【DEVELONLecture Hall】

Recall the apprenticeship of the Excavator

It all started with the butter.

Why does the Excavator need to beat butter??

Hit which parts?How to fight?

Let's reveal the secret today.!

PART 1

Where does the name of butter come from??

Butter used in construction machinery

Generally calcium-based grease or lithium-based grease

Because of the golden color

Like the butter used in Western food.

So they are collectively called butter.

PART 2

Why does the Excavator need to beat butter??

If the Excavator is used as a body,

When working in sports

Body joints

That is, dozens of positions of big and small arms and buckets.

There will be friction

When the Excavator is working under heavy load

The friction of related parts is also more serious.

In order to ensure the safety and smoothness of the whole movement system of the Excavator

It is necessary to add proper butter in time.

PART 3

How should I beat the butter??

1

Before maintenance,First retract the big and small arms of the Excavator,Decide the posture according to the surrounding environment,It is possible to fully extend the forearm。

2

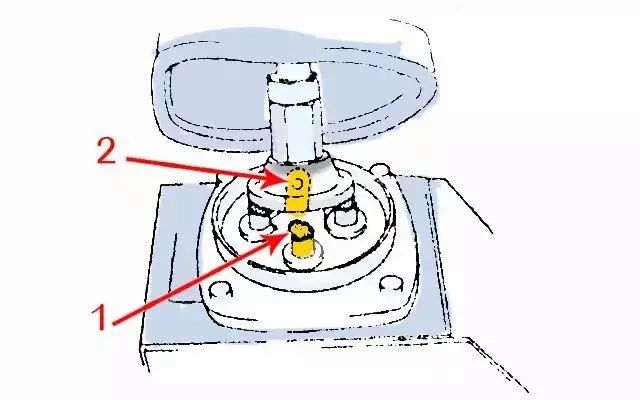

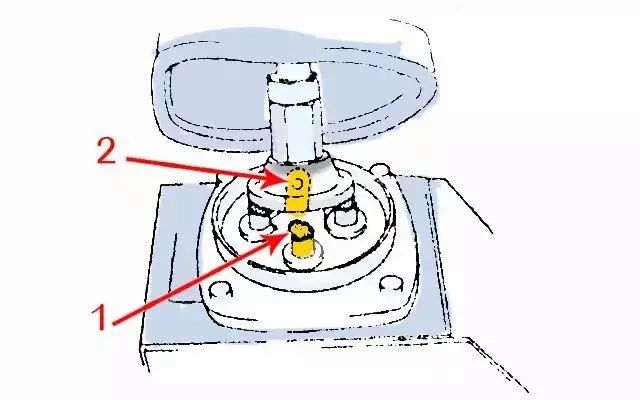

Press the tip of the grease gun firmly into the grease fitting.,Align the grease gun head with the grease gun nozzle。Fill by swinging the pressure arm of the grease gun,Fill until the grease overflows the pin shaft just。

3

The 2 pins of the bucket need to be oiled every day,Until oil spill。The forearm and forearm play less and more frequently.,About 15 times each time.。

PART 4

What are the parts of the butter??

Except for the big arm、Forearm、Bucket

Rotate the big gear ring、Outside the track straightening frame

What other parts need butter??

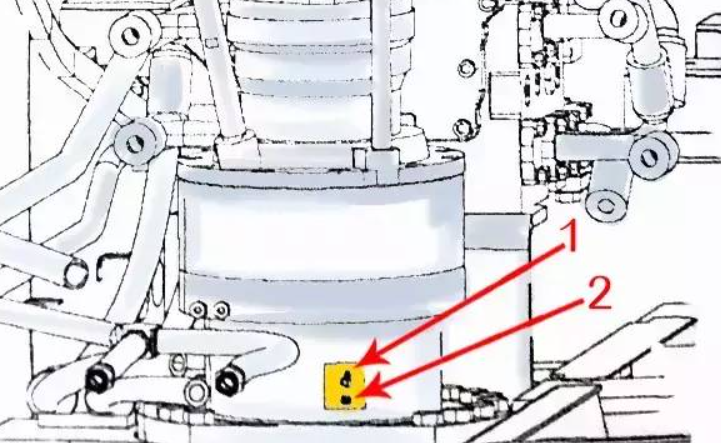

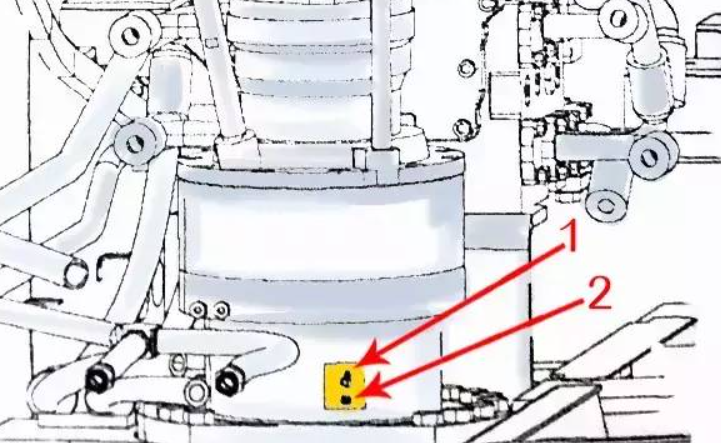

Operate the pilot valve:It is necessary to check the operating pilot spool hemispherical head every 1000 hour,And add butter。

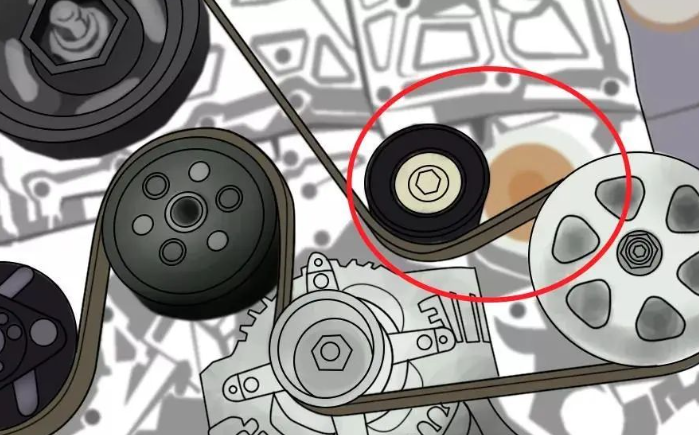

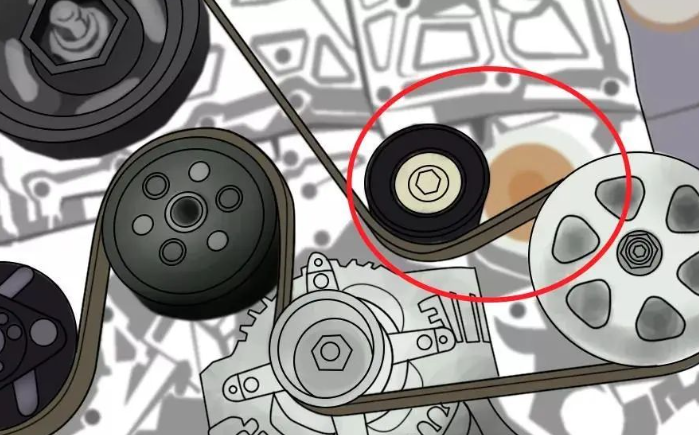

Fan tension pulley:Position of tensioner pulley shaft,Remove the bearing, clean up the impurities and apply the grease.。

Battery column:Work in a wet environment,Apply butter properly on the battery column.,Corrosion can be effectively avoided.。

Bearing of rotary motor reducer:Grease spouts that can't be ignored,Remember to top up every 500 hours of operation.。

Rotate the butter trough:To reduce friction,Use a strip tool to smear each tooth flank,Protect the contact surface between the lubricating oil cylinder shaft and the bearing Bush。

Water pump bearing:Encounter oil emulsification、When the oil begins to carbonize, butter is applied.。The old butter needs to be completely replaced。

Working environment and high-intensity construction requirements

So that there can be no carelessness in adding butter for lubrication.

So the job of digging the butter.

You can't be lazy.~