Deep in the earth,Traditional coal mining

It is being completely reshaped by new quality productivity.

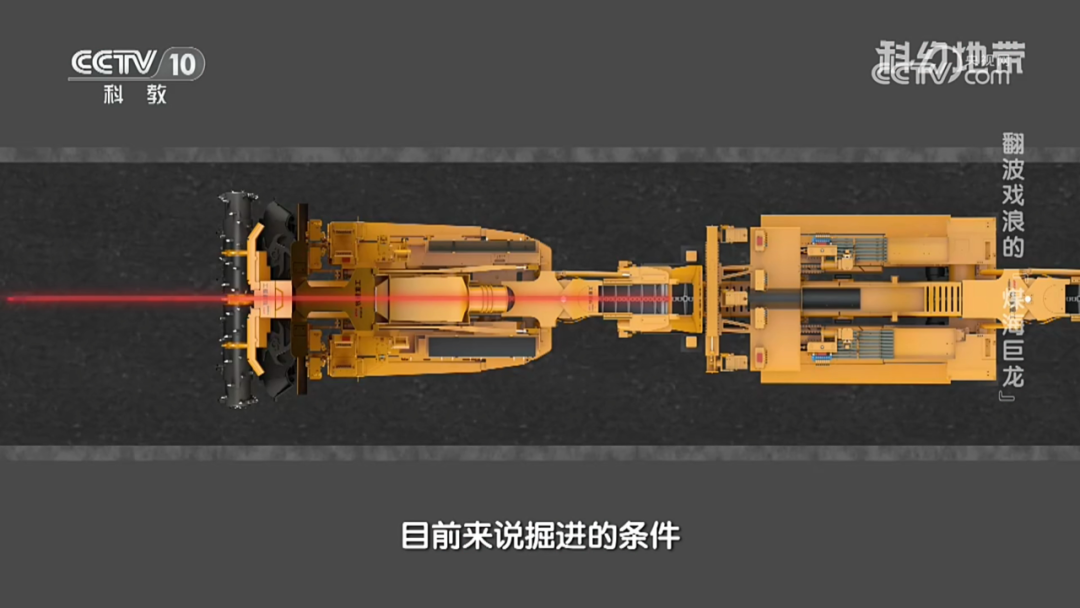

A 100-meter-long steel dragon

Travel through underground coal seams.

R & D personnel of CRCC

Let“Coal Sea Dragon”Play with the waves

Drilling out one industrial vein after another

August 18

Science and Education Channel of China Central Radio and Television Station

《Science fiction zone》Special program

At the length of 38 minutes

Focus on the independent development of China Railway Construction Heavy Industry

Intelligent complete set of equipment for rapid digging and anchoring

Lead the mine intellectualization“A new era”

Domestic coal mine“Pioneer officer”Solve the imbalance of mining

Roadway is a necessary passage for coal mining.

Undertake transportation、Ventilation、Drainage and other functions

Coal cannot be mined without roadways.

A long time

Coal Mine Tunneling Equipment in China

It means digging but not supporting

The roadway cannot be formed at one times

“Foreign monk”Not acclimatized

Growing demand for energy

Coexistence of market and opportunity

Research and development personnel of China Railway Construction Heavy Industry

Bear heavy burdens bravely、Face the difficulties

Developed suitable for China's coal mine roadway construction.

Complete set of equipment for quick digging and anchoring

In order to solve the imbalance of coal mining

Compete on the same stage to solveA worldwide problem

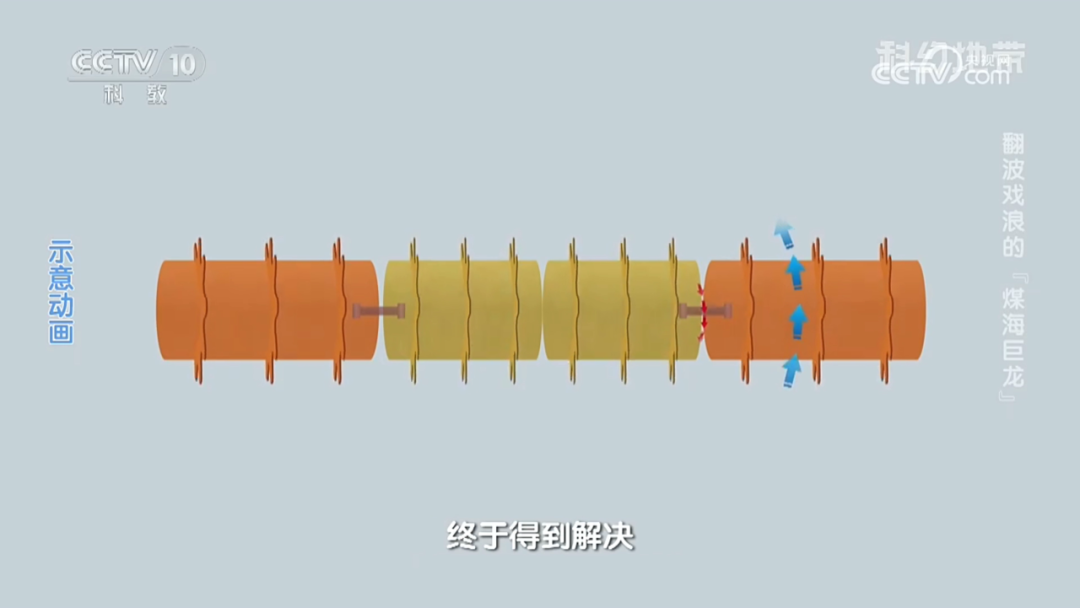

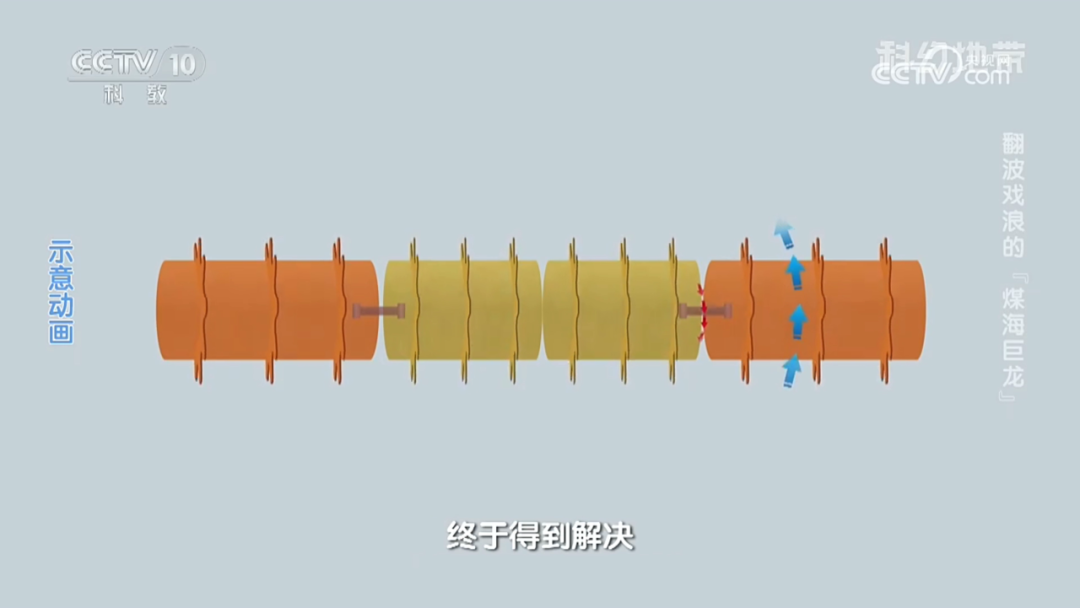

“Anchor digging synchronization”

The most advanced imported digging and anchoring machine

It can't be achieved“Anchor digging synchronization”

How to overcome this worldwide problem?

Time matching is key.

In more than six weeks.

R & D personnel test with stopwatches every day.

Tested over 100 times

Compare thousands of sets of data

Finally, we got the perfect matching time.

At the same time

In order to let“Coal Sea Dragon”

It can eat better.“Ugin”

The R & D personnel adopt the horizontal shaft type telescopic roller

Designed a hard mouth for it“ Tooth ”

Match the width of the drum to the width of the roadway

Adapt to different types of roadway excavation

“A sharp mouth”And“Flexible arms”

Let“Coal Sea Dragon”Realize synchronous operation of digging and anchoring

And that labor intensity is greatly reduce.

And improves the safety of coal mine tunneling.

Let China's Coal Mine Roadway Excavation

Mechanization has been realized

Coal Mine Driving“The little security guard”

400 meters underground,Everything is unknown.

How to predict the geological conditions ahead

And that construction safety is ensure

It has become another difficult problem that needs to be overcome urgently.

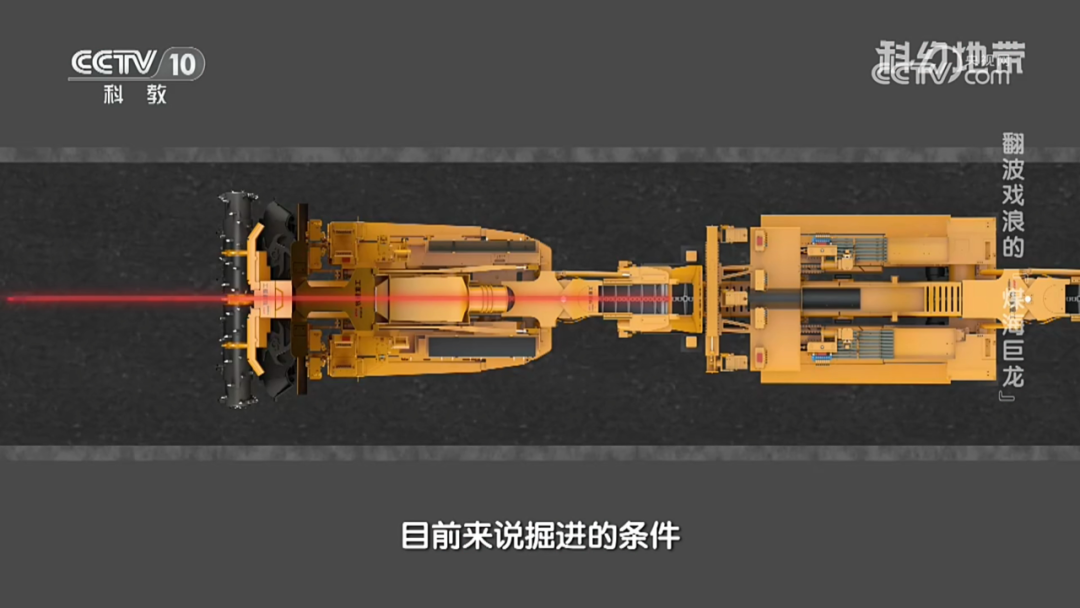

One advance drilling machine

By connecting the drill pipe section by section

Drilling depth of more than 100 meters in advance

Find problems ahead of time、Take measures

To ensure the safety of underground operators and equipment.

A set of dedusting device

Through semi-closed dedusting system

Circulate the airflow at the heading fact

Address the potential risk of dust explosion

2016

The first complete set of rapid anchor digging equipment developed by China Railway Construction Heavy Industry Co., Ltd.

First application to

Sunyingcha No.1 Mine, Dianta Town, Shenmu City, Shaanxi Province

Achieve the highest monthly footage of 1204 meters

Innovation and upgrading of core equipment

Promoting the progress of the industry

Changed the traditional operation

Nearly a hundred people crowded into the narrow space underground.

The labor intensity is high、Poor operating environment

A difficult situation

Fast“Transformation and upgrading”Meet new challenges

In the face of large cross-section roadway and poor geological conditions.

“Coal Sea Dragon”How to proceed“Upgrading”

The first is to solve the working area.

The pulverized coal is large

Flammable、Explosive problem

R & D personnel through simulation analysis

A special foam dedusting system is designed.

While ensuring the strength of the cutting head,

Solved effectively

Noise of negative-pressure dedusting fan

Poor dust removal effect

In addition

The conveying system is often stuck by large coal blocks.

Resulting in poor operation

Seriously affect the construction progress

The R & D personnel designed

Three-channel double-shaft Crusher

The problem of coal block stagnation was successfully solved.

At the same time

The R & D staff also upgraded.

Turn the transport bridge、Cutting drum, etc

Important components

After 103 days of digging

Complete set of equipment for quick digging and anchoring

Precise penetration of 5992 meters of roadway half a month ahead of schedule

And created the world's first

Large section roadway of 10m large mining height working face

The world record of 1750 meters per month

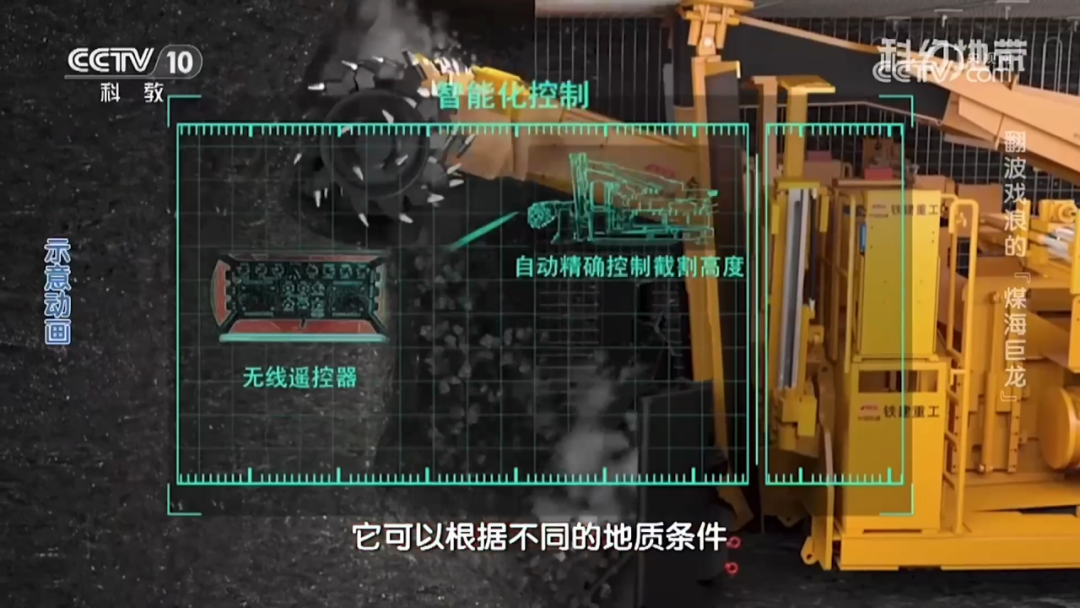

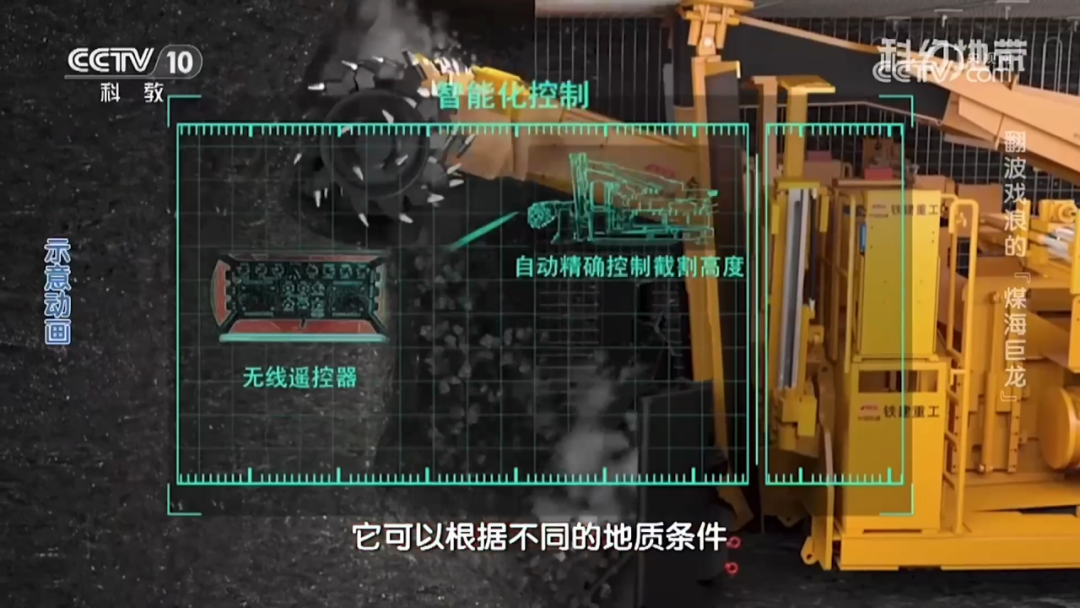

“An intelligent brain”How to build an unmanned mine

In order to reduce the labor intensity of construction personnel

Let“Coal Sea Dragon”Better

Ensuring safety and efficiency of coal mine construction

The R & D personnel proposed

Intelligent coal mine construction、Unmanned

The device is given multiple items“Superpowers”

Underground in a sea of coal

You can't see your hand

In order to let“Coal Sea Corps”Capable of autonomous operation

You have to let it have a pair.“Night vision”

Research and development personnel of China Railway Construction Heavy Industry

According to the experience of tunnel construction

DevelopedUWBContinuous positioning mechanism of

Realize continuous autonomous tunneling

At the same time

Through the radar correction system

Achieve automatic walking of complete set of equipment for rapid digging and anchoring

And then

The R & D personnel decided to give the equipment

Carry out a comprehensive“Upgrade”

Let the complete set of intelligent digging anchor equipment have“An intelligent brain”

Realize remote control and one-button start on the ground

2023

Developed by China Railway Construction Heavy Industries

The world's first complete set of super-large section intelligent fast digging equipment

At Caojiatan Mining Company

It has created a super-large section roadway excavation.

Monthly footage of 3008 meters

Work efficiency reaches 3 to 5 times of traditional tunneling equipment

Set up a survey、Dig、Branch、Transport in one

The tunneling is realized、Anchor protection synchronous operation

And that tunnel speed of the equipment is improved.

It has solved the problem of mining imbalance that has plagued coal mines for a long time.

Speed up the development of coal mine intellectualization

Successfully build mine construction 5.Age 0

For hundreds of years

In every transformation of the energy industry

Innovation and upgrading of core equipment

All promote the development of the industry.

R & D personnel of China Railway Construction Corporation

With“Innovation of construction method、Intelligent leading”It is the core competitiveness

It has overcome a series of key technical problems in the industry.

Developed a large number of innovative mining equipment products

It fills the gaps in China and the industry.

China's mine equipment has been realized.

From“Run with”To“And run”

And so far“Lead the race”The transformation of

Future,These core equipment

It will provide a solid source of content for China's energy security.:China Central Radio and Television Station、Railway Construction Heavy Industry