Choose Linde MyMA full stack application software to easily realize full scene management of warehousing and logistics

December 11, 2024

Nowadays,Digital intelligence technology has penetrated into all aspects of the supply chain.,Build a system that can coordinate the overall situation“Super brain”,Fully get throughProduction side and logistics sideBusiness scenario is the key issue of flexible logistics.。Lind relies onHundred years of professional accumulationAndMore than half a century of automation technology strength,It's outIntegrated full-stack innovation delivery platform,FromTop-level application software systemToDispatch system,And then toLogistics equipment for carrying out handling tasks,Provide for customersEnd-to-end total solution。

MyMAFull-stack application software platform,Independently developed by Linde“Super brain”,AchievableProduction、Logistics Process System Reengineering、Execute operational strategyAnd optimizationAndDigital Kanban Management,Achieve cross-platform automation control,Get throughLine-side storage、Production line distributionToWarehouse storageYesFull service scenario,Help customers achieveIntelligentTransformation。

Upper system

LindMyMAFull stack application software

LindMyMAFull stack application software,It's LindweiUpgrade from manual handling to automationA model carefully built by our customers.Full function、Easy to useYesApplication software,Effectively help customers faster、Flexible lead-in system,And improve the comprehensive capacity of Material Handling and reduce costs。

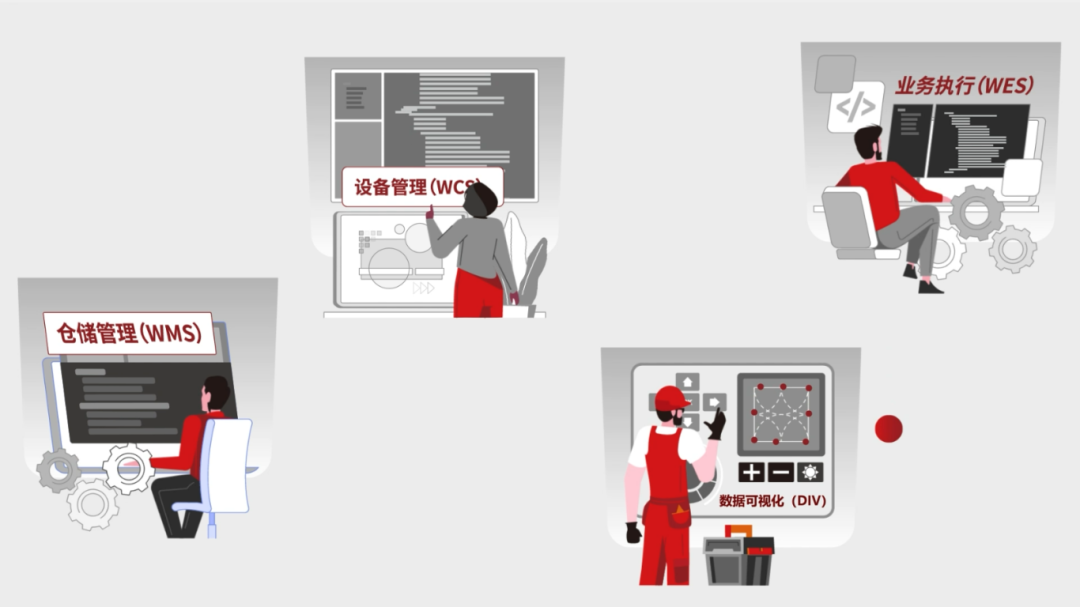

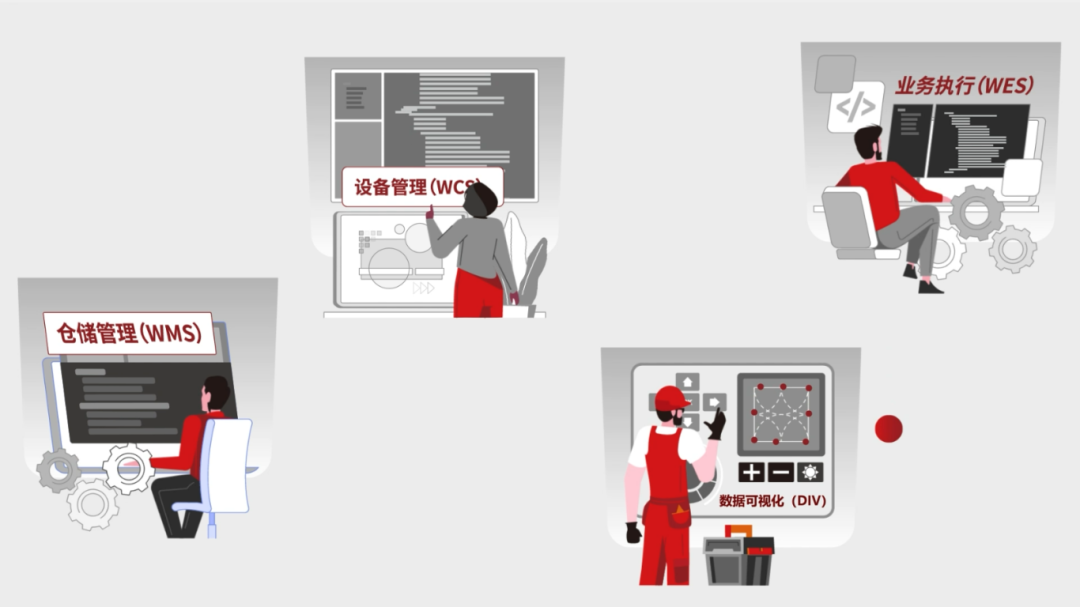

Four functional modules

Accurate access to the whole logistics link

01

WMSWarehouse management

Get throughReceipt、Quality inspection、WarehousingOrOut of the warehouseThe whole process,Real-time synchronization of data in each link,Realize the storage of goods in the warehouseEfficient managementAndPrecise tracking,Ensure warehouse operation is in order。

02WCSEquipment management

As the management center of logistics equipment,WCSSupportMulti-brand、Integration of multiple types of logistics equipmentAndCollaborative work,Can be related toSeamless docking of various automation equipment;And dispatch the logistics system uniformly according to the business rhythm.,To achieve efficient scheduling and accurate control of logistics operations in the warehouse。

03WESBusiness execution

Go deepInsight into the industryCommon needs,Abstracting and refining the complicated warehousing process,And then disassembled and reorganized.,Develop proprietary best practices,Help to achieveVertical industry penetrationAndProcess reengineering。

04DIVData visualization

Through the chart、Curves and other forms of various logistics data,On the big screen.Real-time display,Users can realize it according to their needs.Personalized customization,Output business analysis and equipment operation report,Help customers to find problems in time and take corresponding measures,It provides strong data support for the continuous optimization of warehouse management。

Logistics digitalization、Intelligent,It is not only the current development trend.,It is also the key password for enterprises to optimize the competition pattern.。LindBy virtue ofAdvanced Mobile Robot and Internal Logistics System Integration Technology,One-stop Internal Logistics Flexible Automation Total Solution,Precise Leverage for All IndustriesIntelligent logistics handling benefit。