Respected colleagues in the road construction industry,

In the world of road construction machinery,Equipment maintenance and remanufacturing are not only related to the quality and efficiency of the project.,It is also the key to sustainable development of enterprises.。Today,We would like to introduce you to a company with 30 years of deep industry experience.——Tianshun Great Wall。

Thirty years to sharpen a sword,Focus on professional achievement

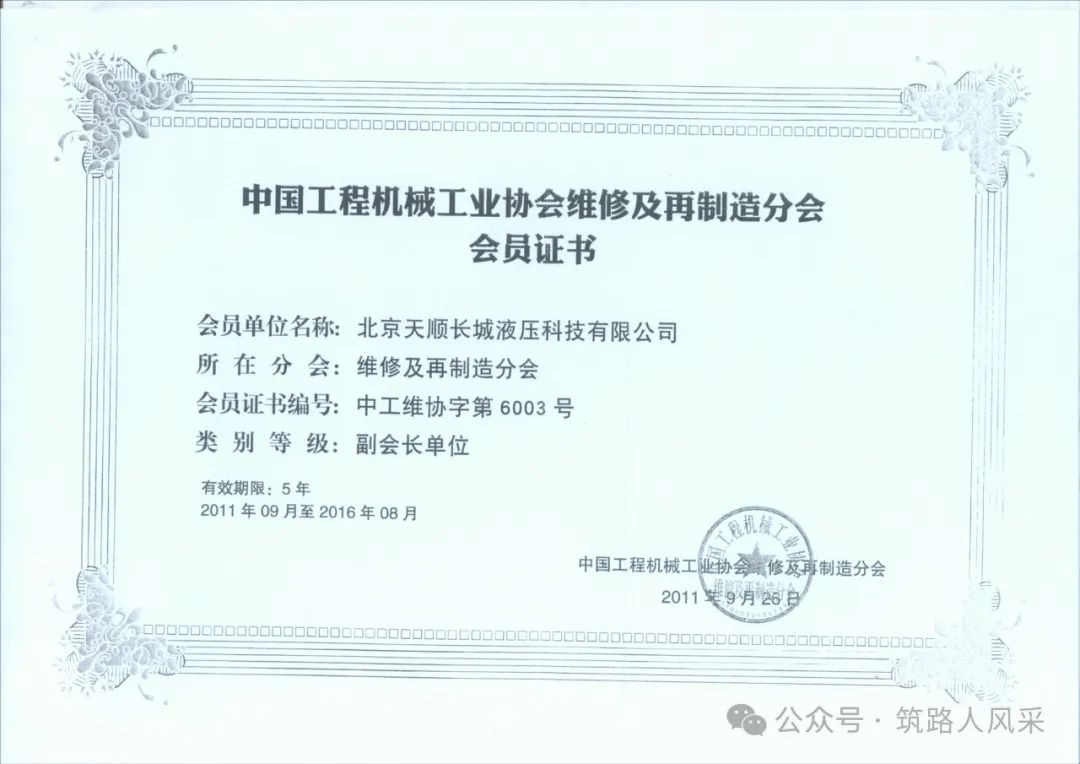

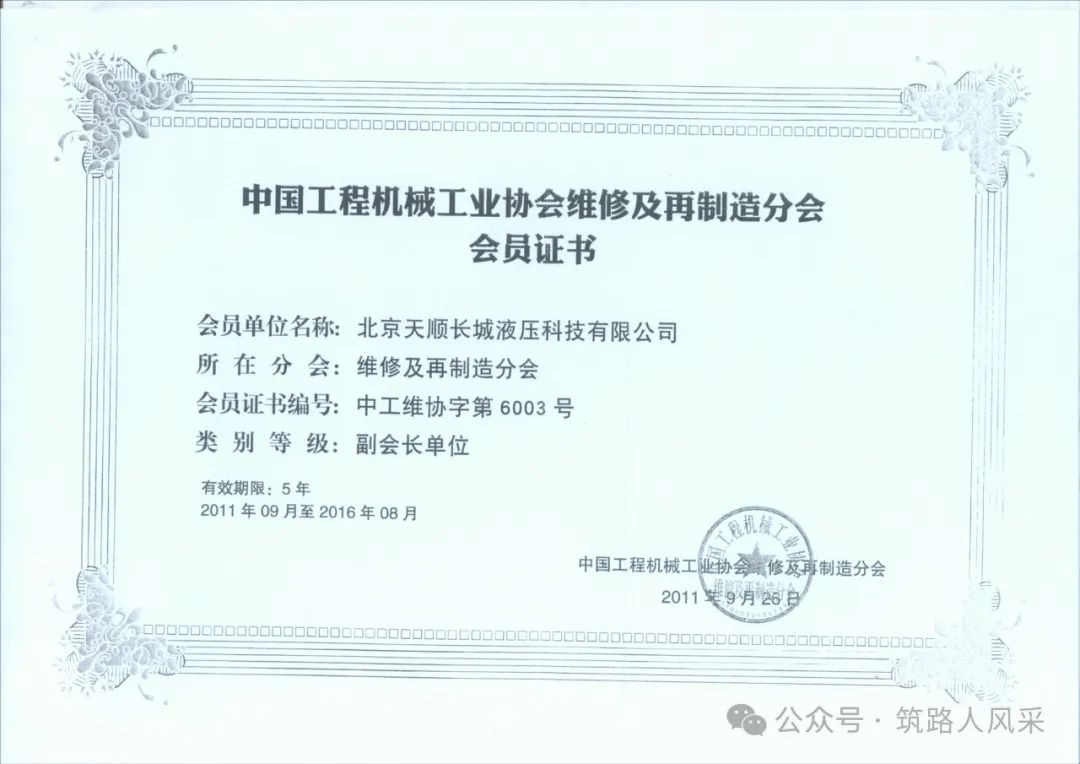

Since its establishment in 1988,Tianshun Great Wall has been focusing on the maintenance and remanufacturing of construction machinery.。As the Vice President Unit of Maintenance and Remanufacturing Branch of China Construction Machinery Industry Association,Tianshun Great Wall relies on its excellent professional skills and service quality.,It has won wide recognition in the industry.。

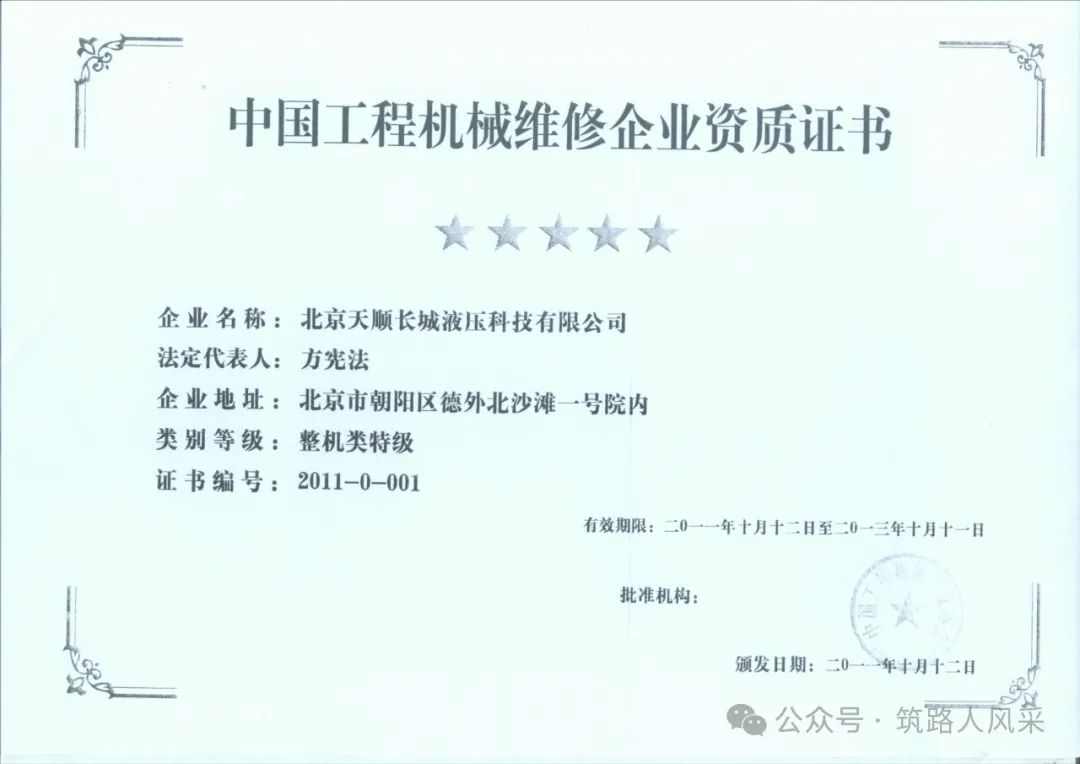

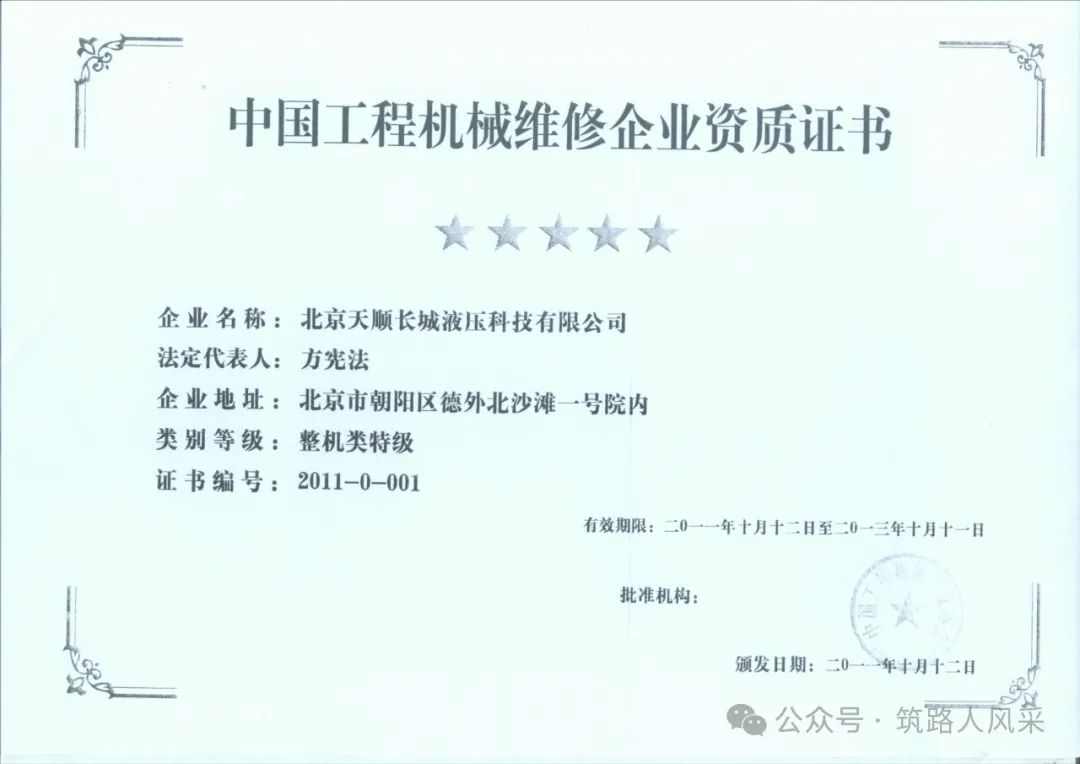

Special maintenance qualification,Quality Assurance

Tianshun Great Wall is one of the first enterprises in China to obtain special maintenance qualification certification for the whole machine.。This qualification is not only an affirmation of the professional ability of Tianshun Great Wall.,It is also the highest recognition of its service quality.。For 30 years,Tianshun Great Wall has always maintained this qualification.,Have a wealth ofBOMAG、VOLVO、VOGELE、DYNAPACAnd other imported construction machinery maintenance experience and parts supply.,Proving its leading position in the industry。

RepairAndRemanufacturing,Double play of environmental protection and efficiency

Today, the awareness of environmental protection is increasing.,The maintenance and remanufacturing service of Tianshun Great Wall is particularly important.。Through the repair and remanufacturing of old equipment,Not only can service life of the equipment be prolonged,,Reduce operating costs for customer,It also saves resources and protects the environment.。

Save 15 tons of steel by remanufacturing a Paver:

1.Less mined ore 4-5 tons/Tons(Crude steel)*15 tons=60-75 tons2.Saving comprehensive energy consumption 0.761 tons of standard coal/Tons*15 tons=11.415 tons of standard coal 3.Saving fresh water 11.15m3/Tons*15 tons=167.25 tons4.Reducing CO2 emissions2.2 tons/Tons*15 tons=33 tons 5.Reduce the emission of toxic substances(SO2、CO、Inhalable particulate matter, etc.)6.Transportation energy consumption、Emissions 7.Processing energy consumption、Emissions 8.Other consumption

A few notes:

1.Different Pavers have different remanufacturing values

2.Remanufacturing should be based on the principle of ensuring product performance

3.Remanufacturing manufacturers must have good reputation and technical ability.

4.The implementation and timing of remanufacturing should be based on the principle of maximizing benefits.

5.Remanufacturing should be based on users.、Manufacturer、The principle of mutual benefit and win-win for the country

Innovative technology,Lead the industry trend

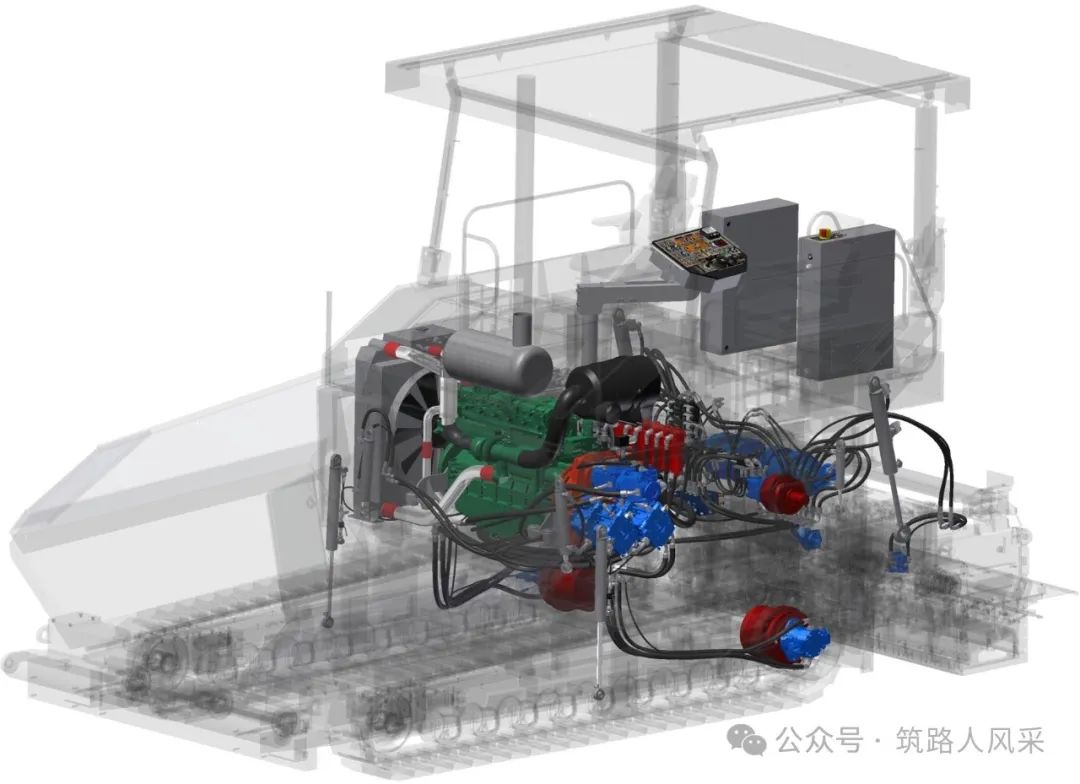

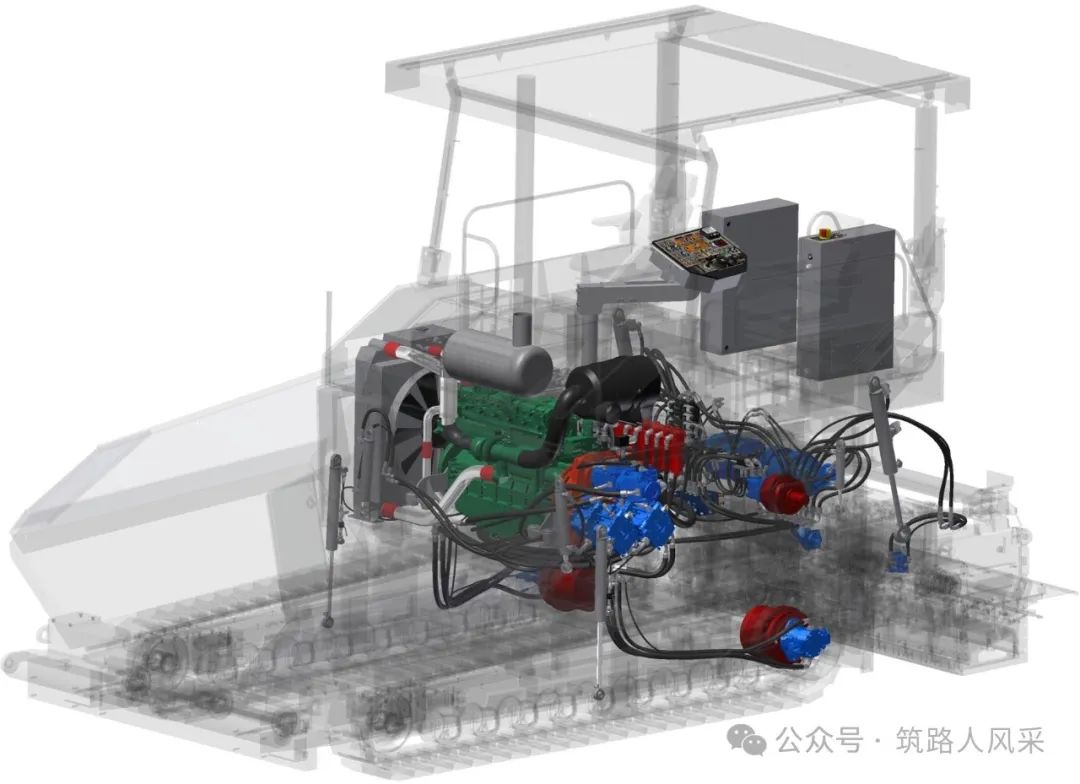

Tianshun Great Wall continuously invests in research and development,Use the latest technology to improve the level of maintenance and remanufacturing。Whether it is the upgrade of the engine.,Or the optimization of the hydraulic system,Tianshun Great Wall can provide customized solutions for customers.,Ensure that the equipment performance reaches or even exceeds the new machine standard。

Business module 1:Fully upgrade the service

We offer a full range of Paver repair and remanufacturing services,Focus on improving the performance and life of older Pavers。Our team of professionals works on repairs and upgrades in the following key areas。

Key points of technology upgrade:

Circuit system maintenance:Carry out overall inspection and maintenance of the electrical system of the Paver,Ensure reliability and safety of electrical components,Improve machine stability and efficiency。

Hydraulic system optimization:Careful overhaul and maintenance of the hydraulic system of the Paver,Includes replacing worn parts and upgrading the system,O as to enhance the response speed and bearing capacity of the hydraulic system.。

Power system upgrade:Depth diagnosis of the power system of the Paver,Perform necessary repairs and upgrades,To ensure optimal engine performance,While reducing fuel consumption and emissions。

Appearance upgrade and transformation:Modernize the appearance of the Paver,Including painting renewal and structural optimization,Improve the beauty and durability of the machine。

Wear parts replacement:Regularly inspect the key wearing parts of the Paver,Replace promptly to avoid further damage and downtime,Ensure continuous and stable operation of the machine。

Elegance of road builders,Zan 161

Business module 2:Engine upgrade serviceOur services are focused on improving the environmental performance and operational efficiency of older Pavers,Through advanced technical means,General Guoyi、The engine of the second national standard is upgraded to meet the fourth national emission standard.。This process does not only involve the technological upgrading of the engine itself.,Improvements in aftertreatment systems are also included.,To ensure that the equipment meets more stringent emission regulations.,Maintain or improve their original work efficiency。

Key points of technology upgrade:

Oil supply system optimization:Increase fuel injection pressure,Optimize the combustion process,Reduce the emission of pollutants in tail gas。

Upgrading of post-processing system:Adopt selective catalytic reduction(SCR)Technology or exhaust gas recirculation(EGR)Technology,By adding urea solution or particulate trap(DPF)Treatment of nitrogen oxides and particulates in tail gas,In order to meet the fourth national emission standard。

Engine performance is improved:Through turbocharging、Combination of Electronic Control System and High Pressure Common Rail Technology,Improve the combustion efficiency and power output of the engine,While reducing emissions。

Intelligent control system:Upgrading engine control system,Achieve more precise combustion control and emissions management,In order to meet the requirements of the fourth national emission.。

Cooling system optimization:Equipped with efficient cooling system,Ensure that the engine can operate stably in high temperature environment.,Prolong the service life of equipment。

The performance of the whole machine is improved:While upgrading the engine,Optimize the design of the whole machine.,Reduce energy consumption,Improve operation efficiency,For example, increase the displacement of the distributing motor、Use a feeding motor with higher pressure resistance, etc.。

Elegance of road builders,Zan 40

Business module 3:Machine assembly modification and expansion technology upgrade serviceWith the change of market and the diversification of construction demand,The business of machine assembly and expansion of old Pavers has become particularly important.。Upgrading through professional technology,We are able to upgrade the original low utilization rate of the machine assembly Paver.,To meet the construction needs of municipal and rural roads.。

Key points of technology upgrade:

Structure principle and technology upgrade:The structural principle of the Paver includes the frame system.、Power system(Engine system and hydraulic system)、Electronic control system and other key components。In the machine assembly and modification telescopic service,We will focus on technical upgrades to these systems.,To ensure that the modified Paver can adapt to different construction environments and requirements.。

Adaptive transformation:The modified Paver will have better adaptability.,Flexible response to changes in the width of municipal and rural roads,Improve construction efficiency and pavement quality。Telescopic function through the mounting end,The paver can adapt to the change of road width.,Reduce the labor intensity of the construction party and the operator。

Performance improvement:Through the circuit system of the paver、Hydraulic system、Maintenance and upgrade of core components such as power system,We can significantly improve the performance of older pavers,Make it meet or exceed the performance standards of the original new product.。

Environmental protection and safety:In the process of transformation,We will use environmentally friendly materials and technologies.,Ensure that the modified paver meets current environmental standards。At the same time,By improving the design and upgrading the control system,Improve the safety of paver,Reduce uncertainties in construction。

Cost-benefit analysis:The reconfigurable business of the old paver can not only extend the service life of the equipment,But also can reduce that maintenance cost and improve the work efficiency.,Thereby bringing better economic benefits.。

Elegance of road builders,Zan 39

Business module 4:Environmental protection heating system gas to electricity upgrade serviceConsidering environmental protection and safety,The heating system of the old paver can be changed from gas heating to electric heating.。Uniform heating of electric heating system,Easy to use,No pollution,And that heat deformation of the screed plate and the vibrate beam is small.,And is favorable for improve that construction quality.。

Key points of technology upgrade:

Environmental protection is improved:

The electric heating system does not produce exhaust emission,Compared to traditional gas heating systems,Electric heating system is more environmentally friendly。This modification helps to reduce the paver's environmental impact during construction,Especially in areas with high air quality requirements.。

Enhanced security:

Electric heating system compared to gas heating system,Lower security risk。The electric heating system does not involve the storage and use of flammable gases,Thereby reducing the risk of carbon monoxide leakage or gas explosion。

Heating efficiency and uniformity:

Electric heating systems provide more uniform heating,Leave no dead ends。For example,The electric heating system of Tianshun Great Wall paver is designed with annular heating strips.,Ensure even heating。This uniform heating helps improve the quality of the paving,Reduce pavement problems due to uneven heating。

Convenient operation:

Electric heating system is easy to control,Easily controlled by automatic temperature controller and timer,Convenient and energy-saving。This intelligent control mode can reduce the workload of operators.,And that construction efficiency is improve。

Reduce deformation and improve construction quality:

Electric heating system due to its uniform heating properties,It can reduce the thermal deformation of screed and vibrating beam,Thereby being beneficial to improving the construction quality.。

Energy efficiency and cost-effectiveness:

Electric heating system up to 95% thermal efficiency%,More energy efficient than gas systems。This not only helps to reduce energy consumption,,It also reduces long-term operating costs.。

Adaptability and flexibility:

Electric heating system allows zoned heating,Users can heat specific areas of the building as needed,Thereby saving energy。This flexibility is particularly important for the construction of pavers in different working conditions.。

Business module 5:Telescopic upgrade service of paver mounting end

In the field of pavers,The flexibility and adaptability of lifting equipment is the key to improve construction efficiency and reduce labor intensity.。For machine piecing paver,Increase the end expansion function through technical transformation,It can effectively enhance its applicability in different construction environments.。

Key points of technology upgrade:

Technical transformation objectives: Integration through end-telescoping functionality,Enhance the construction adaptability of the spreader,So that it can flexibly respond to different widths of pavement construction needs.。

Functional advantage analysis:

Enhanced adaptability: The modified paver is able to accommodate a wider range of pavement widths,No need to change equipment frequently,Reduce construction preparation time。

And that labor intensity is reduce: Telescopic end function reduces the need for manual adjustment during construction,Reduce the labor intensity of the operator。

Construction efficiency is improved: Quickly adjust the paving width,Reduce construction interruption due to equipment adjustment,Improve the overall construction efficiency。

Key points of technical implementation:

Structural design optimization: Telescopic structure at the design end,Ensure the stability and structural strength of the paver at different widths。

Control system upgrade: Integrated advanced control system,Realize precise control of end expansion and contraction,Ensure the paving quality。

The operation interface is simplified: Design intuitive operation interface,So that that operator can quickly grasp the telescopic function of the end,And that operation convenience is improve。

Evaluation of construction benefits:

Cost savings: Reduce additional costs due to equipment replacement and adjustment。

The construction period is shortened: And that construction speed is improve,Reduce project completion time。

Quality Assurance: Telescopic end function ensures even spreading,Improve the quality of pavement construction。

Safety and Environmental Considerations:

Safe operation: Ensure safety of end telescoping operation,Reduce safety risks during construction。

Environmental standards: Environmental protection standards are followed in the process of renovation.,Reduce the environmental impact of construction。

Beijing Tianshun Great Wall,Zan 39

Business module 6:LocalFunction upgrade service

We offer paver feature upgrade services,It aims to improve the efficiency of the equipment through modernization.、Safety and adaptability。Through these upgrade services,Our customers will be able to be more efficient、Safer、More reliable paver equipment,To meet the high standard requirements of modern construction.。Our modifications are designed to extend the life of the equipment,Reduce maintenance costs,And improve the construction quality.,Ensure that your engineering project goes smoothly、Accomplish efficiently。

Key points of technology upgrade:

Modification of ceiling lifting system:

We offer a comprehensive upgrade service for ceiling lift systems.,Optimized by electronic control system,Realize the double improvement of operation convenience and safety。The upgraded system will adopt advanced electronic control technology.,O as to improve the response speed and stability of the lifting of the ceiling.。

Hopper turnover mechanism upgrade:

For Hopper Folding System,We carry out structural optimization and reinforcement,Ensure the stability and durability of the hopper in high-intensity operation。The upgraded hopper folding system will be more flexible.,Easy to clean and maintain quickly。

The middle seam of the main machine screed is changed into a pin roll:

We have improved the connection mode of the center seam of the host screed.,Replace the traditional way with pin connection,O as to improve the flatness and the service life of the screed.。This modification will reduce the displacement variation of the screed during operation.,Improve the paving quality。

Enhanced adaptability:

The upgraded paver will have better adaptability.,It can meet the needs of different working conditions and road conditions.。This is essential to improve construction flexibility and reduce adjustment time during construction。

Elegance of road builders,Zan 22 Beijing Tianshun Great Wall,Zan 20 Xinjiang Road Machinery Liu Gang,Praise the elegant demeanor of 17 road builders,Praise 68

Business module 7:Special equipment modification

In view of some pavers which can not meet the construction conditions at this stage due to their design and age.,Special equipment modifications are available。Through customized transformation plan,Transform these equipment into special equipment suitable for specific working conditions.,Uch as pavers adapted to shoulder operation,Or a paver that transfers pavement material,So as to fully utilize and develop the value of these equipment.。

Key points of technology upgrade:

Reconstruction of Paver Adapting to Shoulder Operation:

By introducing“Dirt shoulder”Paver construction method,We can adapt the paver to shoulder operation。This method can eliminate the need for formwork during construction.,Uniform compaction using the machine's own weight and vibration,Control the flatness and slope of the road surface at the same time。The modified paver will have higher construction efficiency and quality.,At the same time, reduce site damage。

Transformation of Paver for Transferring Pavement Material:

For pavers that need to transfer pavement material,We can use modern asphalt paving construction artifact——Tianshun Great Wall transfer Vehicle。The transfer Vehicle can be used in combination with a paver.,And that efficiency is greatly improve、Avoid segregation,Bring super high construction quality。The modified paver will be able to spread the material evenly,Reduce segregation of coarse and fine aggregate,And that durability of the pavement is improve,At the same time, the transportation cycle of the skip is accelerated.、And that transportation efficiency is improve。

Xinjiang Road Machinery Liu Gang,Zan 34

Service first,Customer satisfaction is our pursuit

Tianshun Great Wall always insists“Customer first”The concept of service。From technical consultation to after-sales service,From equipment maintenance to remanufacturing,Tianshun Great Wall provides all-round support,Ensure that every customer has a satisfying experience。

Elegance of road builders,10 thumbs up

Join us,Create the future together

We sincerely invite you to pay attention to the official account of Road Builder.,Get the latest industry news、Technology sharing、Service cases and exclusive offers。Let us together,With professionalism and innovation,Promote the sustainable development of the road construction industry。