The other day,Sunward Intelligent Debugging Platform welcomes one.“New guest”——High meter-class chassis without bridge expansionSWT32JSelf-propelled straight arm type aerial work platform。

This arm Truck adopts modularization,Standardization,Intelligent and other design means,Machine、Electricity、Liquid collaborative development,And has high reliability、Strong adaptability and high efficiency。It has a maximum operating height of 32 meters.,Double load design,Limited load 340Kg,Unconfined Load230Kg,Four-wheel drive,Gradeability up to 45%,It is equipped with the new fourth national engine.,It is suitable for complex working environment.、Aerial work platform with narrow site space。

Sunward Intelligent High-altitude Machinery Project Team“Pilot innovation”R & D concept,Not afraid of challenges,Dare to innovate,Combined with the company's technical accumulation for many years.,Developed this four-section straight-arm aerial work platform。So what are the highlights of this product??Look down together.。

Part.1

32m Class Chassis Technology without Bridge Expansion

The chassis is designed to be weighted and reinforced.,Four-wheel hydraulic motor driven,Antiskid solid tyre,Front axle adaptive floating function,Safe and reliable,High-performance chassis without bridge expansion,Able to adapt to stenosis、Complex working conditions and environment。

Part.2

Design of engine swivel out bracket

Design of the bracket of the Independent Spin-out Engine,Rotatable 30°,Convenient for overhaul and maintenance of power system,The maintenance space is large,Work efficiently。

Part.3

Fourth National Emission Standard

Engine equipped with the fourth national emission standard,Powerful power system,Exhaust aftertreatment system withDOC+DPFType, Adapt to the latest emission requirements of China IV,Help to achieve“Double Carbon”Aim。

Part.4

Multiple safety protection system

Equipped with tilt protection system、High Altitude Guardian Warning System、Overload limiting system, etc.,It can ensure the safe operation of the equipment under the allowable working conditions from multiple aspects.。

Part.5

Design of Pentagonal Jib Section

Boom system adopts four-section telescopic boom,Pentagonal section,High strength material design,Have better torsion resistance、Bending resistance,Higher security,Boom movement is more neutral。The guide slider is made of imported macromolecule self-lubricating material,Excellent abrasion resistance and excellent impact strength。

Part.6

Control technology for smooth movement of boom

The oil cylinder adopts two-way in-place buffering.,Hydraulic full proportional control,Control strategy of boom motion,Establish the functional relationship between the boom length and the luffing angle,O that the telescopic action of the boom is more stable and accurate.、Safe and reliable。

Part.7

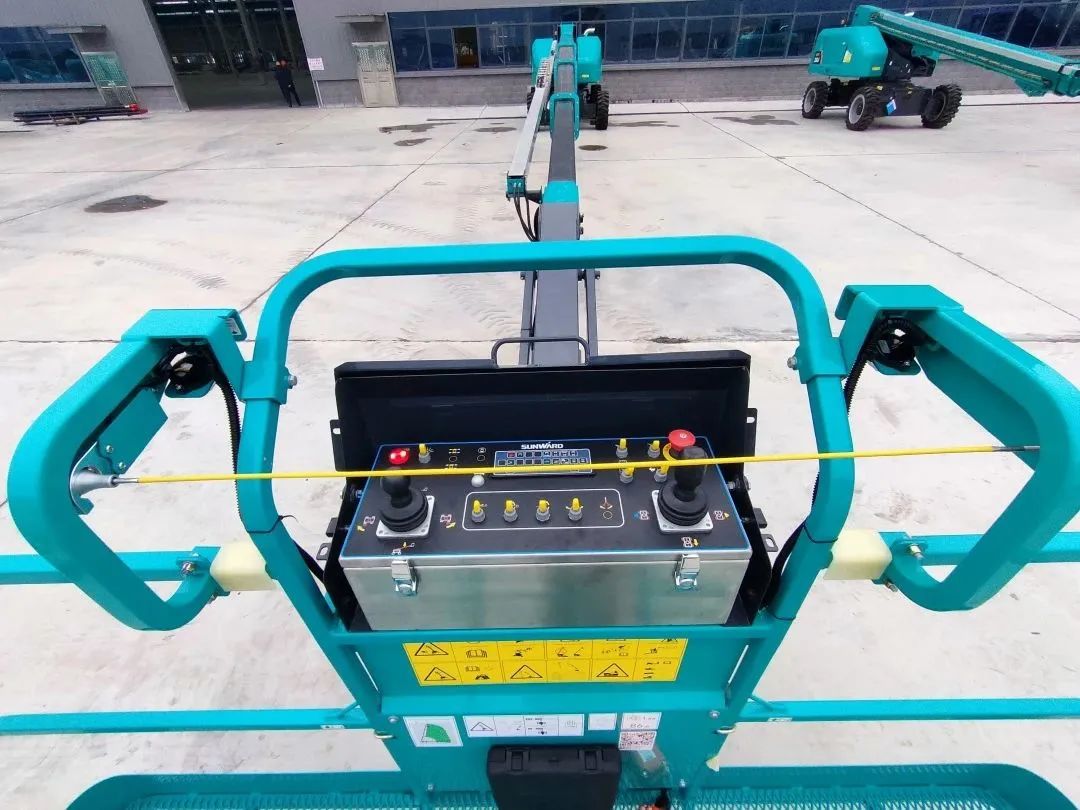

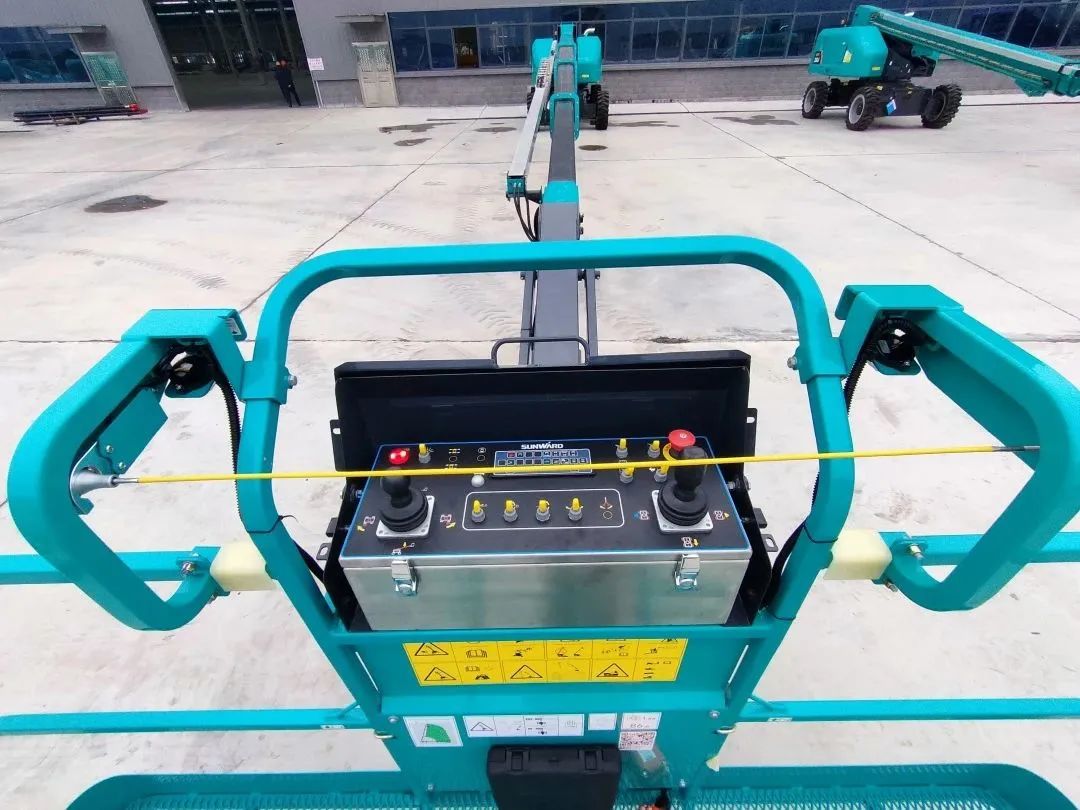

Independent development of controllers and control systems

The Vehicle adopts the controller and control system independently developed by Sunward Intelligence.,Meeting the high-precision motion control of the boom type aerial work platform、Intelligent fault diagnosis、Personalized function customization requirements,Mobile electronic control unit suitable for wide temperature range、High humidity、Strong corrosion、Severe working conditions such as large vibration。

Part.8

Shanhe Xiangyun Remote Monitoring and Management Platform

The aerial work platform remote data monitor and remote equipment management can be realized,And connect the data to the industrial Internet of Things.,Realize big data fusion。

Part.9

Intelligent Fault Diagnosis and Maintenance System

The intelligent maintenance system can remind the maintenance personnel to prepare the maintenance items and refresh the maintenance status in advance.,At the same time, use mobile phonesAPPView and operate,Ensure long-term stable and reliable operation of the equipment。

In addition,The difference between this arm Truck and other products is that the luffing mechanism is controlled by gravity drop valve.,More energy efficient、More efficient,At the same time,The working platform is sensed by a high-precision tilt sensor.,Combined with electric leveling technology,More precise and stable control,Make the operator feel more comfortable。

Since the establishment of Sunward Intelligent High-altitude Machinery Division,,Has launched a diesel version of the crank.SWA16J、SWA21J,Diesel version straight armSWT22J、SWT28J,Electric version crank armSWA16JE、SWA22JEAnd other products,SWT32JIs the latest development of a suitable station.、Wharf、Airport、A construction site、AeriaL Work Platforms in outdoor environments such as bridges,It is also a high-meter self-propelled straight arm product developed by the company.,It's successful offline.,It shows that the product spectrum of Sunward intelligent arm Vehicle series has been basically improved.。The electrification of arm car products is the trend of industry development.,The follow-up R & D team will launch the electric version of the crank while the iron is hot.SWA18JE、Electric version straight armSWT22JE、SWT28JEAnd more styles of AeriaL Work Platforms.,To meet the needs of customers in the market.。

Coming up,Sunward Intelligent High-altitude Machinery R & D Team will uphold“Create value for customers”The concept of service,Continue to penetrate into the market,Continuously improve product competitiveness,Remain true to our original aspiration、Forge ahead,To be the creator of world value in the field of equipment manufacturing,Let Sunward Intelligent High-altitude Machinery Products Shine in the Global Market。