In the process of aggregate crushing,Due to the lithology of the base metal、Feed particle size、Feed quantity and feeding uniformity、Equipment wear and many other factors,The gradation and particle shape of the crushed aggregate are changed。If it is not found or adjusted in time,Change in that quality of the raw material will result inDecline in concrete performance,If the strength is not up to standard、Poor liquidity and so on.,Resulting in the decline of project quality,The stability and durability are not as expected.。

Traditional manual sampling detection is affected by many factors.,The results are not stable,And has a long hysteresis.,Inability to detect anomalies and resolve problems in a timely manner,Resulting in concrete quality problems,Or change the formulation during downstream production,Increase the amount of cement additives, etc.,Increase the production cost。

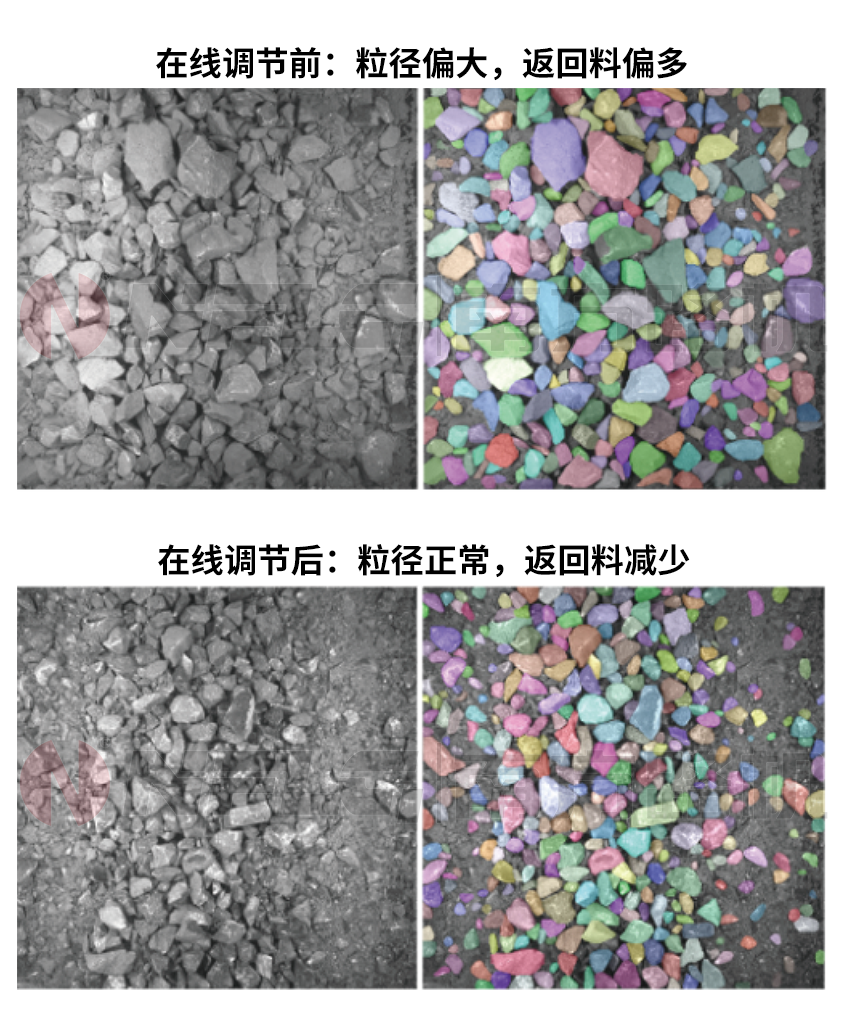

Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing),CanReal-time monitoringParticle Size and Gradation of Aggregate at the Discharge End of Crushing Machine,And make judgment in time.、Give adjustment suggestions,The crushing host system can automatically adjust the corresponding parameters according to the adjustment suggestions.,Ffectively improve aggregate quality。,Duration 01:00

Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing),CanReal-time monitoringParticle Size and Gradation of Aggregate at the Discharge End of Crushing Machine,And make judgment in time.、Give adjustment suggestions,The crushing host system can automatically adjust the corresponding parameters according to the adjustment suggestions.,Ffectively improve aggregate quality。,Duration 01:00

(Click on the video,Solve the problem)

At the same time,Aggregate intelligent crushing management system(AggEyes-AICrushing)It can also monitor the important control parameters of the main Crusher and the use of vulnerable parts.,Prompt the available production time of wearing parts through intelligent analysis of lining plate wear,Remind customers to prepare wearing parts in advance,Further improve production efficiency。

Product highlights:

Ø Real-time monitoring,24hOn duty

Ø Data quantification,Quality traceability

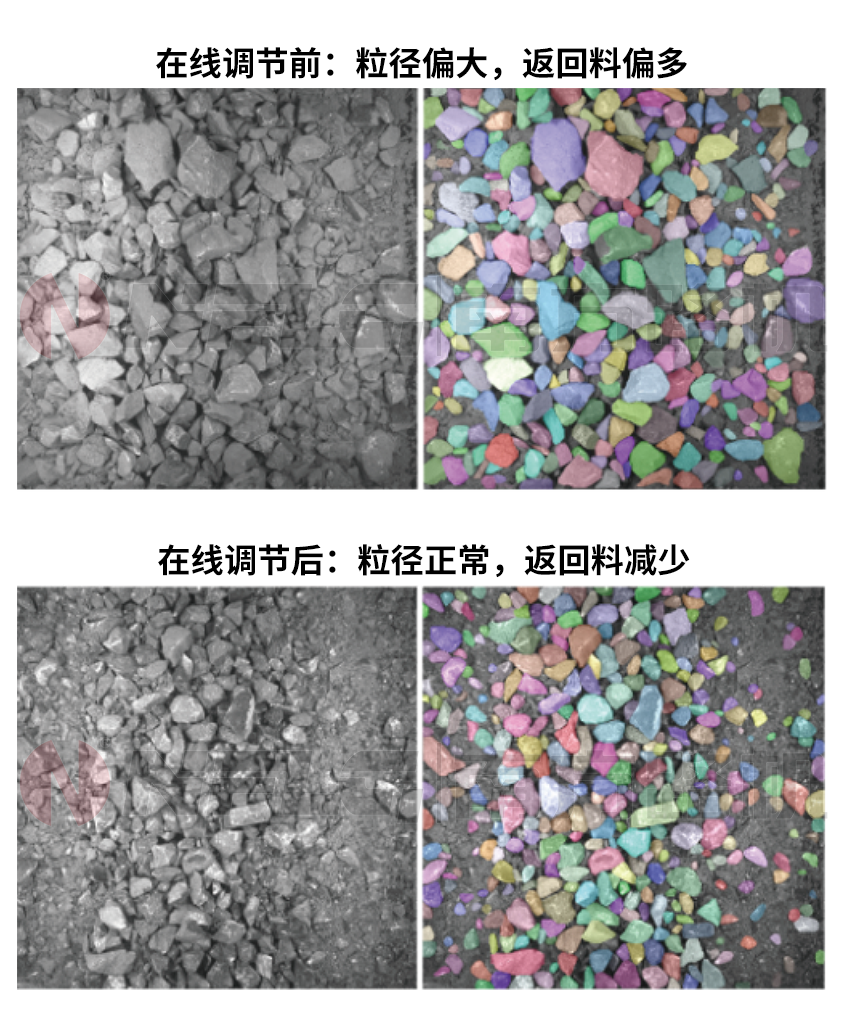

Ø Picture display,Intuitive understanding of the production site

Ø Intelligent control,And that aggregate quality is improve,And that production efficiency is improve

Site application:New Building Materials Co., Ltd.

Monitoring tools:Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing)

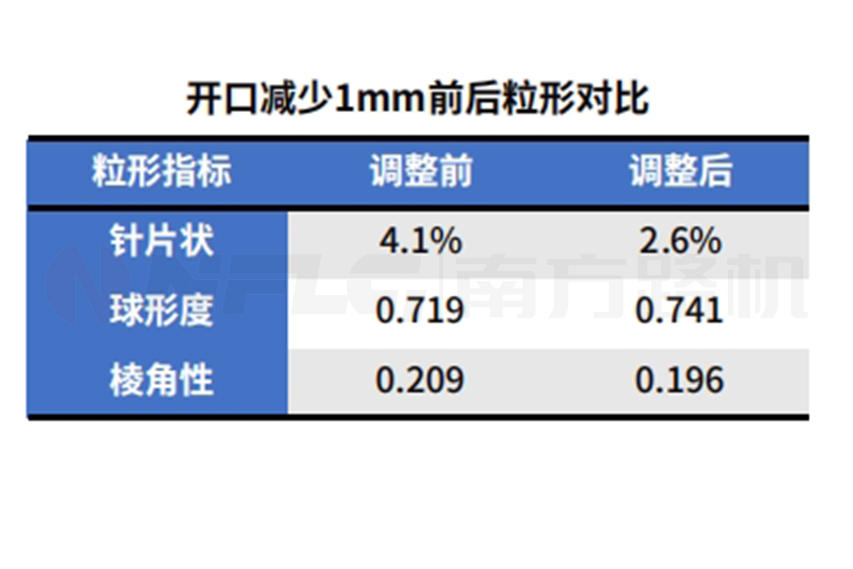

Monitoring data:Particle size、Grain shape

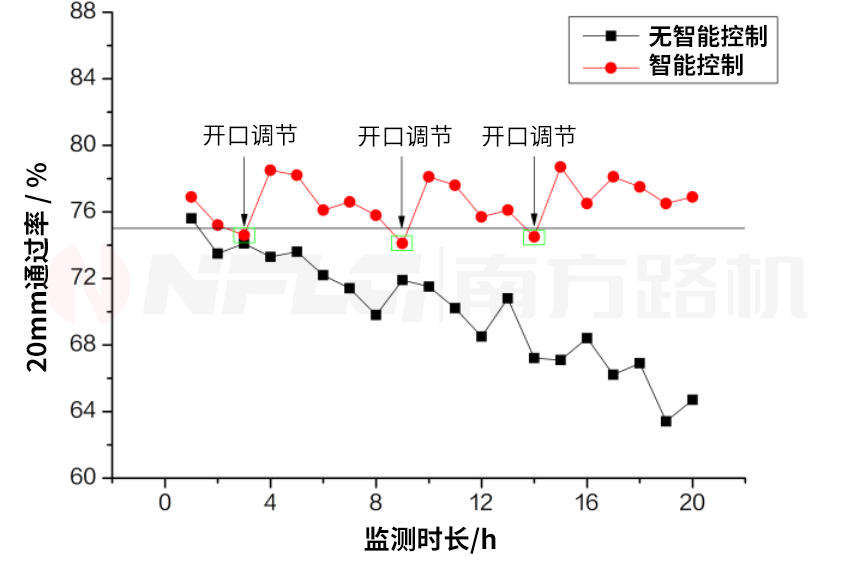

Adjustment standard:20mmPass rate

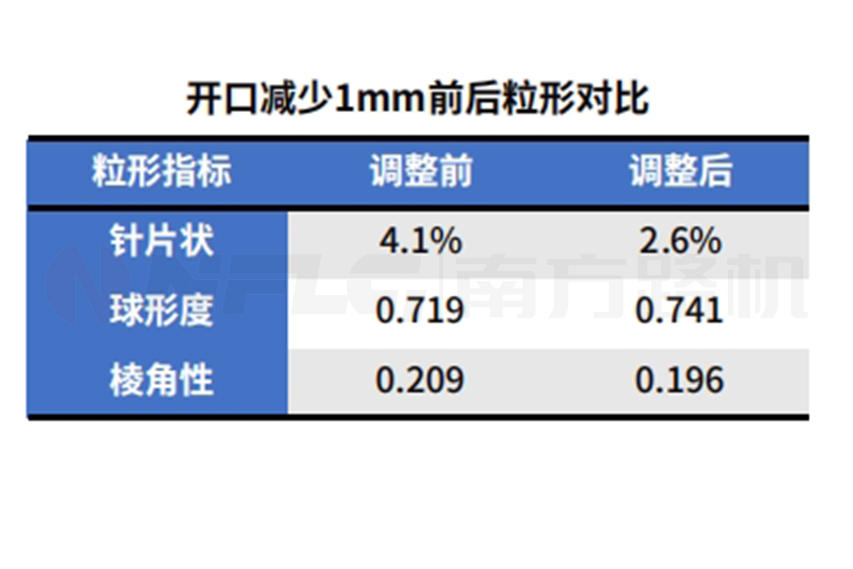

Single adjustment:Lift 1.5%~3%The yield of

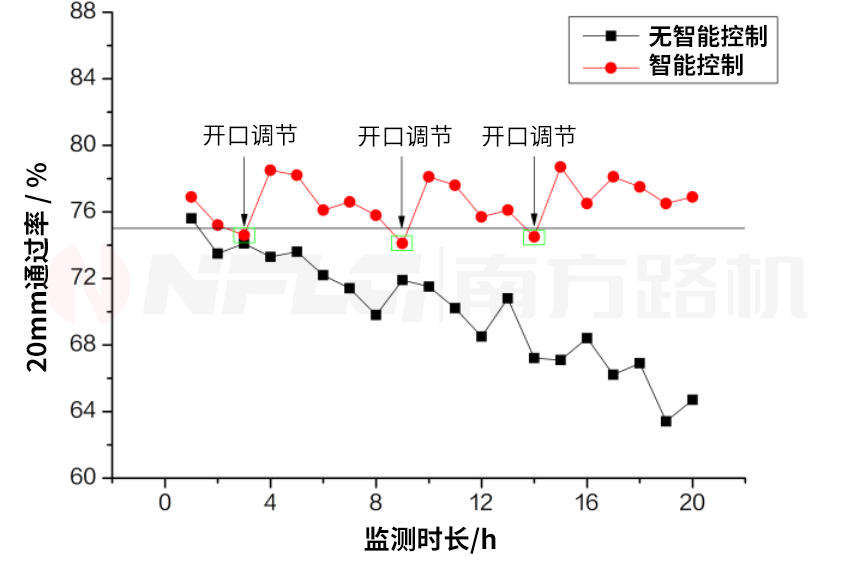

The project is set by20mmParticle size passing rate range of 75%~85%,The update period is 30min,The monitor device 24hOpenAnd statistical data,When the particle size is too large or the gradation fluctuates greatly, an alarm prompt is given andInstruct the cone breaker to adjust the opening。

After adding intelligent control,Cone Crusher discharge 20mmThe pass rate is more stable,When less than 75%Time,The production can be controlled by adjusting the discharge port,Ensure the stability of production gradation。

In an increasingly competitive mine、Mixing and other construction industries,The competitiveness of enterprises is the competition of production capacity, but also the competition of quality.。Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing),Leading edge technology helps enterprises to ensure quality、Build a brand,Achieve cost reduction and efficiency increase!

Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing)

Intelligent Aggregate Crushing Management System of Nanfang Road Machine(AggEyes-AICrushing)