Jintai Grasps Drilling and Milling Equipment with Full Power, Huizhan "Yangcheng Corolla" Baiyun Airport T3 Terminal

December 02, 2022

The third phase expansion project of Guangzhou Baiyun International Airport is the largest expansion project in the history of civil aviation in China.。Jintai Double Wheel Milling、Rotary Drilling Rig、A total of 7 sets of Hydraulic Grab equipment were used in the third phase expansion project of Guangzhou Baiyun International Airport to effectively speed up the construction of diaphragm walls and increase efficiency.。

It is reported that,New Baiyun Airport StationTTerminal 3 is now under full construction.,There are more than 200 builders and more than 30 underground foundation construction equipment on the site.。Construction follows“Whoever can do it will do it.,Leave if you can't”The principle of,Strict card control of construction quality,Improve safety management,Strengthen civilized construction。

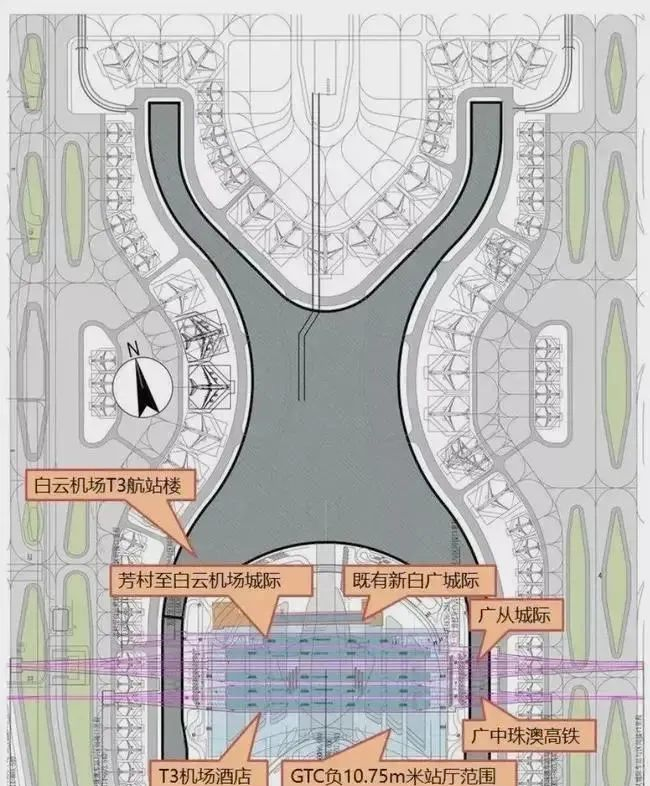

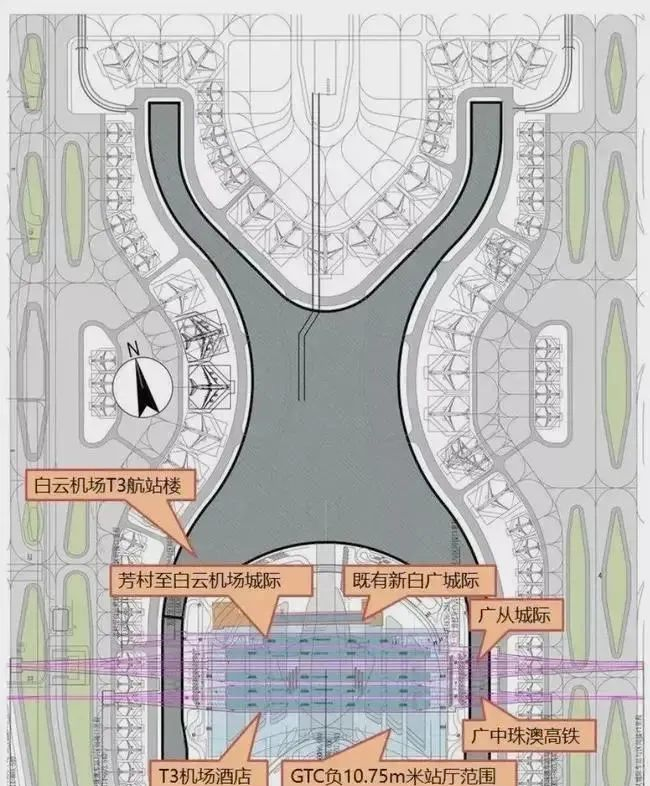

“Corolla of Yangcheng”Baiyun AirportTTerminal 3

T3 The length of the foundation pit of the terminal expansion project is about 1456.m、Width is 18.2m~171m、The depth is about 6.9m~38.1m。Main soil layers within the scope of foundation pit:Plain fill,Silty clay,Coarse sand、Gravel sand、Completely weathered carbonaceous shale、Highly weathered siltstone、Highly weathered shale、Highly weathered carbonaceous shale、Medium、Weathered limestone,Highly weathered carbonaceous shale, etc.。Formation hardness is 20~75MpaThere are karst caves between them.,The hole-seeing rate is 48.9%。

The efficiency of Jintai rotary excavation is fast.,The precision is high,No deviation

In order to improveT3. Progress and accuracy of diaphragm wall construction of terminal expansion project,It is adopted on site“Grasp, drill and mill”Combined process for construction。The construction technology has been tested by the market for a long time.,Wall forming efficiency can be improved by 40%Above。In addition,“The key to building a wall quickly,It also depends on whether the rotary digging is straight or not.”。Baiyun AirportTTerminal 3 expansion project has strict acceptance criteria for vertical accuracy,The guide holes of several existing rotary excavation equipment fail to meet the requirements.,Kim TaeSH38 Rotary Drilling Rig relies on its own profound technical background,There is no deviation hole in hard formation and ultra-deep pilot hole.,Smooth construction,It has been unanimously approved by the site project department.。

Jintai gas lift reverse circulation Double Wheel Milling machine is easy to use.,So it's still“Hyun”

Baiyun AirportT3 Terminal Expansion Project“Grasp, drill and mill”Double-wheel milling equipment for terminal core construction,Kim TaeSX40AAndSX40BDouble Wheel Milling is the main machine type in this section.。There are two types of diaphragm walls in this construction section.,1200 respectivelymmThe meat wall and 800mmA plain wall。Groove depth of 39m、42m、46m、66m。In actual construction,Kim TaeAType double-wheel milling is slightly faster thanBType Double Wheel Milling,BThe construction efficiency of double-wheel milling is almost the same as that of field pump suction double-wheel suction.。Kim TaeBThe construction efficiency of the double-wheel Milling Machine is improved by 40% in the hole guiding state%Above,Milling efficiency of the original 3-day groove,Directly increase the speed to 2 days per slot,The fuel consumption is only 50% of that of the field pump suction Double Wheel Milling%,The verticality is stably controlled within one thousandth.。It is worth mentioning that,The data is from Jintai, who was offline in 2019.SX40BProvided by Double Wheel Milling。

Jintai is a professional manufacturer of overall solutions for foundation construction.,Rich experience in R & D and manufacturing is rare in China,Most of its products belong to modular design.,And can effectively realize multi-purpose of one machine.,Flexible and convenient,Low cost of customer input、Good value for money。 Upon understanding,ThisSX40BThe predecessor of the double wheel mill is a Jintai.SG60 Hydraulic Grab,Before it was converted into a two-wheel mill.,The equipment has 1 in the form of grab bucket.40,000 hours of service。2019,Because customers have a deeper demand for equipment for diaphragm wall operation,Thereby bringingSG60 Hydraulic Grab transformed into JintaiSX40BDouble Wheel Milling,The actual work in the four years after the restructuring has exceeded 10,000 hours.,It has served Hangzhou Metro Line 3 successively.-Gudang station、Foshan-Diejiao station、Guangzhou-Tangxi station、Disaster Prevention and Mitigation Infrastructure Projects of the Macao SAR Government。The equipment has been used so far.,In addition to normal wear and tear and maintenance,Still old and strong。So,Users have great trust in their products.,Several sets of Jintai double-wheel milling equipment have been purchased repeatedly.,This move is enough to serve as the best evidence of trust in Jintai products.。