With the rapid development of the society, environmental protection has quietly become an urgent global problem to be solved, which has aroused wide attention from all walks of life. With the rapid increase of dust, waste gas and water pollution, our living environment has become extremely fragile.

With the advancement of the national urbanization process, the concrete industry continues to grow at a high speed, and the engineering construction for the mixing plant demand is also increasing. In order to reduce the pressure of the environment, protect a better home, a comprehensive elimination of serious pollution of the traditional mixing station, the implementation of green environmental protection mixing station become imperative!

In the face of intensive, energy saving, environmental protection construction revolution, sany heavy industry for 10 consecutive years to maintain environmental protection plant production and sales (national) forefront. In 2019, with more experience in modern r&d and manufacturing, a brand new product will be launched. Green intelligent concrete plant ” .

Sany green intelligent concrete plant to achieve factory - type full packaging. No dust, noise pollution; No waste water, waste residue discharge; Modeling atmosphere, in harmony with the environment; Reasonable planning, high plant greening, to exceed the national environmental protection requirements of the design standards, to create a new generation of environmental protection type mixing station.

1. Garden type ecological factory, fully closed factory

The whole operation area is surrounded by green trees, with complete and clean facilities, no stones, yellow sand, cement accumulation, no harsh noise, no flowing dust, and no sewage discharge. All production is conducted in an orderly manner in a closed environment, and the whole plant is like a closed garden.

Full isolation of dust and noise, full recovery of waste water.

► the production efficiency can be increased by 10%, and the fastest rate for 3-party stations can reach 180 m3 / h.

► noise of pneumatic system shall be reduced to less than 60 db.

ii. Unattended automation of material yard

Sany green intelligent concrete plant raw material approach process automation, can be unattended in the case of orderly operation.

► no loader, no fuel consumption, no exhaust gas, environmental protection and energy saving.

► centralized and rapid unloading is adopted in the material yard, which greatly reduces the waiting time of the raw material Truck.

► in the back yard, no Vehicles running, no unloading operation, dust reduction of more than 70%.

► the daily noise of the plant area shall be reduced to less than 60dB, consistent with the normal conversation sound.

► real-time monitoring of dust concentration, intelligent atomization and dust removal, without affecting production.

3. Intelligent low-voltage transmission

Sany green intelligent concrete plant, the adoption of intelligent low-pressure conveying system. Intelligent control of powder conveying and dedusting, completely solve the problem of wrong feeding and burst warehouse.

Using mixing station's own gas source instead of diesel drive, reduce energy consumption, save more than 60% of the transmission cost. Unloading operation is no longer restricted by time because of disturbing the residents, realizing 24-hour unloading and unattended. The storage temperature of powder is reduced to less than 60℃, which not only saves water, but also improves the strength of concrete.

4. Intelligent metering system

Sany green intelligent concrete factory pioneered high-precision adaptive measurement technology, multi-speed and multi-range, adaptive adjustment of each scale measurement parameters, small formula measurement is also accurate. Sany heavy industry has independently developed the self-learning algorithm of weighing parameters and the automatic correction technology of drop, making the measurement true and accurate.

5. Seamless material flow technology

The seamless material flow technology independently developed by sany can automatically calculate aggregate unloading parameters without manual adjustment, eliminate the phenomenon of belt stacking and cutting, realize seamless belt aggregate conveying, shorten feeding time, reduce energy consumption by 5%, and improve production efficiency by 10%.

6. Efficient stirring

18 years of technical precipitation, 20,000 sets of products synchronous verification, sany homemade environmental friendly stirring host stirring material kneading and extrusion fully, mixing dispersion is low, stirring efficiency is higher. Longer and wider discharge door, 15% longer than the traditional discharge door, 50% less residual material, after the production of 20,000 square meters is still smooth as new, no shaft waste generation. In addition, sany green intelligent concrete plant also has the advantages of less washing times, less water consumption and less sewage discharge.

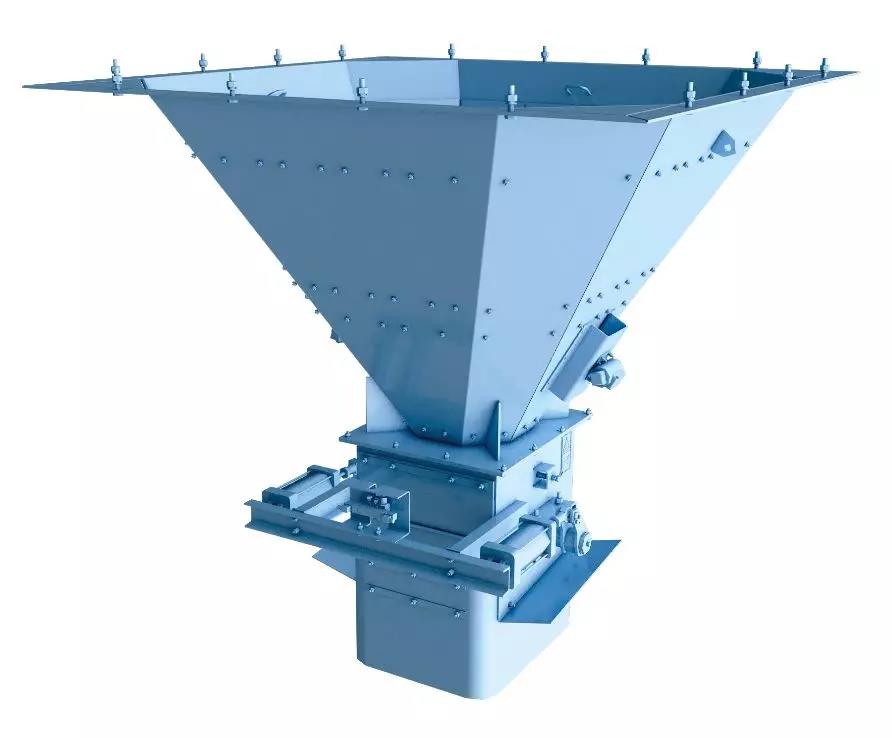

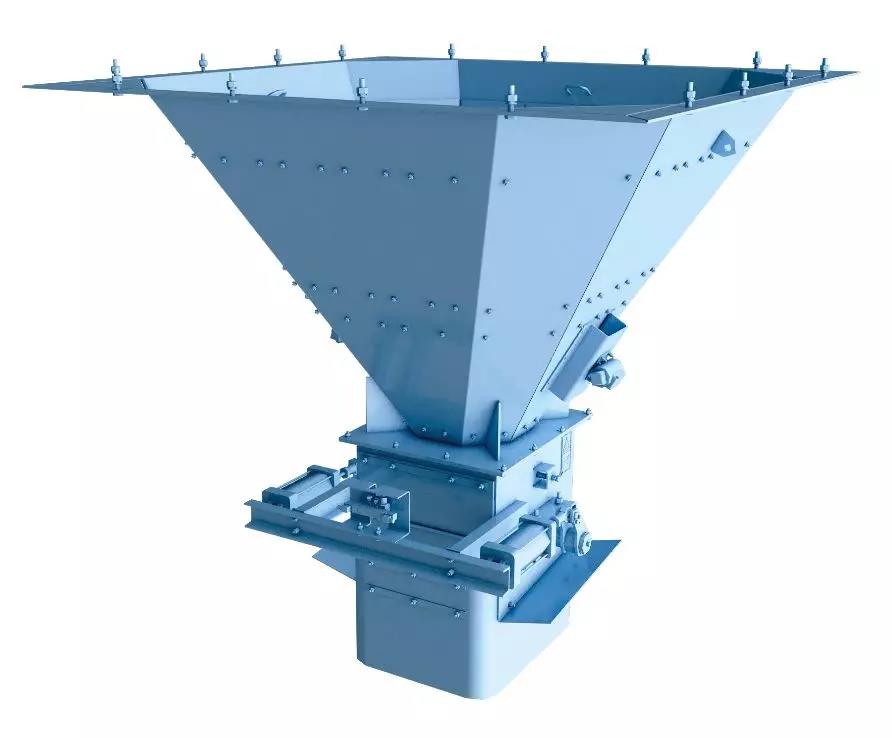

7. Efficient unloading

The re-application of the discharge door with large inclination Angle discharge hopper can realize full speed discharge and increase the production efficiency by more than 8%.

Zero drop into the mixer, no splash; Automatic bucket wash door, no residue.

8. Automatic sand and gravel separation and sewage treatment system

Sany green intelligent concrete factory can automatically clean the interior of the mixer tank, automatically separate the sand and gravel, automatically mix the slurry and water evenly, recycle 100% sand and gravel and waste water, and prevent the pollution caused by the leakage of additives. Achieve slurry water cleaning agitator, reduce the use of clean water, improve the utilization of slurry water.

9. Intelligent control system and ERP management system

Trinity green intelligent concrete plant adopts intelligent control system and ERP management system, do the connectivity, support automatic weighing system for unattended, remote centralized control system, intelligent scheduling system, slump dust-free online observation, since the inductive Vehicle cleaning system, dust on-line monitoring and emergency response system, mobile phone APP, cloud services.

In & other; Scientific and technological innovation ” Leading the development of the industry to Intelligent environmental protection ” Imagine a green future, sany green intelligent concrete plant ” Together with you to build a better home.