Global climate change is one of the greatest challenges facing mankind in the twenty-first century.。As an engineering equipment company,,How to drive the industry to reduce greenhouse gas emissions,However, the overall work process can not be compromised.,A seemingly contradictory and difficult problem to solve,This time, Liebherr has the highest commitment to green development.,He gave his own answer.。How can Liebherr continue to innovate and contribute to the green trend?。

The latest masterpiece in the field of crane energy saving and environmental protection

New from the Liebherr factory in EingenLTC 1050-3.1 The compact crane has been fully upgraded。The new version of the compact 50-ton crane is equipped with an internal combustion engine,At the same time, the motor is added.,O that the crane can be driven by electric power during the hoisting operation.,And retain full crane performance。

LiebherrLTC 1050-3.1EPhoto Collection

Apart from the support of the power system,,LTC 1050-3.1EIt still has the performance of traditional internal combustion engine on the road and crane operation.。This win-win situation helps to reduce large amounts of carbon dioxide emissions.,It also means whether the crane operation is driven by a zero-emission electric motor or an internal combustion engine,All familiar use characteristics of the crane will be retained。

From the inside out.“Cleanliness”

Liebherr's commitment to green is by no means a mantra.。For Green、The development of zero emissions is practiced in every design detail.。The new LiebherrLTC 1050-3.1 Low emission internal combustion engine that meets the stringent emission standards of the European Union as standard,Maximum power up to 243 kW(326 bhp)。It is worth mentioning that,The engine can use hydrogenated vegetable oil without any limitation. (HVO) As fuel,Compared to conventional diesel fuel,It can reduce its carbon dioxide emissions by as much as 90 percent%。

According to the working condition,The internal combustion engine or the electric motor can be selected in the heavy lift mode,Emissions and noise can be kept to a minimum when the motor is selected for operation,Create a green and clean environment in an all-round way。

The motor can be operated?In fact, there is a universe inside.

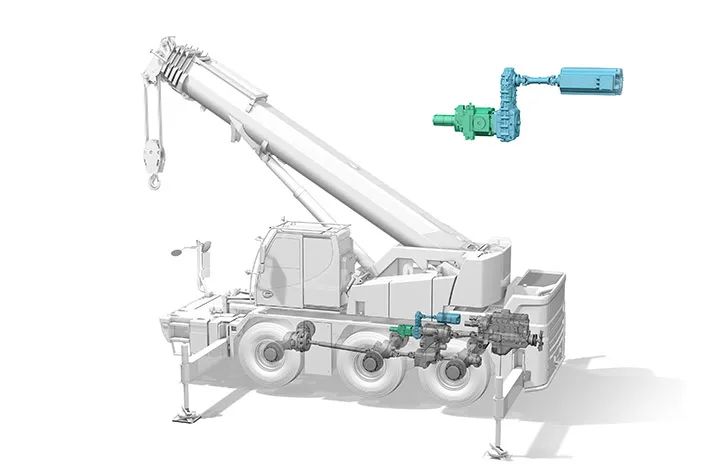

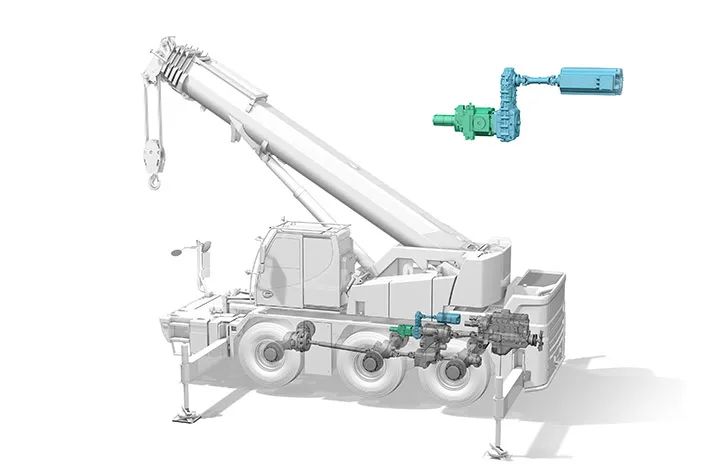

LiebherrLTC 1050-3.1ENewly developed electric motor power units can produce 72kWThe power of,Enable unrestricted operation of the crane,In other words.,Its performance is almost the same as using a 6-cylinder engine.。Motor driven hydraulic pump,The hydraulic pump is installed in theLTC 1050-3.1 on the power shift transmission,Transfer the power to the crane.。

The motor drives the crane pump through the distributor gear

Simply add the electric motor and transfer case and the required control equipment to the conventionalLTC 1050-3.1 Version,It can be converted to an electric version。The transfer case is located directly between the hydraulic pump and the powershift transmission。

The motor drives the crane pump through the distributor gear

This ingenious and simple solution gives the operator the flexibility to switch between diesel hydraulic power and electro-hydraulic power,At 125AFull performance can be achieved at DC current of,But the crane is at 63.AIt also runs well under the power supply.。If proper electrical infrastructure is not available on site,The crane can be operated with an external conventional battery pack。

Multi-Liebherr“Star”Equipped and empowered

Liebherr alsoLTC 1050-3.1EEquipped with 36mTELEMATIKTelescopic boom version。In addition, it is used for remote control of driving and height adjustable lifting cab.RemoteDriveOption is also available for new cranes。At presentLTC 1050-3.1EPrototypes with power units are currently undergoing intensive testing,Liebherr expects to deliver the first batch of the model in 2023。

LiebherrLTC 1050-3.1ESmall File

|

Maximum lifting capacity

|

50t

|

Engine/Power

|

243kW

|

|

Radius

|

3.00m

|

Crane engine

/Power

|

72kW

|

|

Telescopic arm from

|

8.10m

|

Drive/Steering Standard

|

6 x 4 x 6

|

|

Telescopic arm to

|

36.00m

|

Drive/Steering option

|

6 x 6 x 6

|

|

Truss jib from

|

1.50m

|

Number of axles

|

3

|

|

Truss jib to

|

13.00m

|

Total counterweight

|

6.50t

|

|

Engine

|

6-cylinder diesel engine

|

Travel Speed

|

85.00 km/h

|

|

Engine/Fabrication

|

Cummins

|

_ |

_ |