In the near future,Wittgen W 380 CR New Mobile Cold Recycling Technology of Foamed Asphalt in Liaoning ProvinceSSuccessful application in road repair project of 102 Shenyang-Haikou railway,This is also the continuation of Wittgen's green road regeneration process.GSuccessful application in Liaoning Province after the restoration project of Dandong Fengcheng Section 304。

This green energy-saving、Flexible and efficient road repair technology has been fully recognized by the relevant local departments with good economic and social benefits.。

Project overview

SShenhai Line 102 is an important passageway between Shenyang and Liaozhong in Liaoning Province.,6 lanes in both directions,Original pavement width 30 m。After years of traffic load and UV aging,The pavement condition index decreased to a certain extent.。

The main pavement disease before maintenance is fatigue crack.、Rut、Net crack, etc,Poor flatness,It seriously affects driving comfort and safety.,A comprehensive and complete restoration is urgently needed.。

In order to better respond to the national call for low-carbon roads and circular economy.,And for new materials.、New Technology、New technology、Popularization and application of new equipment,After research, it is decided to apply the new low-carbon mobile foam asphalt cold recycling technology based on synchronous paving to repair some sections of the road.。

Maintenance plan

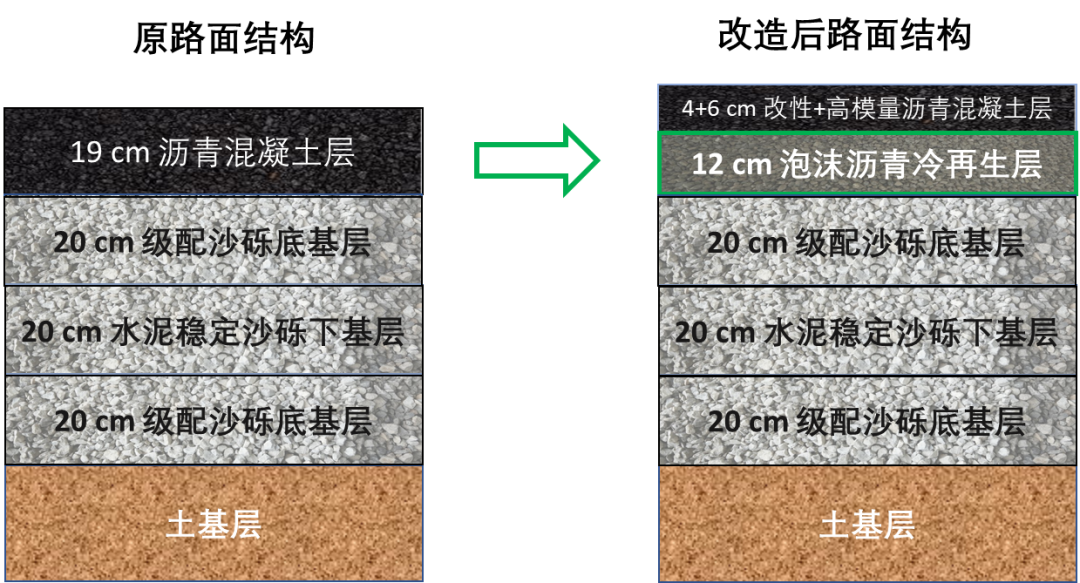

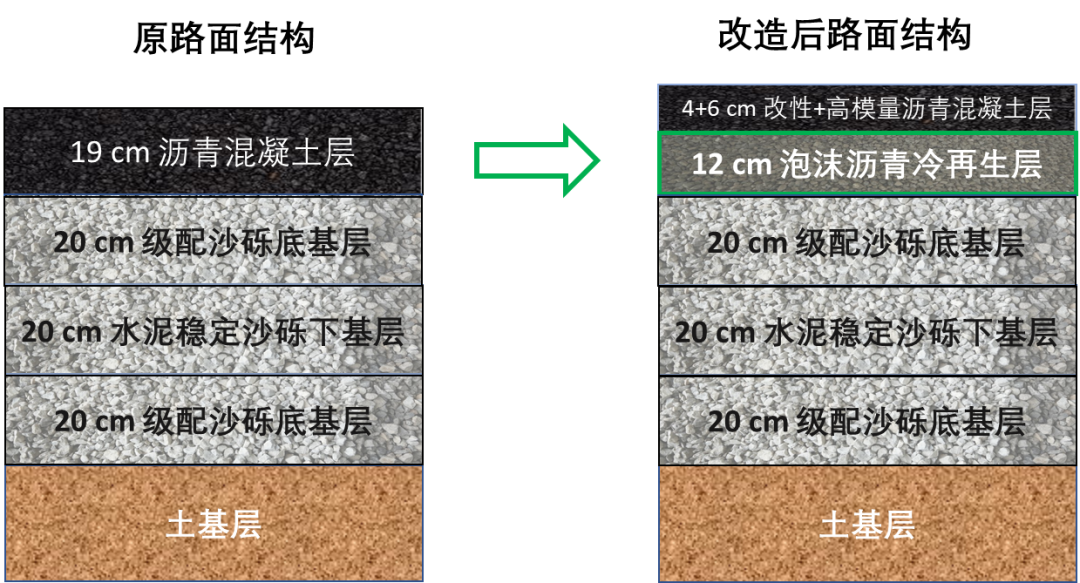

First of all, it is necessary to deal with the local diseases of the original pavement base.,Then to the original 19 cm After a certain thickness of asphalt concrete surface is removed by milling,Carry out cold regeneration of that foamed asphalt,Forming 12 after back spreading and compacting cm Thick foamed asphalt cold regeneration layer,And finally, carrying out overlaying on the surface.。

Construction process

Because there is a central green belt in the middle of the two-way road,,During the construction period, the two-way traffic will be temporarily diverted to the one-way three-lane road on one side.,Closed construction of the opposite three lanes on the other side。Due to the fact that only one-way roads are available,The traffic pressure it carries has increased dramatically.,Therefore, it is necessary to adopt efficient construction methods.,Shorten the construction period to minimize the impact on social traffic。

Wittgen used in the project W 380 CR Cold Recycling Machine,Cold regeneration can be performed on one lane at a time。In this application,The side of the original road surface is pre-milled by a Wittgen Milling Machine.,Thus enabling a flexible approach to larger regeneration widths.,Thereby reducing longitudinal construction joints.。

W 380 CR The cold Recycling Machine cuts and crushes the original pavement material,Precise addition of foamed bitumen and water by means of a spray bar placed on the milling cover,And the mixture is stirred together with the cement pre-spread on the old road surface to generate the foam asphalt cold recycling mixture。The undercutting mode of the reGenerator milling and mixing rotor also optimizes the particle shape of the cut material,Improving the gradation of recycled mixture,Thereby ensuring high-quality construction.。

And then W 380 CR The cold recycled mix is conveyed by a conveyor belt to the following Vogler Paver hopper,Carry out back paving through the synchronous paving process of the Paver.。Through the milling drum of the cold Recycling Machine to the Paver screed approx. 25 m Within the length of the,Down-cutting process through milling drum,And the remixing of the synchronous paving process.,And that dynamic uniformity of the regenerate material in the transverse direction and the longitudinal direction is ensured.,It effectively eliminates the discreteness of pavement materials.。

After that,Foamed bituminous material after repaving,Formed by multiple times of rolling by a Road Roller,Forming a compact and flat foam asphalt cold regeneration structure layer。The whole construction process adopts flow operation.,The regeneration process is completed at one go。

Humvee HC 228i D The fourth national discharge full-hydraulic single-drum roller carries out high-efficiency compaction

After multiple passes of compaction,The formed foamed asphalt cold recycling structure layer has certain bearing capacity.,Carry out rubber asphalt macadam seal layer on that rubber asphalt macadam seal layer,Traffic can also be opened temporarily when needed.。

Taking out complete and compact core sample after cold regeneration of foamed asphalt

Technical advantages

Wittgen W 380 CR One lane can be regenerated at one times,And the milling can be completed at the same time.、Broken、Addition of foamed bitumen and water、Mixing and other processes,Improve construction efficiency,And that construction period is shorten;100%Recycling pavement material,Reduce the use of new materials,Reduce transportation costs while reducing construction costs,The economic benefit is remarkable。

Wei has something to say

It is a general trend to develop sustainable and green road maintenance technology.,Wittgen's high-performance cold recycling technology based on synchronous paving has been successfully used in Hebei、Shaanxi、Shanxi、Hubei、Jiangsu、Szechwan、Anhui、Liaoning、Heilongjiang、Xinjiang、Inner Mongolia Autonomous Region、Beijing、Successful application in Tianjin and other places,Both social and economic benefit,China's transportation network has entered the stage of laying equal stress on construction and maintenance.,National and provincial trunk lines are facing more and more maintenance needs.,It is of great practical significance.。

Learn more about the technologies and applications of the Wirtgen Sustainable Road Maintenance Program,You can also do it on November 26.-Held at the Shanghai New International Expo Center on the 29thbauma 2024 Construction Machinery Exhibition,EPavilion 1E1.Visit booth 510,Live communication with our experienced and professional application team,To provide you with more targeted recommendations。