Another Spring Festival is approaching.,The winter break is at hand.。In order to help the vast number of Uyghur fans during the winter break of the equipment,Be able to clean and maintain the mobile impact crushing equipment and mobile screening equipment correctly.,Make sure the love machine is safe“Celebrate the Chinese New Year”,Win in next year's construction“The starting line”!In the last issue,Xiaowei has brought a set of winter break maintenance strategies for Kelei equipment.,Today, we will give you a guide to winter cleaning.。

Kelei Mobile Counterattack BreakHow to clean up?

Before cleaning,Important system parts of the equipment need to be greased first.,Refer to the previous issue for the key lubrication parts.(Maintenance of Kelei equipment before winter break)。Cleaning is the first step in preparing the equipment for winter break.,The main purpose is to prevent the equipment from freezing and forming hard plates.。

The temperature is low during the winter break.,If a large amount of dust accumulated inside the equipment in daily use is not cleaned in time,In addition, there is a lot of moisture inside.,It will cause icing.,Once the parts are frozen, they are very easy to burst and cause equipment damage.。

It is also worth noting that,Because the Kelei equipment is mainly used for crushing or screening mineral materials and stones.,In the process of crushing or screening,It will produce a lot of mineral powder or stone powder.(0-5 mm)Residual。Many stone powders themselves are good binders.,Uch as cement powder or lime, etc.;Under the combined action of cement powder or lime and water,A substance that forms something like cement.。If you don't get it cleaned in time,,These cement-like substances form hard lumps very easily,Seriously affect the operation of machine parts,Or even hurt the machine。

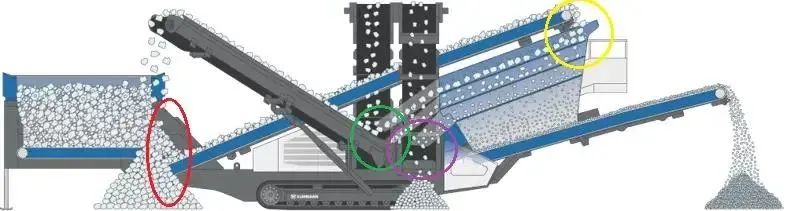

So,For Kelei Mobile Counterattack Break,We need special cleaning for the following key parts of the equipment:

Vibrating feeding unit:During normal operation of the equipment,Most of the accumulated material in the material channel will be washed away with the material flow.,However, some dead corners or edge areas in the channel are prone to the accumulation of sticky or wet materials.,Thorough cleaning of these deposits is the first task before the winter break.。

We need the help of a crowbar.,Screwdriver,Hammer,Shovels and other tools,Vibrating the edges and corners of the feed trough、Crevice zone between vibrating feed chute and vibrating hopper wall、Vibrating feed trough and pre-screened crevice zone for cleaning。

Vibrating discharge chute:The vibrating discharge chute belongs to the centralized passage of the crushing host after crushing.,Accumulation may also occur to varying degrees due to differences in the composition or wetness or dryness of the crushed material。

The key parts to be cleaned are the vibrating discharge chute and the area directly below the discharge conveyor belt.、Bottom plate zone of vibrating discharge chute、The joint zone of the vibrating discharge chute and the conveying belt,The latter two parts need to be opened for cleaning.。

Crushing bin:The crushing bin is the main working area for stone crushing.,Of course, it is also the zone most likely to produce material accumulation.,It should be noted that:

1.Crack zone between upper impact plate and crushing bin,Manually move the upper impact plate up and down at least 5 times;

2.Crack zone of counterattack and broken warehouse,Manually move the lower impact plate back and forth at least 5 times;

3.Back cavity of the lower impact plate,Especially, the area near the hydraulic cylinder of the lower impact plate shall be cleaned carefully.;

4.Open the back door of the crushing bin.,It is necessary to clean the dust on the rod of the hydraulic cylinder.。

Electrical cabinet:At the work site of the equipment,Whether it's the carriage of stone./Loading and unloading process,Or the feed of the Crusher?/Discharge process,Or the crushing process of the equipment,Dust cannot be completely avoided.。

Over time,A small amount of dust may enter the electrical cabinet,This dust will have a very direct impact on the service life or failure rate of the electrical components in the cabinet.,It should be noted that:

1.Large areas of dust, please use dry./Wipe and clean with wet towel,And avoid dust splashing.;

2.A small amount of dry dust needs to be vacuumed;

3.Most of the parts in the electrical cabinet are plastic insulated electrical components.,The temperature decreases in winter,The plastic shell is brittle。If adjustment of electrical components is required,Be sure to handle gently,Otherwise, it is easy to break the plastic shell part.。

Travel track system:During most of the crushing work,The number of applications of the walking track is not much.,But the front and back of the walking track、Inside and outside of travel track、There may be entrapment residue between the gap between the traveling track and the chassis frame and the chain link of the track.。

If these inclusions are not removed,Once the device is moved,It will cause serious scratches and even damage to local parts.。It should be noted that,After cleaning the periphery of the traveling track,It is recommended to move the equipment back and forth for a certain distance.,Then park on a flat and solid ground.。

How to clean the mobile screening equipment of Kelei?

That's all for Kelei's mobile counterattack equipment.,Let's take a look at how the mobile screening equipment should be cleaned before the winter break.。

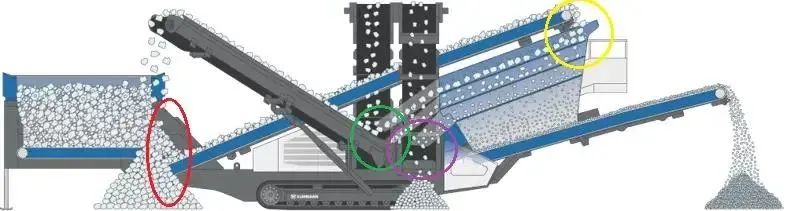

For Crewe screening equipment,To avoid material accumulation on the equipment,In particular to the freezing and solidification of the sticky and wet accumulated material under the condition of long-term low temperature.,It is necessary to discharge all stones in the material circulation channel of the equipment before shutdown.,Accumulated materials that cannot be discharged need to be cleaned manually,It needs to be cleaned up:

1.Hopper conveyor belt/Combination part of feeding and conveying belt of screen box;

2.Screen box feed belt/The blanking area of the screen box;

3.Corner area of transverse transfer conveyor belt;

4.Transverse transfer conveying belt/Joint part of oversize conveying belt;

5.Corner and crack of bottom blanking area of side conveyor belt。

Wei has something to say

The above is the winter of Kelei equipment brought to you by Xiaowei.“Clean up”Guide,If Uyghur fans still don't know something.,You can contact Kelei's service team for consultation.,It can also be used during the inspection of the service team,Use the opportunity of on-site communication to answer questions and solve doubts。In addition,Ours《Dimensional classroom》The operation of Kelei equipment will also be carried out irregularly.、Maintenance and other courses,Partners who want to learn,Please pay attention to the relevant tutorial information released by our official account.!