The series of group standards of "Stir Arm Castings for Construction Machinery" of Skoma passed the examination

January 11, 2024

Recently,The Young Entrepreneurs Branch of China Foundry Association and the Standards Working Committee jointly organized a meeting in Shanghai.《Castings of stirring arm for construction machinery part 1:Steel castings》《Castings of stirring arm for construction machinery part 2:Ductile iron castings》《Castings of stirring arm for engineering machinery Part 3:Wear-resistant alloy casting》And other three group standard review meetings。

After careful examination and full discussion,The Expert Group agreed that:《Cas of stirring arm for engineer machinery》Series of group standardsIt fills in the blank of product standard of stirring arm castings for construction machinery.。Among《Castings of stirring arm for construction machinery part 1:Steel castings》And《Castings of stirring arm for construction machinery part 2:Ductile iron castings》Cast steel is proposed.ZG370-New brand of 710,It is innovative in terms of the material used for the stirring arm components.,Reaching the leading level in China;《Castings of stirring arm for engineering machinery Part 3:Wear-resistant alloy casting》The relevant technical requirements for the casting of stirring arm for engineering machinery by cast-in process of wear-resistant alloy were given,It is the first time to use the cast-in technology of wear-resistant alloy to manufacture the stirring arm castings.,In the aspect of producing stirring arm parts by bimetal composite technologyBe innovativeSex,AchieveInternational advanced level。

Stirring arm castings are widely used in construction、Chemical Industry、Metallurgy、Feed、Garbage disposal、New materials and many other fields,It covers a wide range of industries.,Market demand is growing.。Stirring arm casting products in China have gradually formed a series.,Harsh and complex working conditions have a negative effect on the strength of the stirring arm casting、Toughness、Wear resistance、Service life and other indicators put forward higher requirements.,However, at present, the technical level of stirring arm casting production enterprises in China is uneven.,The function failure caused by serious wear of castings affects the normal production of downstream application enterprises.,And bring greater economic losses.,In order to ensure the quality of stirring arm casting,Reduce the loss of downstream enterprises caused by bad castings,A series of standards for stirring arm castings are specially formulated.,The performance of the casting of the stirring arm was studied.Specification requirements。

The release of this series of standards will effectively improve and standardize the casting quality of mixing arm for construction machinery.,Prolong the service life of the mixing arm,Reduce the unit production cost of downstream users,Promote the realization of the whole industrial chainPollution reduction and consumption reduction,Improve quality and efficiency。

As the main drafting unit of the standard、The leading enterprise in the construction machinery mixing industry,Zhuhai Shigaoma Company has been committed to the R & D and innovation of mixing system.,Take the lead in developing high wear-resistant alloy stirring arm,The stirring arm is provided with the advantages of high abrasion resistance,、Strong impact resistance、Not easy to break、Unique mechanical structure, etc.,The maintenance cost can be greatly reduced.,Reduce safety accidents caused by replacement of vulnerable parts such as mixing arm,Won the praise of the majority of users.。I have the honor to participate in the drafting of this standard.,It is a great inspiration and inspiration to us.。Zhuhai Shigaoma Company will take this as an opportunity,As always, continue to explore the cutting-edge technology of mixer manufacturing,Develop and produce new products with more scientific and technological content and excellent performance,Make positive contributions to the technological progress of the industry。

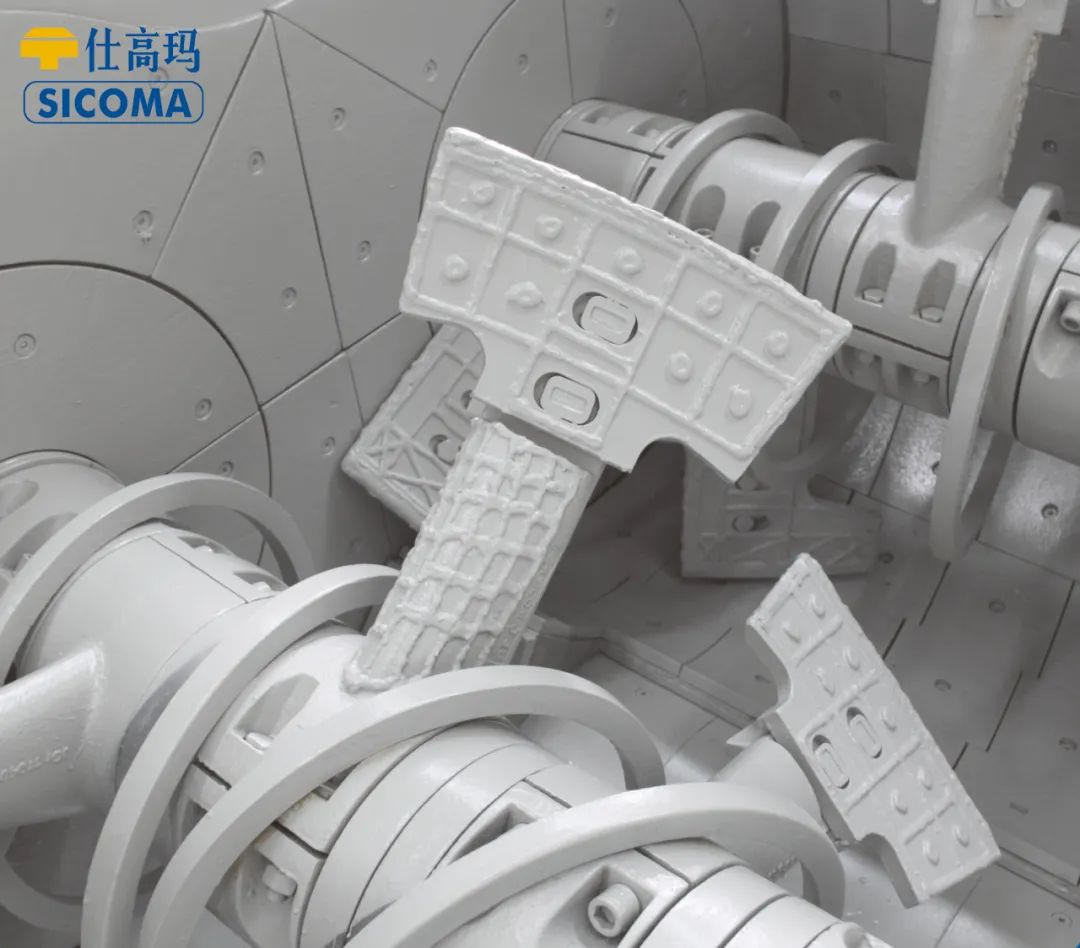

Common alloy stirring arm

High wear-resistant alloy stirring arm (Welding process)

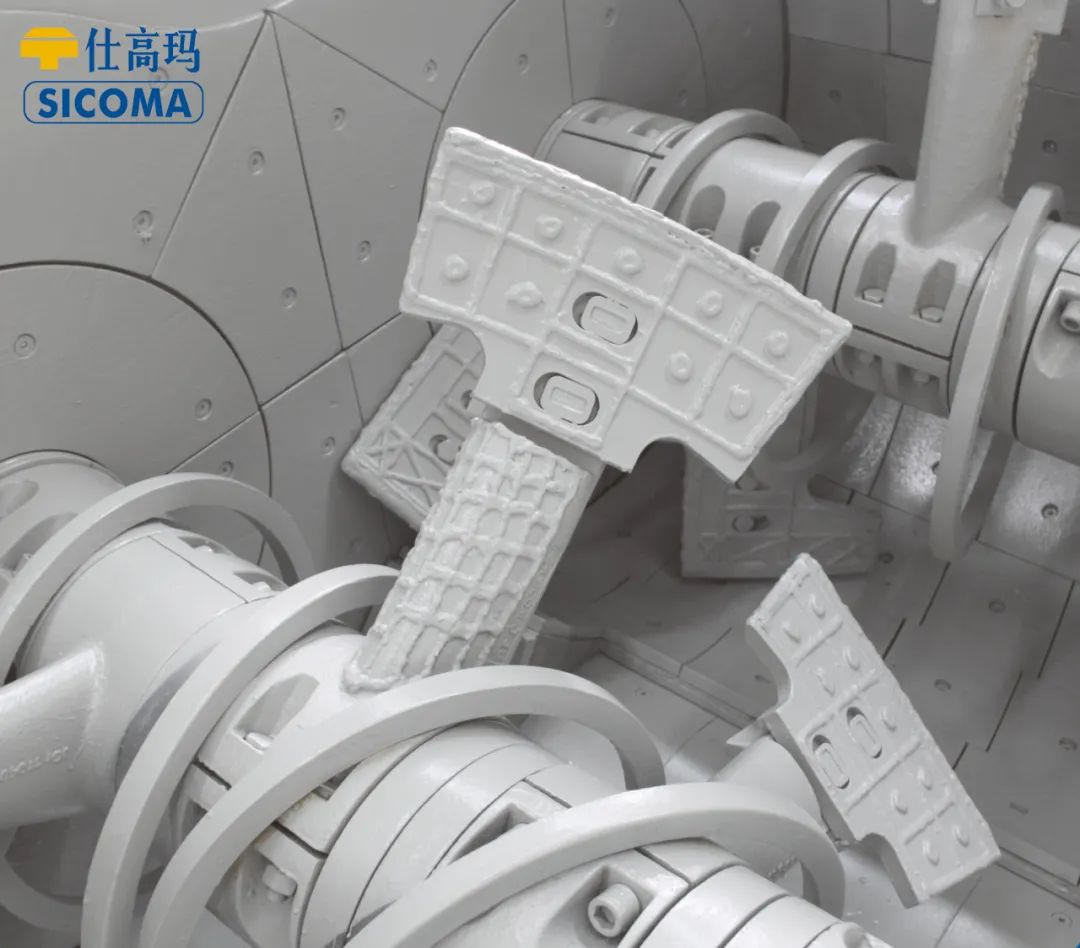

High-wear-resistant point-shaped alloy stir arm (Melting and casting process)

(Source of information:China Casting Association Youth Enterprise Branch)

(Source of information:China Casting Association Youth Enterprise Branch)