Benchmark! Typical! Four projects of Trinity were selected.

October 09, 2024

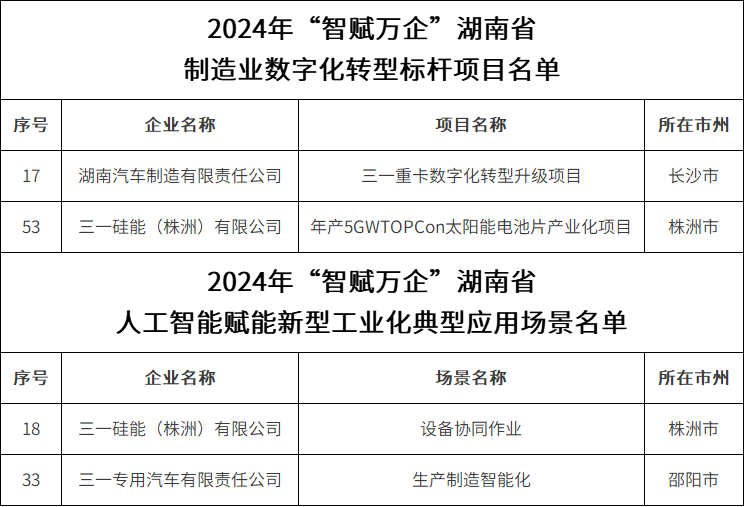

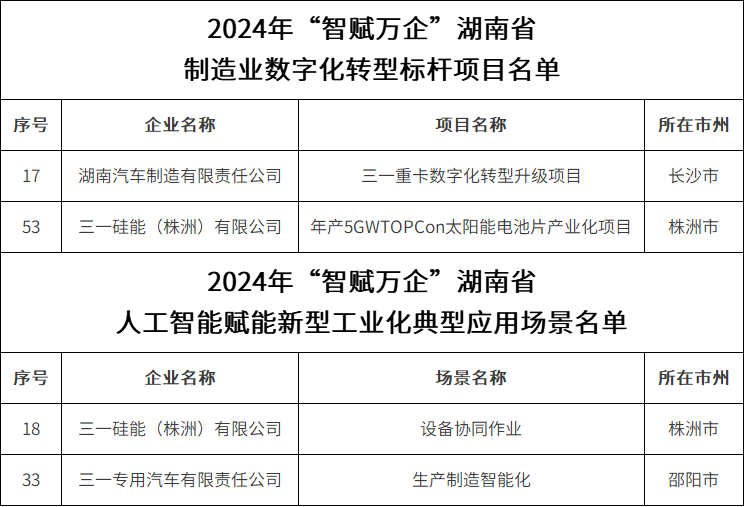

Recently,Issued by Hunan Provincial Department of Industry and Information Technology in 2024“Wisdom endows ten thousand enterprises”List of Benchmarking Projects for Digital Transformation of Manufacturing Industry in Hunan Province and List of Typical Application Scenarios of Artificial Intelligence Enabling New Industrialization,Three, a total of four projects were selected.,Leading the industry's digital upgrade。

Note:Sany Special Purpose Vehicle Co., Ltd. belongs to Sany Heavy Industry.

Among,Sany Heavy Truck Digital Transformation and Upgrading ProjectBase on multi-link process flow in heavy Truck complete Vehicle production proces,Deployment of intelligent manufacturing equipment,With 5G+Based on industrial Internet technology platform,Build an automated production line,Application of modular technology,Realize flexible configuration of production line,Realize automatic mixed line production of multi-type products,At the same time, select advanced warehousing in the industry.、Intelligent production equipment for logistics and other process links,Greatly improve the flexibility of production line equipment、Extensibility、Multi-model compatibility,Realize digital transformation in R & D and design、Manufacturing equipment、Production management、Demonstration application of marketing and other links,It has built an intelligent network heavy Truck automation hybrid production line with an annual production capacity of 40000 units.。

Annual output 5GWTOPConSolar Cell Industrialization ProjectThrough intelligent manufacturing technology, the production efficiency and product quality have been significantly improved.,IncludeSmart FactoryAnd that production speed and the continuous operation capability are improve.,Reduced manual intervention,The production cycle is shortened.,Improve the utilization rate of production capacity;Quality testing equipment and data analysis toolsThe integration realizes the real-time monitoring and precise control of the production process.,Ffectively reduce that defective product rate,The high quality and performance consistency of the products are guaranteed.;Intelligent manufacturing systemThe implementation optimizes the allocation of resources.,And that waste is reduce,Reduced operating costs;Automatic production lineIt also reduces energy consumption.,Labor costs are reduced,Improved material turnover efficiency,Inventory costs are reduced。

At the same time,This series of automation、Internet of Things、Application of key technologies such as big data analysis and intelligent production equipment,Also referred to as Trinity Silicon Energy(Zhuzhou)The photovoltaic cell factory was built.Equipment collaboration scenario,Intelligent operation of the whole process from raw material processing to finished product assembly。