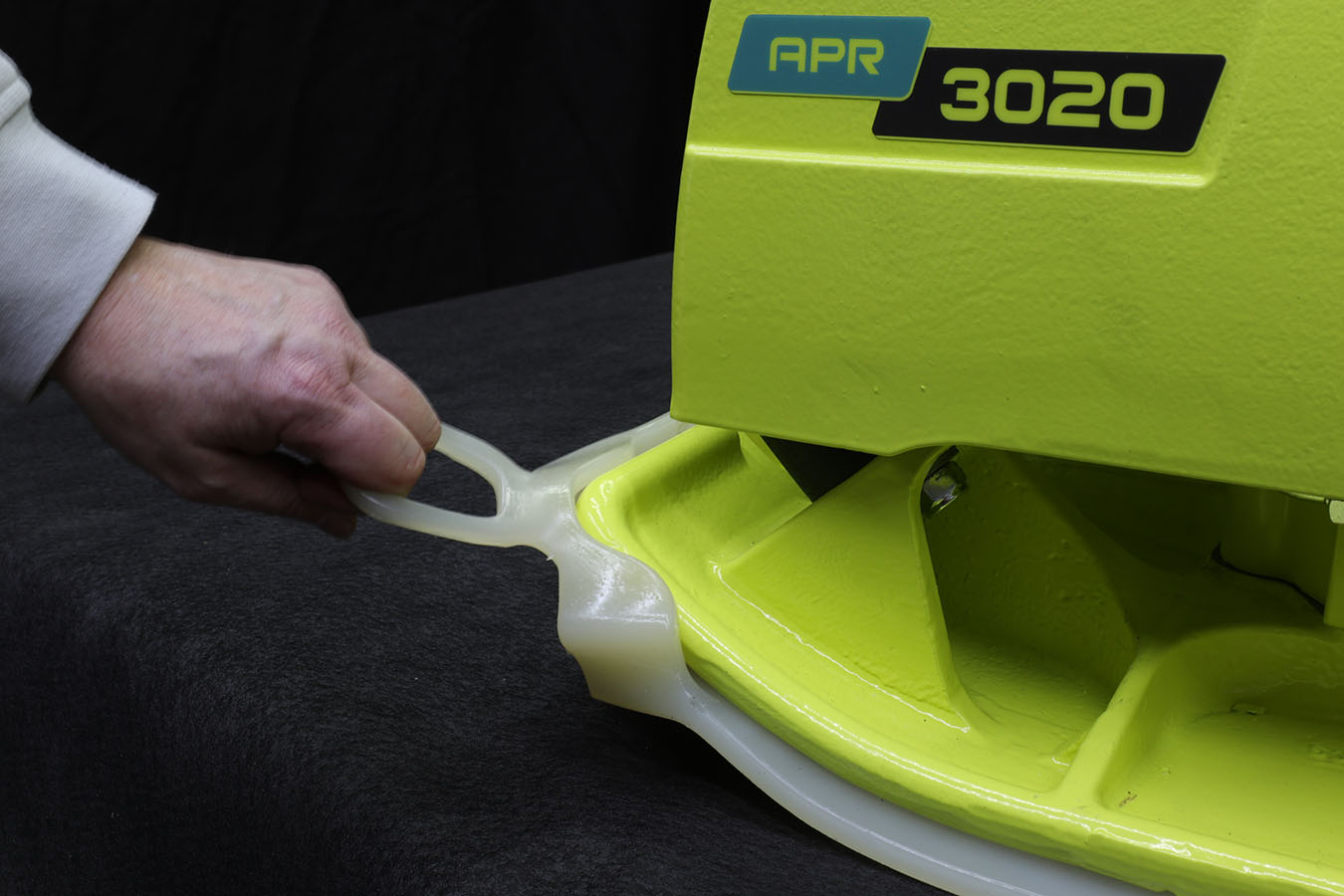

Ammann APR Plates are equipped for every situation, in part due to their varied sizes – from the 100-kg light model with a working width of 30 cm to the 440-kg machine with a working width of up to 75 cm. The plates compact soil and gravel, and that’s only the start. A water tank makes them the machines of choice on asphalt. A mat can be installed – without the need of a tool – to tackle compaction of Paver bricks.

Individual models in the APR series can also be upgraded with ACEecon, an optional compaction measurement system developed by Ammann. An LED display helps the operator to easily identify the current degree of the material’s compaction. This prevents over- or under-compaction and work is carried out more quickly and efficiently.

Ammann has set the bar high in terms of comfort when it comes to maintenance, too. Inspection and maintenance points are accessible – and tools aren’t needed to perform routine tasks. The base plate itself is maintenance-free and self-cleaning. The newly designed frame protects all components and can be used to lift the machine during loading.