The error of the whole ship is controlled to 0.87% by the dynamic precision weighing system of the micro-special door machine.

March 17, 2023

Portal landline in Xigang District

Recently,Micro-special is the dynamic accurate weighing system for 9 portal machines in the west port area of the first wharf.,Successfully passed the owner's acceptance,It is verified by the statistics of dynamic accurate weighing system for on-site loading and unloading and the comparison of actual weighing.,Finally, the error of the dynamic accurate weighing system is 0..87%。

The picture shows the on-site corn unloading operation.

After the system is installed,At the unloading dock, there is a cargo ship unloading corn at the site.,According to statistics,Gantry crane accumulatively grabs 3490 buckets。

The picture shows the driver working in the cab.

Dynamic weighing is carried out synchronously,Finally, the 46836 of gantry crane dynamic weighing ship weight..91 tons。

Micro-dynamic accurate weighing system is based on the balance relationship between motor power and load torque.,And fuse that transient response of the load sensor,Accurate measurement statistics and safety protection in the dynamic loading and unloading process of the crane are realized.,Solve the problem of low efficiency of traditional measurement and statistics。

The picture shows the Truck weighing each bucket.

After the completion of the unloading of corn from the cargo ship at the dock,The corn is transported to the designated place by the Truck.,Each bucket of goods shall pass through the weighbridge on site for unloading inspection.。According to the actual field statistics,1895 times of Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicles leaving the port and passing the weighbridge,The weighbridge is statically weighed and the total weight of the whole ship is 47250..5 tons。Calculated,The weighing error of the whole ship cargo in the dynamic accurate weighing system of a wharf reaches 0..87%,Weighing in motion accuracy error far below acceptance expectations2%。

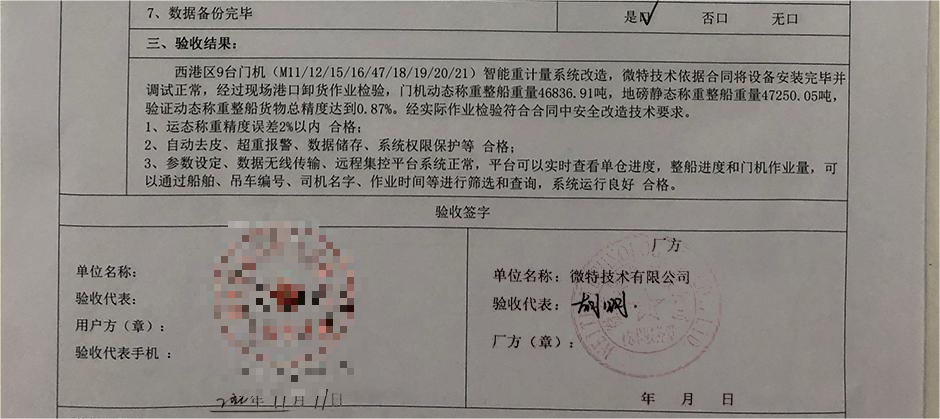

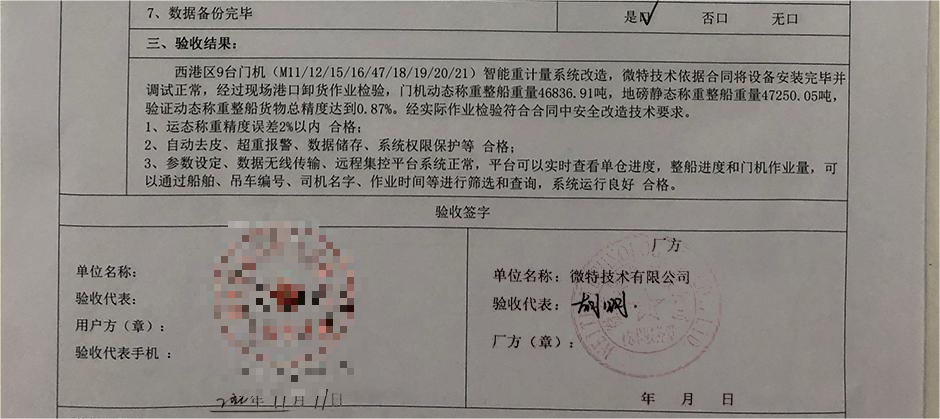

The picture shows the construction acceptance form signed and sealed by the customer's engineering department.

The actual operation test results far meet the customer's expectations.,The customer manager expressed his gratitude to the Weite after-sales engineer

Dynamic precision weighing system and torque developed by Weite Technology Co., Ltd.、Overload limiters differ primarily in accuracy and function。Torque、The national standard of overload limiter requires that the comprehensive error should not exceed 5%,The dynamic precision weighing system can reach 1%Within,Its core technology is Weite's unique intelligent dynamic professional algorithm.,The weight of the goods can be accurately calculated in the motion state of the goods hoisted by the equipment,No impact on lifting operation。