As the pioneer of modern pavement compaction technology,Dynapac pioneered the theory of vibratory compaction in the 1960s.,And apply it to Dynapac roller.。Since then,Generations of Dynapac rollers have created numerous excellent projects in the road construction industry.。“Flatness”As one of the most important parameters of pavement compaction quality.,It has become the core competitiveness of Dynapac Road Roller in the industry.。Today,Let's get close to the compaction setting and start-stop function core of Dynapac tandem roller.,Reveal Dynapac“Super flatness”How to achieve。

Flatness is usually divided into longitudinal and transverse directions.。Longitudinal evenness and gradation of asphalt mixture、Temperature、Adhesive layer, etc,Not discussed in this article。While the lateral flatness is related to the pavement equipment.,It is not just about the performance and operation of the Paver.,Roller performance and operator operation have a greater impact on the lateral flatness.。

The Paver is usually equipped with a leveling instrument or a balance beam for paving.,Its control system and leveling instrument/The accuracy of the balance beam is improving day by day,So in general,,The flatness of the paving surface will not fluctuate greatly.;Moreover,Even if the Paver stops and waits, it will affect the lateral flatness.,It can still be made up by the roller behind.。Therefore, the compaction operation becomes the last key link of the pavement smoothness.,The higher requirements for the operation of the operator and the performance of the roller are self-evident.。

Fundamentals of Dynapac Compaction Technology——Swedish Compaction Test Centre:

Dynapac is located in SwedenKarlskronaThe compaction test center was established in the 1960s.,It is the big data foundation for the development of Dynapac compaction technology.。The test center has collected various compacted materials from all over the world for many years.,Compaction database under various working conditions is obtained through test summary and accumulation.,It can match the most scientific and reasonable compaction scheme for different construction projects and working conditions.,It provides comprehensive and reliable data support for the compaction quality of Dynapac roller.。

About the rolling speed:

In useCC2200~CC6200 series high frequency vibratory roller,Dynapac recommends a rolling speed of 3~Six kilometers/Hour。The operator can observe, control and adjust at any time through the display screen.。

In order to allow customers to fully understand and control the rolling speed,Dynapac rollers are equipped with a Compactor gauge display.。Every 1m traveled by the roller,The vibration times of the drum will be displayed in the lower right corner of the working interface of the display screen.,In order to help customers control the speed。Here Dynapac reminds users,This value cannot be less than 32,As shown in the figure below:

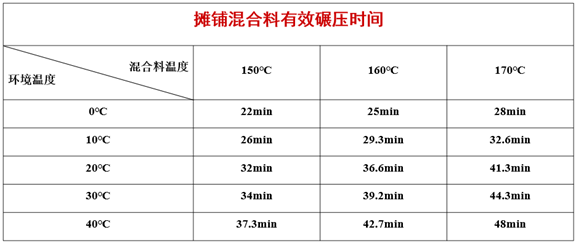

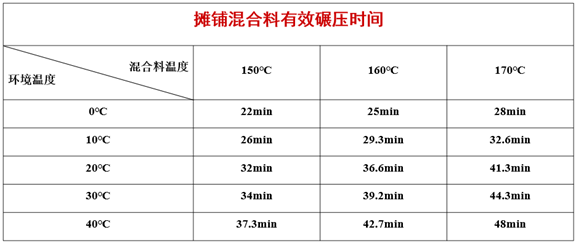

About the rolling time:

Dynapac Compaction Test Center has obtained the following data based on years of test accumulation and summary,Customers are advised to control the effective compaction time according to different materials and ambient temperatures.。

Setting of the parking mode of the roller:

During compaction,If the driving speed of the Road Roller rises sharply, it will occur on the road surface.“Steak nest”,Thus affecting the smoothness of the road surface.;You must stop when changing the direction of travel,However, the asphalt mixture at high temperature has not been cooled and shaped.,Roller is affected by inertia when it stops.,The steel wheels are bound to push up a bulge in the road.,Such bulges will greatly reduce the smoothness of the road surface.。

Dynapac roller is specially designed with the function of soft start and soft stop to solve the above problems.,That is:The driving speed of the Road Roller is uniformly increased at the time of starting,Avoid“Steak nest”The production of;At the time of parking,The drum will continue to roll forward for some distance.,Avoid the generation of bulges。And the operator can set it according to his driving habits and familiarity with the machine.,The setup has“SOFT、MEDIUM、HARD”Three modes,The meaning is as follows:

SOFT: Longest buffer distance

MEDIUM: The buffer distance is slightly shorter

HARD: Shortest buffer distance

As shown in the figure below:

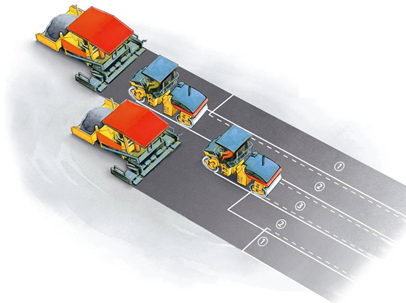

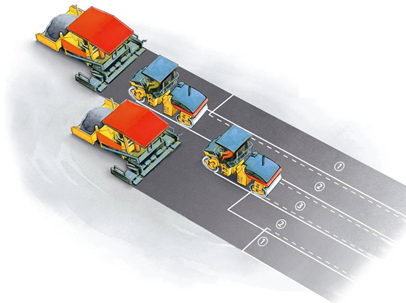

Influence of Roller Stopping Position:

With Dynapac's soft start and soft stop configuration,With the help of dislocation parking,The flatness after rolling can be greatly improved。Here Dynapac advises users to misplace parking,That is:Each stop of the roller is staggered by one wheelbase from the previous stop.,Staircase parking in the transverse direction of the road,As shown in the figure below:

Excellent overall design and motor configuration:In addition,Thanks to the overall layout of excellent articulated design of Dynapac double steel wheel roller,And the left and right sides of the front and rear wheels are provided with the reasonable arrangement of the driving motors.,CCIn the turning process of rolling the ultra-thin asphalt layer by the series double-drum roller,,It can effectively avoid the phenomenon of cracking the road surface.,This ensures optimum flatness in the most technically demanding construction project。

To sum up,Beyond Dynapac's vaunted high-frequency vibration technology,There are still many unique high-tech means to work together.“Super flatness”Escort the achievement of,DynapacCCSeries double-drum roller has become the best choice for asphalt compaction construction with its own technological hard power.。

Dynapac,Committed to high-tech means to achieve the customer's road construction objectives,We not only provide our customers with high-tech compaction and paving equipment,It is also an expert in road construction technology solutions around customers.,Join hands with you,Build the future together!