Attention & other; XCMG foundation ” Engineering class

Install XCMG experts in “ Pocket & throughout;

Current case of work law

construction equipment XCMG double-wheel stirring XCM40

construction project changsha Greenland V island project

geological conditions

The geological conditions from top to bottom are mixed fill, silty clay, medium sand, gravel, strongly weathered SLATE, moderately weathered SLATE.

construction requirements

The retaining structure of the foundation pit of the proposed Greenland V island project is the supporting scheme of cast-in-place pile row pile +CSM equal thickness soil-cement mixing wall water curtain + prestressed anchor cable. The bottom of the soil-cement mixing wall of equal thickness shall ensure that the embedded weathered slab (strength about 17Mpa) shall be no less than 1.7m.

XCMG twin wheels stirring in V island, Greenland, changsha

Located in the eighth bay of liuyang river, in the center of changsha city, the 380-meter super high rise of Greenland V island is the second tallest building in hunan province and the new landmark of ma LAN mountain.

The retaining structure of the foundation pit of the proposed Greenland V island project is the supporting scheme of cast-in-place pile row pile +CSM equal thickness soil-cement mixing wall water curtain + prestressed anchor cable. The bottom of the soil-cement mixing wall of equal thickness shall ensure that the embedded weathered slab (strength about 17Mpa) shall be no less than 1.7m.

Construction area, the geological conditions in turn from top to bottom for miscellaneous fill, silty clay, medium sand, gravel, strongly weathered SLATE, weathering in SLATE, due to the complexity of the project site geological conditions, such as the thickness of the cement-soil mixing wall need through the pebble bed and rock, and less experience of changsha area using this process, therefore, before the formal construction, xugong based method, equipment, technical personnel has reached the construction site, in the whole process of the nanny service, to ensure smooth construction of the clients.

The construction of the groove adopts the double grout mode, that is, bentonite mud is used as the excavation fluid during the sinking process, without grouting; Lift grouting.

The thickness of the first slot wall is 700mm, the length of construction is not less than 7.6m, the lap width of the wall is 400mm, the depth is 14.7m, and the wall enters the weathered SLATE at 1m. The wall forming time is about 3h. The client and the project department are very satisfied with the construction stability and rock-entering ability of the equipment, with full confidence.

XCM40 construction main advantages:

※ fast realization “ Dual use of one engine ” That is, Rotary Drilling Rig and dual - wheel milling stirring rig universal mainframe quick switch.

High-precision automatic control technology to monitor and control verticality, footage speed, grouting volume, etc.

※ work device guide rod structure, rigid feed pressure, milling head cutting ability, good mixing uniformity.

※ the wall depth is large, and the maximum reinforcement depth is 45m.

※ compared with the traditional multi-axis stirring, the effective cross-sectional area is larger.

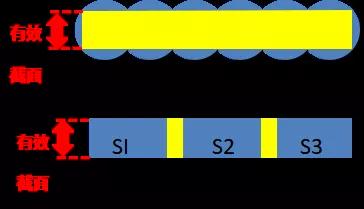

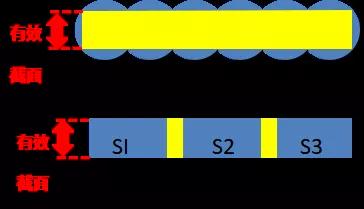

Conventional cement and clay agitator with solid is basically cylindrical, and the pile body is overlapped between piles to form a wall, with a small effective cross section ratio. The wall formed by CSM is cubic, and the effective section ratio is 100%.

wall section comparison

Compared with multi-axis stirring and TRD and other construction equipment, XCM40, the newly developed two-wheel stirring equipment of XCMG foundation, has the advantages of large construction depth and strong rock penetration ability, which fully meets the construction requirements of the project.

Double Wheel Milling deep mixing technology is a kind of soil-cement deep mixing technology newly developed in the world, which has been widely used in many fields abroad (such as foundation pit engineering, seepage prevention engineering, foundation treatment, etc.).

XCMG XCM series twin-wheel milling and stirring trough equipment will have a very bright future in the development and application of underground space in order to improve the domestic technology level and fill the blank in related fields.