Screed is one of the core components of Paver.,Whether the screed is in good working condition may directly affect the paving effect of the road surface.。As the end of the year approaches,The temperature drops,Many areas enter the off-season of construction。It's time to take advantage of the break.,Take good care of your Paver.,Especially the screed for a full maintenance.,LetTAIs back to peak performance,Get ready for the peak construction season next year!

Now Wirtgen China has brought the promotion of screed maintenance package for the old users.。Order now and get a discount,Replace the wearing parts of the screed with a new one for your equipment in one kit,Guaranteeing consistently high paving quality on Vogler Pavers。Quality of original parts,Don't bother and don't waste your wallet.,It is better to take action than to be moved.!

Promotion period:2023Year11Month16From date to2024Year5Month31Day

Top 6 Reasons to Choose a Screed Repair Kit

·Eliminating the need to use any cores greatly reduces cleaning times;

·No need to worry due to new、Assembly problems due to mismatch between old parts or between original parts and non-original parts;

·The screed can be tuned to the desired condition using the original accessories;

·Based on the above advantages,Service time and machine downtime can be reduced;

·The kit contains all the required accessories,There is no need to worry about other parts caused by omission.;

·Ideal match between original parts,Greatly improve the paving effect;

Quality advantages of Vogler screed

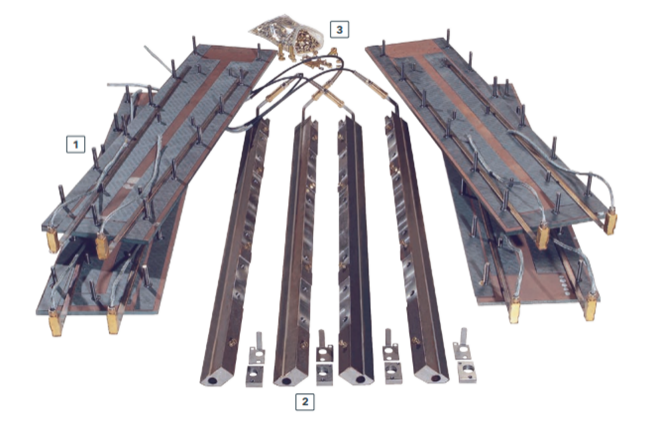

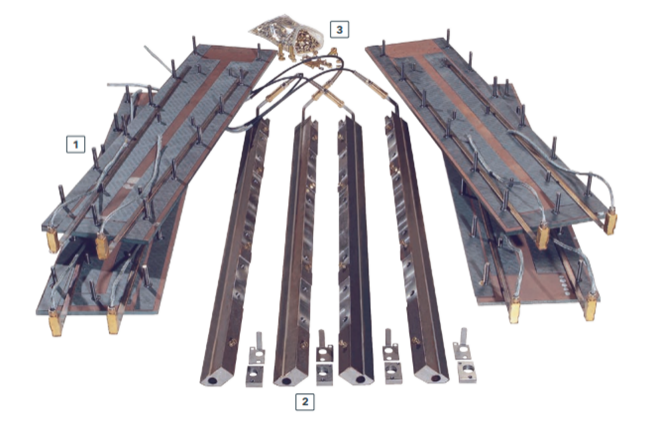

Screed base plate:The wear-resistant steel used to make the screed base plate combines properties such as flexibility and fracture resistance。Due to sliding friction between screed base plate and paving mix,These characteristics play a decisive role in extending the service life of these components。

Original screed in manufacturing process,First of all, the raw material of the bottom plate needs to be cut to the required size by laser.。Later, a chamfer will be milled under the leading edge of the screed base plate to ensure that the material compacted by the rammer will better enter under the base plate.(The direction of travel is forward)。

To prevent cold welding between the rear of the ram and the leading edge of the screed(The direction of travel is forward),This part has also been processed accordingly.,This optimization ensures precise guidance of the rammer,And significantly extends the service life of both components.。Straightening for stress relief,To ensure uniformity.,Through CNC CNC stud welding machine welds the bolts to the upper surfaces。On average, 25 bolts with extremely high tensile and shear strength are required to be welded to each screed base plate。

Rammer:Hard surface and tough core is one of the important characteristics of the rammer.。At the beginning of the manufacturing process,First of all, you need to use CNC The CNC saw cuts the profile to the length required by the rammer。The chamfered structure of the front edge of the rammer ensures that the material is pressed evenly under the base plate,Which in turn results in good compaction.。The service life of these components depends on their hardness.,Induction hardening(This process is also used for pressure beams.)Ensure that the hardness of the rammer is uniform over its entire length,And achieve at least 5mm The hardening depth of。

Toughness and flexibility are maintained inside the rammer,And the surface(Continuous contact with the mixture to be compacted)High wear resistance is maintained。The placement holes for the heating strips are specially developed for Vogler CNC Numerical control deep hole drilling machine drilling。The heating strip placed in the hole heats the rammer and the pressure beam uniformly from the inside over the entire length。Like this,Can prevent asphalt residue from sticking in subsequent paving(Pecially in the preheating phase before starting work),Thereby reducing wear on the contact surface.。

Electric heating system:Fogler is a leader in the field of electric screed heating。Back in 1952,Vogler became the first company to adopt this efficiency.、Environmentally designed Paver manufacturer,Until today,It is still driving the development of screed heating technology through numerous innovations.。

All compacting units are uniformly heated across the entire screed width,To maximize its compaction performance,And ensures the realization of a defect-free and uniformly dense pavement structure.。The process effectively prevents the adhesion of the mixture,And provides an ideal operating temperature for the screed float function。Rammers and pressure beams are fast from the inside with built-in heating strips、Uniform heating。Built-in heating strips are standard on screed,It distributes heat over the entire screed surface.。As an option,The edge plate and edge plate shoes can also be fitted with heating elements。

Promotion scope and consultation method

From 16 November 2023 to 31 May 2024,Purchase AB500-2 TV / AB600-2 TV / AB500-3 TV / AB600-3 TV / AB480-3 TV / AB570-3 TV / SB250 TV / SB250-2 TV / SB300-2 TV / SB300-3 TV / SB350-3 TV Applicable Screed Repair KitEnjoy the discount price immediately!In addition, there are many series of accessories for joint promotion.,Click on the link to see if there is one for you.!(Click on the link to see the specific promotion information)