Facing the increasingly severe environmental challenges and road construction needs,Xizhu Company has deeply studied and successfully mastered the foaming technology of foamed asphalt.,This technology not only effectively reduces the construction temperature of asphalt mixture,,It also significantly reduces energy consumption and harmful gas emissions.,Realize the win-win of economic benefit and environmental protection benefit。

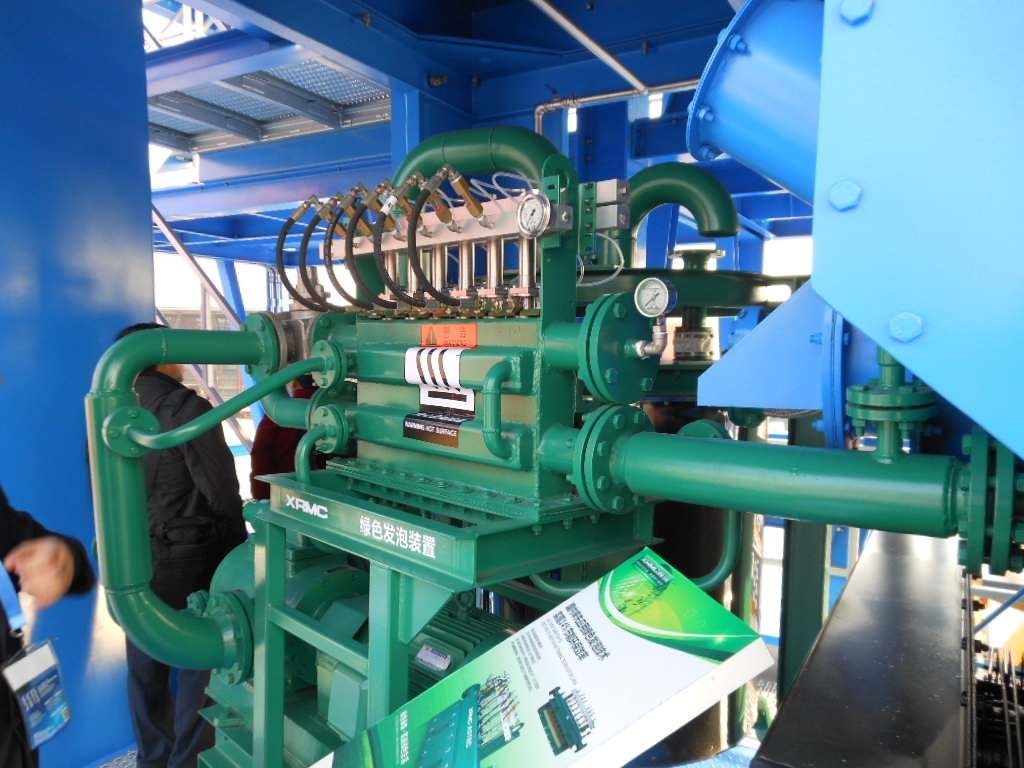

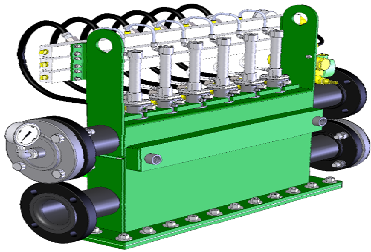

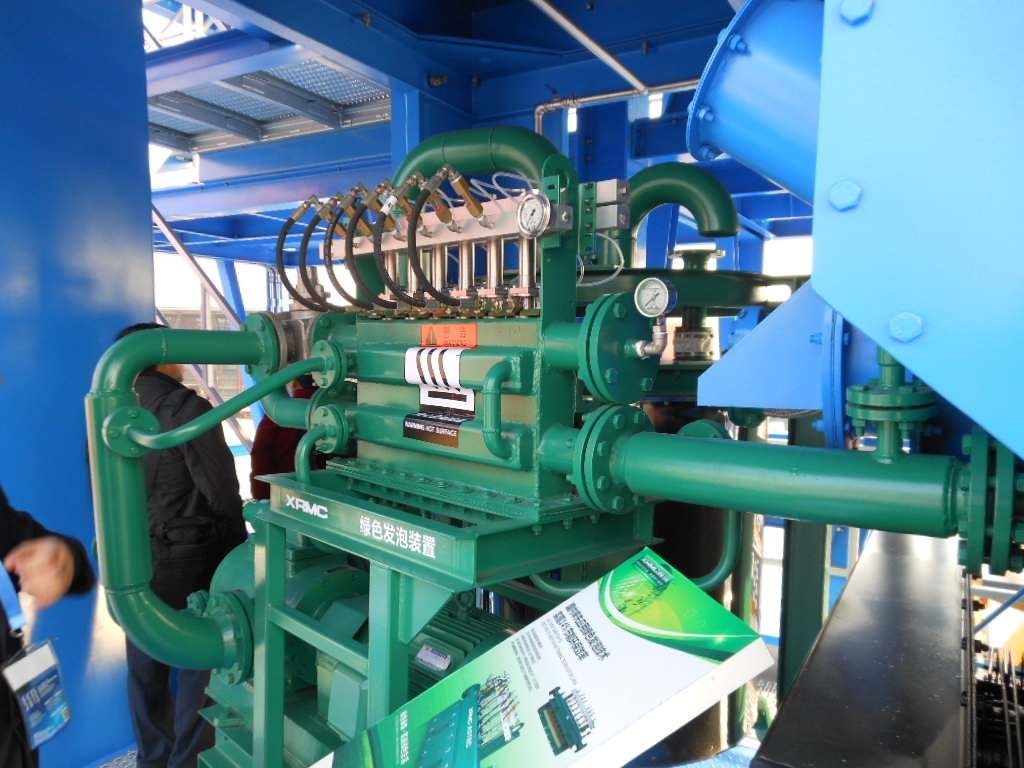

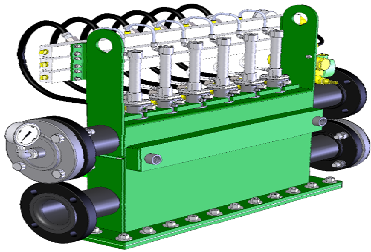

Configuration of asphalt warm-mix foaming deviceSG3000 equipment

The core of foamed asphalt foaming technology is the injection of foaming medium and the expansion and foaming process of asphalt.,This process improves the mixing and compactability of the mixture。Compared with the traditional hot mix asphalt technology,,It has obvious effect of energy saving and emission reduction.,The specific advantages are as follows:

01

Replace expensive additives with water,Lower

Production cost。

02

Mixture temperature decreases by 20~40℃。

03

Extend the construction season,Add asphalt pavement

Construction flexibility、Convenience;In particular

During construction at night and in low temperature environment,Tool

HaveBetter workability。

04

Save 10%~20%The fuel。

05

CO₂、SO₂、NOxWait for discharge

Significantly reduced。

06

Asphalt flue gas during production and paving(Have

Poisonous and harmful gases)Significantly reducedLess,To Shi

Workers andPeripheral ringThe environment is less harmful.。

07

High proportion of recycled materials can be added,

50%Above。

08

Better performance of paved road、Longer life。

09

The operation is simple and convenient,No need to add complex equipment,

Suitable for various road conditions and construction conditions。

10

Maintenance cost of mixing station is reduced,Mixing plant

And that safety is improve。

Asphalt warm mix foaming technology has unique advantages and wide application prospect,It is gradually becoming an important technological innovation in the field of pavement engineering.。It can not only improve the efficiency and quality of pavement construction,It can also actively respond to the call of green travel.,Contribute to the new era of green travel。