Yufeng Intelligence——A leader in the field of intelligent logistics,Focus on smart warehousing、Intelligent workshop、Platform system and other diversified applications,Provide customized consulting planning、System integration、Software development、Intelligent equipment production and other one-stop intelligent logistics system solutions。

Typical case Electric Power Industry

Typical case Electric Power Industry

This project is based on“Four-way shuttle intensive storage+miniloadLight high-speed Stacker stereo storage+WCSSystem+Multi-logistics equipment cooperative transportation”As the overall solution of the project。Realize the power company light、Intelligent Storage and Distribution Operation Mode of Heavy Material。

Four-way shuttle dense storage area integrates storage and sorting,Four-way shuttle car cooperates with heavy-duty hoist to realize fast operation in six dimensions,Comprehensively improve the efficiency and accuracy of logistics operations;Use of scattered light materialsminiloadLight Stacker,Cooperate with light roller conveyor lineRealization“The goods have arrived”Picking,Further improve material automation、Intelligent production line and unmanned storage。

There are many kinds of materials based on electricity.、Diversified storage requirement,The robot system is equipped with 3DVision Camera,It breaks through the limitation of the use scenario of the traditional automatic single palletizing.,It solves the problem of dismantling bagged materials in the industry.,Matched with automatic quick change of various fixtures,Realization“One-to-many”Complete the picking efficiently、Unstacking work,Integrate the four-way shuttle warehouse and the box warehouse completely。

Typical caseFurniture industry

After detailed investigation of customer needs, Yufeng Intelligence,For product characteristics、In-depth analysis of multiple dimensions such as business process and site layout characteristics,And in combination with 3DSimulation technology continuously optimizes and improves the process.,Final planning and design to“Torage system of tray type stacking machine three-dimensional warehouse+CircumferenceRGVWarehousing system+Multi-logistics equipment cooperative transportation”As the overall solution of the project。From a single intelligent storage function to covering Material Handling、Regional distribution、Intelligent logistics system extension with automatic storage,Through the organic integration of intelligent warehousing software and hardware,It realizes the automatic transportation and storage of finished furniture sets of various specifications.,In storage capacity、Lean management, cost reduction and efficiency enhancement have been significantly improved.。

The intelligent storage functional area of this project includes 2 finished product warehouses.,Deploy the double deep Stacker、RGV、AGVAndWCS、WMSAnd other intelligent software systems,The digitalization of the whole warehousing system has been realized.、Intelligent、Visual operation and management!The area in front of the storehouse has changed the traditional conveying form of the conveying line.,Adopt the mode of circular track, one track and multiple Vehicles,Reduce costs and equipment track footprint while meeting customer efficiency requirements,And inIn a limited space,Maximally optimized storage location layout,To meet the storage needs of future order growth。

The project has achieved a customer storage capacity of 400 containers.,The annual production capacity can reach 4000 containers.,It has been in stable operation.;The whole set of intelligent furniture warehousing logistics system can quickly respond to the logistics supply of customer enterprises.,Meet its capacity needs,And continue to provide logistics support in the future capacity growth stage.。

Typical caseNew Energy Vehicle Industry

The project covers an area of 5000㎡,Based on Yufeng Intelligence“High speed stacker、Conveyor line system、Software system, etc”Intelligent logistics warehousing solution with module configuration,In libraries with very high space utilization,The stacker accesses the goods at a high speed to complete the warehousing operation.,Compared with the traditional warehouse, there is no restriction on the storage of parts.,Realize the high-level storage of auto parts of various specifications and materials of granular ton package type。

Full library 5GOverlay,Comprehensive digital intelligence enabling upgrade:Intelligent logistics warehouse with advanced 5GPrivate Network,Realize the full library 5GOverlay,With 5G+The intelligent three-dimensional warehouse solves the problem of network packet loss in the traditional large-scale equipment three-dimensional warehouse operation scenario.、The shaking is violent、Communication interruption and other problems。The hardware perfectly adapts to the factory production rhythm.:Especially in terms of hardware, the stacker scheme with mature technology is adopted.,From material packing、Warehousing、Improve the distribution and informatization.,Optimize logistics operation mode,Lean for Logistics Work、Agility、Intelligent、Greening has laid a solid foundation。

5GAfter the smart warehousing project is put into operation,The storage space capacity has been greatly improved.,Fast、Accurate implementation of parts warehousing、Information processing and other operations,Through the monitoring and analysis of operation data,Accurately grasp business pain points,Continuous optimization of business capabilities,Reduce cost and increase efficiency;Intelligent logistics warehouse storage capacity per unit area increased by more than 3 times,Logistics efficiency improvement 40%,The cost of single storage space is 20% lower than that of ordinary shelf%,Efficiently meet in-plant logistics needs。

Typical caseShoemaking industry

Project implementation area:Raw material warehouse、Semi-finished product warehouse、Production line、Upper surface semi-finished product warehouse。Yufeng IntelligenceFlexible and intelligent logistics solution integrating software and hardware,Under the existing layout of the new plant area,Fusion“MES+WMS+WCS”System,Through the elevator、Forward typeAGV、Bin typeAGV、Backer roller simple typeAGV、Unfolding machine、Application of intelligent equipment such as intelligent conveyor line,Help customers to solve multi-region、Complex warehousing and logistics problems across floors。

All AGVThe robot is intelligent by YufengUnified management of self-developed dispatching system,With customersWMSSystem seamless docking,Multiple processes respond in a timely manner,Efficient handling of raw materials、Production line distribution、Finished product/Tasks such as warehousing of semi-finished products,Improve logistics efficiency,Realization“Move、Save、Produce、People、Send”Synchronization of foreground and background data of each link,And that production cycle of the product is greatly shorten.,Achieve double improvement of production efficiency and product quality。

Typical caseCross-border e-commerce

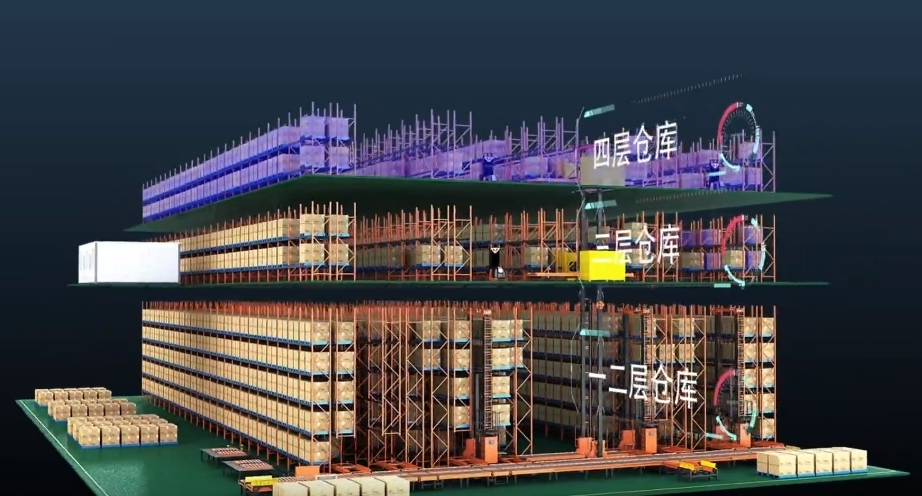

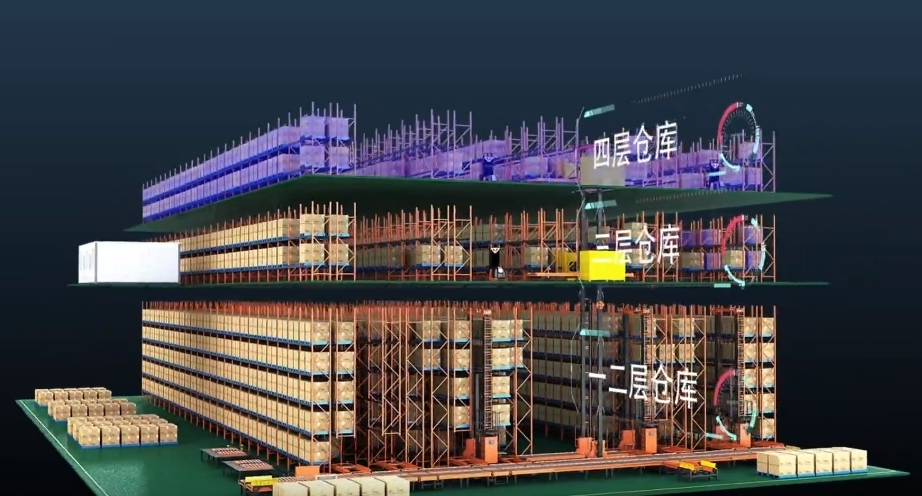

In order to greatly improve storage efficiency,The high-level three-dimensional storehouse is built into four floors.,Equipped4 double deep stackers,Beam rack with 3888 cargo spaces,Suitable for storage of heavy goods,Convenient access to goods,Have 100%Selectability of,And that operation efficiency is high。

The double-deep stacker runs in the lane between the shelves of the three-dimensional warehouse.,A portion of the cargo is stored on the first floor via a stacker,The other part of the goods is sent to 3 by the elevator.、4th floor,And then through a forkliftAGVConnect to the warehouse,Complete the storage of goods。The high-level three-dimensional warehouse is equipped with roller conveyor line and chain conveyor line.,Computer and bar code technology are used in management.,Equipped with data analysis、Warehouse management software including data mining and other functions。

After the completion of the high-level three-dimensional warehouse project,Maximize the use of spatial layout,Library capacity increased by 60 percent%,The efficiency of entering and leaving the warehouse is up to 145%,Solve the problem of customer storage area shortage、Low warehousing efficiency and the like.。The data is the best illustration.,Yufeng Intelligence has made outstanding achievements in helping the intelligent upgrade of the warehouse.。The company aims at the actual needs of different industries.,Provide excellent logistics robots and intelligent logistics solutions,Enable enterprise digitalization、Intelligent transformation。

Typical caseSanitary ware industry

The whole plant intelligent logistics system solutions includeVertical Warehouse Storage System、Conveying system、Robot palletizing system、AGVIntelligent logistics systems such as distribution systems andWCS、WMSAnd other intelligent logistics software management systems,Seamless connection with factory production line,Raw materials、Semi-finished product、Material packaging of finished products、Store、Sorting、Efficient connection between the whole process of logistics operations such as distribution and production assembly,Integration and application of automation、Internet of Things and other technologies,Break down data barriers,Improve the level of intelligent management,Realize efficient coordination of picking, storage and distribution。

Black light factory"Reduce energy consumption:AGVThe robot runsNo need for factory lighting,Support 7*24 hours of uninterrupted operation,Significant reduction in plant energy consumption;AGVEnter automatically when you are free“Sleep”Pattern,MakeAGVIts own energy consumption is minimized。

The whole process is intelligent、Digitize:Enter from the material、In-plant transshipment、Production、Assembly,And then to the finished product factory.,Realize the whole process intellectualization。BesidesAdopt advanced intelligent production and assembly equipmentOutside,In the construction of logistics intelligenceUsing different forms of semi-finished products&Finished product warehouse、Spare parts library andAGVAnd other intelligent logistics systems;WMS、WCSWait for the system to put the device、Efficient connection of materials and people,Make factory logistics efficient,Continuously improve the level of plant operation and management。

Typical case Electric Power Industry

Typical case Electric Power Industry