The data is about economic development.“Barometer”、Evaluation of the effectiveness of the work“Weights and measures”。September twenty sixth,CCTV《Morning News》Broadcast《In the data“China's vitality”》Series of reports,From“Excavator index”Feel the momentum of China's economy。This index shows the operating rate and working conditions of all kinds of construction machinery and equipment.,Be called“A barometer of China's economy”。

The heat of national infrastructure construction is steadily improving.

CCTV financial Excavator index shows,In August this year, the overall operating rate of construction machinery in China was 63.99%,Since this year, the average operating rate has exceeded 60 percent%,The national infrastructure construction heat is steadily improving.。

Li Haowei, Data Institute of National Industrial Internet Big Data Center:On the whole,Our country as a whole has been affected by some epidemics this year.,However, the operation of construction machinery is still in a state of steady growth.。

From the area,This year 1—August,Northeast、The heat of construction in many provinces in the northwest and southwest has maintained growth.,With the introduction and implementation of a package of policies to stabilize the economy,,In July, the overall operating rate of machinery in 17 provinces and cities achieved a positive growth.,In August, Jilin Province set the highest point of the national operating rate this year.——78.01%。

In addition to infrastructure construction,In construction machinery and equipment,Equipment such as front cranes and Stackers are used for container loading and unloading at ports.,Closely related to import and export trade。The provinces and cities with active foreign trade this year are mainly concentrated in the southwest.、Central China、Northeast China and other regions,The performance of many inland provinces and cities is outstanding.。August,The operating rate of port equipment in Sichuan Province has reached 88%,The highest this year。

Major equipment has made historic breakthroughs.

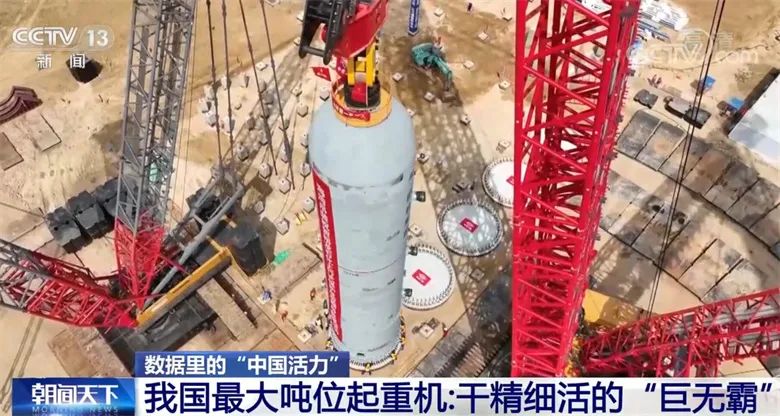

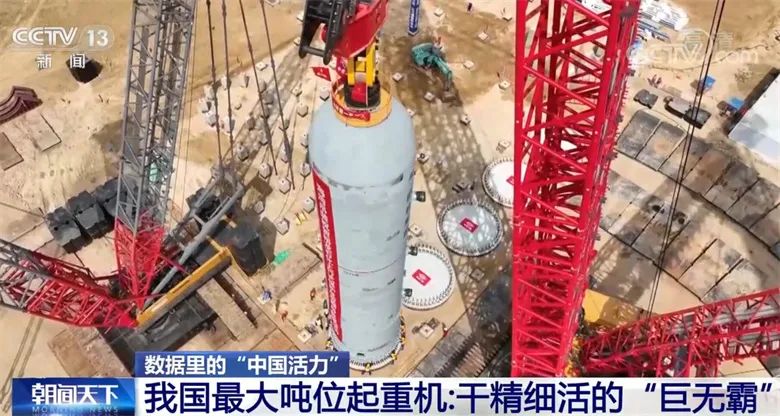

In recent years,Many major equipment in China have made historic breakthroughs.,4,000-ton Crawler Crane,All-terrain crane of 2000 tons,There are more than 100 tons of hydraulic Excavators and so on.,Construction machinery and equipment continue to move towards high-end。Coming up,Let's go to see a domestic product.“Big Mac”——The largest tonnage crane in China at present。Its lifting weight can not only reach 4500 tons.,It can also do fine work down to the millimeter.。

Not so long ago,Refining and chemical integration construction site in Longkou, Shandong,One is 32 high..7 meters、Reactors weighing more than 1400 tons were hoisted to designated locations.,The hoisting equipment is the 4500-ton Crawler Crane with the largest tonnage in China.。Don't look at them. They're all huge.,However, the position of hoisting and placement is accurate to millimeter level.。

Zhang Yang, Vice President of Zhejiang Sany Equipment Research Institute:We have all kinds of sensors in the car.,Move a handle,It can move a little.,Make sure we don't hit the hole at the end.。

Large tonnage cranes are expensive.、And that production cycle is long,It has been relying on imports for more than a decade.。In more than 10 years of research and development,The scientific research team cooperates with many universities in China.,Repeated trial-and-error experiments with digital prototypes。

Zhang Yang, Vice President of Zhejiang Sany Equipment Research Institute:We made a digital prototype.,It is equivalent to a physical machine.,We got exactly the same thing on the computer.,Including mechanical, electrical and hydraulic power systems, are all built.,And then co-simulate。

After more than a decade of trial and error,,Domestic large-tonnage cranes can finally play an important role in the construction of major projects,Not only the heaviest lifting tonnage in the world,It can also be deformed,Width of the lower part of the herringbone system、Narrow at the top,Not only improves the stability of the crane,,It can also disassemble 4500 tons into two 2000 tons that operate independently.,The modular design not only meets the lifting requirements of the construction party for various weights,,But also can save the loading and unloading of the crane.、The cost of transportation and other links。

In addition,Before construction,The enterprise will also carry out according to the needs of each engineering operation.“Tailor-made”,While ensuring the safety of the project,The material production of crane parts is gradually localized.,And that manufacture cost is reduced,And drive upstream and downstream enterprises to work together.。

Zhang Yang, Vice President of Zhejiang Sany Equipment Research Institute:We cooperate with well-known steel mills in China.,One is steel plate,One is steel pipe,Delivery can be made in three months.。We've been building a crane for less than a year now.,The cost has been reduced by half.,(Now)Steel mills have begun to export the steel we use to foreign countries in turn.。

Source of content:CCTV News