One Specification for use of steel wire rope

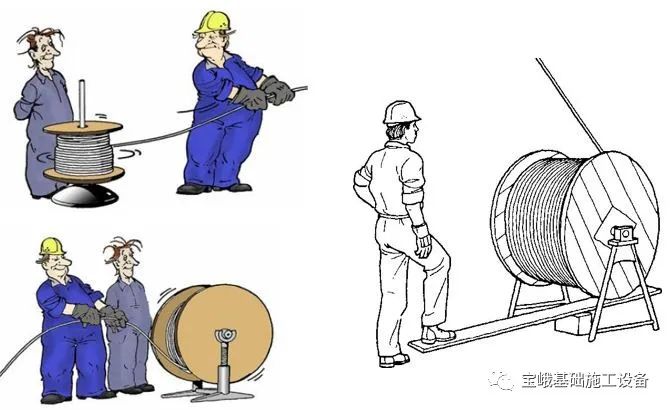

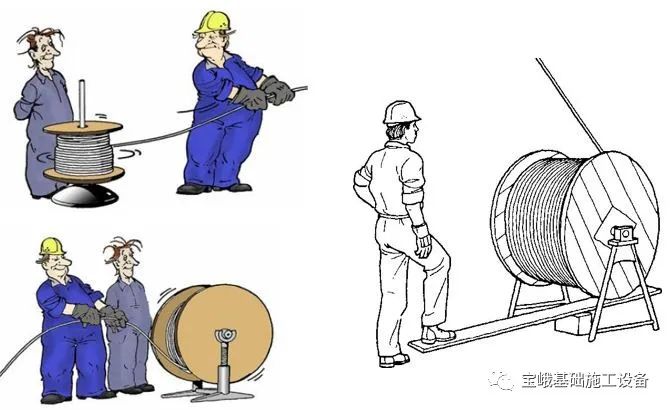

When installing the wire rope,Take special care not to contaminate the wire rope。

The correct installation of the wire rope requires the assistance of the wire rope reel support

The upper part is not installed according to the operating specification,Cause the steel wire rope to be polluted by silt。

The upper part is not installed according to the operating specification,Cause the steel wire rope to be polluted by silt。

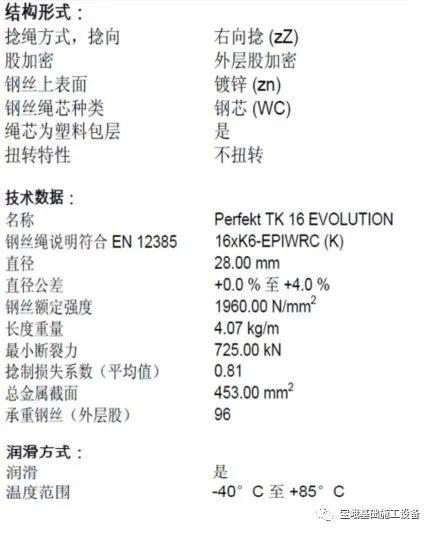

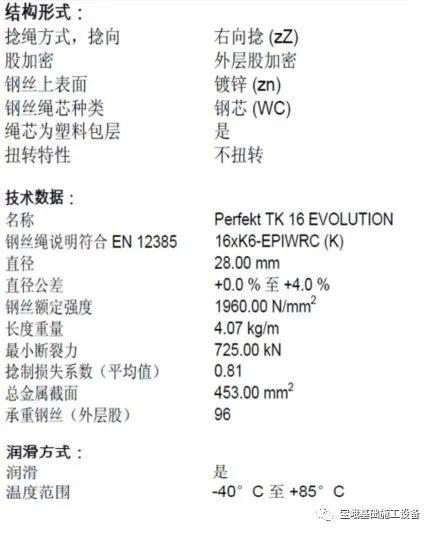

2. Use the correct wire rope for each machine(All parameters shall comply with the original requirements of the machine.)

Each machine has the specifications and dimensions of the wire rope for its own use.,And all related technical and safety requirements。The following wire rope parameters are only the specified data for the main hoist wire rope of one machine。So,When the customer selects the wire rope,The original steel wire rope should be considered first.,In order to avoid damage to machine parts or accidents and so on.。

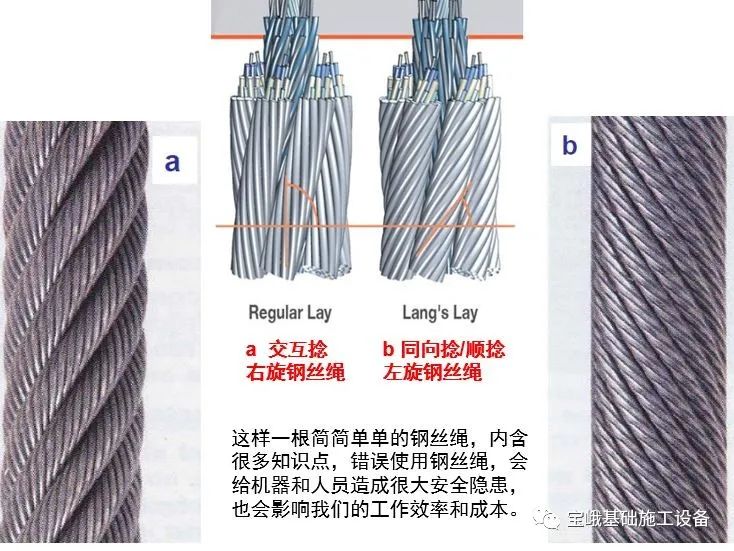

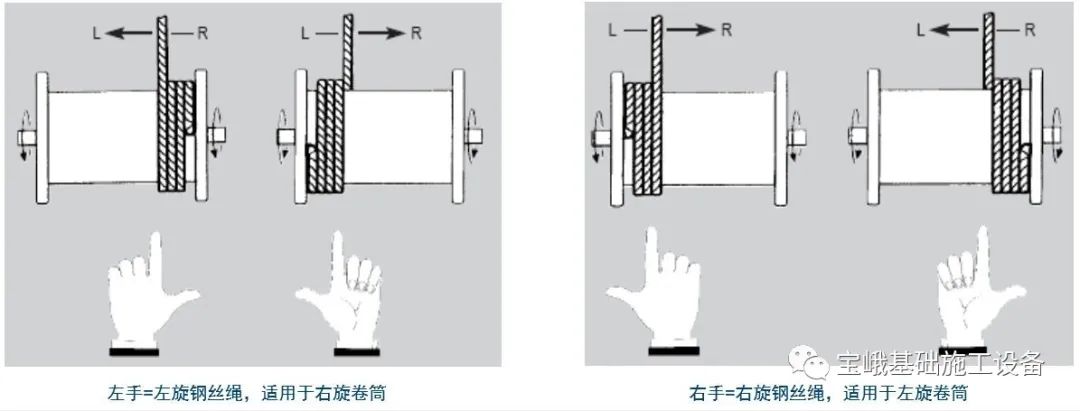

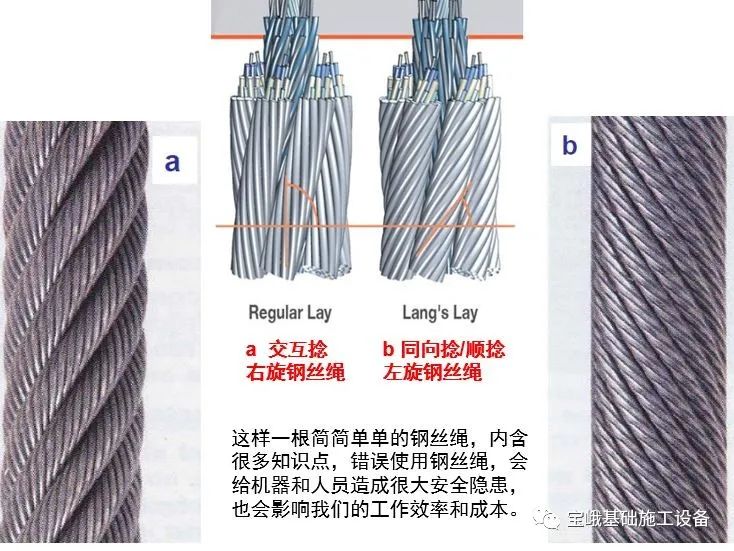

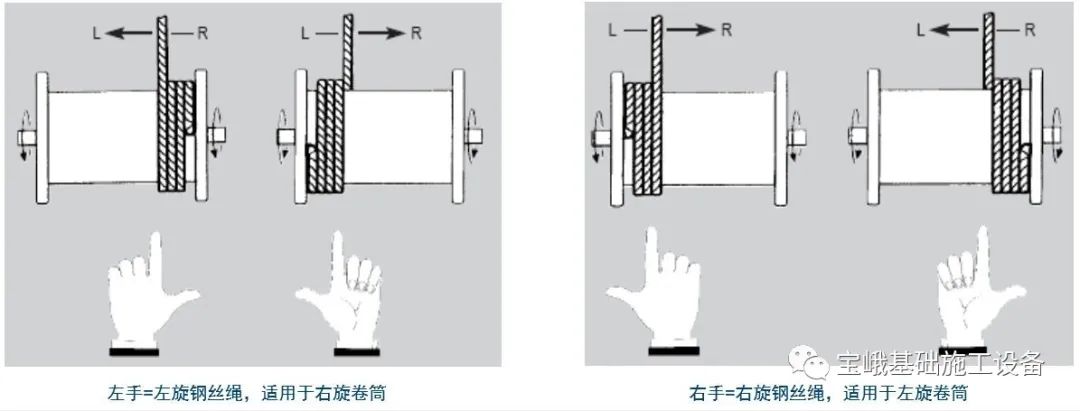

The wire rope is composed of several steel strands.,The steel strands are twisted by steel wires.。All strands and wires are helical。There are two types of lay directions for wire rope:

The direction of the strands of the alternate lay wire rope is opposite to the direction of the wires in the strand。

The direction of the strands of the corotating wire rope is the same as that of the wires in the strand。

Select the correct direction of twist,It is very important for the working performance of the wire rope.。Interactive twisting has a wide range of applications.,Can be used as the most commonly used standard twist direction。Due to better resistance to damage at the point of contact of each layer of winding,Co-twist is particularly suitable for multi-layer spool winding applications.。

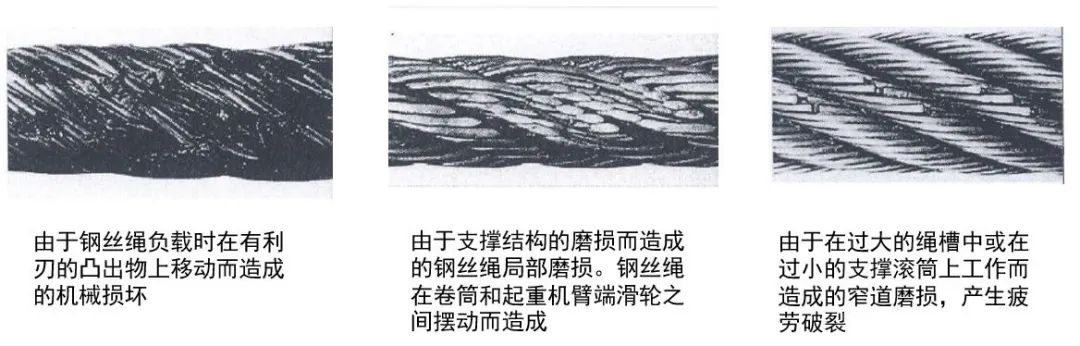

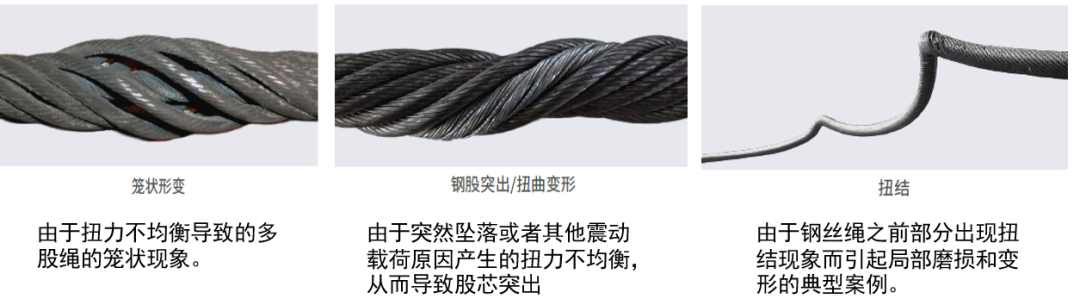

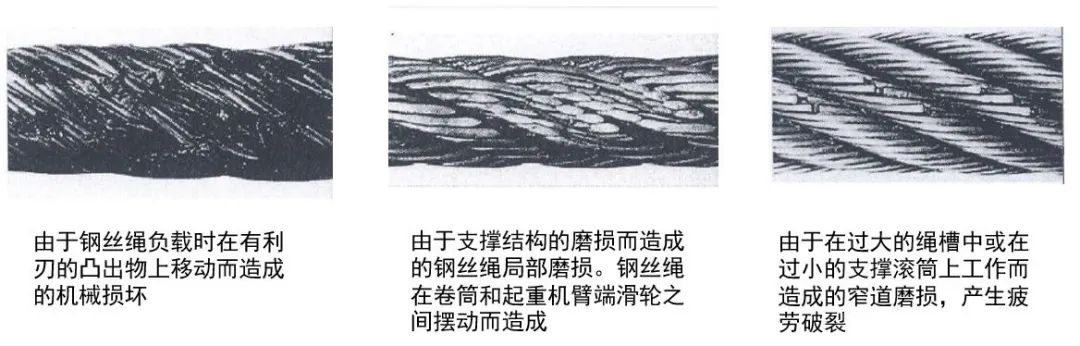

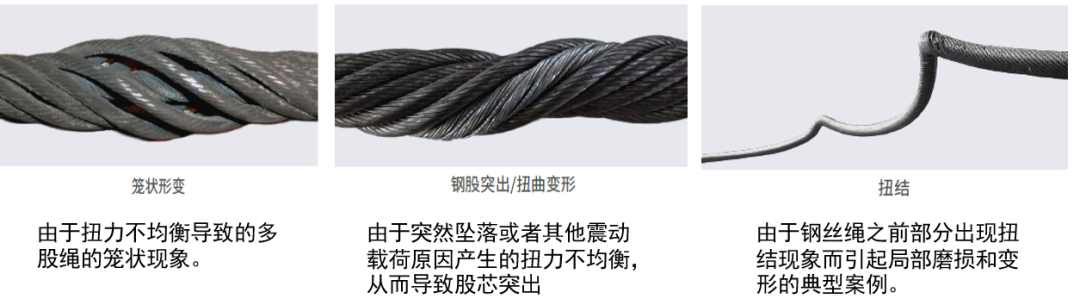

II. Common wear and fracture of steel wire rope

Examples of wire rope wear

3. How to check the wire rope correctly

Inspection of wire rope rotation(The rotation direction of the wire rope and the rotation direction of the drum shall be matched correctly.,The rope can not be loosened in the winding process.)

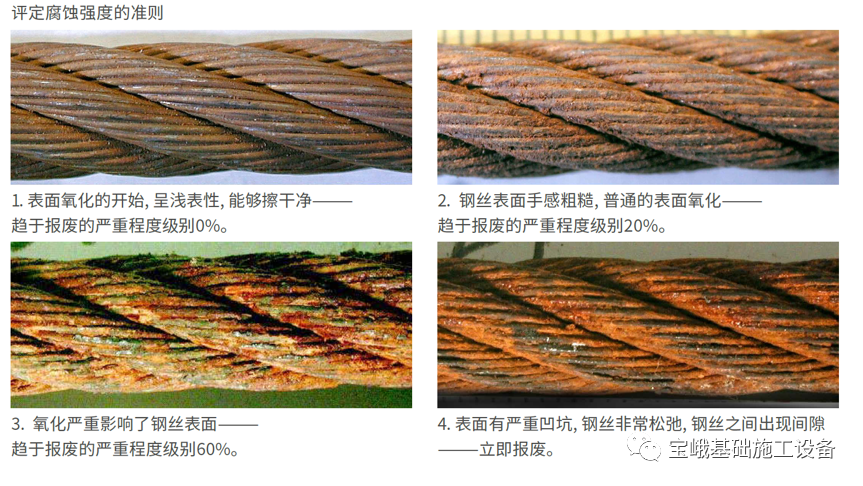

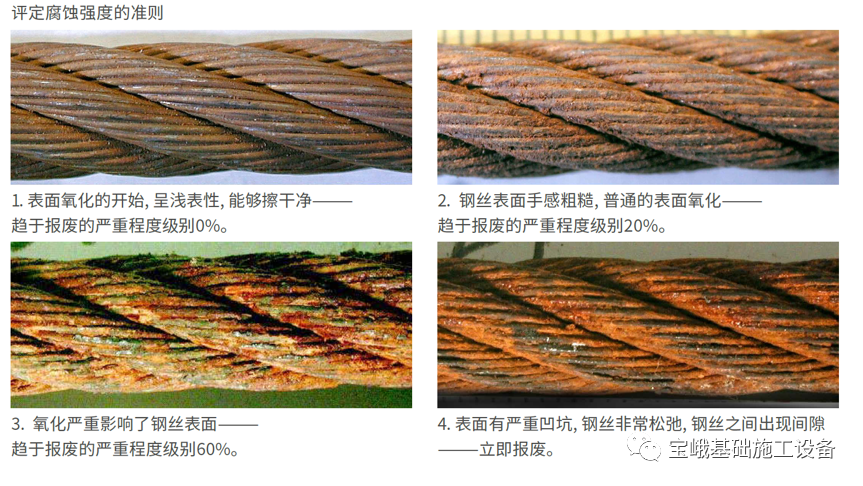

2. Inspection of external corrosion

Proposal:The first case can be used temporarily.,Work under the constant supervision and inspection of the operating personnel of each shift,Replace in time if there is any problem.。In the latter three cases, immediate replacement is recommended。

3. Check the broken wire of the wire rope

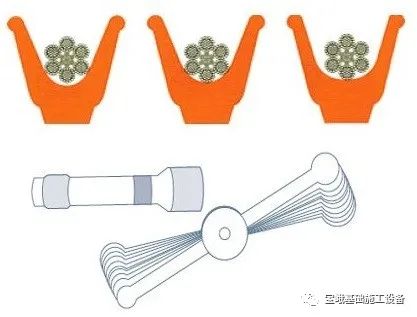

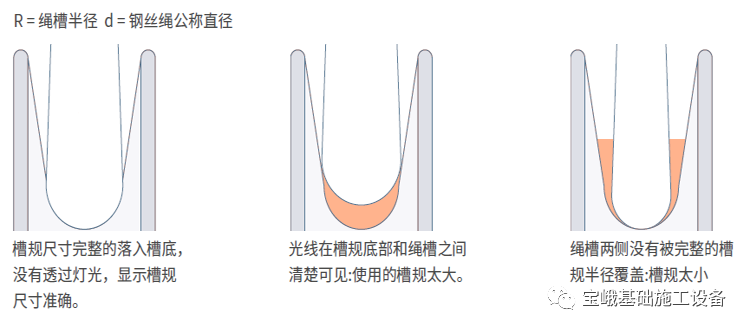

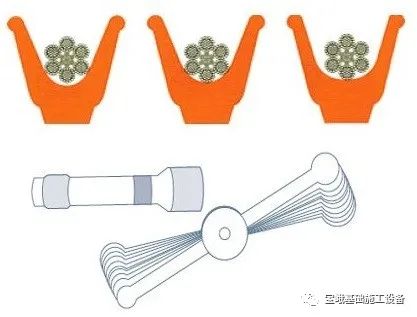

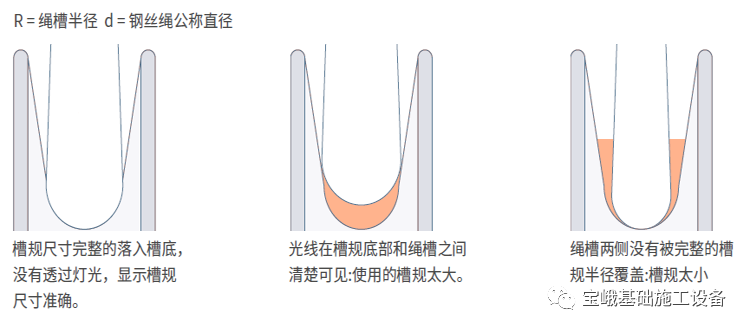

4.How to check the groove of pulley rope

The inspection of the wire rope includes not only the inspection of the wire rope itself,It also includes the inspection of the pulley on which the wire rope runs.。The measurement of the rope groove diameter requires a special measuring tool:Groove gauge and flashlight。

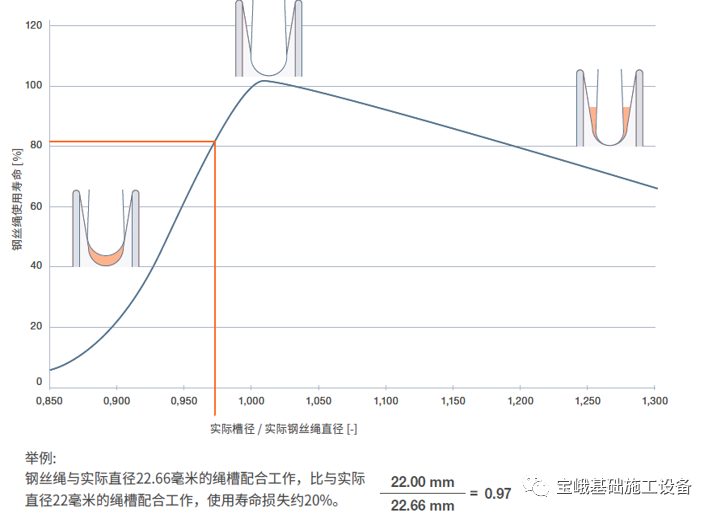

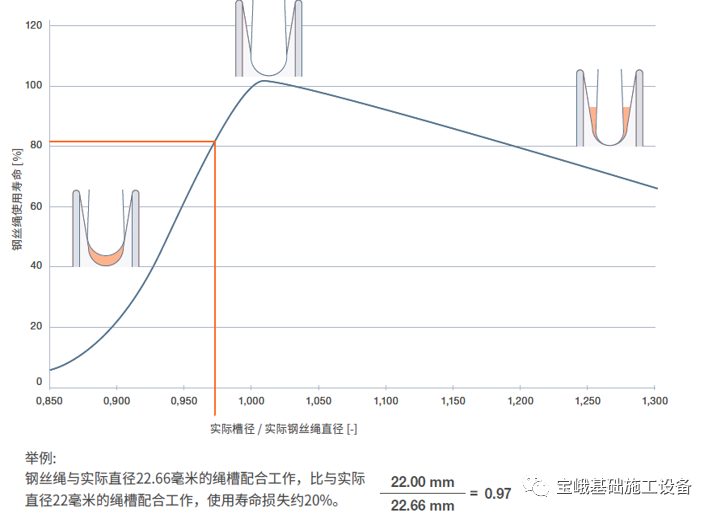

5. Effect of the Ratio of Wire Rope Diameter to Pulley Diameter on the Life of Wire Rope

According to the standard,Rope groove radiusRShould be at 0525xd - 0.550xdBetween,The optimum rope groove radius is 0..537x7。(D-Rope groove radius,d-Wire rope diameter)

For example:

For steel wire rope with nominal diameter of 22 mm,The following values apply:

Minimum slot diameter allowed:23.10 mm

Optimum groove diameter:23.66 mm

Maximum allowable groove diameter:24.20 mm

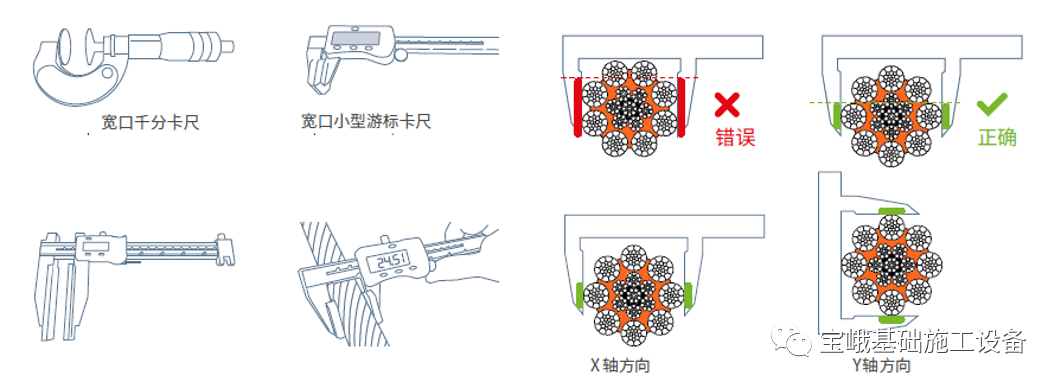

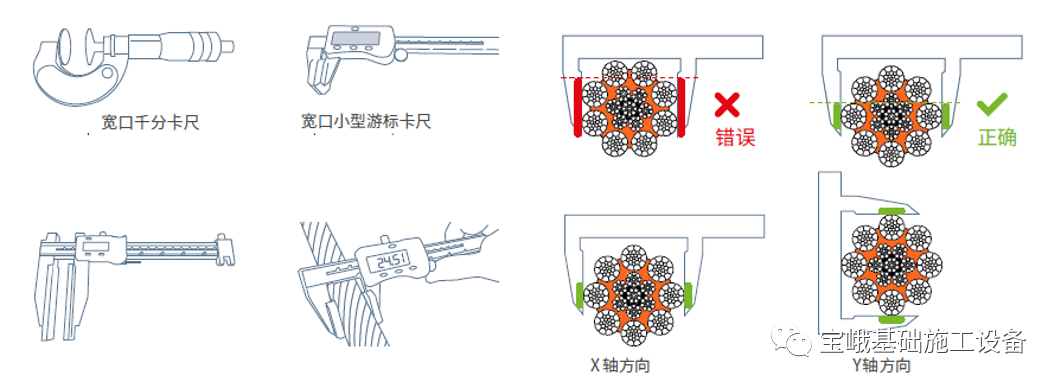

6. How to measure the wire rope correctly

Four. How to Extend the Service Life of Wire Rope

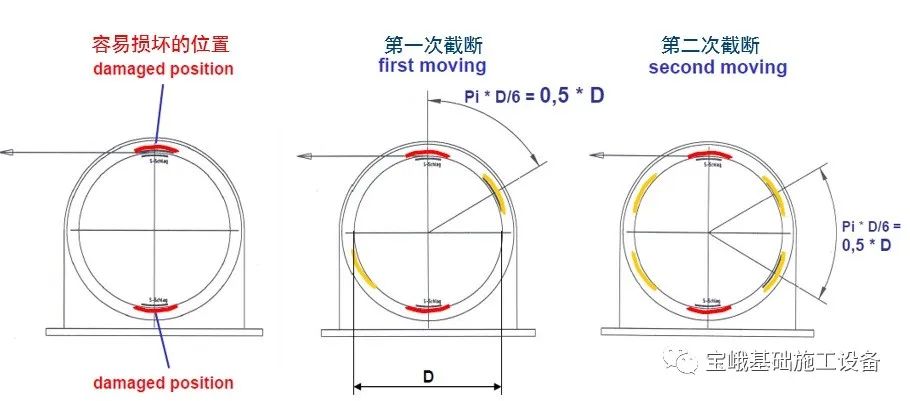

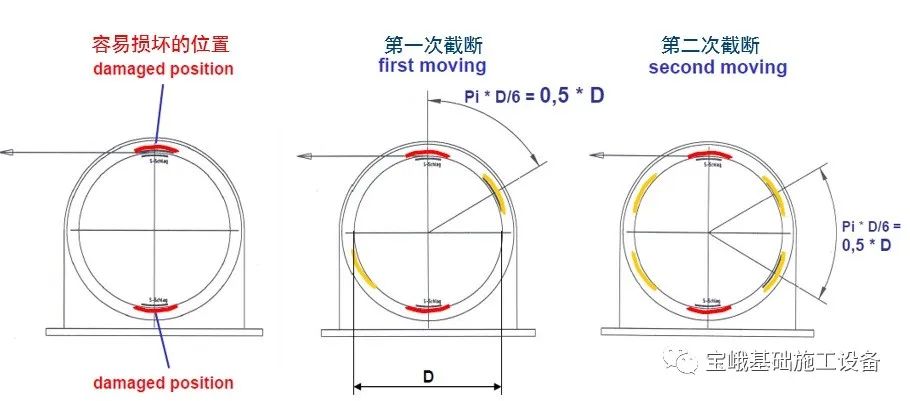

How to Extend the Life of Wire Rope(Truncation of wire rope)

Cut off the wire rope twice=>Triple life of wire rope!!

Two wire rope position movements(By cutting off a part of the rope,Half the diameter of the drum)Make the previous force maximum.,Displacement of the part with the most serious wear,To improve service life.。

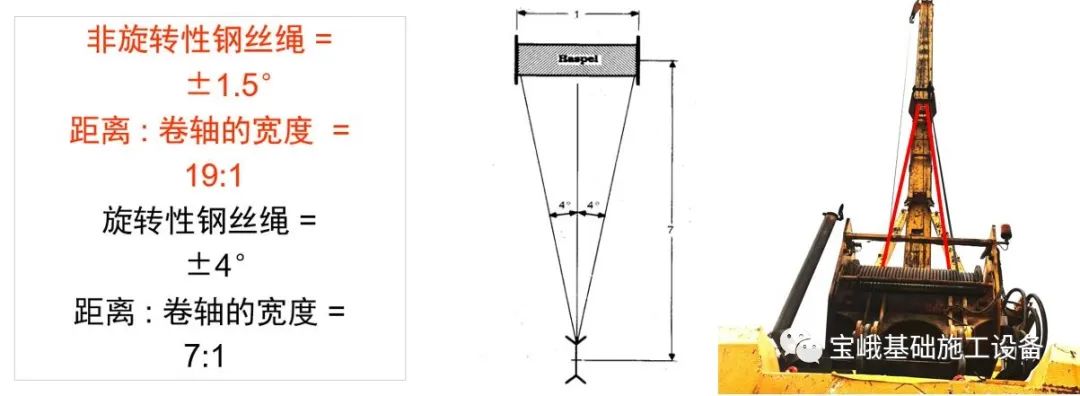

2. Shorten the total length of the wire rope

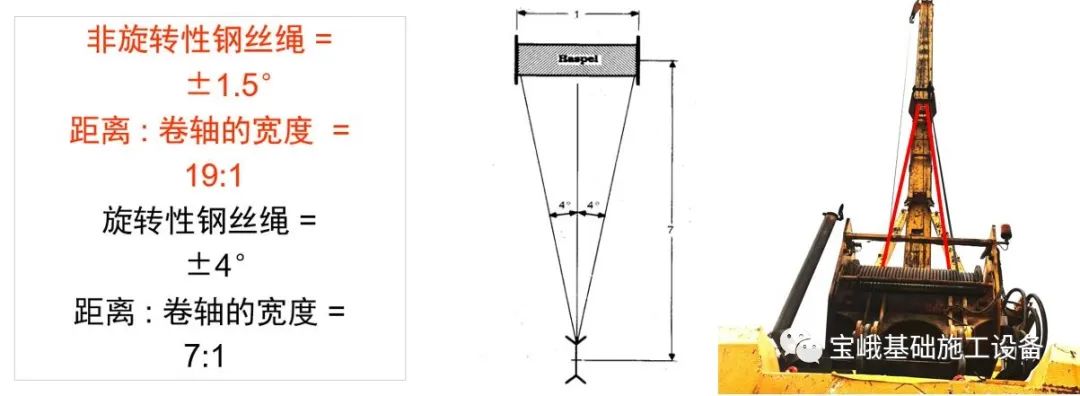

The short steel wire rope can meet the drilling depth of the existing construction site.,Try to choose a long wire rope suitable for this depth.。Shorten the total length of the wire rope,Helps to reduce the angle between the wire rope on the drum and the pulley,And simultaneously reduce that friction between the ropes on the reel.,But also reduces the transition abrasion between the steel wire rope and the pulley.。Thereby prolonging the service life of the steel wire rope.。

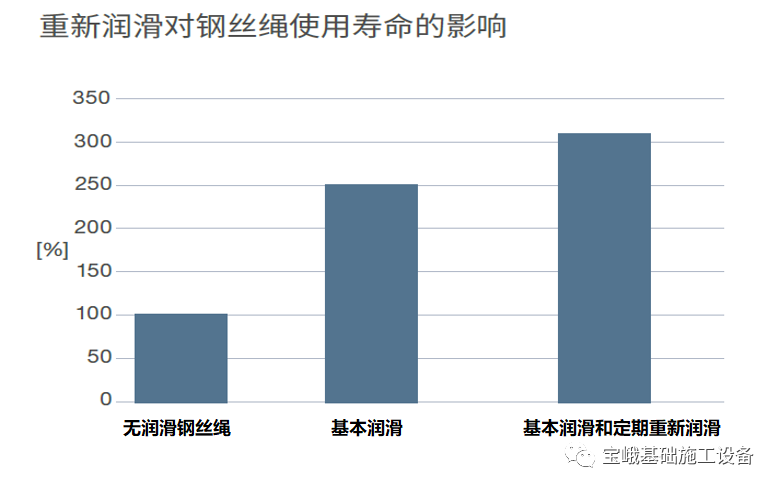

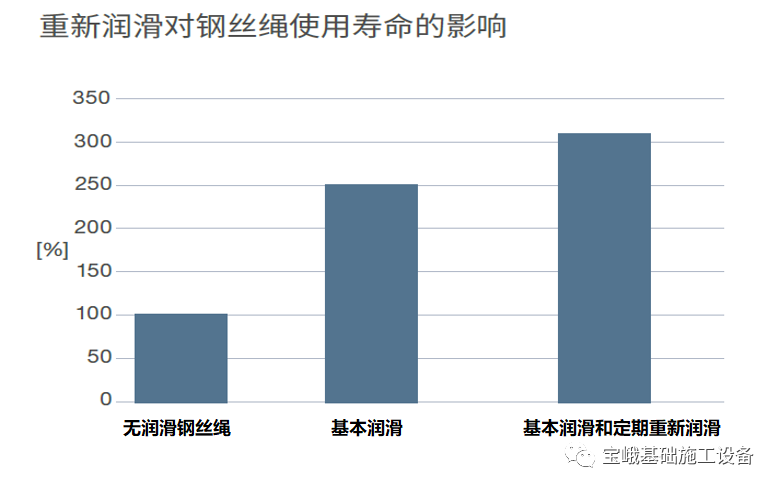

3. Relubrication of wire rope

a. Importance of wire rope relubrication

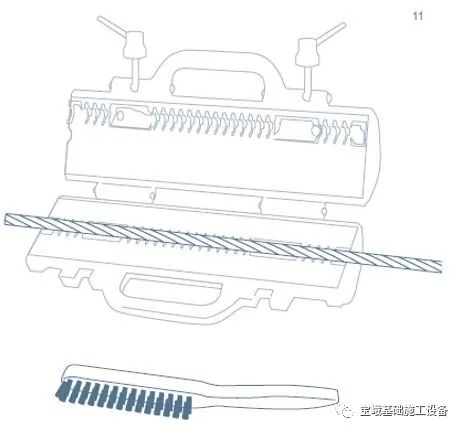

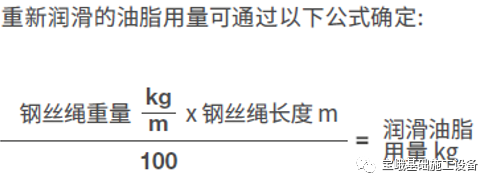

b. Rerolubrication times of steel wire rope and dosage per times

In general,Steel wire rope in the whole service life,We recommend 10 relubrication。For applications with a relatively short service life(Rapid wear due to high strength),Relubrication must be performed as required by the equipment application。

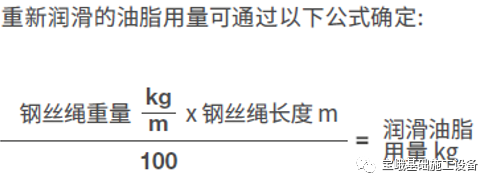

c. Preliminary work for relubrication of wire rope

The wire rope shall be cleaned before lubrication.,For adequate re-lubrication,Make the newly added grease fully effective。Use new grease without removing the existing dry grease,This will destroy the effect of re-lubrication.,Because the existing grease often dries out,Loss of lubrication。In addition,If there is no dirt on the surface of the wire rope,It will be easier to examine more closely.,To detect possible rope damage。

There are many ways to remove the grease that is already on the surface of the wire rope。One approach is to use a cleaning tool system,Remove the impurities on the surface of the wire rope by rotating the brush。The other is the traditional method.,Use a wire brush to remove the grease from the wire rope surfaces。By relative motion,The grease can be simply scraped off the surface of the wire rope。The more grease is removed from the surfaces,The better the new grease works.。This method requires a lot of work and time.,Depending on the length of the rope。However,If no other method is available,This method is very effective.。

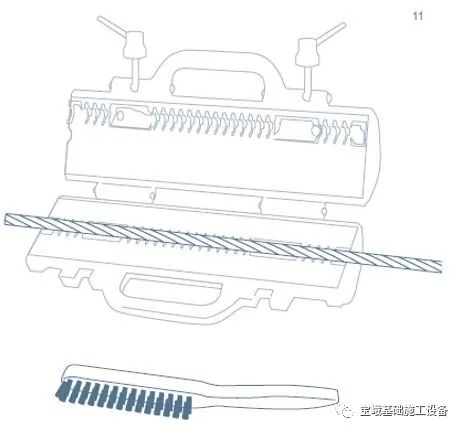

d. Use of relubrication oil for steel wire rope

Two types of grease are commonly used:Wax-based grease and oil-based grease。The choice of base grease depends on the type of equipment、Type of wire rope and application environment。Some greases are also used to meet special requirements.,Such as:Water solubility、Drip resistance or nature protection regulation。The type of grease varies from application to application。

In order to improve the service life of wire rope,And protect the inside of the wire rope,The lubricating film on the surface of the wire rope must be stable.。Grease is usually gradually lost during operation.,It must be relubricated regularly during use.。The grease used for relubrication must be compatible with the grease used in the production proces。

e. Use of relubrication oil for steel wire rope

When relubricating rope,Compatible with existing rope grease shall be used/Compatible grease。

Unoli spray oil,MNR 1137426-17.5kg can,MNR 1137423-Carton contain 12 600ml Sprinklers。

The upper part is not installed according to the operating specification,Cause the steel wire rope to be polluted by silt。

The upper part is not installed according to the operating specification,Cause the steel wire rope to be polluted by silt。