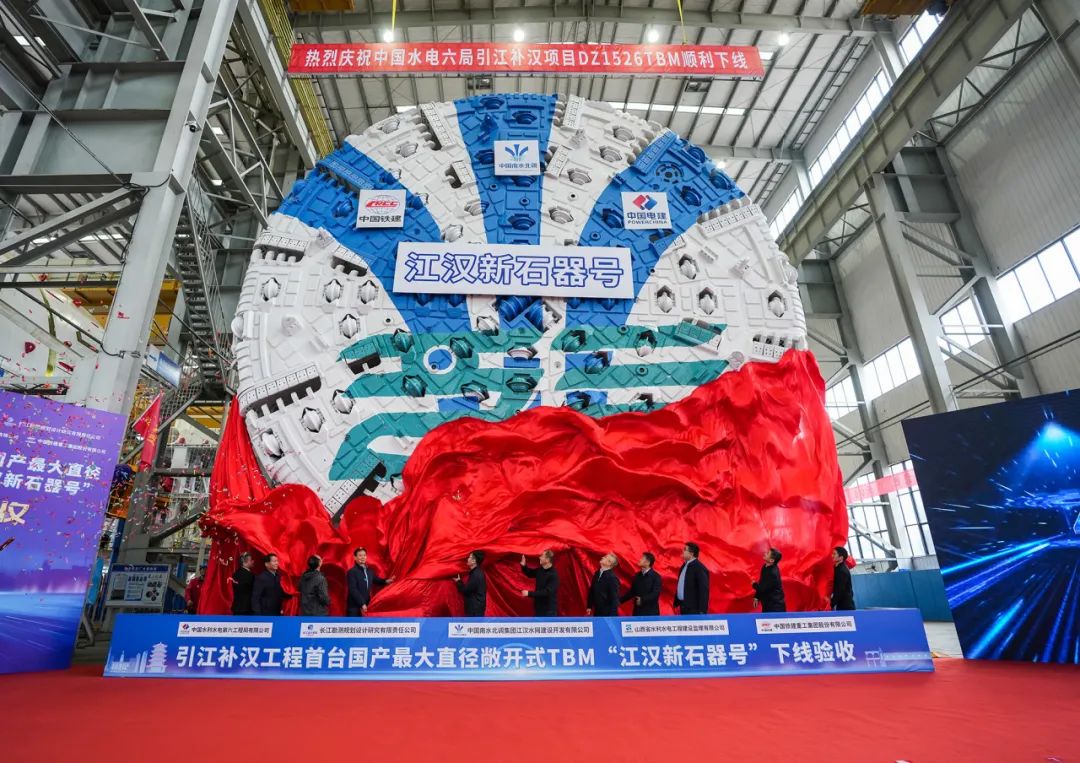

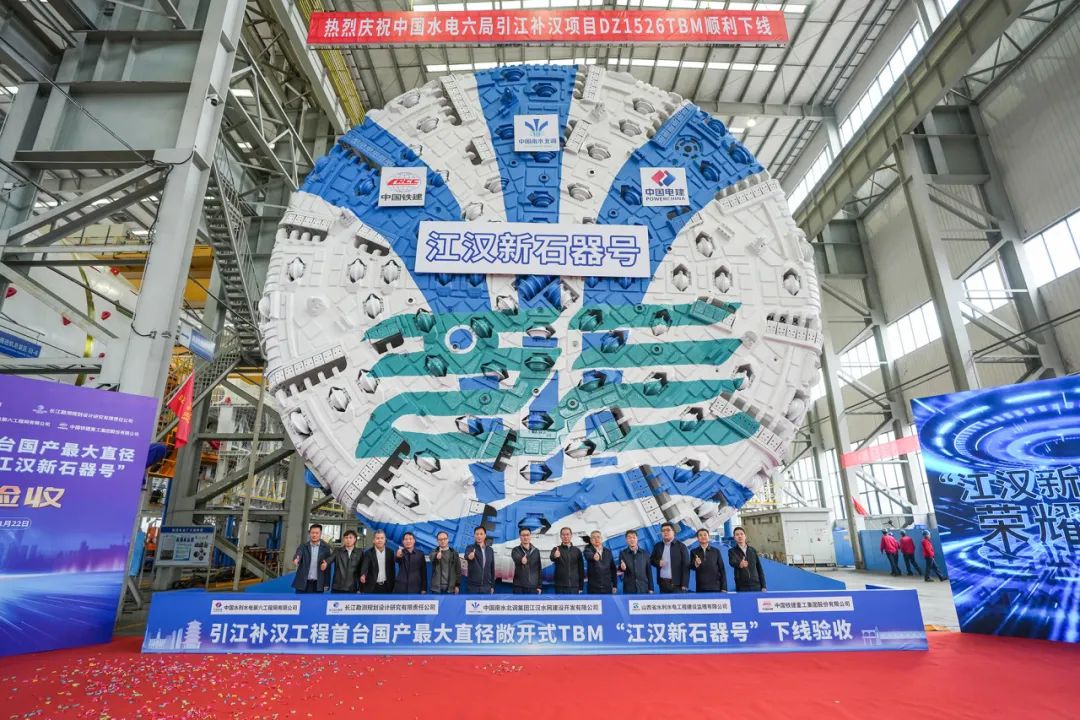

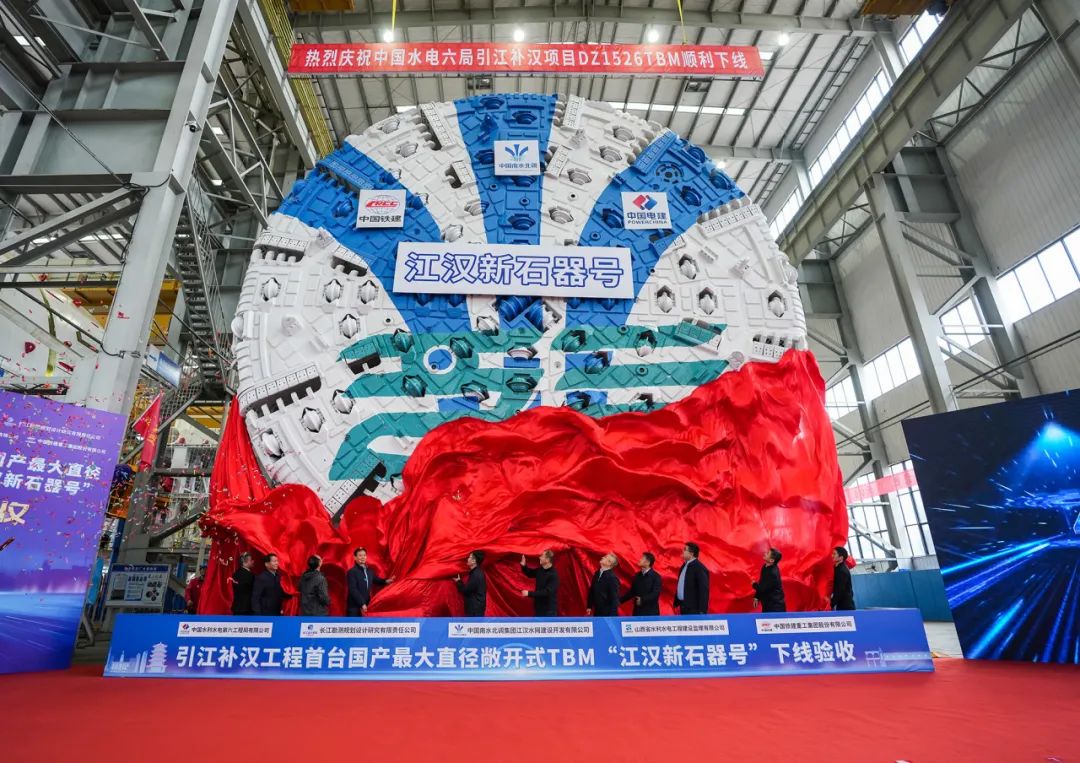

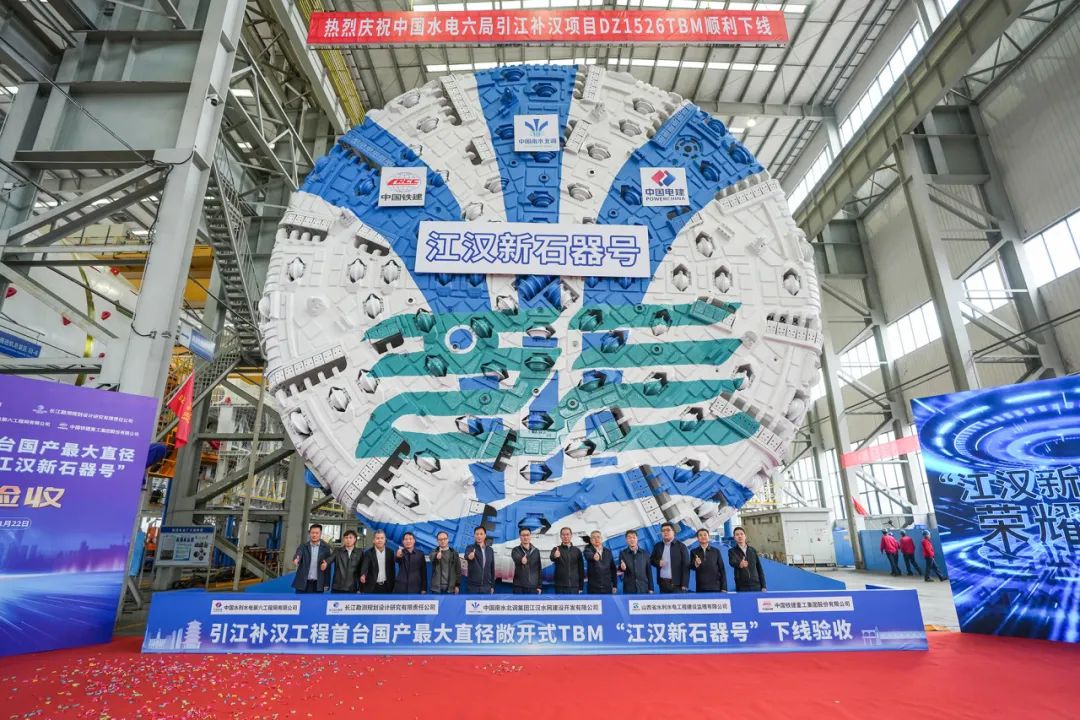

November twenty second,One set of excavation diameter up to 11.93-meter rock tunnel Boring Machine(TBM)Get off the production line of China Railway Construction Heavy Industry,It will be applied to the project of water diversion from the Yangtze River to the Hanjiang River in the middle route of the South-to-North Water Transfer Project.。This is the largest diameter open type made in China so far.TBM,It is also the largest crossing section of the Yangtze River Diversion Project.、Tunneling equipment for the longest soft rock deformation section。

Wang Zhiwen, Secretary of Discipline Inspection Committee of Jianghan Water Network Construction and Development Co., Ltd. of China South-to-North Water Diversion Group,Song Zhizhong, Deputy Chief Engineer of Changjiang Survey, Planning, Design and Research Co., Ltd.,Ren Liqiang, Deputy General Manager of Shanxi Water Conservancy and Hydropower Engineering Construction Supervision Co., Ltd.,Zhao Liqiang, Deputy General Manager of Sinohydro Bureau 6 Co., Ltd.,Deputy Party Secretary of China Railway Construction Heavy Industry Group Co., Ltd.、General Manager Wang Peng and other leaders attended the event.,Deputy Party Secretary of China Railway Construction Heavy Industry Group Co., Ltd.、Vice General Manager He Yongjun presided over the offline ceremony.。

Speech by Wang Zhiwen, Secretary of Discipline Inspection Committee of Jianghan Water Network Construction and Development Co., Ltd. of China South-to-North Water Diversion Group

Speech by Zhao Liqiang, Deputy General Manager of Sinohydro Bureau 6 Co., Ltd.

Deputy Secretary of the Party Committee of Railway Construction Heavy Industry、Welcome Speech by General Manager Wang Peng

Deputy Secretary of the Party Committee of Railway Construction Heavy Industry、Vice General Manager He Yongjun presided over the ceremony.

This Roadheader is named“Jianghan Neolithic No”,Jointly built by Railway Construction Heavy Industry and the Sixth Bureau of Hydropower,The whole length is about 175 meters,The total weight is about 3000 tons,The designed minimum turning radius is 800m,Adapt to the maximum gradient 10%,It is equipped with the industry's first immersive intelligent excavation system.,HaveTBMReal-time visualization of forward geology、Precise autonomous control of tunneling route、Automatic attitude correction、Automatic tunneling step change and the like.,Intelligent driving is realized.LLevel 3TBMIntelligent tunneling。The equipment will be used for the construction of the access tunnel and main tunnel of the Civil Works Bid 3 of the Water Diversion Project from the Yangtze River to the Hanjiang River,Total driving length 16.35 kilometers。

The geological conditions along the water diversion project from the Yangtze River to the Hanjiang River are complex.,Have a large buried depth、Line length、The diameter of the cave is large、There are many faults、There are many soft rocks、The ground stress is high、High rich water pressure and the like.,Facing strong rock burst、Mud burst and water gushed、Large fracture、Soft rock deformation、Multiple construction challenges such as toxic and harmful gases,It is the longest single tunnel in China's long-distance pressure water diversion project.、The hole has the largest diameter、Tunnel with the highest comprehensive difficulty。

In view of project construction risks and difficulties,The R & D team tackled key problems through innovation,Use small spacing、Large-range expansion cutterhead、Double support of steel arch and steel segment、Design of main drive anti-surge gate, etc.,Through the configuration of dual-speed ratio high-torque reducer、Shield lubrication and antifriction system、Shield strain gauge detection and early warning device and other systems,And improves the adaptability of the tunneling machine to bad geology.;Equipped with steel arch transportation and feeding system、Remote-control slag removal equipment,And that construction labor intensity is reduce,Provide strong support for engineering construction。

The project of diverting water from the Yangtze River to the Hanjiang River will further improve the South-to-North Water Diversion Project.“Four horizontal and three vertical”An important part of the engineering system,It is a key step to build the main framework and artery of the national water network.。After the implementation of the project, the South-to-North Water Diversion Project and the Three Gorges Project will be connected.,Connect the Yangtze River Basin、Hanjiang River Basin and Beijing-Tianjin-North China Region,Form a new pattern of water network,To provide better water resources protection for the Hanjiang River Basin and the Beijing-Tianjin North China region.。