As the pioneer of modern pavement compaction technology,Dynapac has created generations of high-performance vibratory rollers with its original vibratory compaction technology.,It has created numerous excellent projects in the global road construction industry.。Today, we bring the installation tips of damping rubber block to the users of Dynapac double steel Road Roller.,Good maintenance will certainly bring longer service life and better construction performance for your love machine.!

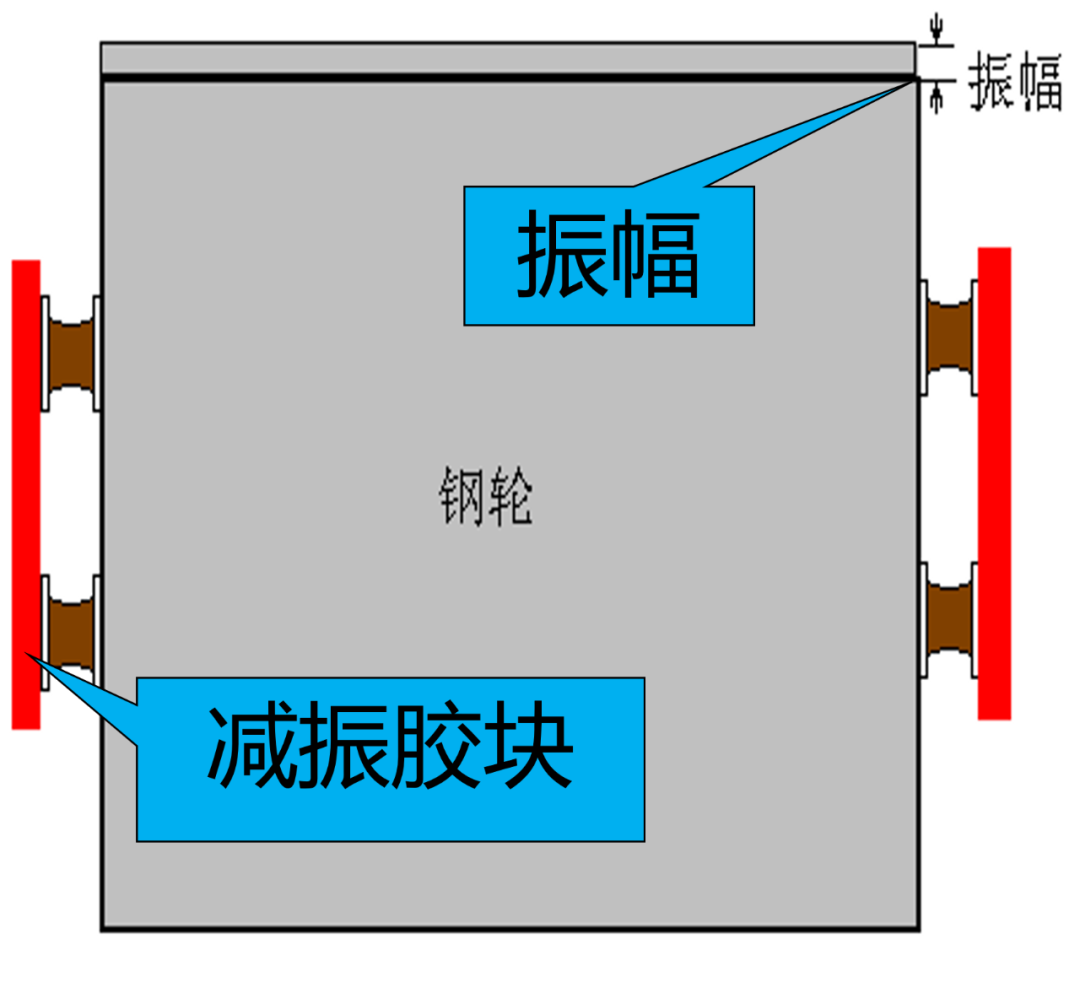

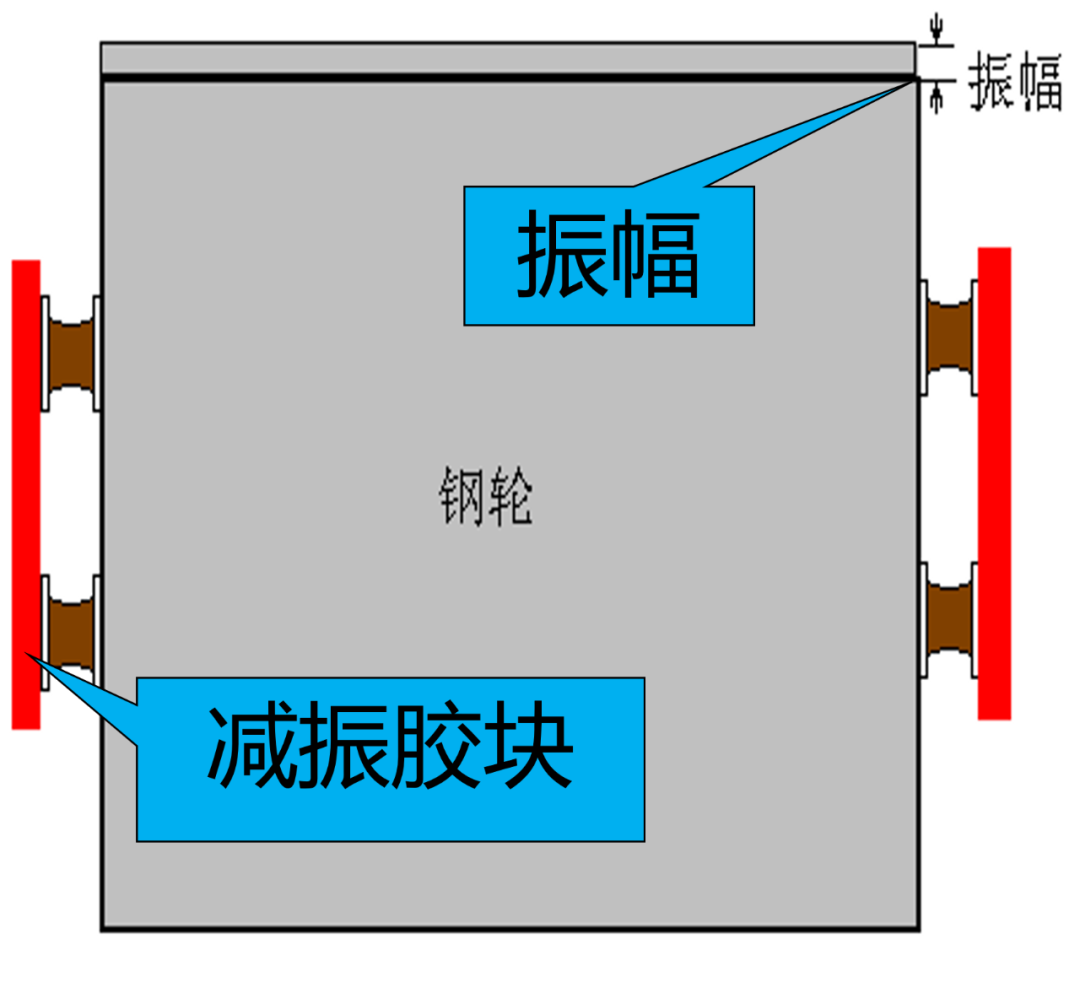

The vibration damping rubber block is arranged between the vibration wheel and the frame,Quickly absorb the vibration of the steel wheel through the damping effect of the damping rubber block,Prevent the vibration of the drum from being transmitted to the body,To avoid damage to body components due to vibration,And provide a comfortable driving environment for the driver.。However, the vibration damping rubber block also affects the amplitude of the steel wheel of the Road Roller while absorbing and damping vibration.,The amplitude of the roller is an important parameter of the roller.,It will seriously affect the compaction efficiency and compaction effect of the roller.。

Function of damping rubber block

Damping、Vibration absorption is the most important role.;Bearing the weight of the frame of the Road Roller;

Transfer the driving force。

The damping coefficient and shear coefficient of the original damping rubber block are accurately calculated.,Perfectly match the required shear factor and damping factor of the roller,O that the Road Roller obtains standard damping effect and amplitude.。If you choose the damping rubber block from the subsidiary factory outside,Its damping effect and damping coefficient do not match with the roller.,Not only will the important parts of your equipment, such as the reducer,,Frame,Damage to hydraulic system,Causing damage to the driver's health,But also seriously affect the compaction efficiency and compaction effect of the roller.。So-called“Buy cheap and use expensive.”That's what it means。

Period for inspection and replacement of damping rubber block

Check if the damping rubber block is damaged every week or 50 hours.;

If it is found that the damping rubber block has been cracked,The depth of the crack shall be checked,If the crack depth exceeds 15mmIt needs to be replaced immediately,So as not to cause other injuries to the equipment or the driver;

The crack depth of the damping rubber block can be detected by needling with a metal pin.;

The damping rubber block is a rubber element, which will be aged due to the influence of natural environment and working conditions.,Its damping coefficient,Parameters such as shear coefficient will change.,Therefore, even if the damping rubber block is not cracked,,In use 2500-It also needs to be replaced after 3000 hours or 3 years。

Incorrect installation will reduce the service life of the damping rubber block.;

Improper strapping of the roller during long-term storage or transportation will also reduce the service life of the damping rubber block.;

The service life of the damping rubber block will be seriously damaged by the frequent emergency stop of the Road Roller at high speed.。

Install the damping block correctly

If one or more of the damping blocks at one end of the drum are found to be cracked,Damaged damping blocks must not be replaced,All damping rubber blocks at this end shall be replaced at one time.,Because the hardness and thickness of the new and old damping rubber blocks will be inconsistent.,Therefore, if only the damaged damping block is replaced, the new damping block will be broken soon because of the inconsistent stress.。

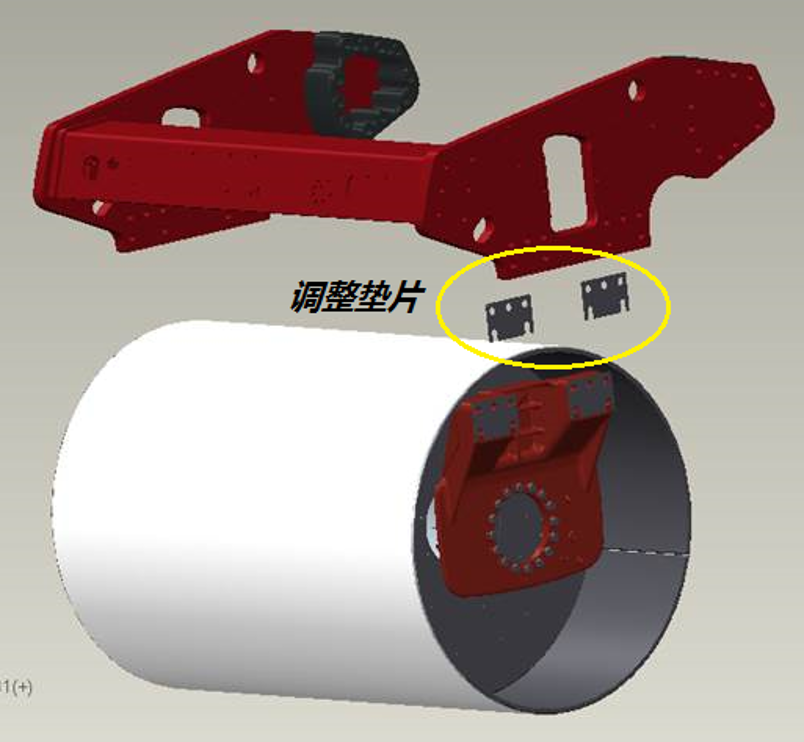

Mounting of damping blocks requires a 2-3mmPre-compaction of i.e. 1 at each end-1.5mm,The service life of the vibration damping rubber block can be prolonged。

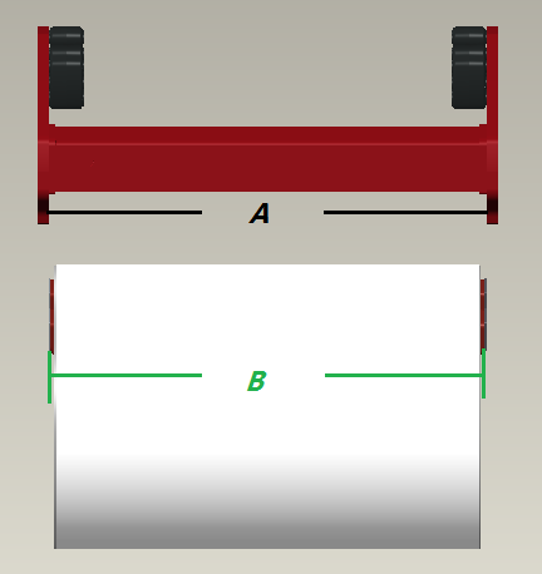

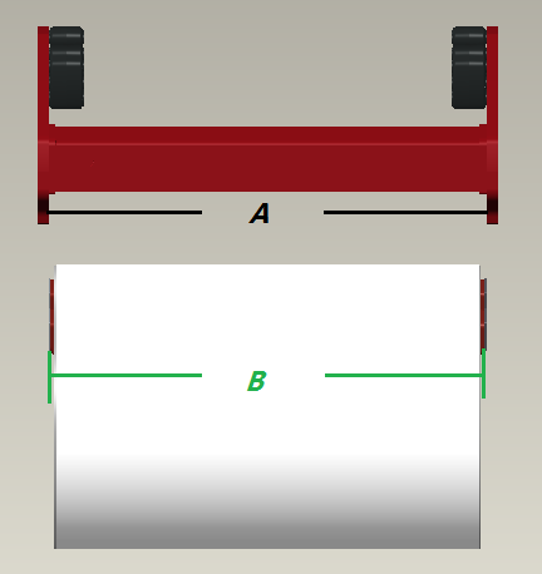

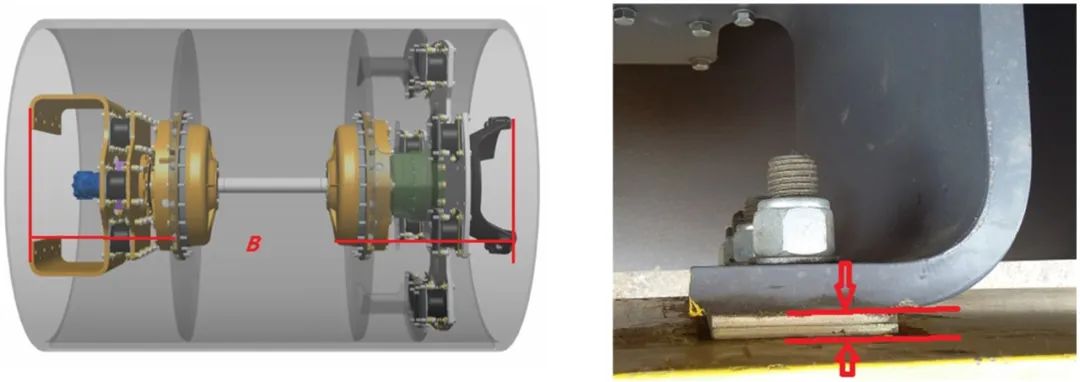

How to pre-compact(Take the large double-drum roller as an example.):

1. Install the damping block, side fork and other accessories on the drum.;2. Measure the width on the inside of the drum end frame,Get a widthA;3. Measure the width between the outside mounting surfaces on both ends of the drumB;

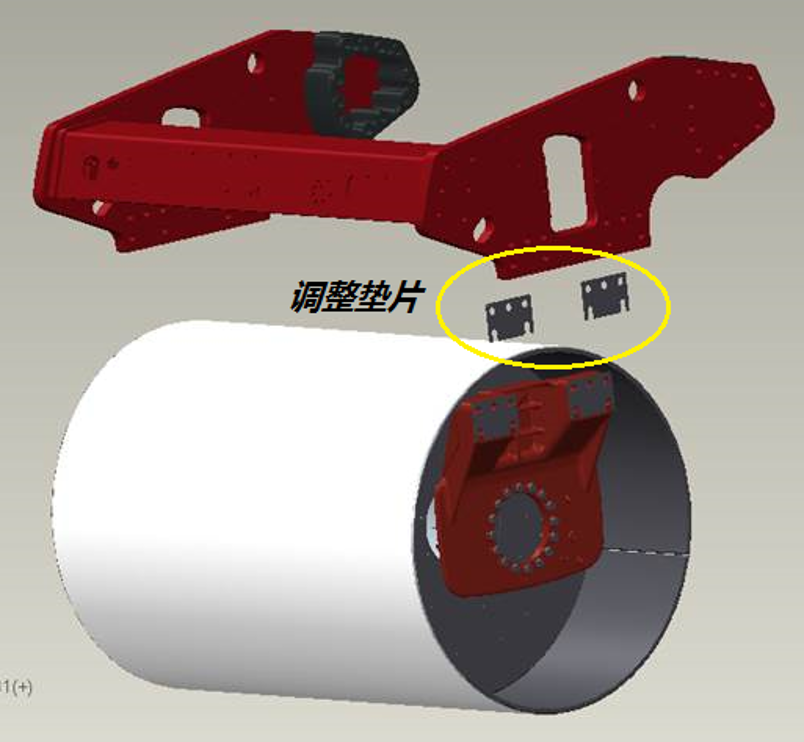

3. Calculate the clearance between the drum side forks and the end frameL=A-B,This is the gap between the side fork of the single-ended steel wheel and the frame.L/2;4. Add 2 between the end frame on the side of the drive end and the side fork+L/2 mm Adjusting shim for,Add 1 between the end frame and the side fork at one side of the vibration end+L/2mmGasket;5. Tighten the connecting bolts to the specified torque.。

Notice:Try to ensure that the steel wheel is suspended in the air during installation.。

The correct installation of damping rubber blocks on single-drum rollers is similar to that on double-drum rollers.,Measure the width on the inside of the drum end frame,Get a widthA,Measure the width between the outside mounting surfaces on both ends of the drumB; And then will(A-B+3 mm)The adjusting shim is installed onUOne side of the type plate。

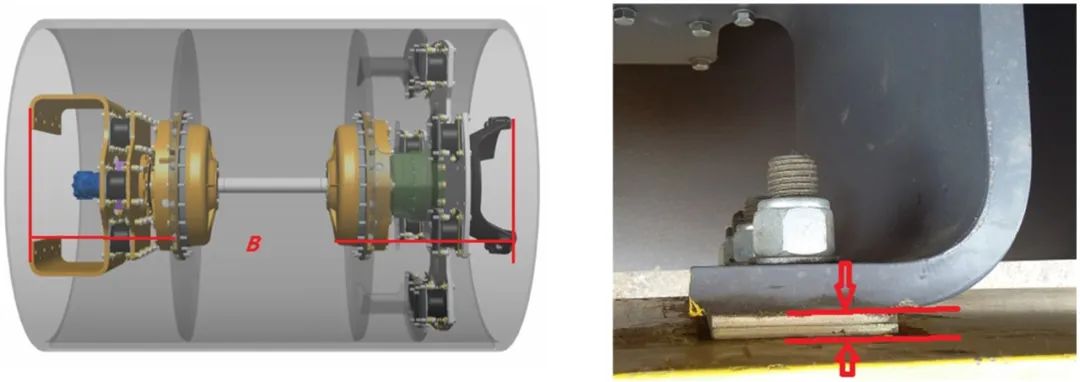

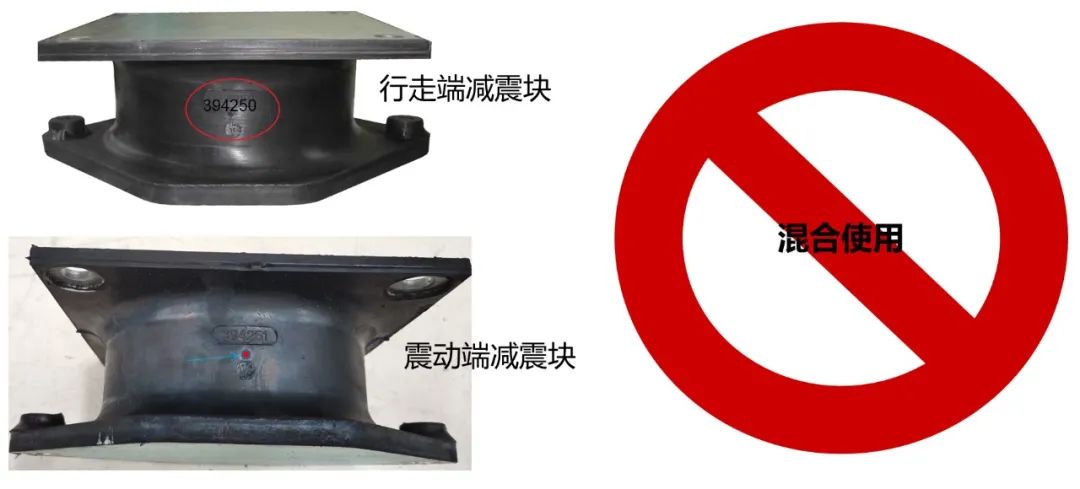

Use effect of inferior rubber block:The rubber block is completely separated from the iron plate :

Use effect of original rubber block:Small cracks appear on the surface of the rubber block,Depth is less than 3mm,Can still be used :

Replacement principle 1

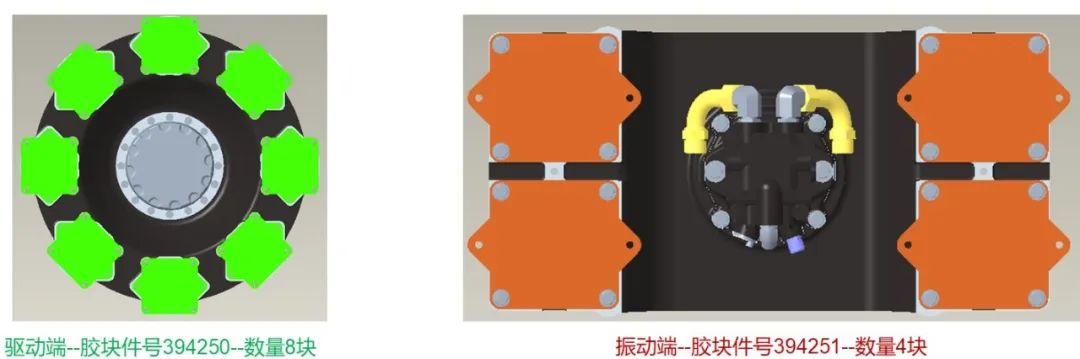

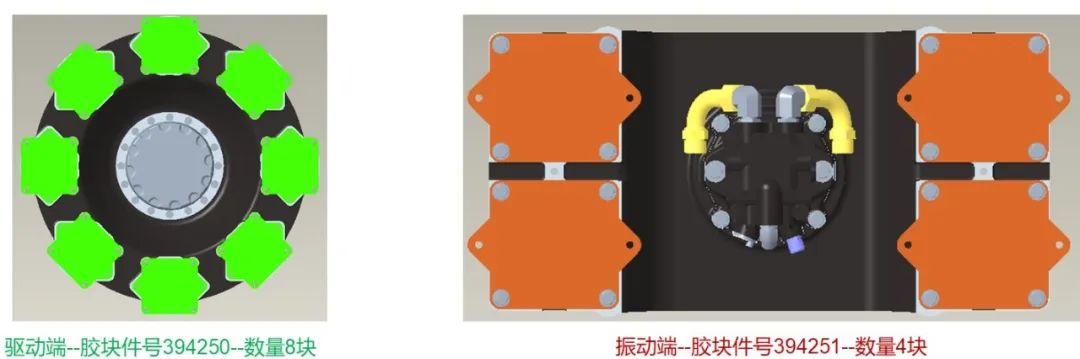

CC5200/CC6200/CC624/CC524 requires special attention:

When only one rubber block on either side meets the replacement requirement,All blocks on this side must be replaced together

Replacement principle 2

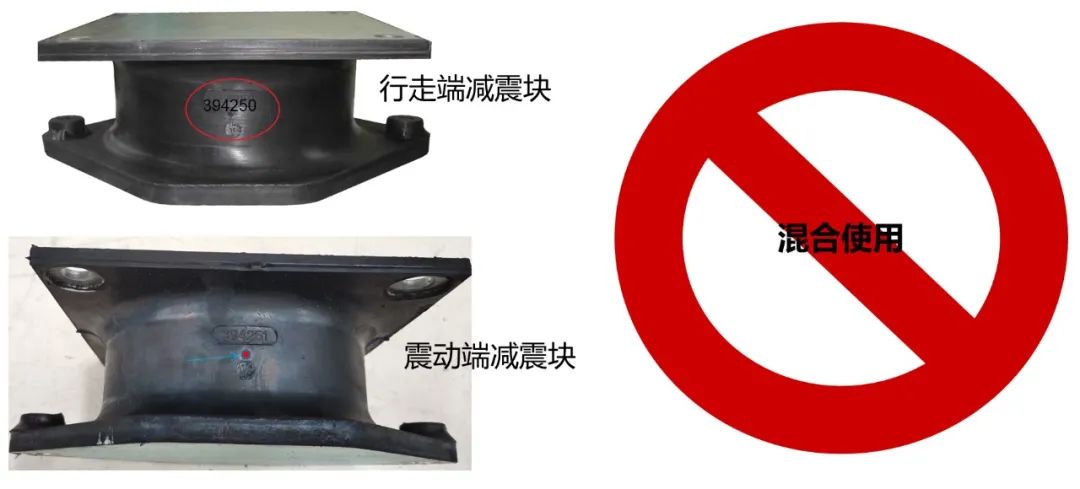

1. Although the dimensions of the rubber blocks on the drive side and the travel side are identical,,But the part numbers are different,Because their design parameters vary widely,Never mix;

2. The result of mixing changes the damping and shear coefficients of the original optimized design,Affect compaction efficiency and compaction effect;

3. The result of mixing will be the important parts of the equipment, such as the reducer.、Frame、Severe damage to the hydraulic system,The comfort of driving is significantly reduced.;

Dynapac,Committed to high-tech means to achieve the customer's road construction objectives,We not only provide our customers with high-tech compaction and paving equipment,It is also an expert in road construction technology solutions around customers.,Join hands with you,Build the future together!