With the new modelLH The launch of the 40 grab machine,Liebherr is once again leading the industry with new features and advanced technologies。To enable dealer service personnel to better grasp the innovative features of this new device,Liebherr has invited agents and service partners from all over the country,A three-day professional service and technical training activity was held at the Shanghai headquarters.。

This training is based on“Skill upgrade,Independent innovation”As the theme,Attracted many participants.。Through this training,,The trainees have not only greatly improved their technical level.,It also strengthens the confidence and recognition of the Liebherr brand.。Liebherr is committed to technological innovation and service upgrading.,Make sure every customer's equipment is running efficiently at its best.。

“New”The tide is surging

>> New Technology Enabling Efficiency Upgrading

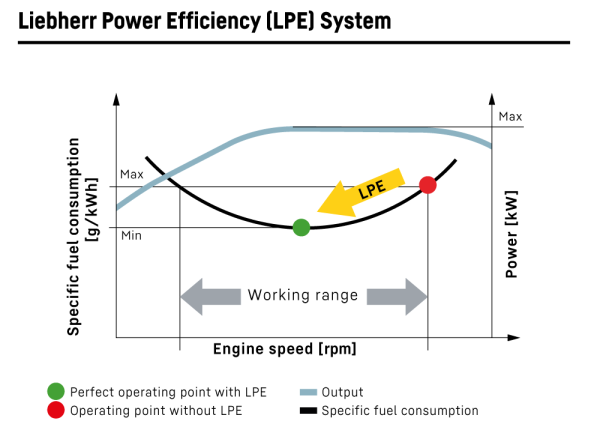

LiebherrLH 40 New Hydraulic Grabber,Through the adoption of a series of new advanced technologies and dramatic improvements,It meets the needs of customers for high efficiency and energy saving.。

Many new technologies independently developed by Liebherr are integrated here.,The complexity of the system has reached an unprecedented height.。All-round technical upgrade from external structure to internal components,Make every effort to ensure efficient operation of the machine。The technology has been upgraded:

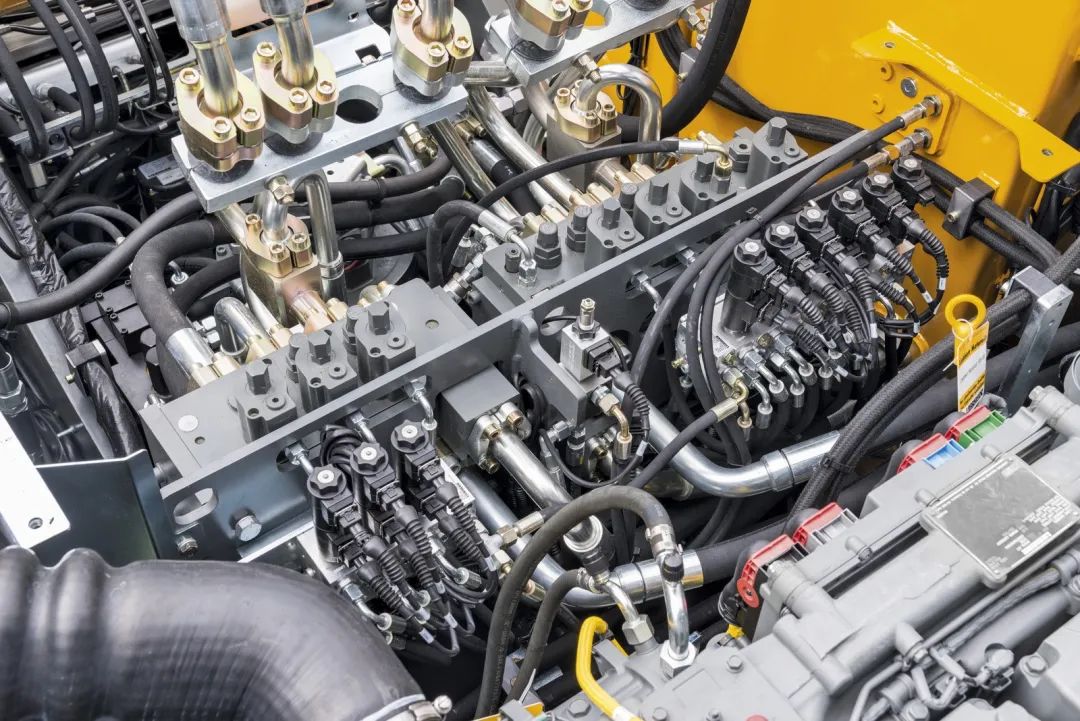

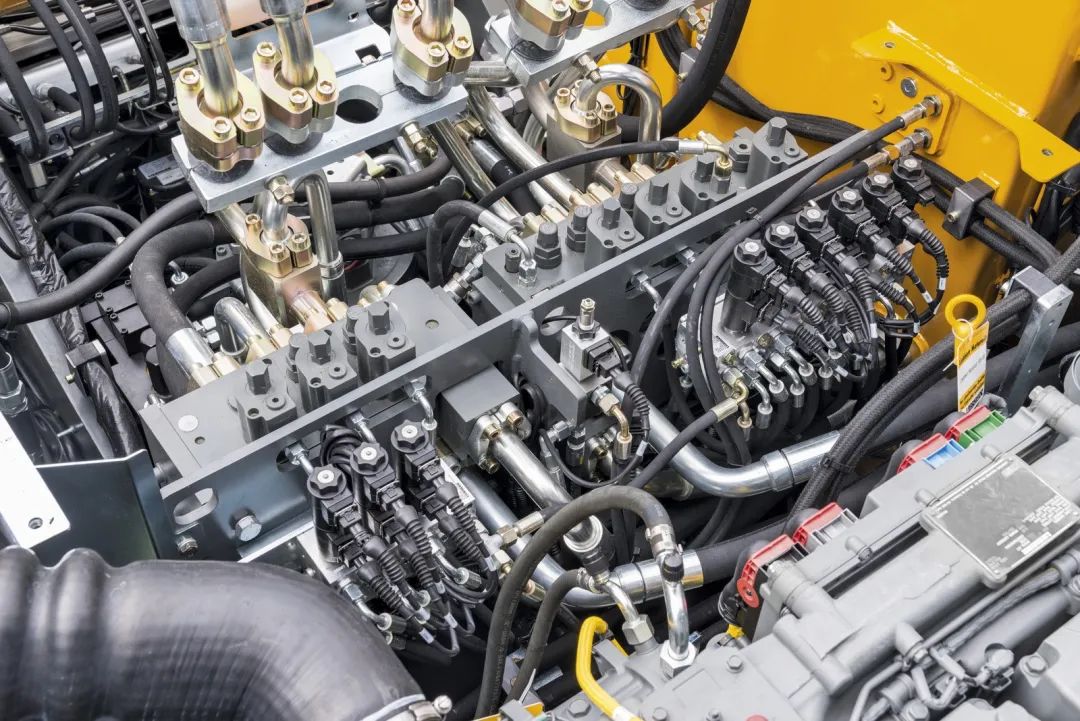

■ Double CircuitLSC(LS+LUDV)Liebherr Synchronous Comfort Hydraulics

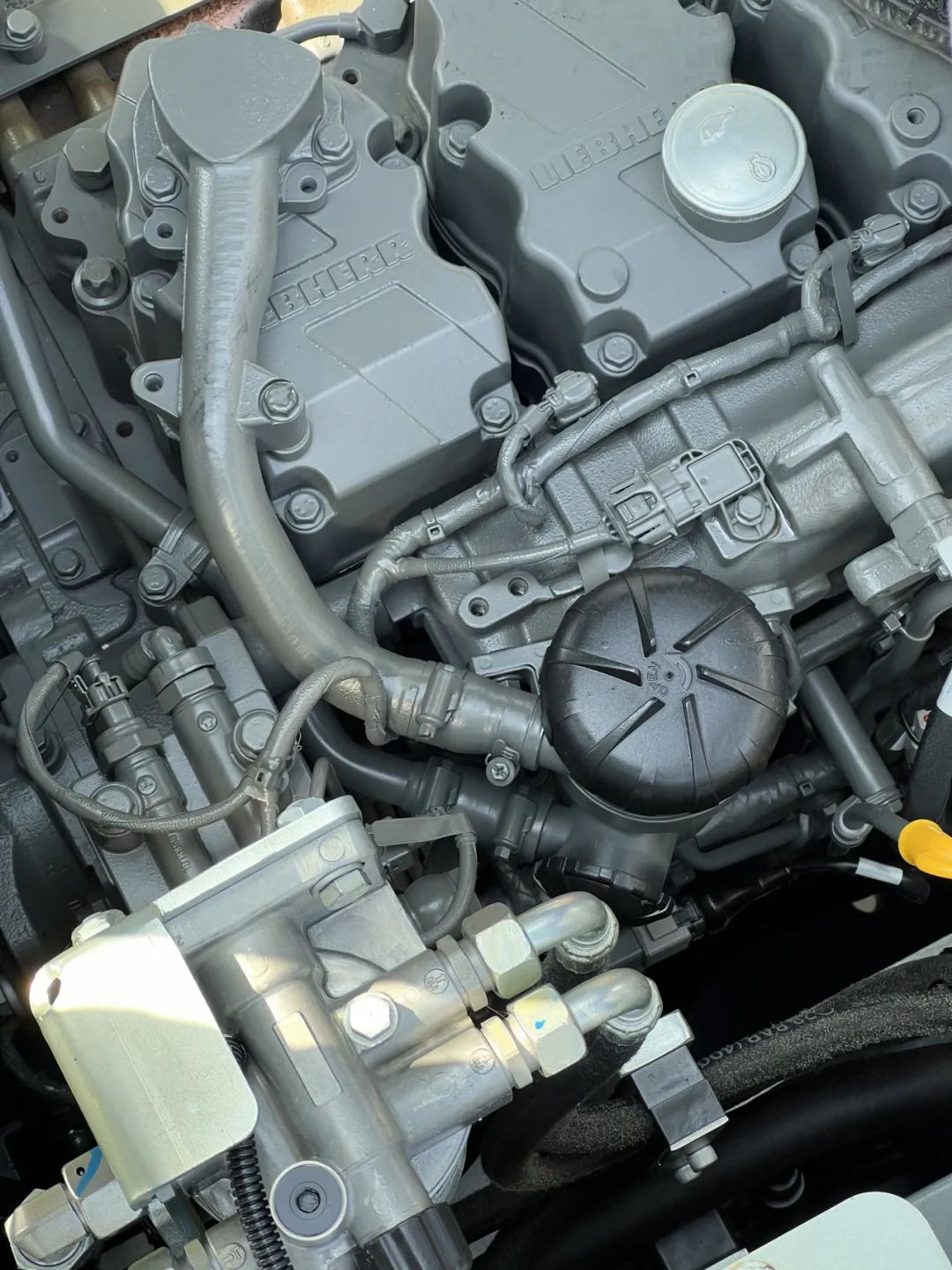

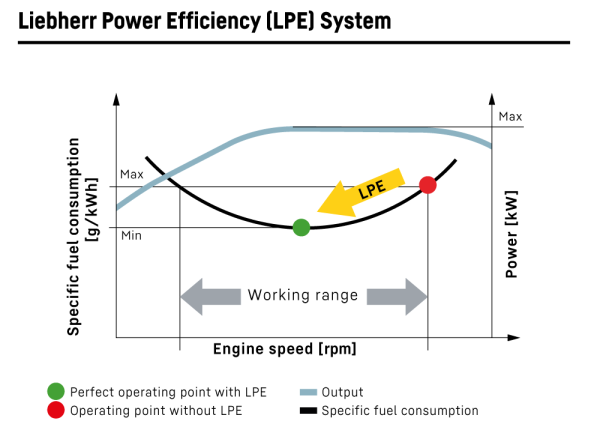

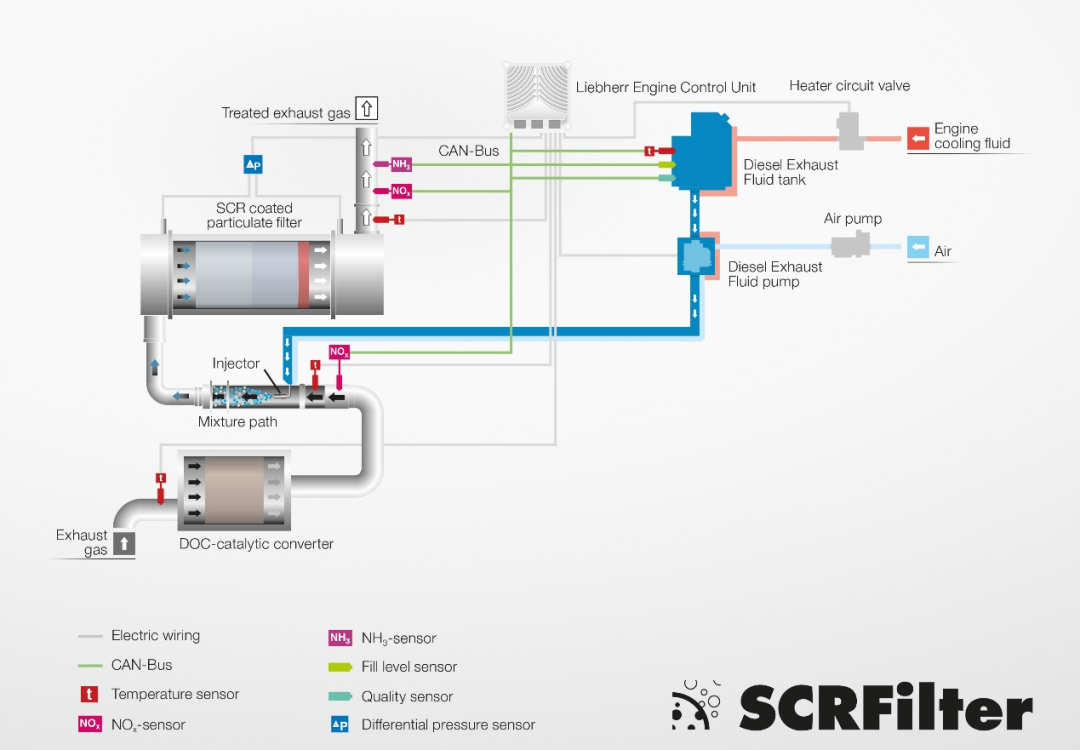

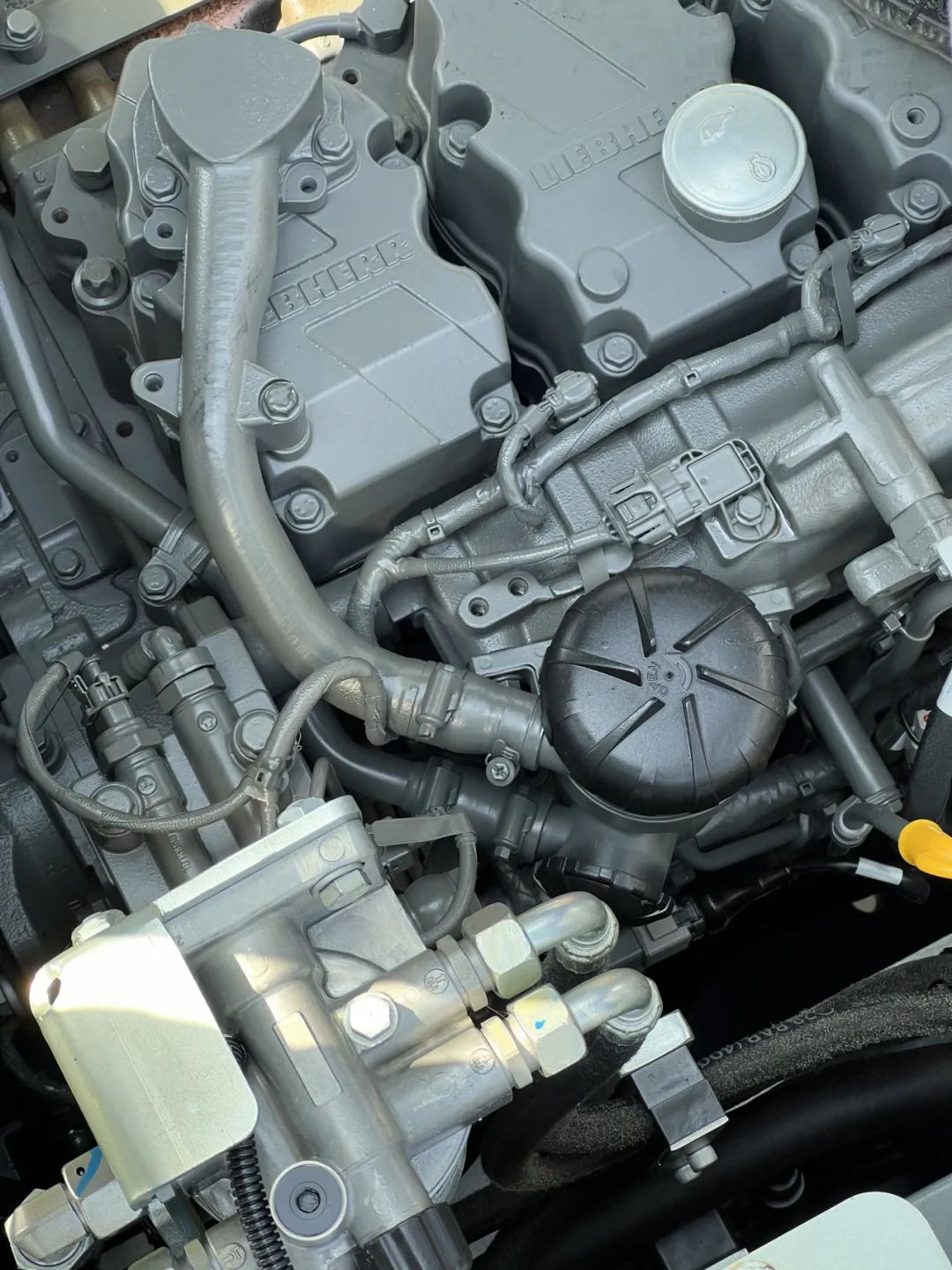

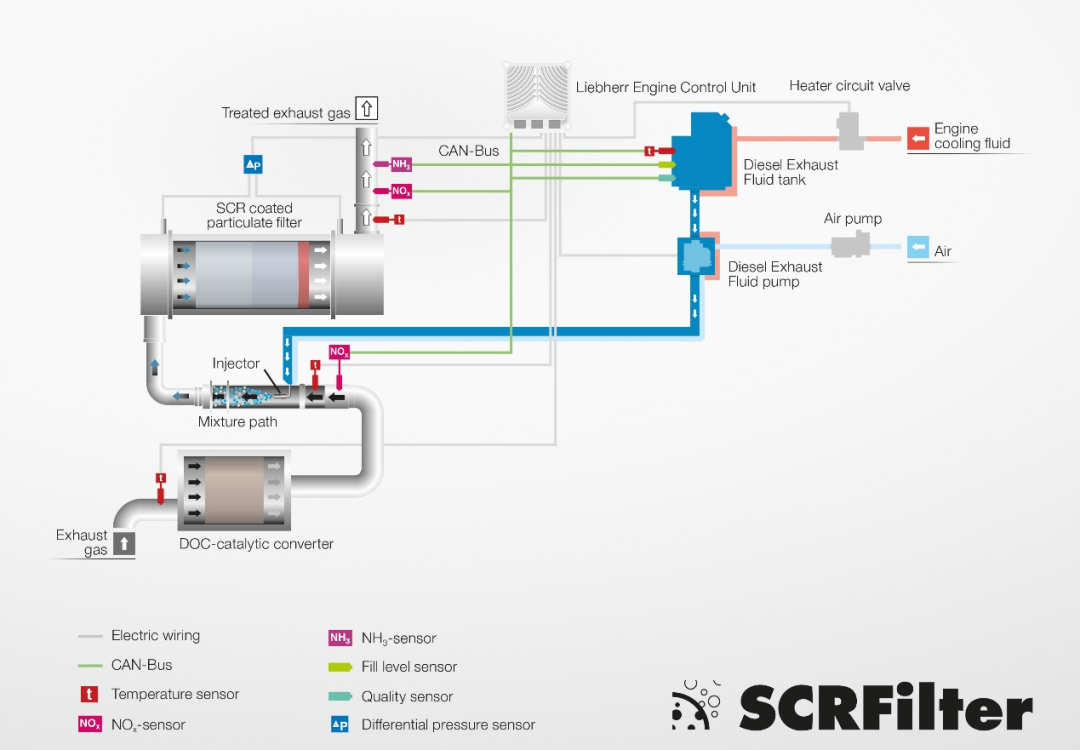

■ Seventh generation Liebherr high pressure common rail engine of Euro 5 andSCRFPost-processing system

■ ERCNitrogen energy recovery cylinder

■ The latest generationECU 3 Main control system of engine

■ PME 5 Main control system of equipmentPremiumEdition

■ Handle steering and full electric control pilot

■ Full set of safety system for action limit and pipeline rupture prevention

■ Mini joystick with additional proportional control and outrigger independent control system

■ Independent closed hydraulic slewing system

■ Fully automatic centralized lubrication system covering the whole Vehicle

■ Emergency operation mode preset for various faults

Immersive practice

>> Fully understand every detail of the machine

The purpose of this training is to improve the professional skills and service level of supplier technicians.,To ensure that future cooperation is more high-quality and efficient.。The training covers the introduction of service system principles.、Common fault diagnosis、Software operation、Introduction and use of special tools、Emergency operation、Service case analysis、Oil Sampling and Service Policy、Emergency spare parts preparation and other key areas。

Through in-depth explanation of the basic principles and working mechanism of the service system、Diagnosis method and treatment process of common faults of equipment、Operation process of relevant software,As well as the use of various special tools,Ensure that the dealer colleagues can master and apply it in practical work.。

In addition,The emergency operation steps and treatment methods are also introduced.,Summarize experience through typical service case analysis,Improve students' ability to solve practical problems,Emphasize the importance and basic process of oil sample testing,It also explains Liebherr's service policy and emergency spare parts management and storage methods.。

Through this comprehensive and systematic training,The service technicians of the major distributors will be able to better understand and master the maintenance and operation skills of Liebherr equipment.,Lay a solid foundation for long-term cooperation among the three parties。

Hands-on diagnosis software

>> Quality service does not drop the chain

During training,It also released and updated a number of service-specific software at the same time.。These software launches and upgrades are designed to further enhance the productivity and ease of operation of technicians.,Ensure more accurate and efficient support during equipment maintenance and troubleshooting。

Liebherr's Next Generation Device On-Line Diagnosis Software

「 LiDIAG 」

Liebherr Troubleshooting Wizard [Earth-moving equipment]

「 TSA 」

Liebherr's new engine on-line diagnosis software

「 LiDIA 」

LiebherrLH 40 has a rich and perfect self-diagnosis system,Cooperate with self-developed online diagnosis software and intelligent auxiliary fault wizardapp,Technicians have a more intuitive understanding of equipment status、Quickly locate the fault and implement the corresponding maintenance measures,This will greatly reduce the time for fault diagnosis and equipment downtime,At the same time, it will also reduce the pressure of front-line service personnel on the spot.“Knowledge anxiety”。 The application of these software will greatly improve the quality of service and customer satisfaction.,Bring more technical support and guarantee for the cooperation between suppliers and Liebherr。