Sany Heavy Industry relies on its profound technological accumulation and innovation ability.,Initiate“Intelligent slump detection”And“AIIntelligent unloading”Two disruptive technologies,To improve the production efficiency of concrete、The realization of intelligent control of factory quality and the reduction of labor costs have brought about breakthrough changes.。

The guardian of concrete quality:SANY slump intelligent detection technology

1

Industry challenges

1.Manual detection of traditional slump cylinder is inefficient,It is impossible to inspect every Vehicle.;

2.Subjective judgment of quality inspector,Standards vary,It is easy to cause improper slump control.;

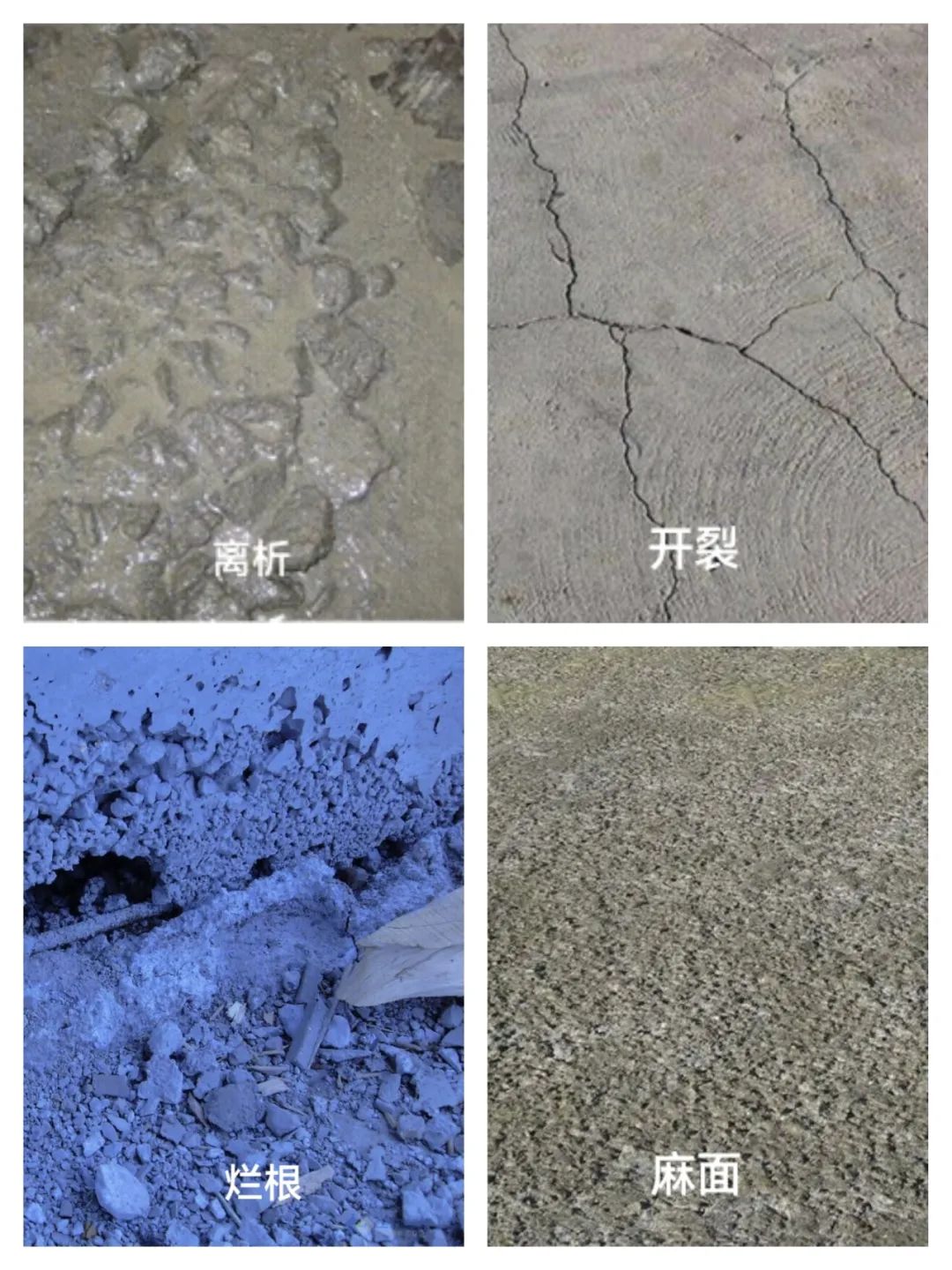

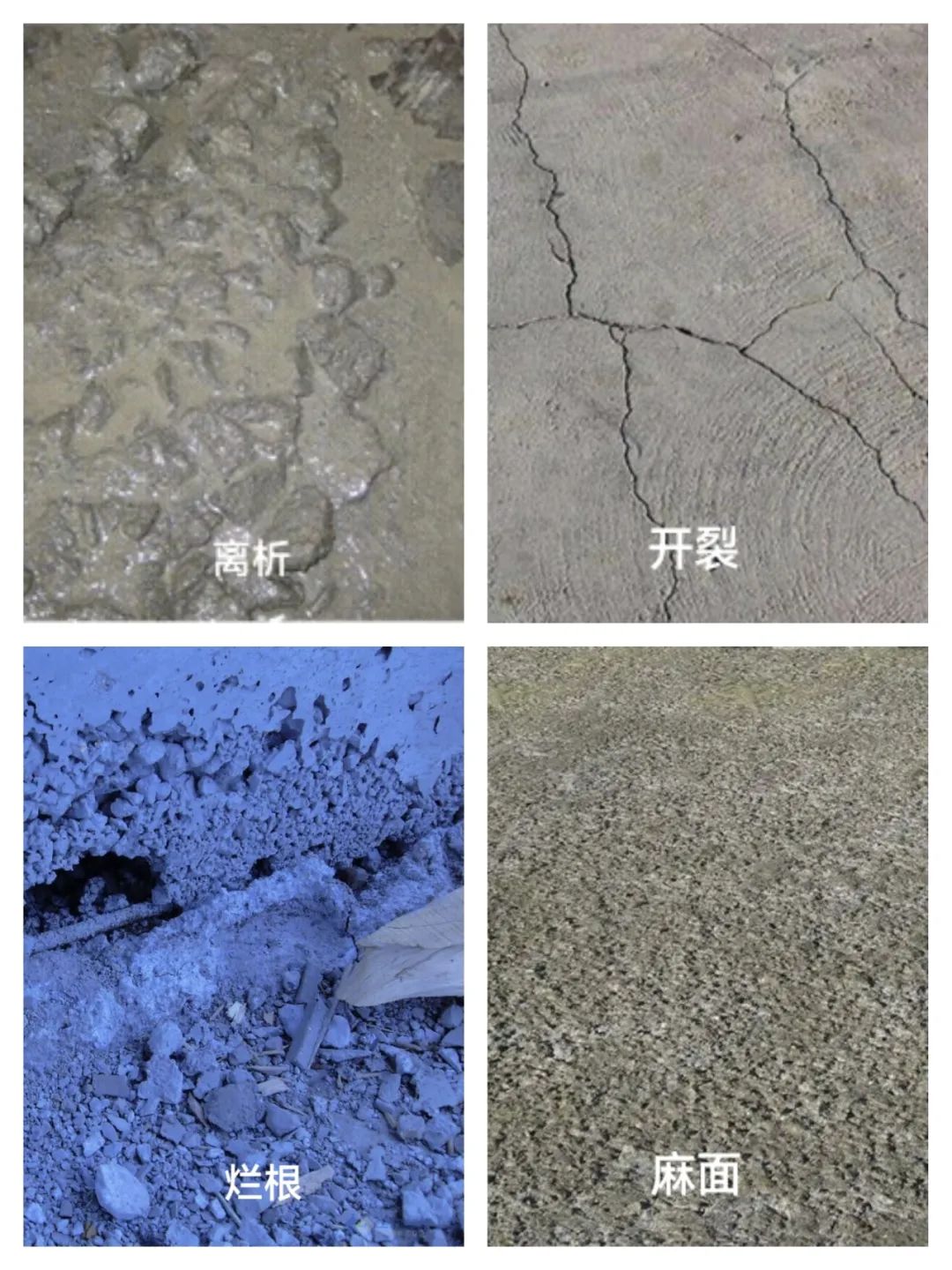

3.Abnormal slump can lead to segregation、Cracking、Rotten roots、Quality problems such as Pockmarked surface。

2

Technical analysis

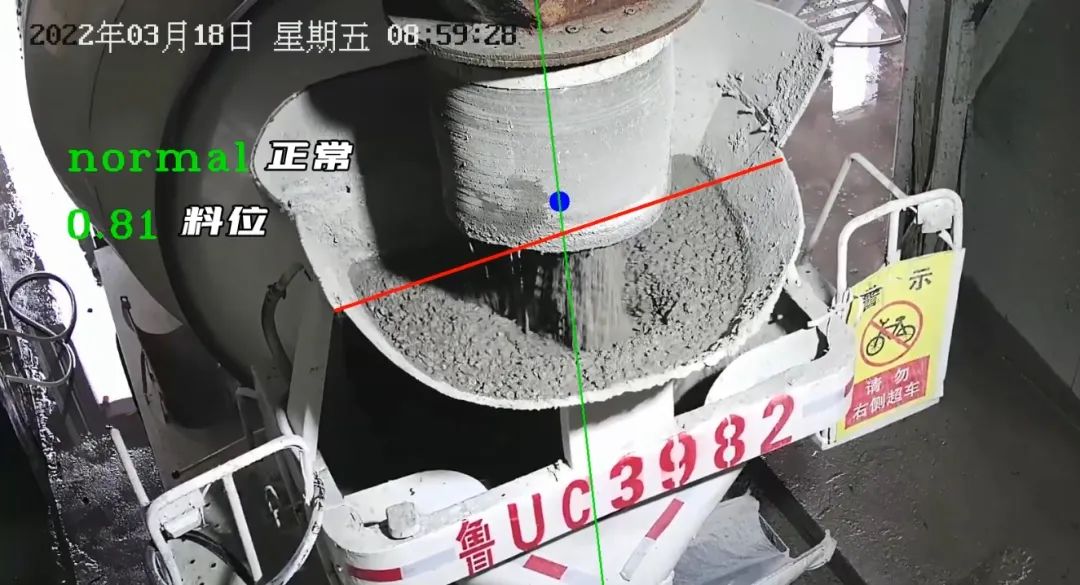

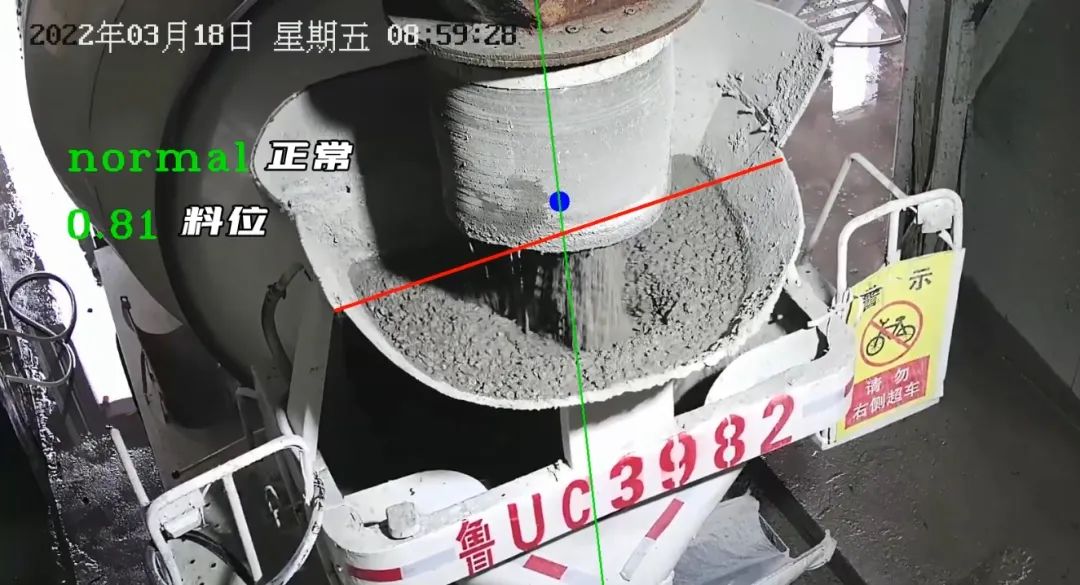

Trinity“Intelligent Detection Technology of Slump”Building a slump large data feature database,Self-developed multi-modalAI Algorithm 、Multi-dimensional feature fusion modeling,Achieve early warning of abnormal slump in production proces、Real-time analysis and detection of pan slump,At present, the accuracy rate in the industry exceeds the level of professional quality inspectors.、The detection accuracy is up to±20mm(National Standard±30mm)The only batch application technology。

3

Customer value

// The boss is at ease:AIQuality inspection,Avoid manual subjective deviation,Ensure that the inspection standard of each disk is uniform;

// Don't worry, boss:7x24h Online ,Every disk must be inspected,Guarantee the stability of concrete quality;

// The boss is free from worry:Through digital quality supervision,Realize traceability of production process,Strengthen the level of enterprise risk management and control。

New Unmanned Unloading Height|TrinityAIIntelligent unloading technology(2.0)

1

Industry challenges

All the time,The unloading process of traditional mixing station relies on manual command.、Manual control,Unloading is inefficient,It is easy to produce spillage.,Causing environmental pollution and material waste。

2

Technical analysis

TrinityAIIntelligent unloading technology(2.0),Based on computer vision+Self-developed deep learning multi-task integration model,ByAIThe system takes over the whole process control of unloading.,Unloading process without manual intervention, 50% improvement in unloading efficiency%,Overflow prevention success rate is greater than 98%,Fficiently prevent material overflow and spilling。

3

Customer value

// Increase efficiency and reduce cost

Intelligent judgment of reversing alignment、Intelligent Control of Overflow Prevention in Unloading,The whole process does not require manual intervention.,50% more efficient%,And that labor cost is reduce(>50%),And that economic benefit of the enterprise is improve;

// Green and environmental protection

AIAlgorithm Specification Receiving Hopper Alignment Criteria,Eliminate the risk of spilling from the source,Adapt to any intensity/Slump concrete,Intelligent detection of material level height,Adaptive control of discharge door,Solve the problem of overflow fundamentally;

// Enhance customer experience

AIReal-time push of detection pictures,Visualization of the detection process,Improve the level of enterprise digitalization,Enhance the customer experience。

Future,Sany will continue to devote itself to technological innovation and product development.

Bring more intelligent solutions for the mixing station industry

Let's look forward to it together!