The selection of suitable parts according to different crushing materials can effectively improve the working efficiency and operating effect of the crushing equipment, reduce losses and improve economic benefits. As one of the key components of the mobile jaw crushing device of lei trowel MOBICAT EVO series, the jaw plate has a crucial influence on the crushing effect of the device. Below, we will explain the crushing technology of crowley float MOBICAT EVO series mobile jaw crushing equipment, and provide different types of jaw plates for different working conditions, so that you can make a correct judgment more quickly when choosing spare parts.

crushing principle

When the crushing equipment works, the raw material is broken in a wedge-shaped crushing chamber composed of a fixed jaw and a moving jaw on an eccentric shaft. The crushing of the material is completed by an elliptical motion stroke, and the material will not be transported downward under the action of gravity until the particle size is less than the opening of the outlet.

low-wear material

Lei trowel jaw is made of special manganese steel castings with a very strong matrix. During the crushing process, through compressive stress, the manganese steel castings will form a high wear resistant surface, thus ensuring a long service life.

& have spent  & have spent

& have spent

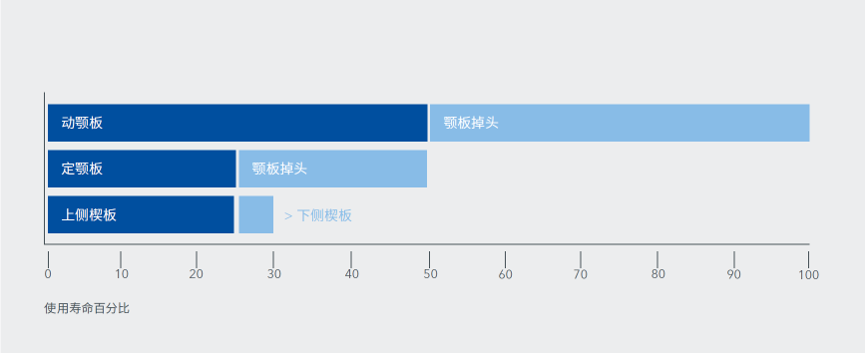

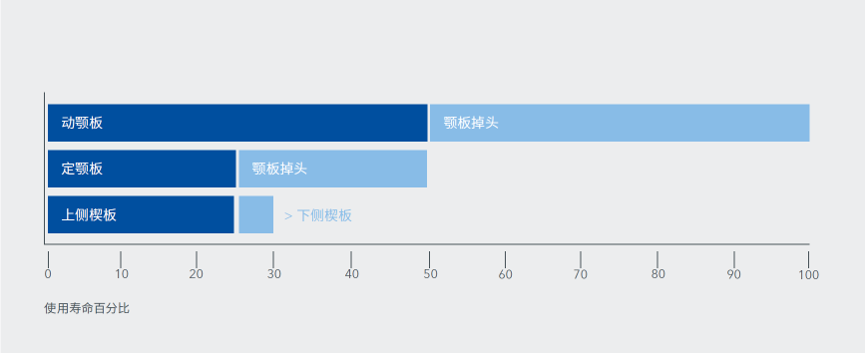

Ideally, wear occurs mainly in the lower half of the jaw plate. If the jaw teeth are completely worn (smooth jaw), a u-turn or replacement is required. When the jaw becomes smooth, the crushing capacity is significantly reduced because the material is primarily compressed rather than crushed. Equipment needs more force to break, which unnecessarily increases the construction cost, and produces higher wear and poor crushing effect. Timely replacement of worn jaw plate can improve the crushing effect and significantly reduce the construction cost.

& have spent  & have spent

& have spent

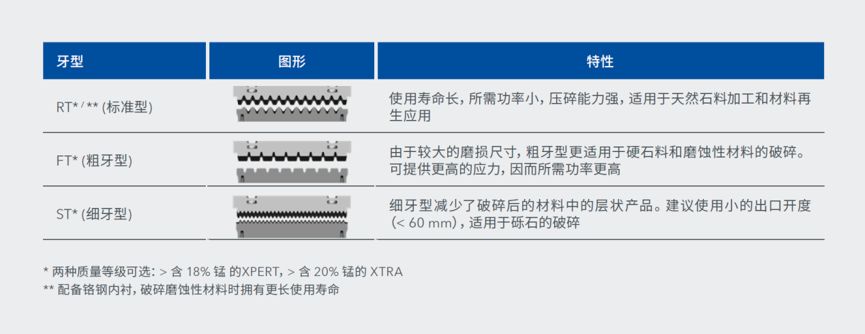

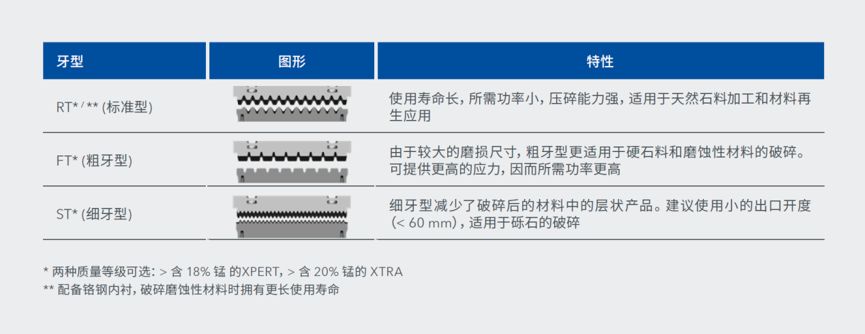

Crewel offers a wide range of components. Choosing the right jaw plate depending on the material can have a crucial impact on the effect: abrasive stone and coarse stone, for example, require different jaw plates.

& have spent  & have spent

& have spent

For natural stone processing applications and materials recycling applications of various types of materials, such as low and medium abrasive natural stone, abrasive natural stone, abrasive and low abrasive circular materials as well as rubble and recycled materials, lei trowel has prepared suitable solutions.

If you want to know more about the production process of crewel mobile crushing equipment, please contact the local agent of vitgen for further consultation. Crewel staff will provide you with more specific Suggestions according to your working conditions.