Xiaohan Avenue Upgrading and Reconstruction Project starts at the intersection of Xiaohan Avenue and Tianxian Road.,The route is laid along the existing old road from west to east.,It ends at Tongjiahu Bridge on Xiaohan Avenue.,The total length of the route is about 33.078km。This project is constructed according to the standard of two-way six-lane first-class highway and urban arterial road.。

Project overview

Xiaohan Avenue connects the central city of Xiaogan.—Airport Economic Zone—Tianhe Airport—An important traffic artery in Wuhan,It is an important infrastructure for the eastern expansion of urban development.。It is also the implementation of the main functional layout of the city.,Optimize the town、Agriculture、Three types of ecological development space,Create a new pattern of node city development in Wuhan metropolitan area,Realization“Global filial piety”The need for ideas。The road from the intersection of Xiaohan Avenue and Tianxian Road to Jingzhu Overpass is damaged.、Severe aging,Especially, the pavement of the motor lane is seriously damaged.。The main pavement diseases are rutting.、Cleft reticulum、Pothole、Peeling, etc。

The pavement structure design of the reconstructed motorway and auxiliary road is as follows::

5 cm AC-13C Fine-grained modification SBS Upper layer of asphalt concrete+Rubber asphalt synchronous crushed stone seal layer+ 12 cm Foamed asphalt cold regeneration lower surface layer+Old road base grouting。

Late August 2022,Hubei Xiaogan Yongcheng Construction Co., Ltd. uses high-performance foam asphalt cold recycling equipment W 380 CR The pavement of the second bid section of the project has been efficiently regenerated and repaired.。

Construction scheme

The construction party adopts the mode of half-width construction and half-width traffic protection.:First, construct the upstream half of three lanes.,Start in the inside lane of the road,And continue construction to the next intersection.,Twice regenerated longitudinal lapping 10 cm。

Material design

Adopt 2 m Milling Machine according to the design milling depth of 10 cm On-site sampling of asphalt concrete,And use Wittgen WLB10S Indoor test equipment for mix proportion design and mixture related performance test,Specific design results and mixture performance are shown in the following table.。

Construction process

The mechanical equipment used in this project includes Wittgen high-performance cold Recycling Machine. W 380 CR One,One gravel distribution Truck,One cement distributor Truck,Three water Trucks,One thermal insulation asphalt tanker,Vogler Paver Super 1880 L One,Humvee HD One 138 double-drum Road Roller, HC 228 D One single steel wheel,Rubber-tired roller HP 280 One,One 50 loader,One 20-ton dump Truck。

Prior to project construction,The construction party shall adjust the parameters of the Recycling Machine in advance.,Uch as the amount of asphalt、Moisture content、Travel speed and other control indicators。The gravel distributor shall distribute the newly added aggregate on the old pavement according to the designed mixing amount.,Then the cement spreader uniformly spreads the cement on the surface of the new aggregate according to the designed cement dosage.。

During construction,W 380 CR The cold Recycling Machine shall adjust the regeneration depth in strict accordance with the design elevation at all times,The front end pushes the asphalt tanker and the water Truck to move forward,The mixed finished recycled material is conveyed to the hopper of the Vogler Paver by the conveyor belt at the rear end.。The Paver spreads the recycled material evenly on the original base course.,The Hummer roller closely follows the Paver for rolling,Complete the cold in-place recycling construction of asphalt pavement。

W 380 CR Coordination of local regeneration unit

W 380 CR Efficient construction of local regeneration unit

The Paver is used for synchronously paving the foamed asphalt recycled mixture

Vogler Super 1880 is used in this construction. L Carry out paving,Paving width setting 3.8 m,Paver rammer preliminary setting 4.Level 5,Control the paving speed at 3~4 m/min,Loose laying coefficient approx. 1.45。

The recycled mixture is closely rolled by the Hummer roller

In this construction section,For initial compaction, the single-drum roller shall be used for front static compaction and rear vibration compaction for one time.,Repeat the weak shock again.;Double drum roller shall be used for vibration compaction for 2 times.;The final compaction shall be carried out for 5 times by pneumatic tyred roller.,No mixture displacement during rolling compaction。From the pavement effect after rolling,Pavement uniformity and compactness are very good。

Construction quality inspection and performance evaluation

In order to ensure the construction quality,On-site foamed asphalt cold recycling mixture of test section、Compactness of the reclaimed layer、The forming condition and bearing capacity were tested.。

01Performance of In-Place Mixture

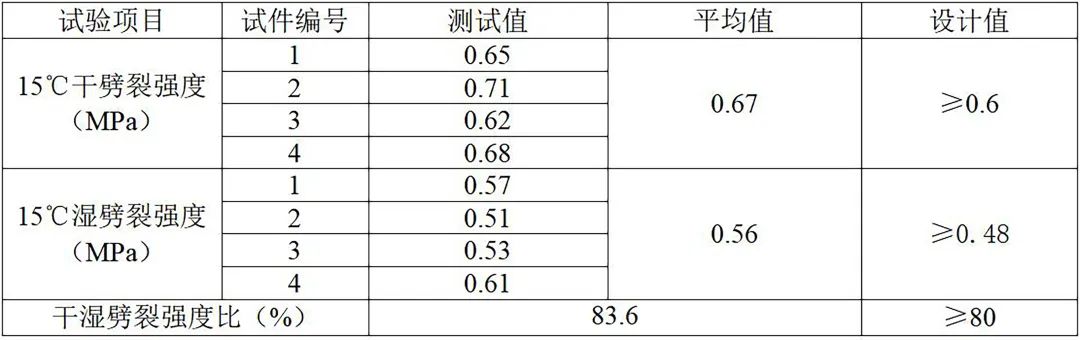

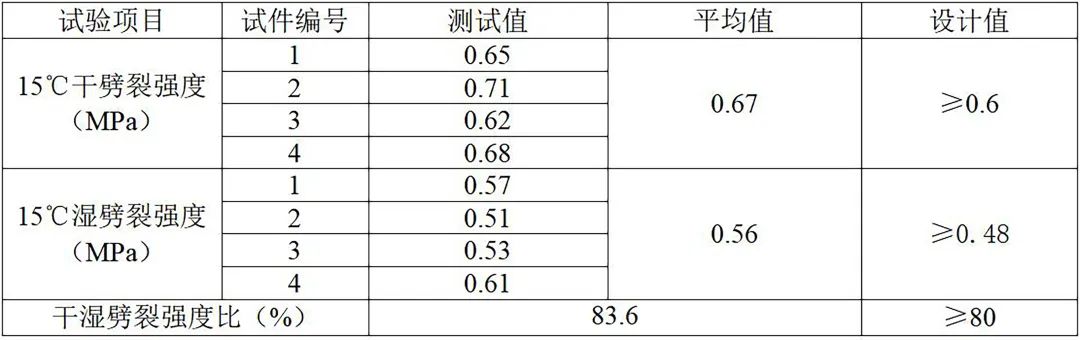

According to《Technical specification for recycling of highway asphalt pavement》(JTG/T5521-2019)Requirements of,Forming the foamed asphalt cold recycling mixture retrieved from the site into a Marshall test piece;,Dry and wet splitting strength test was carried out after curing,The test data are shown in the following table.。

Splitting strength test result

It can be found from the test data that,The splitting strength of the mixture on site fully meets the design requirements.,It shows that the quality of on-site mixture is good.。In addition,The test data also show that,The rutting resistance of the site mixture fully meets the design requirements.,It can meet the technical requirements of the lower layer of heavy traffic.。

02Compactness

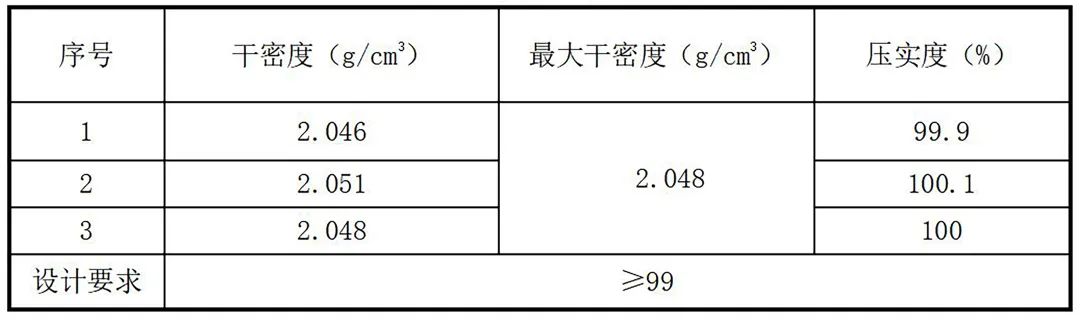

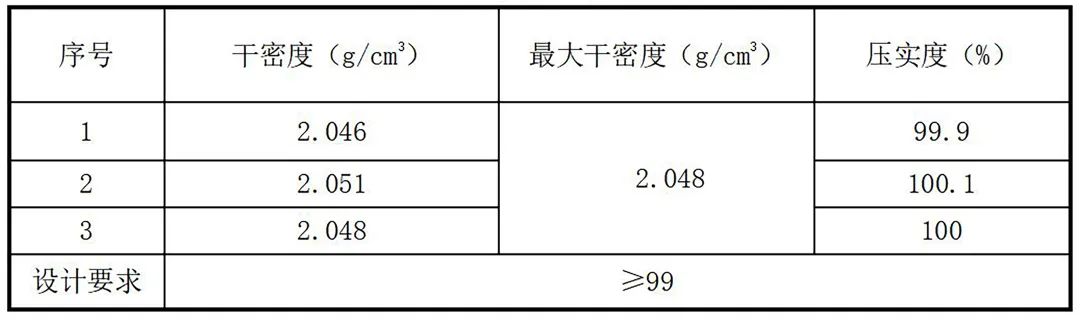

The maximum dry density of foamed asphalt mixture is 2.048 g/cm³,The optimum moisture content is 5.7%,The compaction degree of 3 places in the test section shall be tested on site.,The test results are shown in the figure below.。According to the test data,,The field compaction degree meets the design requirements.,It shows that the existing compaction process can meet the requirements.。

Test results of gauge compactness

03Coring

Coring on site after 3 days of construction,The appearance of core sample is complete and dense.,It shows that the forming effect of regeneration layer is better.。

Open to traffic

The foam asphalt cold regeneration layer is closed for natural curing for 2 days and then is directly opened to traffic.,The following figure shows the surface condition of the foamed asphalt cold recycling layer after 2 weeks of traffic opening.。From the point of view of the effect of open traffic,High-performance foamed asphalt cold recycling layer withstands the continuous action of traffic load,The surface is more dense,There was no aggregate spalling or rutting.。

Surface condition of foamed asphalt cold recycling layer after 2 weeks of traffic opening

Advantage analysis

Application of Synchronous Paving Foamed Asphalt Cold In-place Recycling in Xiaohan Avenue Lifting Project,No matter from the technical point of view,Or from the perspective of economic and social benefits?,Compared with traditional maintenance method,BubbleCold in-place recycling of asphalt foam has the following advantages:

1、Use of old pavement materials(100%Make use of)A large amount of asphalt and sandstone materials can be saved,And that engineer investment is saved,Protecting natural resources and saving cost,It has remarkable economic and social benefits.;

2、Due to the omission of the excavation of the old pavement structure layer、Clear、Transportation, backfilling and other processes,Direct in-place cold recycling construction is simple and convenient、Shorten the construction period;

3、Since the integrity of the pavement structure is maintained and the base is not damaged,And that bear capacity of the base is effectively protected.。

4、W 380 CR Regeneration width up to 3.8 m,Seamless regeneration of one lane at a time,Ensure the continuous construction of one lane,Construction efficiency increased by 50 percent%Above;

5、The old asphalt materials are milled and transported to the Paver in a centralized manner.,Material inhomogeneity is eliminated,The thickness control of the regeneration layer is more accurate,And that flatness is bet,Can meet the technical requirements of the lower surface layer of the high-grade highway。