01 Application background

On October 25, 2021, the Ministry of Transport issued《Digital traffic“Fourteen five”Development planning》(Delivered to the planning department〔2021〕Number 102)Notice of。“Development planning”The Communist Party of China mentioned it thirteen times.“Digitize”、Fourteen times“Intelligent”。And point out in particular,Guided by Xi Jinping's Socialist Thought with Chinese Characteristics in the New Era,Thoroughly implement the Nineteenth National Congress of the CPC and the Second Session of the Nineteenth Central Committee、No.3 middle school、No.4 Middle School、The spirit of the Fifth Plenary Session,Based on the new development stage,Implement the new development concept,Construct a new development pattern,Integrating development and security,To digitize、Networking、Intelligence is the main line,Take reform and innovation as the fundamental driving force。

Guangdong Province is the birthplace of the tide of national reform and opening up.,It is also a pioneer in exploration and innovation.。The reconstruction and expansion project of Maozhan Expressway is an important measure to inject strong vitality into the economic development along the line.,It is also a strategic layout to further enhance the interconnection between Western Guangdong and the Pearl River Delta and to promote the development of the Great Bay Area of Guangdong, Hong Kong and Macao.。The First Company of the 12th Bureau of China Railway is an important builder and participant of national infrastructure.,Actively respond to the call of the state,Resolutely implement the spirit of the document,Insist on taking innovation as the guide,A vision of the world,Be brave to explore and try,Scientific use of digital technology,Take the lead in introducing the new technology in the reconstruction and expansion projects of expressway in the province.DPavement paving is Topcon 3DIntelligent paving system。By adopting 3DIntelligent Paving System Replaces Traditional 2DApplication of Paving Technology in Reconstruction and Expansion Project of Mao-Zhan Expressway。

Commonly used 2 for paving of water stable layerDSliding shoe paving process,It is usually carried out by erecting a steel wire line.。First,Due to the self-pollution of the steel wire rope、Accuracy error caused by elasticity, deflection, etc.。When the Paver is working with the throttle increased during the transmission of materials,The shaking of the car body will make the skid shoe jump on the wire line.,Plus the deflection error of the wire rope's own sagging,So that the elevation is accurate only in the vicinity of the pile.,However, a large error may occur in the position between the two piles.。This will result in the transmission of data containing errors to the Paver,Causing the screed to be adjusted too often,The paved road surface will be wavy to a certain extent.,It is difficult to effectively control the paving accuracy and ensure the smoothness.,Poor ride can significantly reduce the life of the road,And will cause certain material waste and so on.。And the erection of the yardstick requires professional surveyors to set out in advance.、Leveling,And auxiliary personnel are required to erect it.,It will also bring more artificial errors.。

Adopt 3DPaving technology can effectively overcome the problems of datum line drooping and so on, which are easy to occur in conventional construction of hanging steel wire.,The traditional working procedures such as measurement and lofting are saved.,And that operation efficiency is improve.,And that construction safety risk is reduce.。

“3DPaving technology through satellite global navigation and positioning system and laser high-precision measurement system,Elevation accuracy and plane accuracy of three-dimensional control paving,Equivalent to 3 for the road surfaceD‘Print’,Flattening accuracy error can be controlled at about 3 mm。”Maozhan high-speed reconstruction and expansion project manager said.。

Construction workers only need to put the road surface.、Paving thickness and other relevant data are input into the system.,The system will form the relevant 3DData,Feed back to Paver,The screed of the machine can be adjusted up and down in time.,No more manual operation。

02 System introduction

Topcon 3DThe intelligent paving system consists ofGNSSReference Station、Domain laser transmitter、mmGPSMobile stations andPAutomatic control system of 63 Paver consists of four parts。When the system is working,GNSSThe base station transmits to the mobile station in real time through wireless communication technologyRTKDifferential signal,At the same time, the domain laser transmitter sends elevation information to the rover station in real time.;mmGPSWhat the rover will receive respectivelyGNSSSatellite signal、GNSSOf the base stationRTKDifferential signal and elevation information of the domain laser transmitter,Carry out joint processing and calculation in real time,Instant access to real-time centimeter-levelGNSSPlane positioning accuracy and millimeter-level elevation control accuracy。

3DPaving control system configuration diagram

PAutomatic control system of 63 Paver is equipped withPZS-MCDomain laser receiver andMC-R3 GNSSThe receiver simultaneously carries out centimeter-levelRTKPlane positioning and millimeter-level elevation positioning,The 3D coordinate data of real-time positioning is transmitted toGX-60 Control box,The system will get the current 3DCoordinate information and previously imported road surfacesBIMModel design data for comparison,And the elevation correction information of the corresponding point is generated in real time,The elevation correction information generates a driving signal with a corresponding proportion through a series of algorithms.,Hydraulic cylinder that drives the Paver's tow arm through a solenoid valve,This in turn causes the screed to adjust in the appropriate direction,Make up for the fluctuation of road surface,Realize the flatness according to the design requirement、Automatic pavement of gradient, thickness, etc.。

In the field of engineering construction,Achieving dynamic quality management has always been a common pain point and difficult problem.。Millimeter scale 3DReal-time matching of paving control system in paving process 3DDigital construction design,Automatic、Intelligent control of screed lift,No manual intervention required。However, it is affected by the construction environment.,To ensure that the screed remains in working order at all times,At the same time, the system is also equipped with a real-time detection of paving quality.mmGPSMobile Station。During paving,mmGPSThe mobile station dynamically detects whether the paving surface at any position meets the construction design requirements.,In case of any deviation from the design,According to the deviation value,Can be the first time in the systemGX-60 Adjust the Paver screed lift in the control panel,To ensure that the screed is always stable and completes the paving work with high quality.。

After completion of paving and compaction,Can also be used againmmGPSThe mobile station shall conduct further paving quality inspection and data collection on the completed road.,Provide high-quality data basis for the acceptance of each layer of paved road surface。Based on the above adoptionmmGPSQuality control and inspection of each link in the paving process of the mobile station,It can really realize the whole process construction monitoring and dynamic quality control of the whole paving operation.,To complete the paving operation with high quality according to the road design,Final delivery of high-quality construction results。

03 System advantage

1、Simplify the process,Improve efficiency,Reduce labor costs

SupportBIMImport of model design data,The work of manually erecting the reference datum is saved.,No calculation by the surveyor、Design、Measure、Setting out、Pile driving、Pull wire、Prepare for erecting guide beam, etc.,Only a small number of inspectors are needed.,Once the Paver is ready, the paving operation can be started directly.。

2、All-weather operation,Shorten the construction period

Compared with the traditional operation mode,The system is automated、Intelligent paving operation,Not affected by ambient light,The operation accuracy is consistent,Capable of continuous operation 24 hours a day,Effectively promote the construction progress,Shorten the construction period,Improve the quality of night construction。

3、Dynamic quality control and management in the whole process of construction

Pre-inspection before paving and real-time continuous control of paving process can be realized.。Base before pavingBIMThe design can check the digital model of the road design in advance.,And the accuracy of benchmarks and control points,Real-time display of paving status by combining figures and graphics during paving,CombinemmGPSReal-time monitoring of paving quality by mobile station,Real-time detection of the paving process and acceptance of the confirmatory test after paving,It is the embodiment of dynamic quality control and management in the whole process of construction.。

4、Single millimeter-scale laser transmitter controls entire area

Original domain laser technology using 1+NBroadcast signal distribution model,One transmitter can provide millimeter-level elevation datum for multiple Paver systems and rovers in the area at the same time.,The operation is convenient,It greatly reduces the number of professionals and the cost of comprehensive investment.。Up to four transmitters can be set up alternately at the same time,Expanded scope of work。

5、The system compatibility is good

Millimeter scale 3DThe paving control system adopts plug-and-play design.,No need to change the hydraulic system of the machine,It can be directly compatible with all Pavers of domestic and imported mainstream brands on the market.,It can be used for the paving of the water stable layer.,It can also be disassembled and assembled to any brand of asphalt Paver for repeated use.,And any Paver manufacturer does not need to open an authorization code separately.。

6、Effectively improve the safety of the construction site

Apply mm 3DPaving systems can significantly reduce the number of auxiliary workers on site,Reduce man-machine cross operation,It is an important technical support means to effectively improve the safety management level of the construction site.,Especially for the reconstruction and expansion projects with continuous construction.,The significance is particularly important。In line with the current situation of our country“People-oriented,Safety first”The concept of construction management,And really put it into practice.。

7、High standard of flatness、Smoothness and thickness control

Accurately control the absolute elevation of each layer of pavement in the whole process.,At the same time, the slope of paving shall be taken into account.、Flatness control,Minimize the waste of high-quality raw materials,Eliminate the influence of human error,Controllable paving operation precision,Effectively improve the smoothness of paved pavement,Significantly improve the service life of the road。

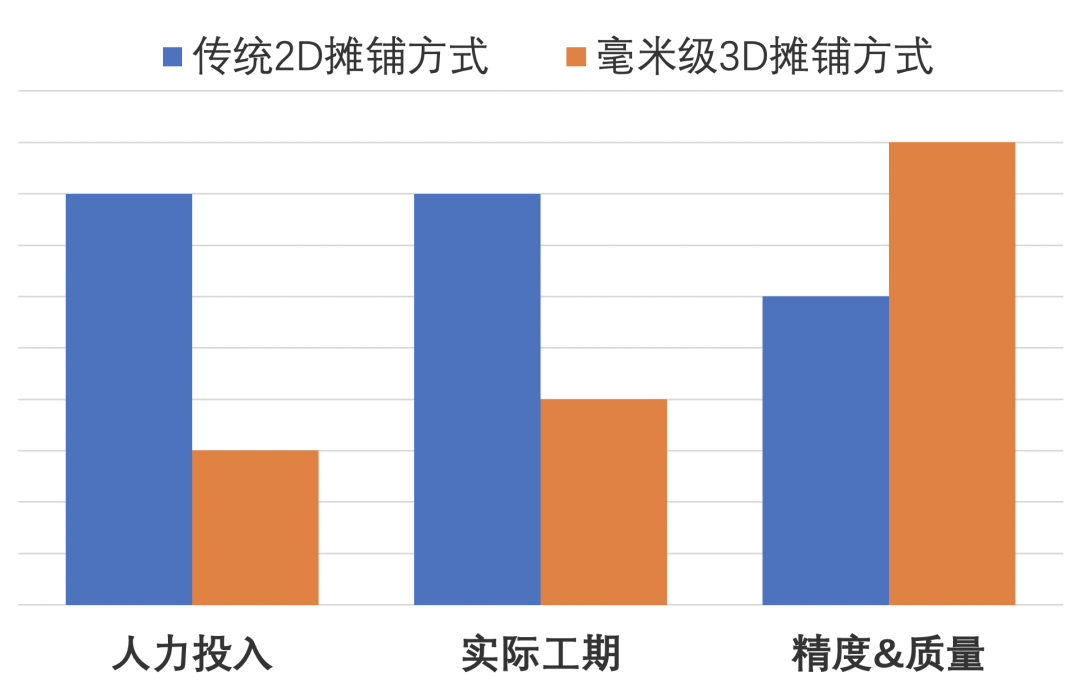

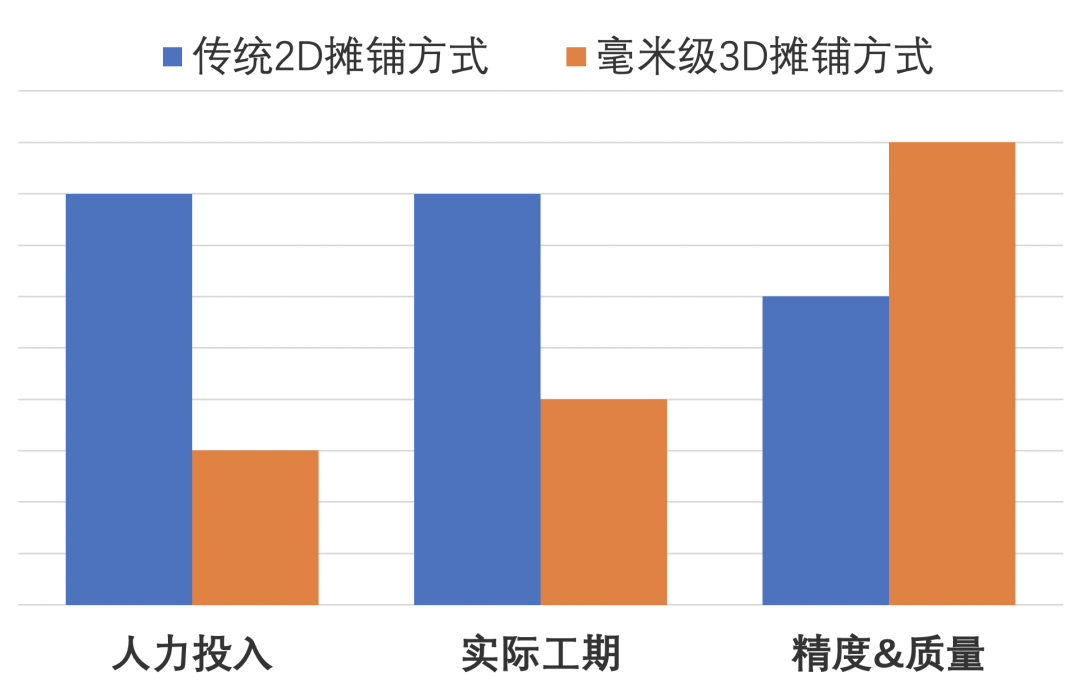

3DComparison between paving process and traditional process

|

Project

|

Traditional construction method

|

Millimeter High Precision 3D Paving control system

|

|

Quality

Control

|

Post control,Cause rework,Waste of resources。

|

Real-time process detection,Ensure the accuracy of construction。

|

|

Benchmark

Set up

|

Measure and set out in advance、Pile driving、Lofting Datum

Line and a lot of other work.。

|

The links of setting benchmark, such as pile driving, lofting and steel wire pulling, are omitted.,Thereby subtracting

Less human factor error,Reduce the preparation time for paving,Improve control

Accuracy and efficiency。

|

|

Slope

Control

|

Slope control cannot be carried out in real time.,Make a curve

Industry can not strictly meet the design requirements。

|

Full digital display,Precise control of elevation and slope;Display paving slope in real time

Difference from design surface,Strict control of slope and thickness。

|

|

Process

Record

|

The elevation of the current point cannot be displayed and recorded。

|

GNSSPlane and domain laser elevation precise positioning,Continuous measurement in the whole process,

Real-time acquisition、Record paving process data。

|

|

Design

Present

|

Can only be displayed as a gridCADDesign count

According to,Cannot realistically represent any of each mesh

A few real coordinates。

|

In strict accordance with the design InstituteCADProject data for design,Directly according to 1:1

The proportion of construction is carried out on site.,Directly through fromBIMFrom design to construction

Bottleneck of application,Real presentation of the coordinate value of each point on the construction site,Will

Perfect combination of construction data and design data。

|

|

Personnel

Input

|

Drive and set steel drill、2 persons for hanging steel wire、Pendulum aluminum alloy

2 people,Watch the computer 4 people、8 persons in total。

|

You only need to configure 2

Surveyor。

|

04 System application effect

Expressway reconstruction and expansion project,There is no extra space at the junction of new and old roads.,There are many limitations in the construction of suspended wire method.:One is the lack of space.,The computer sensing system cannot be installed to walk.;The second is the interference of steel drill and steel wire in the rolling process.,The steel drill shall be removed before rolling.。Other than that,The difficulty of reconstruction and expansion is the splicing of new and old pavement.,Based on the elevation of the old pavement,Dynamically adjust the new pavement level。In view of the above limitations and characteristics,Topcon Millimeter 3DHigh-precision intelligent paving system is more suitable for expressway reconstruction and expansion pavement construction。

Splicing of new and old roads,Suspended line construction is limited

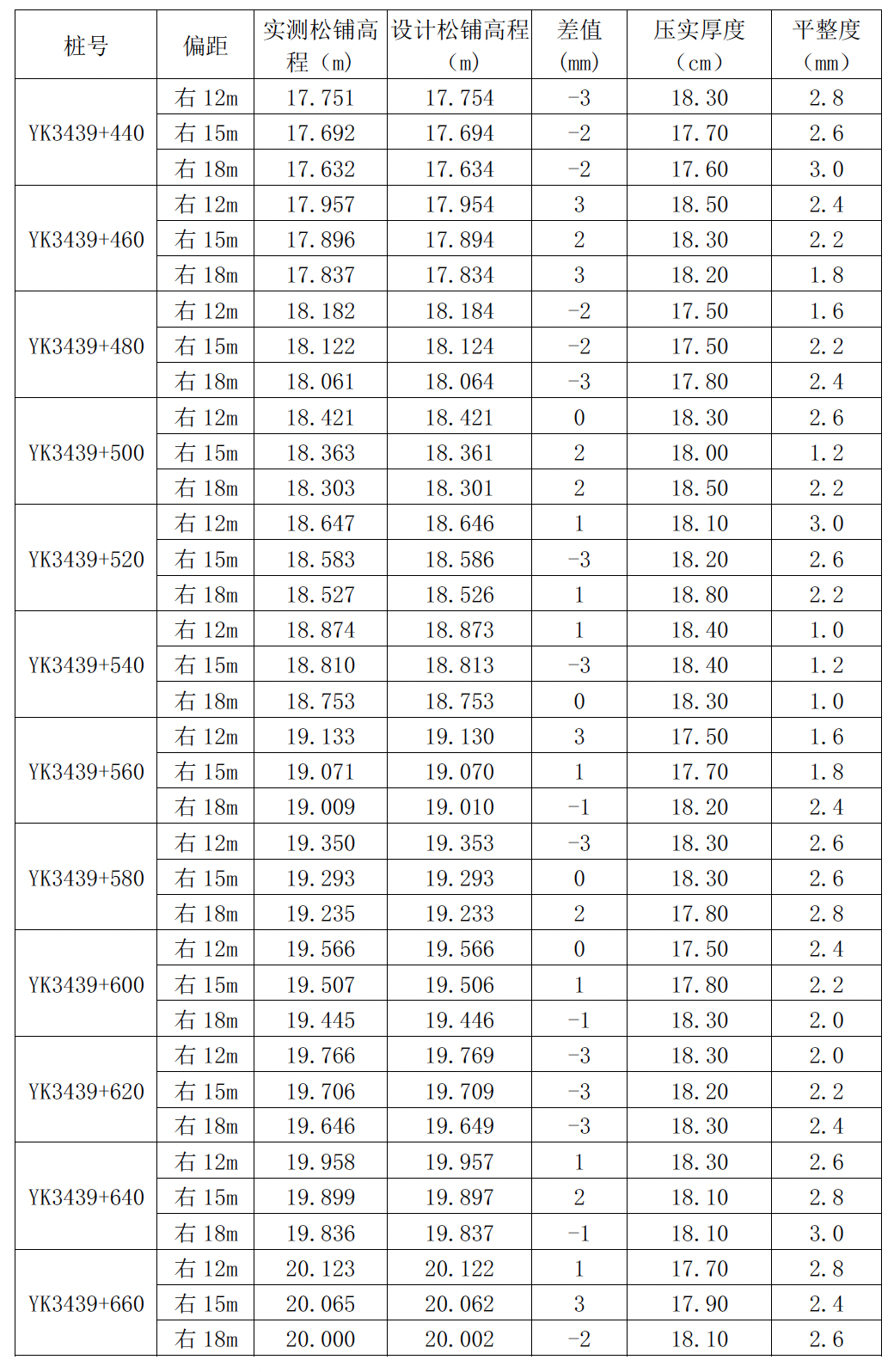

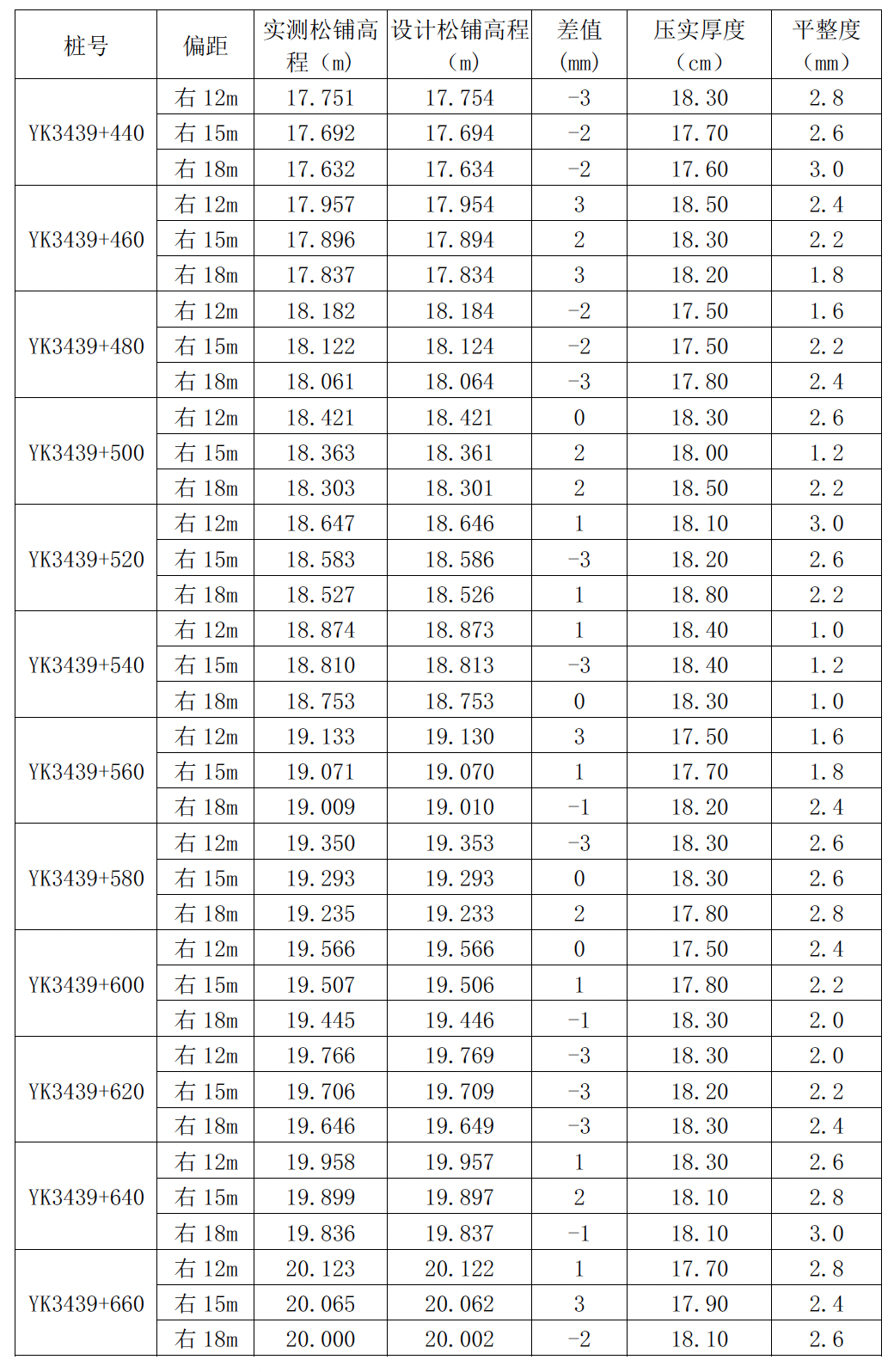

3DStatistical Table of Paving Results

Pavement structure layer shall be paved in millimeter level 3DPaving control system,Breaking the need for piling in advance for paving the pavement structure layer、The tradition of hanging lines。Millimeter scale 3DPaving control system adoptsGNSSLaser Elevation Positioning in Plane and Domain,Continuous measurement in the whole process、Detect;Strictly in accordance with the design of the project data directly in the field according to 1.:The proportion of 1 is constructed on site.,Directly get through the industry fromBIMBottleneck from design to construction application,Perfect combination of construction data and design data,O that the thickness of the paved pavement structure layer is uniform,The surface is flat;Real-time acquisition、Record paving process data,Precise control of elevation and cross slope;The lofting and piling are omitted、The link of hanging line,The dependence of paving on thread-hanging precision is solved.,Reduce human error,Flatness accuracy up to±3 mm,At the same time, it solves the problem of lofting and piling at the overlapping position of new and old roads.、Limitation that the Road Roller can not roll in place after hanging the line,Whole process dynamic monitoring、Detect the paving operation,It really realizes the dynamic quality management of the whole process of paving construction.,To help Guangdong Province“Ping An Centennial Quality Project”The construction of licking bricks and tiles。

Contribution:Reconstruction and Expansion Project of Maozhan Expressway of the First Company of China Railway 12th BureauTJHuiqiang, Chief Engineer of Bid 5 Project