At the 7th China International Import Expo,Caterpillar Oil & Gas shows how to help the new future of the oil and gas industry,These include the practice of circular economy through the application of remanufacturing repair technology.。Before,The Oil and Gas Division has published an academic paper on the subject《Operational Excellence:Rethinking Reuse in Circular Economy、Recycle and reduce cost and increase efficiency》, The paper was written bySociety of Petroleum Engineers Selected issues,And at the same timeADIPECPresented at an academic conference,Let's find out.——

Increased demand for remanufactured parts,It marks a change in the development trend of oil and gas operators.。

With the pursuit of low-carbon and sustainable development and social responsibility of enterprises,,The use of remanufactured components becomes a key strategy to help reduce waste and pursue direct business economic and social benefits of sustainable development.。While oil and gas companies benefit from returning cores and purchasing remanufactured parts that perform like new and are economical,Support circular economy。

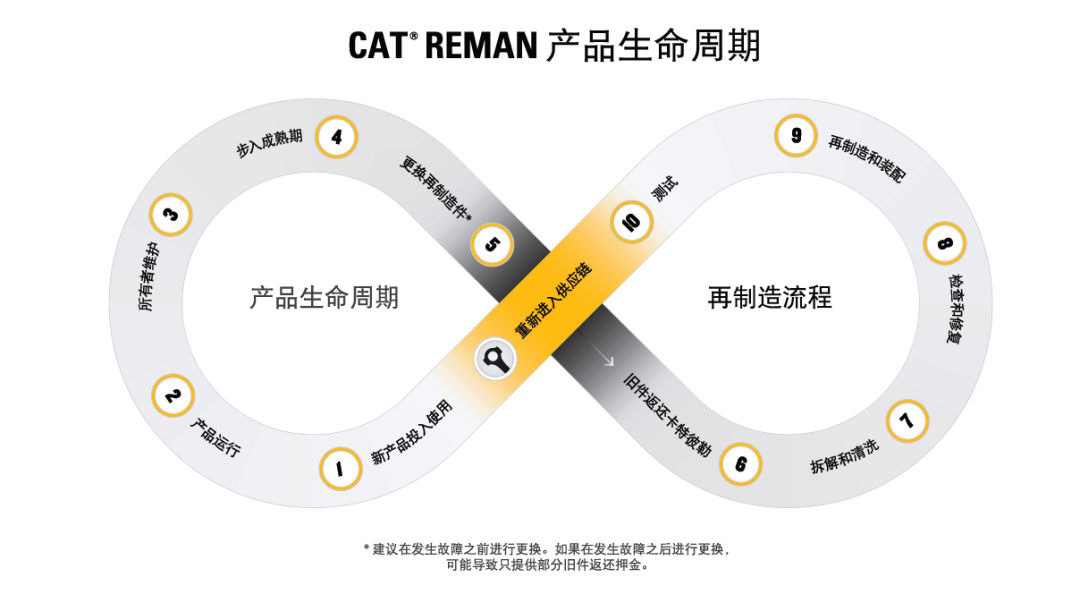

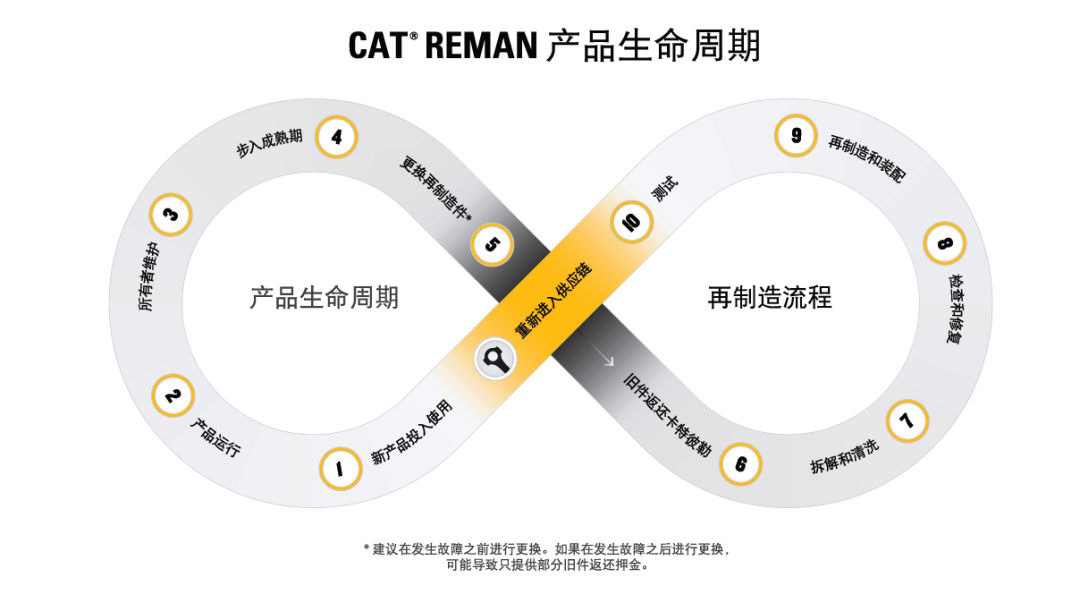

A picture to understand

How Caterpillar passedCat® Reman

Practice circular economy

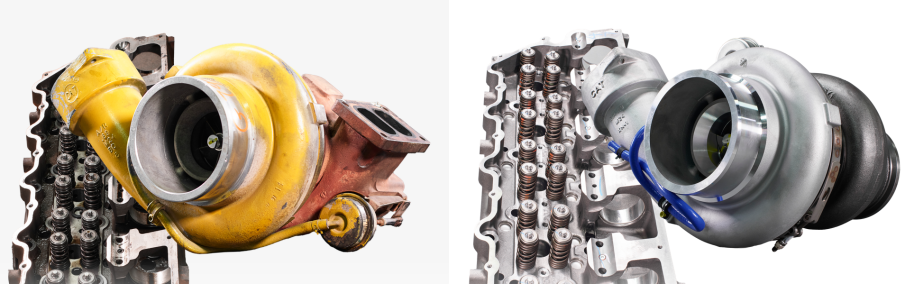

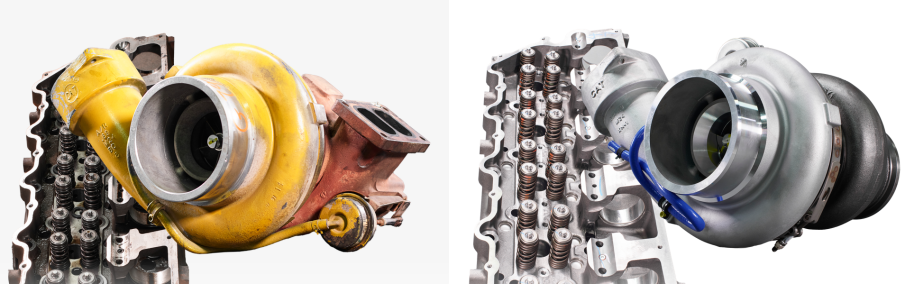

Cat RemanPieces comparable to new ones

How is it done? ?

Thanks to advanced remanufacturing processes and procedures

Completely disassembled、Clean and check all parts,Ensure product quality and durability

Comply with the latest engineering changes,For better performance and longer component life

Perform multiple quality checks,Including comprehensive and in-depth product offline leak testing, etc.

Cast to exacting Caterpillar standards、Heat treatment and testing

Use the latestCatRemanufacturing machinery and technology for processing and assembly

In the oil and gas industry,More attention has been paid to recycling schemes.,Including priority renewable programme inputs、Recycle and reuse by-products and wastes。Recycling of core materials and other critical components from scrap,Making Remanufacturing Possible。

Advantages of Remanufactured Parts in Circular Economy Mode

Real case

Middle East Drilling Companies Benefit from Remanufactured Parts

One in Saudi Arabia and the United Arab Emirates(UAE)Large drilling companies doing business,Be able to demonstrate the difference made by the use of remanufactured parts。Drilling equipment managers send old engine cores back to the factory for remanufacturing,And then return to the site for use.。Compared with using new parts,Companies saved an average of 37 percent.8%The cost of,Recycling for manufacturers 71,900 lbs of material for remanufacturing。

Oil and gas companies participate in the circular economy through the use of remanufactured components,Achieve climate-related goals,It is to build a better world.、A very meaningful part of the idea of a more sustainable world.。