”

“The new energy automobile industry is in the stage of vigorous development.。However,It is expected that by 2030,4 Million Electric Vehicle Batteries Will Die。These lithium-ion batteries contain valuable raw materials.,Its recycling is both economically and environmentally important。

At present,The battery disassembly process is complex and costly,Manual operation is often required。Face this challenge,Liebherr's federally funded“ZIRKEL”Under project cooperation,Automated battery disassembly technology is being developed,In order to promote the whole economic chain of battery recycling.。”

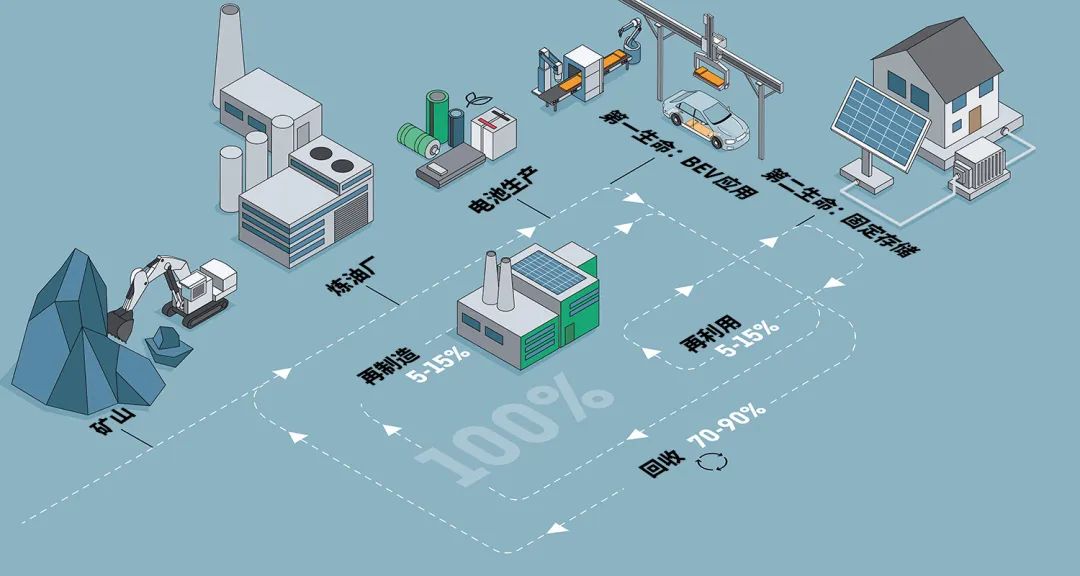

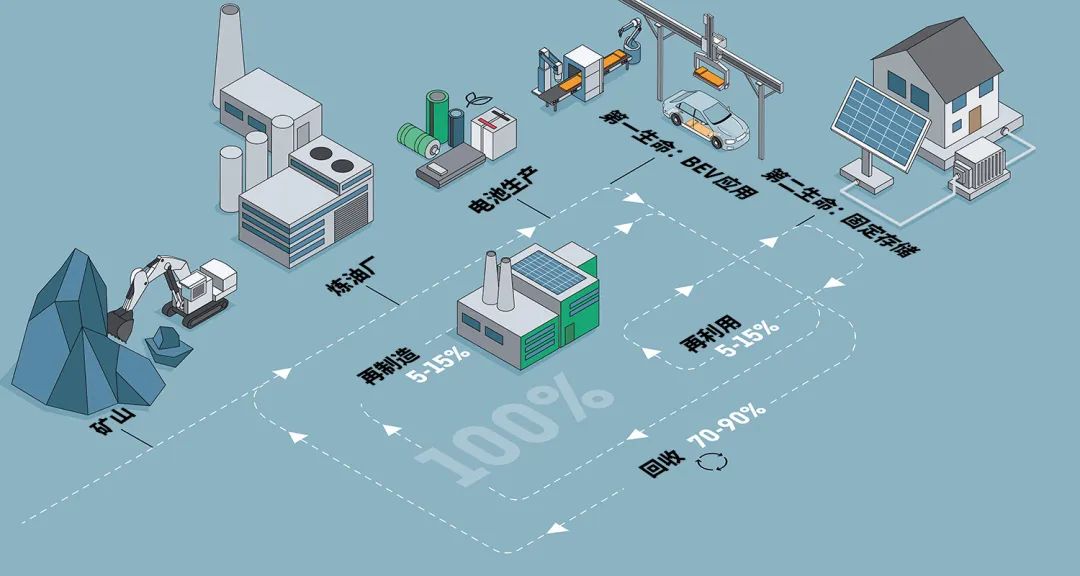

When the total capacity of lithium batteries for new energy Vehicles decays to 70% of the original capacity%-80%Time,They need to be scrapped.。Most obsolete batteries are recycled.,Its raw materials are used to produce new batteries.。According to the battery condition,A small number of old batteries can be reused in electric Vehicles.(Remanufacturing)Or as a stationary energy storage device。

According to the new EU Battery Regulation,All batteries must eventually reach a certain recovery rate.,And use a certain proportion of recycled materials in the production of new batteries。This requires the industry to find the most effective recycling solution.,To cope with the future growth of battery recycling.。The goal is to achieve sustainable and carbon-neutral battery manufacturing across the entire production chain,And maximize the recycling of materials.,Reduce waste generation and dependence on key raw materials。

Life cycle of high voltage battery system、Secondary application、Remanufacturing and recycling

High recovery rates through automation

Due to the variety of battery types and frequent update iterations,At present, most of the disassembly and remanufacturing processes still rely on manual work.。Liebherr Automation Systems EngineerJan PollmannPoint out:“Batteries cannot be recycled in batch。”To cope with increasing recycling volumes and improve recycling efficiency,It is urgent to promote process automation.。

In addition,Automated disassembly also protects worker health and safety,Keep them away from high voltage and dangerous goods.,Reduce risks such as fire。

The challenge of automated disassembly

In addition to a wide variety of batteries,The automated disassembly process faces a number of additional challenges:Used batteries may be corroded、Deformation or damage etc.。It is sometimes difficult for the vision system to identify a contaminated component。Sealant、The concentration and properties of the adhesive or hot melt adhesive change over time,May be difficult to clear。

Risks such as high voltage or dangerous goods should not be underestimated.。Finally,Disassembly of flexible components such as cables or cooling hoses is also difficult to automate。Product Manager Automation Systems, LiebherrViktor BayrhofExplain:“In principle, disassembly is only a reverse assembly.,But it is many times more complex.。”

Liebherr innovates the whole process of automatic disassembly of self-developed battery pack

In order to effectively solve the problem of disassembling the scrapped lithium battery,,The German Federal Ministry of Education and Research (BMBF) Funded“ZIRKEL”The research project brings together an interdisciplinary team.,Team members come from scientific research institutions and enterprises.,Work together to study the whole circular economy of batteries.。Within the framework of this project, Liebherr has developed a strategy and process for the automatic disassembly of battery packs。

The purpose is,Maximize the recovery and reuse of raw materials by mechanically disassembling and sorting components。What we do is.:Removal of valuable components or components containing hazardous substances at an early stage,In that case,Yeah, the so-called“Black block”(That is, the mixture of raw materials left after the battery is crushed.)The amount of pyrometallurgical and hydrometallurgical processing is reduced,Such processing is cost intensive and energy intensive。

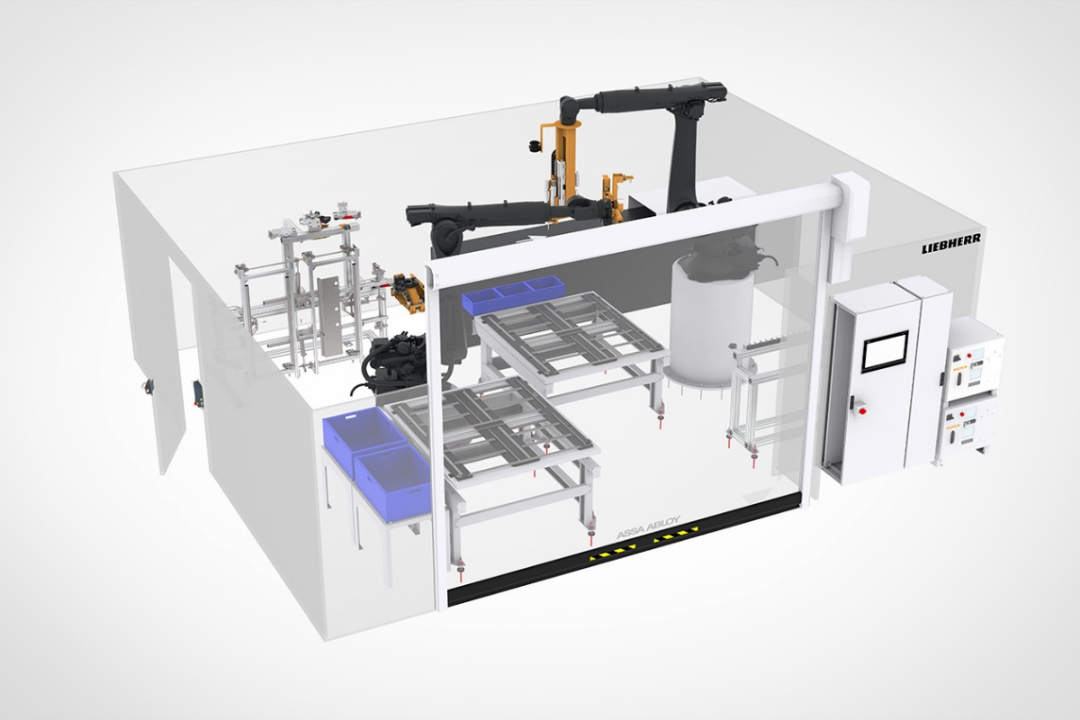

The automatic disassembly system has been put into pilot operation.

Liebherr's first pilot system is already in Wolfsburg.Open Hybrid LabFactoryInstalled in the research park。

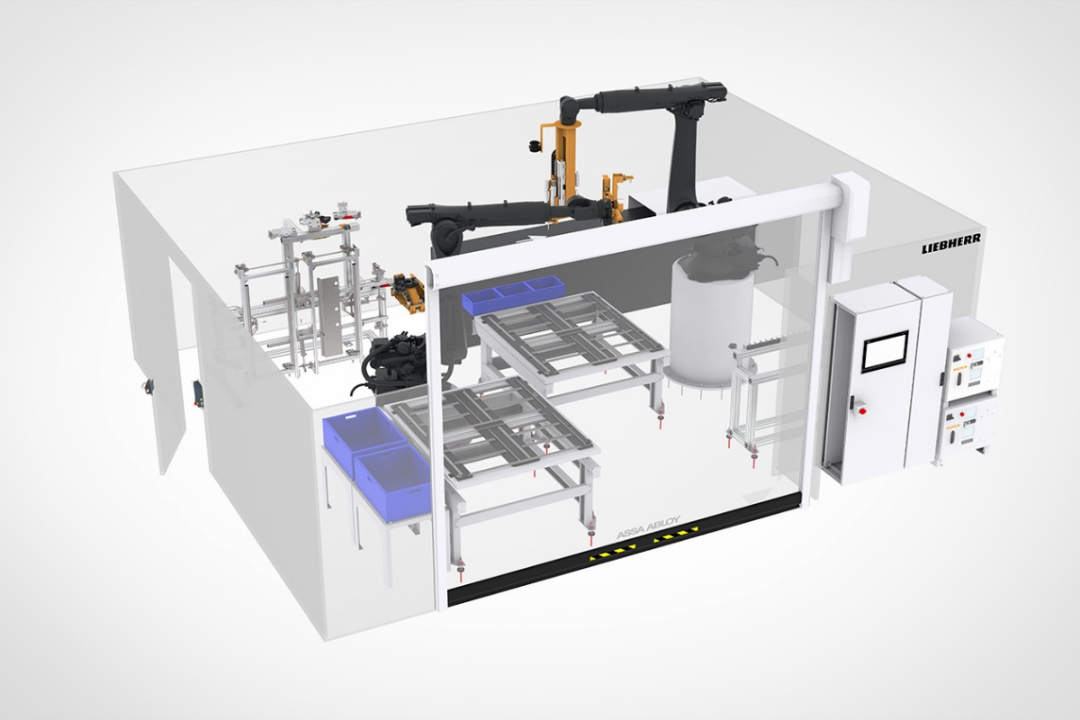

3 of the partially automated prototyping stationDLayout

Liebherr will continue to support the project on site.,And began a further series of tests.。The test results will be incorporated into industry guidelines for the design of the planned battery recyclable products.。