Innovation is Sandvik's DNA.,We are not only good at making use of our own advantages to bring forth new ideas.,It is also good at absorbing new members with strong innovative ability.,It is also supporting entrepreneurial teams to innovate together in various ways.。Today,Please follow Xiao Ke to have a look.,What innovative ways have we unlocked?!

Small stature and big energy

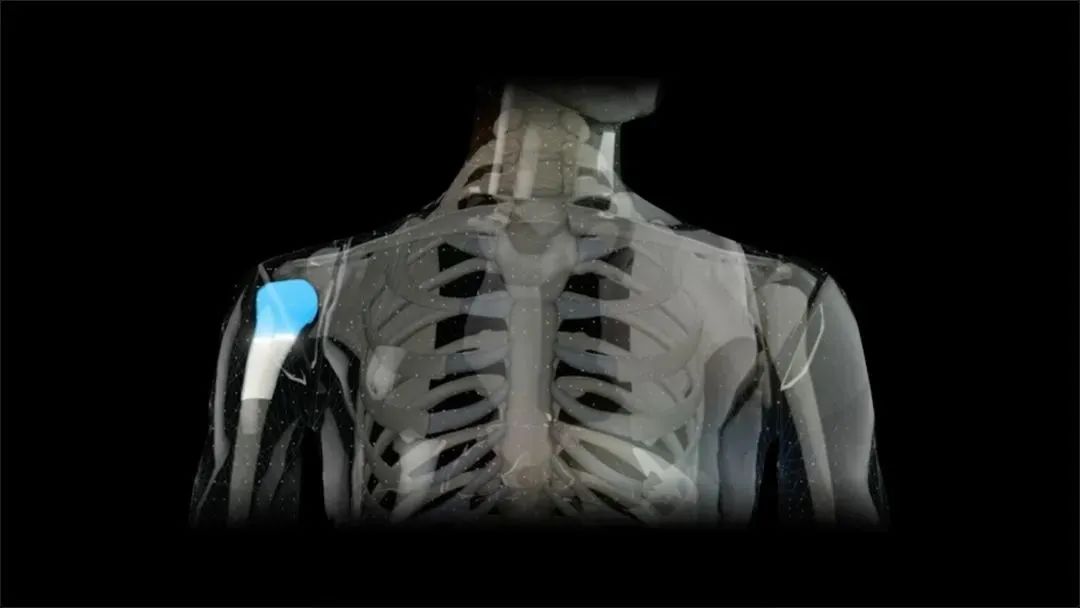

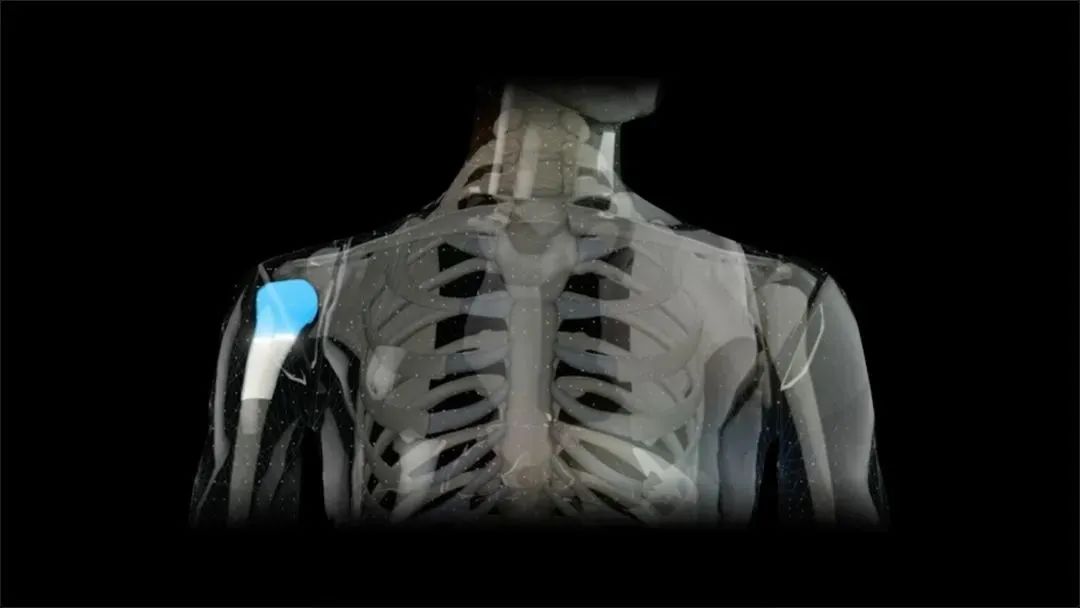

Enter the medical industry with precision cutting tools

How to produce a drill thinner than a human hair?That's not going to be hard for Sandvik.。

Sandvik'sSphinx ToolsThe company can accomplish this task well.,ProducedThe minimum micro drill is only 0..03mm,The average diameter of a human hair is 0..04-0.09mm。Sphinx ToolsIt is one of the most famous precision cutting tool manufacturers in the world.,Mainly for medical treatment、Car、Global customer design for aerospace and other industries、Manufacture and sale of precision cutting tools,In particularAtThe medical industry,Sphinx ToolsPrecision cutting tools are playing an increasingly important role.。

1

With a professional system,Create high precision cutting tools

“

In the medical field,Accuracy is critical,If you want to make medical tools into the human body, you need a lot of specific expertise.。Sphinx ToolsIt maintains a good strategic partnership with many equipment companies in the medical field.,Professional knowledge system for manufacturing precision cutting tools。

To ensure that the manufacturing process meets the precise requirements and strict regulations of the customer,Sphinx ToolsAccording to the materials specified by the customer、Tolerances、Hardening、Electropolishing、Laser marking、Even packaging requirements,To build the tools you need.,Make sure nothing goes wrong。Sphinx ToolsAlso has a certified clean room,In order to meet the needs of customers for aseptic packaging of some knives.。”

2

Customized production,Comply with standard specifications

“

The medical industry has very high requirements and standards for cutting tools.,There are strict special rules.。So,Sphinx ToolsThe production process will be inspected.、Procedures such as verification and certification,And ensure that the product complies withISO 9001:2015 andEN ISO 13485:Specifications of the 2016 Standard,Enable tool traceability and repeatability。At present,Sphinx ToolsThousands of medical cutting tools are produced each year,All of them are customized production.,Mainly used in orthopedics and trauma surgery.。”

Despite the challenges in the current healthcare market,,ButSphinx ToolsSandvik's expertise and knowledge have further consolidated its leading position in the field of precision cutting tools.,And continue to develop in the field of medical cutting tools,Make new contributions to human health。

Everything can be made.

Use 3DPrinting helps humans explore the sea of stars

Print an unbreakable guitar、Print carbide parts、Printing human implants……In recent years,Metal powder and additive manufacturing from Sandvik(3D Print )Has been applied to automobiles、Aviation、Space Flight、Medical treatment and other fields。

Click on the image to learn more

Now,With the emergence of micro-satellites and the increasing number of companies dedicated to space exploration.,The aerospace industry is developing rapidly.。Sandvik's metal powder and additive manufacturing are also moving further into the aerospace market.。

Technical Director of Sandvik Metal Powder and Additive ManufacturingPasi KangasPasi KangasExpress:“Metal powder and additive manufacturing are recognized green technologies,When manufacturing a part,The metal powder may be used according to actual needs,The remaining material can be recycled and reused.。So,This is very energy efficient.。For example,If you use titanium to 3DPrint Aerospace Parts,Lightweight parts will be obtained,This will also reduce the fuel consumption and environmental impact of the aerospace process.。”

“In the near future,We expect additive manufacturing to enter the era of mass production.,For example,Mass production of space engines,And printing technology will become more advanced and stable.。”KangasVery optimistic about this industry.。“ Later ,There will be more rare parts.,Pass 3DPrint the way to manufacture.。This will bring great value to the whole industry.,For example,You only need 20 parts.,There's no need to make 800.。This will help our customers greatly improve productivity.,And that production cost is save。”

“Zhi Zao”New idea

Driving Dynamic Cutting with Innovative Software

Late last year,By Sandvik and Partners SynerLeap And Microsoft's Startup Challenge.,Digital innovators from around the world presented their innovative solutions。These solutions will help make mining and manufacturing safer、Smarter and more sustainable。

Among,From FinlandDreijaA team of company representatives developed a software using dynamic cutting data and machine learning.。This software provides cutting advice for industrial metal cutting applications.,Recommend appropriate machine production setup parameters。

“Thanks to artificial intelligence,Our software learns faster than humans.,Ability to analyze dependencies between thousands of different parameters,For example,Speed、Temperature、Raw material characteristics, etc,The optimal setting for indexable tools is obtained.。”Team members ShadrunovExplain。He said:“Through this software,Reduces waste and energy consumption during processing,Reduce machine wear,Saves time in machine setup,So as to improve the sustainability of processing.。”

ShustrovPoint out:This solution is especially useful for new employees who lack experience in the machining industry.。It allows new employees to quickly have years of practical experience.。

At present,The team is developing models with Sandvik.,And testing with selected customers。Wait until the software is officially launched on the market.,Will help customers significantly improve productivity,Let's wait and see。

Ok ,That's all for today.。Innovation is one of the keys to Sandvik's industry leadership.,It is also an important driving force for the world to move forward with engineering technology.。Future,Xiao Ke will continue to introduce our innovative products and technologies to you.。Current period,We introduced precision cutting tools.、3D Print 、Dynamic cutting software,Which one interests you most??Leave a comment in the comments section below.。