Innovative Cold Milling Solutions,Regeneration,Soil stabilization and concrete slipform spreading

Wittgen(Wirtgen)Will be inWirtgen GroupAndJohn DeereOn the joint booth.,Cold milling is on display、Regeneration、A range of quality products in the field of soil stabilization and concrete slipform paving。In addition to introducing nine models from three product areas,,The Wirtgen Group will also introduce digital solutions as well as machine-assisted systems。

Comprehensive Cold Milling Product Line

WirtgenThis will bring a powerful half-meter cold Milling Machine. — W 50 Ri,Used for post-discharge construction。The outstanding advantages of this model are mainly reflected in two points.:Simple control concept and many automation functions。 W 120 FiFront discharge Cold Planer working width up to 1.3 m。F Series medium Milling Machine equipped withJohn DeereEngine,Designed to meet the specific needs of cold milling operations。The exhibition of these two large Milling Machines makes the product range of cold Milling Machines more comprehensive.。W 210 FiAnd that application range is wide,It includes a series of construction from pavement repair to full milling and then to fine milling.。W 250 FiThis large Milling Machine is powerful.,The company focuses its research and development mainly on material loading capacity and machine performance.,Designed to help maximize production to the extent possible。

F Series Cold Planers can also be equipped with innovative Mill Assist Machine control system and method for digital recording of construction sitWirtgenMilling output tracking and recording system。

Cold regeneration and soil stabilization proces - Consistent with sustainable development,And is economical and efficient

W 380 CRi ,WR 200 XLiAnd WR 250i Resources can be fully and efficiently utilized,This occupies a certain prominent advantage in the market.。W 380 CRiPost-discharge mode can be adopted for cold recycling construction,Mixing performance up to 800 t/h,Used for large-width pavement repair operation。CR The series of Recycling Machines can be used for cold recycling construction in situ(CIR),But also can carry out full-depth cold regeneration construction.(FDR)Project。In addition to cold recycling construction,WR Series Wheeled Reclaimer is also suitable for soil stabilization。Working width 2.4 m,And has strong milling and mixing performance.,The configuration is comprehensive and high-quality,It can fully meet the needs of large area operation.。With digital solutions from Wirtgen,AutoTracAutomatic steering assist system and WPT(WirtgenPerformance Yield Tracker System),The construction efficiency has been greatly improved.。

Flexibility is key,Fully meet the application of front paving and side paving slipform paving

WirtgenWill carry SP 15i AndSP 94i These two customized concrete slipform Pavers are unveiled to everyone.。SP 15i Highly flexible。Pecially when a concrete monolith is laid on its sides,Paving molds of various shapes can be flexibly installed on the left or right side of the complete machine.。The bridge of the machine can be operated telescopically.,Therefore, the operator can have a wide and clear view of the working area.,This ensures a high quality paving result。In addition,This model is also equipped with Wittgen's professional research and development. AutoPilot 2.Automatic Navigation System for Slipform Paving,Realizing non-datum line slipform paving。SP 94i It is a fully modular positive paving slipform Paver.。EquippedTeleMoldThe four-track Paver of the system will also make a brilliant appearance in Las Vegas.。This Paver allows for fast、Flexible change working width。Up to 3 feet on each side,Six feet in all。

Innovative Cold Milling Machine Technology

Using the Milling Assist System,The working efficiency of the milling operation can be greatly improved。In automatic mode,The system adjusts intelligently based on milling performance and construction cost,Select the appropriate mode of operation。As a result, the engine speed and the drum speed are automatically adjusted accordingly。In low gear range,It can greatly reduce the fuel consumption and wear of the cutter head.。In the high range,Even in the face of large area milling operation,An ideal milling texture can also be obtained.。The operator can select three operation modes.:“ECO Energy saving mode”,“Performance optimization” And “Milling texture quality”。

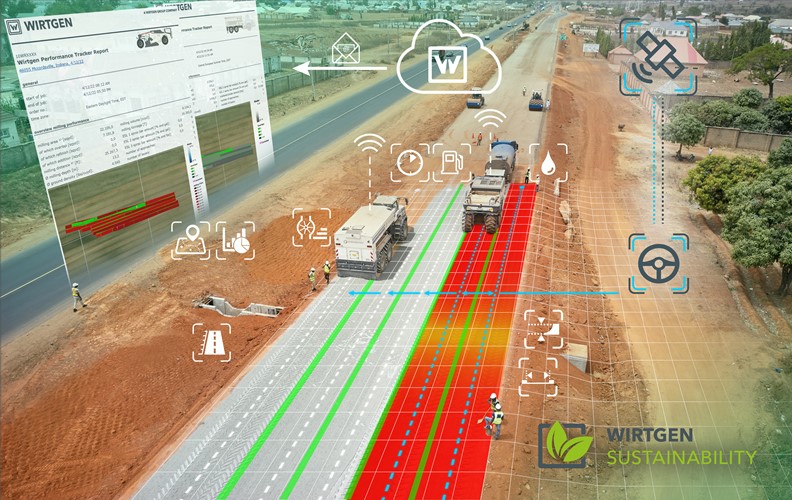

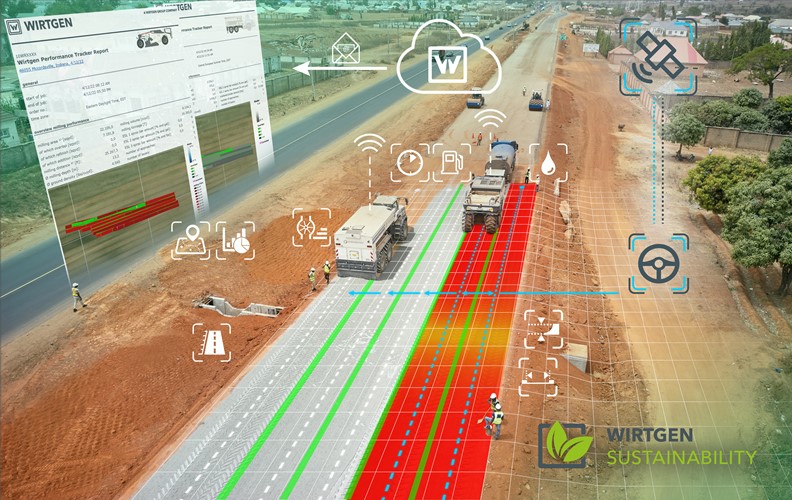

Use Wirtgen Milling output tracking and recording system(WPT)It can accurately calculate the milling area of the machine.、Milling output and energy consumption data。The laser scanner is used to measure the cross section of the road surface that needs to be milled。And then with the help of GPS Positioning system and other sensors accurately measure milling area and milling volume。The operator can continuously track the most important information in real time through the control panel display.。After completion of milling construction,All data related to production and energy consumption will be generated automatically,And send it to the operator's mailbox.。This greatly reduces construction time and construction costs.。

FromWirtgenCold milling experts in the United States Tom Chastain To be held on March 16, 2023,Las Vegas Convention Center, 208 West. - Held in Hall 210 Conexpo In the educational lecture, the application of cold milling construction and advanced cold milling technology are introduced in depth.。

Reclamation and soil stabilization construction using resource-saving technologies

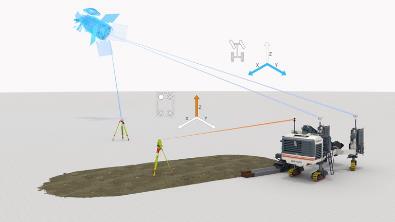

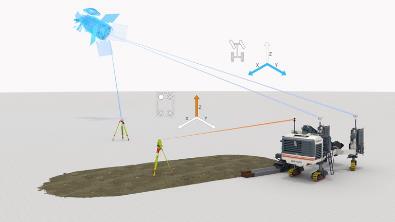

WirtgenWR Series of Recycling Machines equipped with satellite-based positioning and navigation AutoTrac Automatic steering assist system。It not only makes the construction more accurate and efficient,,It also greatly reduces the workload of the operator.。It can be within the tolerance of centimeter level.,The specified overlap spacing between rows according to the preset reference road surface and the adjacent road surfaces,Precise control of steering,This allows the machine to continue working at the desired working width。Therefore, the work efficiency can be remarkably improved.,Achieve double harvest of benefit and environmental protection。

WR Series machines are also available withWirtgen Performance Yield Tracker System。The system will collect all relevant important construction parameters.,Provide a comprehensive database for job site analysis and documentation。For example, in soil stabilization construction,Working width、Depth of work、Construction area、Fuel consumption and other parameters are all recorded.,The operator can obtain relevant information at any time.。

Non-baseline slipform paving improves construction efficiency and safety

Compared with the traditional measurement method,,WirtgenProfessional research and development AutoPilot 2.Automatic Navigation System for Slipform Paving,So that that slipform pave without a reference line is realized。The system provides precise control of the machine's height adjustment and steering,Suitable for all side Pavers and side Spreaders。It can also refer to GNSS Signals and various onboard sensors(Depending on the configuration,Uch as airborne ultrasonic sensors,)Data provided。Non-datum line slipform paving is adopted.,The construction party does not need to carry out the time-consuming installation and removal of the baseline.。Even for small radii and complex terrain,It can also be fast、Accurately complete the paving operation。

WirtgenAutoPilot 2.0 Slipform Paving Autopilot for machine control and remote control from a single source。

W_photo_W100Fi_00003_HI

Wirtgen F Series medium and large Cold Planers can also be equipped Mill Assist Machine control system and Wirtgen Milling output tracking and recording system。

W_Innovation_WR-Series_00004_HI_EN

During construction of soil stabilization,AutoTrac And WPT The system has made outstanding contributions to the realization of resource conservation.。

W_graphic_Autopilot_00002_PR

The Wirtgen AutoPilot 2.The automatic navigation system of slipform paving can adopt slipform paving without datum line.,The construction efficiency and the construction safety are obviously improved.。