In order to let you have a deeper understanding of the heating and thawing of the after-treatment of the fourth national system of XGMA loaders in winter when the temperature is low.,Let's take Shangchai as an example.,Give you a brief introduction to the basic structure of the system、Principle and process of heating and thawing。

01

Basic structure of the system

1.Urea tank:

This is an important component for storing the urea solution,Urea level is installed at the top\Temperature sensor、Integration of water heating inlet and outlet and urea solution inlet and outlet。

SCR The urea tank of the post-treatment system is generally heated by water.。In which there is a solenoid valve for switch on and off that coolant,When the urea temperature is lower than -8℃Time,The solenoid connector is energized,ECU Open the solenoid valve,Hot engine coolant flows through the urea tank in the direction of flow shown by the arrow on the valve body,Heating the urea solution,Thereby realizing thawing,When the urea temperature is higher than 5℃Time,The heating solenoid valve is closed。

2.Urea pump:

As the power source of urea hydraulic motion,Yes SCR Key executive components of after-treatment system。It comes with 4 connectors,Pressure sensor interface, respectively、Low pressure urea inlet and outlet of urea liquid path and urea outlet of high pressure pipe,And the pressure of the urea pump after pressure building is 9bar ,However, the pressure building needs to meet the requirement of no relevant failure.、The exhaust temperature exceeds 160℃、Thawing of the system is completed and there is no blockage or leakage in the urea pipeline.、The nozzle shall be free of blockage and other conditions.,Moreover, the urea must be filtered by the filter element of the urea pump before being sprayed out.。

The urea pump and the urea pipe are generally electrically heated.,Consists of electrically heated urea pipe and urea system heating control relay。The urea tube heating controller is a relay and fuse box assembly.,When ECU After the heating instruction of the urea system is sent out through the signal input judgment of the ambient temperature sensor and the like,The coil of the heating relay is energized to work.,The relay contact outputs power to the positive terminal of each electric heating wire.,And give ECU Provide feedback signal of main relay sticking fault,The cathode end of the heating wire is subjected to ECU Control output to ejector tube、Liquid return pipe、Outlet pipe and heating wire ground wire of urea pump,And then heat them up to thaw them.。

3.Urea nozzle:

Belong to SCRActuator for quantitative urea injection of aftertreatment system,There are three on the nozzle. SAE Male end of standard quick connector,The smaller of these is the urea nozzle adapter.,The other two are cooling water inlet and outlet interfaces.。

Because of that high temperature in the exhaust pipe.,To prevent the urea nozzle installed on the exhaust pipe from being damaged due to overheating,Two water inlet and outlet pipes are arranged on the urea nozzle,Engine coolant is used to cool the nozzle,Make sure it is working properly。

4.Ambient temperature sensor:

For monitoring the external ambient temperatures,It is an important reference for the control strategy of urea pipeline thawing and heating,SCR The post-treatment control unit will control the start of the electric heating of the urea pipeline according to the current atmospheric temperature fed back by it.(Below-2℃)And close(Above 0℃)。

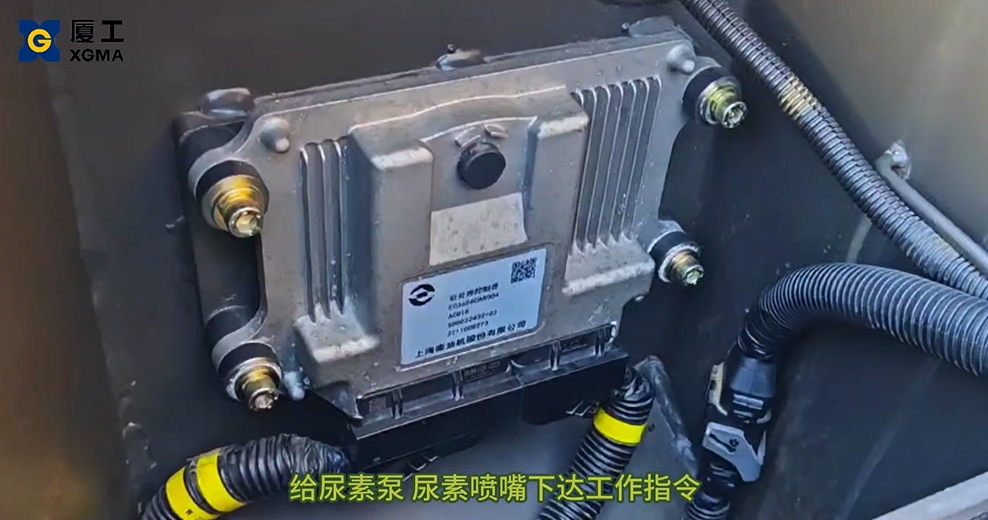

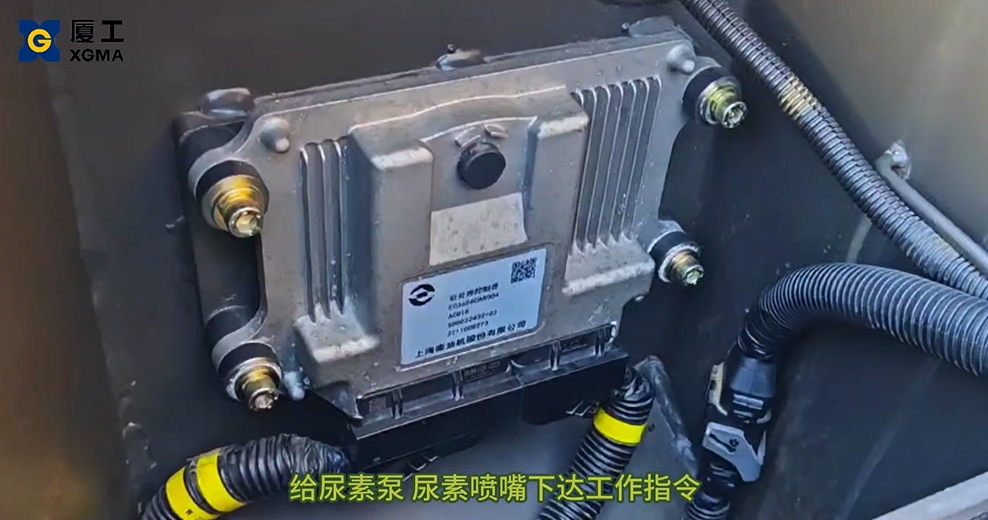

5.Urea injection control unit:

This is the core component of the whole system.,It will read information from various sensors on the diesel engine.,Calculate the amount of urea that needs to be injected.,At the same time to the urea pump、Work order from urea nozzle,Control the whole set SCR Operation of the aftertreatment system,It also has a control program for defrosting and heating urea.,By reading the ambient temperature sensor values,Control the opening and closing of the electromagnetic water valve for post-treatment heating,Execute the whole set SCR Urea thawing and heating function of post-treatment system。

02

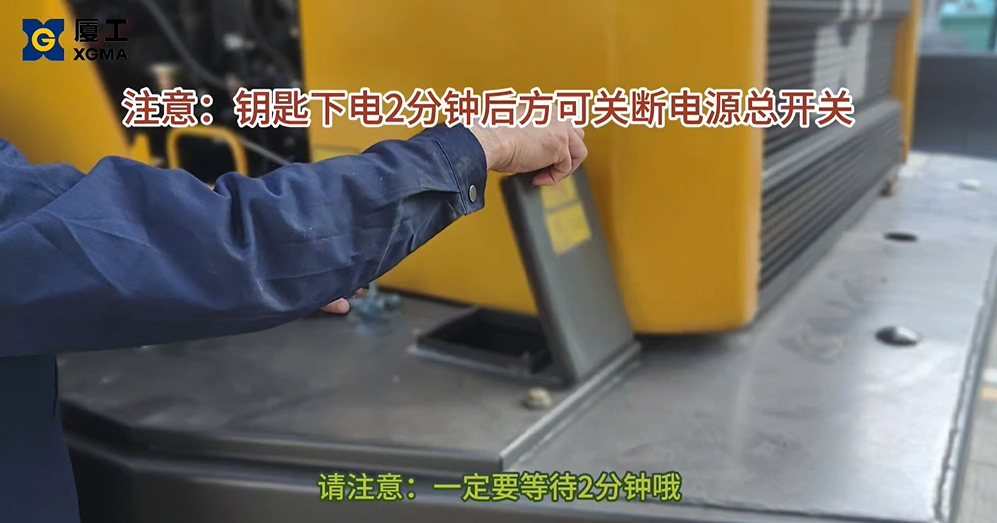

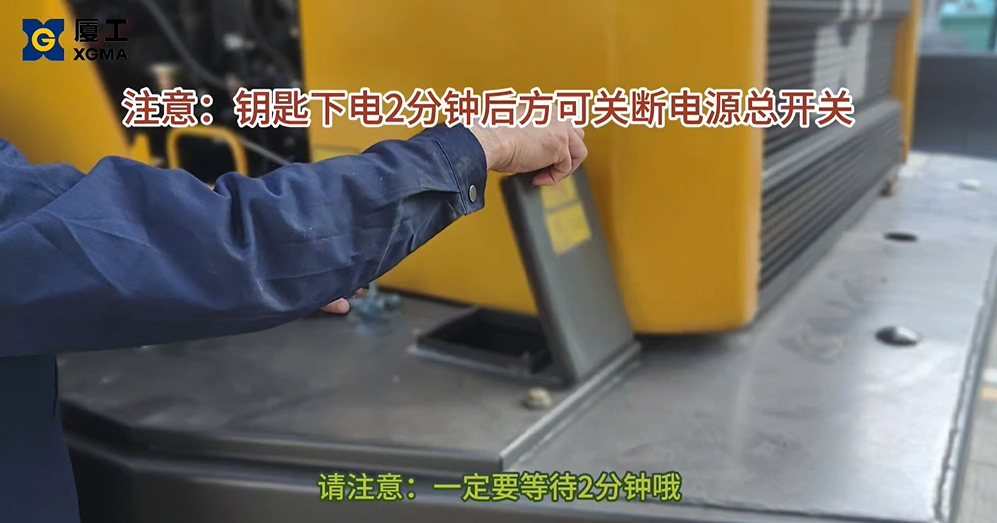

Protection of electronic control unit

After the electric lock is powered off,ECUIn pre-dormancy state,It needs to be maintained at this time ECU The whole Vehicle is powered for at least 2 minutes.,Otherwise, it will affect ECU Data storage for、Perform a diagnostic test、Fault storage to memory, etc.,It will also affect the reverse suction of the urea pump.,Resulting in a report“Abnormal disconnection of main relay”The failure of。

So when the engine shuts down,,You must wait more than 2 minutes before turning off the main switch,Otherwise, the urea is not pumped back in time in winter.,Residual urea in the whole urea system can cause freezing,Block the urea pipeline。

Hope that through the above introduction.,Let you have a clear understanding of the heating and thawing related contents of the post-processing of the fourth national system of XGMA loader.,Make it easier for you to use your device。

If you have any questions or need help,Please feel free to contact our after-sales service team。

Welcome to call the official customer service hotline of XGMA