Hello ,Give me a set of loader electronic scales.!

Boss ,Don't spend that money unjustly.,We can realize automatic weighing with big data algorithm.!

Is that thing accurate??I don't believe it.!

Boss ,We have a patent.,If you don't believe me, you can compare and try the effect.!

Ok!

Customer case Working condition:Commercial concrete station loading(Sand、Stone in proportion),Total length of scraper path: 30m;

Equipment:Great Wall Heavy IndustriesGW58E,Rated load 5.5t/282kWh Power /3.6 Fang Dou

Endurance performance:8~9h

Customer demands:Monitor production per shift(The customer proposed to install an electronic scale.),

Solution

In order to address such customer claims,,Great Wall Heavy Industry Digital Intelligence Team for 24 YearsIndustry's First Zero Cost Solution for Electric Loader Workload Monitoring——It breaks the cognitive limitation of traditional fuel loader that only uses hydraulic pressure signal to make empirical judgment.,Through the analysis of electric loader in different conditions of the three electric bus data.,Deep learning electric loader operation characteristics,Output big data model,Then the shovelling times of each Vehicle are automatically calculated through the model.、Travel distance、Load weight and other data,So that that accurate monitor of the operation amount of the electric loader is realize。

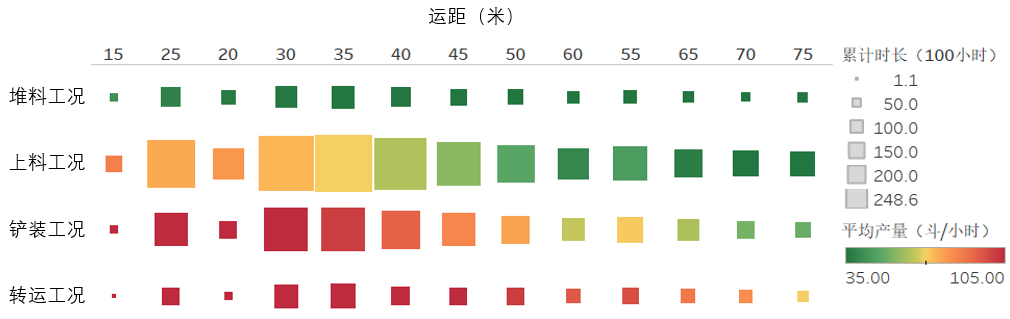

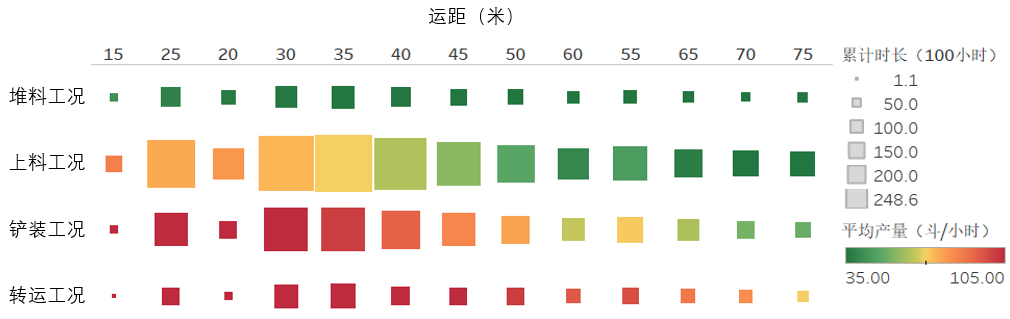

(200,000-hour loader big data working condition identification model)

To put it simply,,Accurately identify when the loader is shoveling through big data analysis,When is the transshipment?,When are you loading?,How many bucket cycles have been performed in a period of times,And calculate the loading capacity of each bucket relatively accurately.。

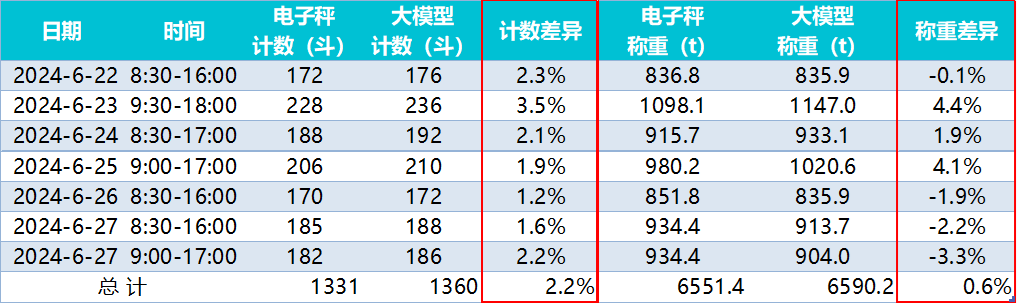

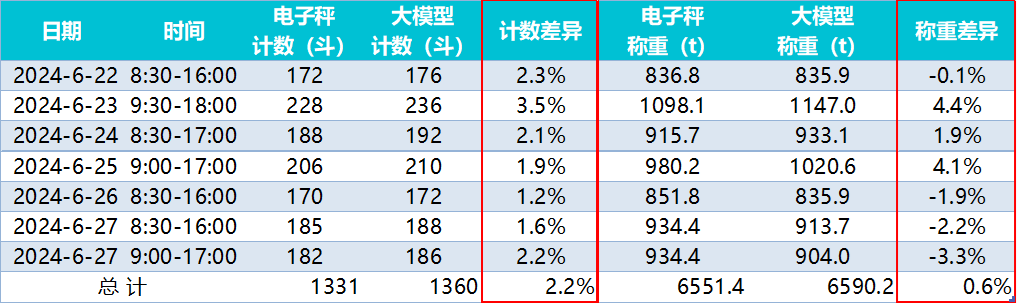

So what is the practical application effect of this scheme??For this case,We actually compared the data of the customer's electronic weighing equipment for 7 consecutive days as follows:

Through the above data, we can find that,The average error of the statistical bucket number of the large model is 2..2%Left and right,Statistical weight error in±4.5%Within。Among them, there is a big difference in the number of buckets, and the model count is slightly more.、Slightly less counting of electronic scale,This is because the driver has not yet adapted to the operation of the weighing equipment.,There is a phenomenon that the lifting height is not in place, resulting in the omission of bucket number statistics.(Disadvantages of electronic weighing equipment)。This shows that,Great Wall Heavy Industry Electric Loader Workload Monitoring 0 Cost Solution Solves Customer Management Demands Well,It can help customers reduce cost input.。

Interpretation of the scheme

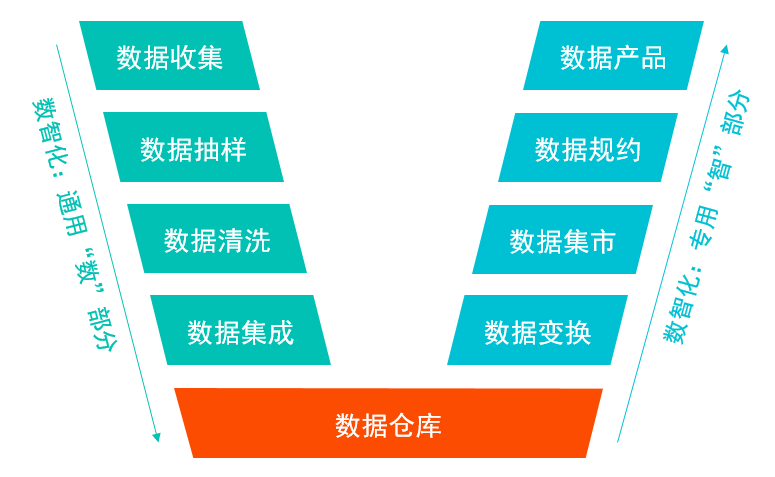

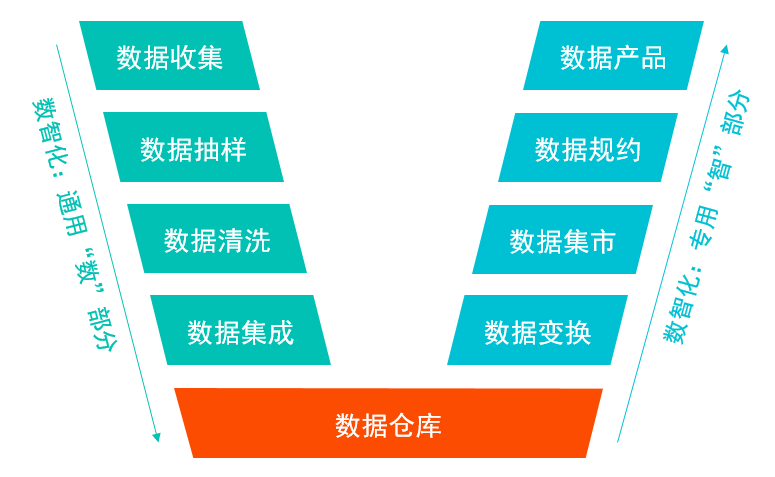

Big data analytics is like cooking.,First, pick fresh and rich data.“Ingredients”,Washed and pretreated,Remove impurities。Catch,Via data modeling and algorithmic“Cooking skills”,Extract the essence of data。Finally,Analyze the results in an intuitive way“Serve”,Satisfy the customer“Taste”。The whole process,From Material Selection to Presentation,Careful planning and meticulous operation are required.。For this case,The implementation path of the zero-cost solution for electric loader workload monitoring is as follows::

Data collection:Importing the data of the three power systems at the Vehicle end into the digital intelligent original database

Data sampling:Extract key variables,80% reduction in data volume%

Data cleaning:Each key variable shall be cleaned at the same frequency for 1 second.

Data integration:Integrate all Vehicle critical data

Data Warehouse:Forming digitalized and intelligent integrated database

Data transformation:Refine the operation action(Shovel/Yun/Lift)Status data and other critical information

Data Mart:Form the full time action data of each Vehicle and other key information data platform

Data protocol:Extraction of working condition characteristics of loader shoveling scene

Data products:Push data of different dimensions such as workload monitoring for individual customers,And accumulate samples,Forming a relevant prediction model

As a subsidiary of the Great Wall Holding Group,Great Wall Heavy Industries makes full use of big data and artificial intelligence resources within the group.,Combined with years of practical experience,Committed to promoting the development of the construction machinery industry。Our goal is to use advanced digital technology and intelligent technology.,Improve the productivity of construction machinery,Continue to provide customers with high-value products and customized solutions!