Road repair projects around the world need to meet the same requirements: they must be economical, efficient and environmentally friendly; The most important thing is to finish quickly. After all, road networks around the world are showing clear signs of ageing. Local pavement repair construction is not consistent with the principle of sustainable development, nor can it fundamentally solve the problem. Nowadays, cold regeneration construction technology is widely used. Compared with other road maintenance methods, its construction cycle is shorter. Therefore, the demand for this process will continue to grow in the future.

project background

In the repair and construction of yushe section of 102 provincial road in shanxi, the whole section is over 10 km long, 9.3 m wide, and the traffic flow is up to 6000 Vehicles per day. Shanxi jinlu highway engineering construction co., LTD., a conTractor in Shanxi Province, adopted two witgen WR 250 wheeled cold regeneration for on-site cold regeneration, which has once again proved to be an ideal solution. Shanxi jinlu highway engineering construction co., LTD project manager xu xinsheng said: “ We aim to achieve 100% recycling of recycled asphalt mixture to protect the environment and save costs. This technology has helped China make great strides. Throughout the &;

highly efficient repair of damaged asphalt layer

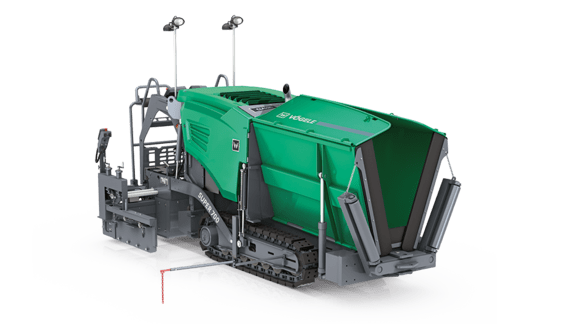

A powerful engine with a power rate of 777 HP can transform a damaged asphalt layer into a high-quality base at once, regardless of the construction area and depth. Cement, water, emulsified asphalt and foam asphalt can be used as additives or binder. In order to obtain the ideal mixing effect, the spraying amount of binder must be precisely controlled during the whole construction process. Therefore, wittgen group adopts a reliable, microcomputer controlled spraying system to accurately measure the binder. Depending on the construction conditions, it can be installed multiple spray rod, and add different binder. For xu xinsheng, the project manager, those were two key factors that led him to choose the model. He said: WR 250 has high efficiency in construction, high spraying accuracy and excellent mixing quality. Throughout the &;

Project manager of shanxi jinlu highway engineering construction co., LTD.

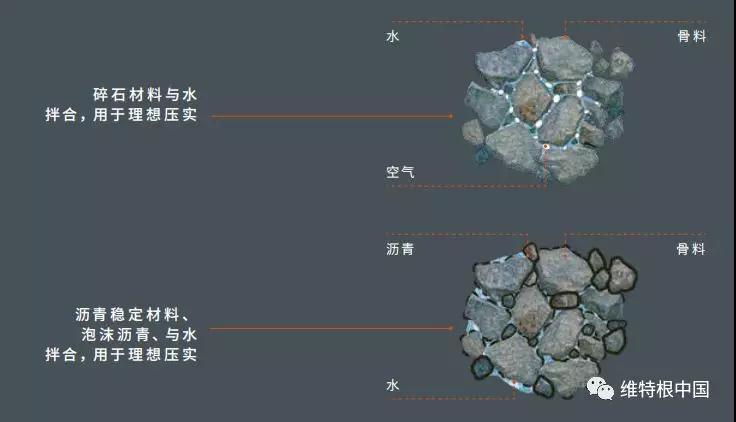

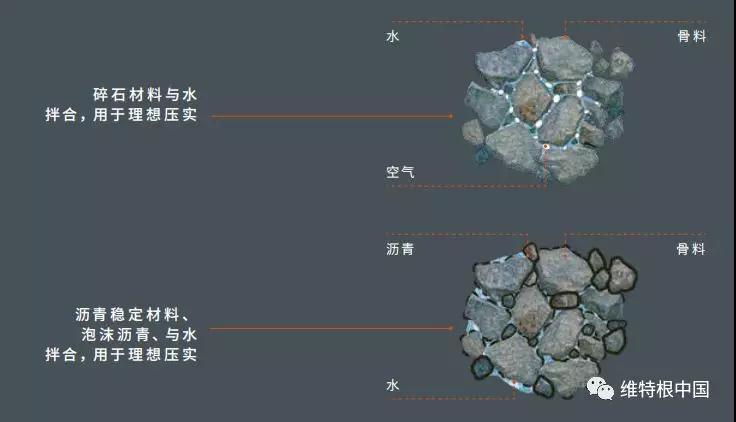

During the pavement repair and construction of shanxi provincial road 102, the project leader chose to use foam asphalt as the binder, mainly because of its obvious advantages: high construction efficiency, resource saving, and long service life of the reclaimed layer. The properties of the cold regenerated mixture produced using foamed asphalt are similar to those of building materials with constant friction between particles, but it is clear that foamed asphalt has higher adhesion and strength.

This type of material is called bitumen stabilized material (BSM). Aggregates are not completely coated in the BSM. On the contrary, asphalt, as a binder, can be evenly distributed. The typical range of asphalt use is 1.5% of mixture mass – 2.5%. After the final compaction, the road-building material has excellent flexibility and higher bearing capacity. This is widely recognized around the world.

excellent mixing mass

The ideal collaboration between the wittgen WR 250's rotor, tool base, quick-change tool base system and efficient cutting tools enables the machine to consistently achieve strong milling and mixing performance, resulting in uniform road construction materials. The WR 250 is equipped with a powerful DURAFORCE milling and mixing rotor, which evenly mixes the pre-spread binder with the soil to produce a homogeneous mixture, which is then compacted effectively by the hummer roller, laying a solid foundation for the overlay of asphalt concrete surface in yushe section.

Xu xisheng is very satisfied with the excellent performance of the vitgen WR 250 cold regeneration. He said: The strong DURAFORCE milling and mixing rotor is the key to obtain excellent mixing quality with the spray rod. Throughout the &;

universality is the key to stable soil construction

At present, many bids for pavement restoration projects still contain provisions for soil replacement, but this is no longer an advanced method. The soil Stabilizer USES its powerful milling and mixing rotor to mix the lime, cement and other pre-distributed Stabilizers into the soil with insufficient bearing capacity, and then converts them into high quality road-building materials on the spot.

The homogeneous soil mixture stabilized by Stabilizer has high bearing capacity, strong water resistance, good frost resistance and high stability. Typical construction applications include building country roads, roads, highways, railway foundations, parking lots, stadiums, industrial parks, airports, DAMS, backfill sites or Landfills.

Wittgen WR 250 is mainly used to improve and stabilize soil. The purpose of soil improvement is to make the soil meet specific properties. There is a difference between soil improvement and soil stability. Soil stable construction refers to the addition of binder to the existing soil to increase its resistance to traffic load and climate-induced stress, so as to ensure that the road has good bearing capacity and lasting frost resistance. Soil improvement is designed to improve the paving and compacting properties of existing soils and to accelerate the construction process.

1. Homogenization: in the homogenization process, the planter is used to mill and mix the rotor strongly, granulate the existing soil and make it soft without adding binder. The Grader is used to treat the stabilized uniform soil and then effectively compacting it with a hummer roller.

2. Lime stability: if the soil structure is to be improved continuously, different machines are required to cooperate. First, the binder spreader evenly spits the Stabilizer in advance, followed by the wittgen soil Stabilizer. The WR 250's powerful milling and mixing rotor mixes pre-spread lime evenly with the existing soil. The rear door scraper with a certain pressure will stabilize the material after the ideal smooth. The Grader is used to treat the soil mixture. Finally, the hummer press is used for effective compaction.

3. Cement stabilization: cement is used for stable construction of soil, aiming at forming water junction gravel base. First, a Tractor spreader spits the binder in advance, followed by a water tanker. The strong milling and mixing rotor of wittgen soil Stabilizer will mix the existing soil with the pre-spread cement to form a uniform mixture. At the same time, water is sprayed into the mixing bin through the spray rod. The Grader is used to treat the stabilized base and is then effectively compacted by a hummer roller.

vitgen WR 250 cold regeneration and soil Stabilizer highlights

◆ strong performance, suitable for arduous conditions.

◆ with a working width of 2.4 m and a maximum working depth of 560 mm, the WR 250 can perform well on challenging construction projects.

Thanks to its efficient milling and mixing performance, the equipment can easily cope with difficult soil stabilization and cold regeneration construction projects.

◆ the ideal performance range for stable soil construction is 6,000 to 12,000 square meters per day.

◆ during cold regeneration construction, when the thickness of asphalt is 20 ~ 25 cm, the ideal performance range is 700 ~ 1,200 square meters per hour.