In recent years,The demand for sand and gravel production capacity shows a sharp upward trend.,As a result, the crushing and screening production line of recycled materials has become increasingly prominent in the industrial chain,They are developing mineral resources.、Production of building materials、Waste material disposal and other fields play a vital role.。

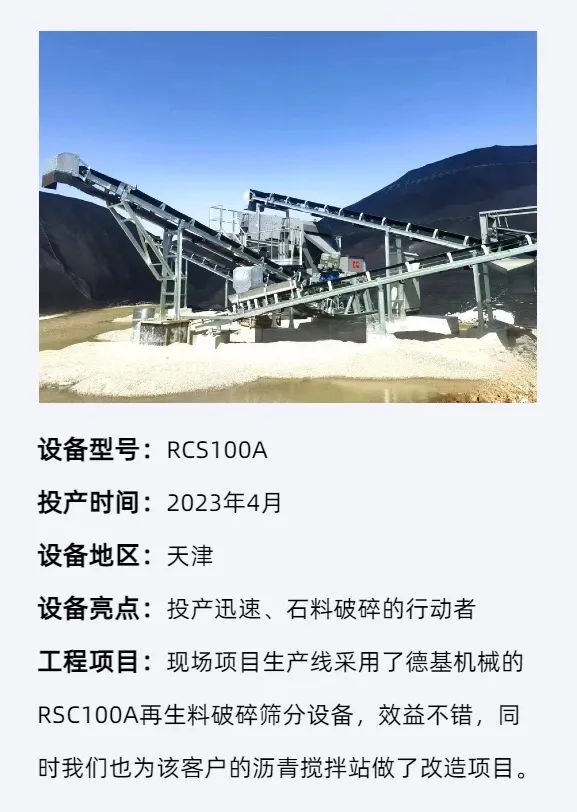

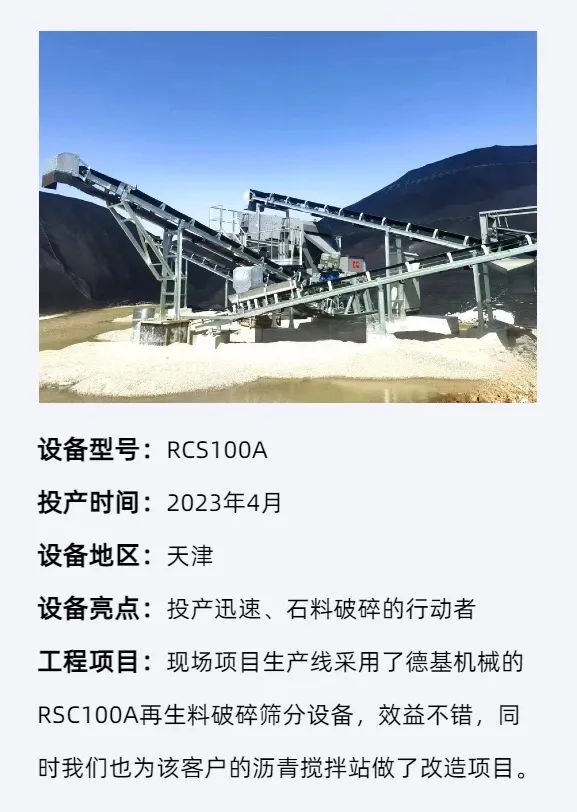

The recycled material crushing and screening equipment of Deji Machinery has been introduced to the market since its launch.,It has accumulated rich experience and technical reserves in project application.,AmongRCSSeries 80-200t/hThe production line has been in Hunan successively.、Jiangxi、Henan、Tianjin、Guangdong、Thailand、Successful application in Hong Kong and other places,Strong market competitiveness。

One

The project has rich experience,Put into production quickly

(Some cases)

Two

Brand core strength

The crushing and screening equipment for recycled materials of Deji Machinery is fixed.、Modular design,Flexible collocation、Convenient installation、Easy to relocate,Applicable to working conditions of Asphalt Mixing Plant,It is the absolute strength of stone crushing.,The crushing ratio is large、And that finis product has good grain shape,More powerful Material Handling capability。

Advantages of crushing and screening equipment for recycled materials

1

The crushing teeth of the double-roller crushing head are of a real kneading type structure.,And flexible crus is realized,The original gradation of the recycled material is hardly damaged by hard extrusion。

One side of the crushing tooth is provided with a slope structure.,Play the role of unloading,Avoid destroying the original gradation due to hard extrusion of aggregate;

The crushing teeth between the two roller heads are engaged in a staggered manner.,Axially asymmetrically arranged,Reclaimed material moves axially while passing through the roll gap,Realize the rubbing and scattering。

2

The two roller heads are arranged in a staggered manner in the horizontal direction,Can realize that passage of the large clump recycle material,In the actual production process, it can pass 150mmPellet and 100mmA lumpy material。

3

The structure of the screening system is the same as that of the vibrating screen in the Asphalt Mixing Plant.,No matter the 2-gear material or the 3-gear material is discharged, it is integrated in a vibrating screen.,Reduce site layout area。

4

Sufficient surplus capacity of crushing head,Length 1200mm,Motor drive power 2×22KW,Effective crushing capacity≥80t/h。

5

The control system is equipped with a self-protection device,When encountering an impassable hard object,Two roller heads will have up to 5 consecutive forward and reverse rotation attempts.,If you still can't get through,The shutdown is forced,Operator intervention check。

Three

Production line construction,And that construction period is shorten

Deji Machinery is more specialized on the road of overall solution.、Maturation,Able to provide customers with a comprehensive production line construction。It is well known,Infrastructure construction of supporting Asphalt Mixing Plant,Yes, the place of production、Layout of production line、Higher requirements for process scheme, etc.,They all need to be supported by professional overall solutions.,Deji Machinery has strong project landing experience in the crushing and screening production line of recycled materials.,It can help users speed up the installation progress to the greatest extent.,And that construction period is shorten,And that construction cost is save。

Deji Zhizao,Green builds the future。Deji Machinery will continue to work hard on equipment R & D and innovation.,Create greater value for customers。If you have the demand for the production line of the crushing and screening equipment for recycled materials,Welcome to contact us.,We will have professional personnel to connect with you.!