XGMA loaders are equipped with oil-water separators for both the third and fourth engines.。In the diesel engine system of the loader,The oil-water separator plays a vital role.,Ensure pure supply of fuel,Thereby ensuring the efficient and stable operation of the engine.。

01

Main functions of oil-water separator

Removing water and impurities from diesel oil,And that combustion efficiency is improve,And prolong that service life of the engine.。

02

Conditions of use

1、Use the recommended diesel fuel type(Conform to satisfactionGB 1914 7 andGB Diesel fuel for 20891 requirement,Recommend Sinopec、PetroChina,Sulphur content≤10ppm):

|

Diesel grade

|

Number 5

|

Number 0

|

-Number 10

|

-Number 20

|

-Number 35

|

-Number 50

|

|

Cetane number

|

≥49

|

≥49

|

≥49

|

≥46

|

≥45

|

≥45

|

|

Freezing point(℃)

|

≤5

|

≤0

|

≤-10

|

≤-20

|

≤-35

|

≤-50

|

|

Applicable minimum temperature

(The diesel engine is working

Ambient temperature℃)

|

8℃Above

|

4℃Above

|

-5℃Above

|

-14℃Above

|

-29℃Above

|

-44℃Above

|

2、Carry out regular maintenance

On the dashboard“Oil-water separation indicator ”Light up,At the same time, the dial appears“If there is water in the oil, please deal with it in time.”And so on have“Water in oil”When prompted by,This filter and the second stage filter need to be checked for water and drained。

”Light up,At the same time, the dial appears“If there is water in the oil, please deal with it in time.”And so on have“Water in oil”When prompted by,This filter and the second stage filter need to be checked for water and drained。

Therefore, it is not possible to wait for the indicator light to come on before draining the water every time.。Maintenance recommendations:The oil-water separator needs to be drained every day.。Every 500 hours or 6 months(Whichever comes first)Replace the filter element of the oil-water separator and the fuel filter elements at all levels。

03

Key points of maintenance

1、Check the piping:Check the inlet and outlet pipes of the separator regularly.,Deal with damage or blockage in a timely manner。

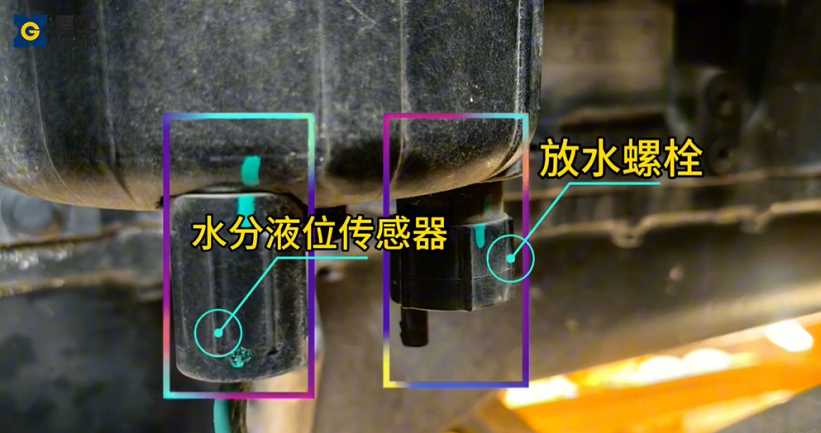

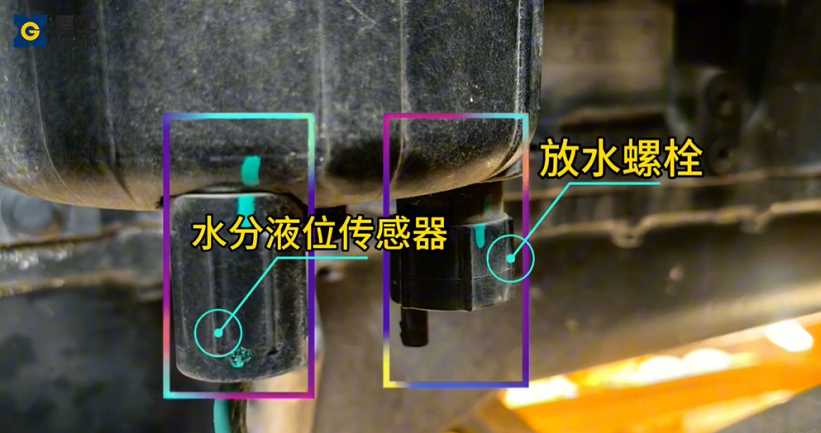

2、Clean sump:Drain the accumulated water at the bottom,Maintain good working condition。

3、Replace the filter:Follow the instructions of the engine manufacturer,Replace the diesel filter regularly.。

04

Fault judgment

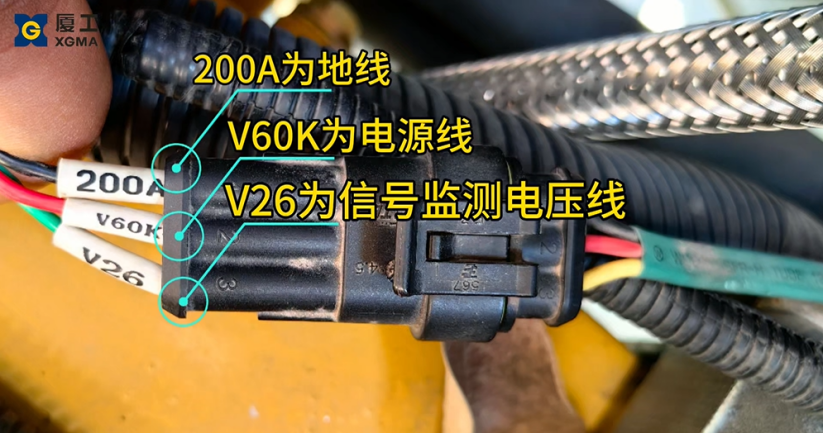

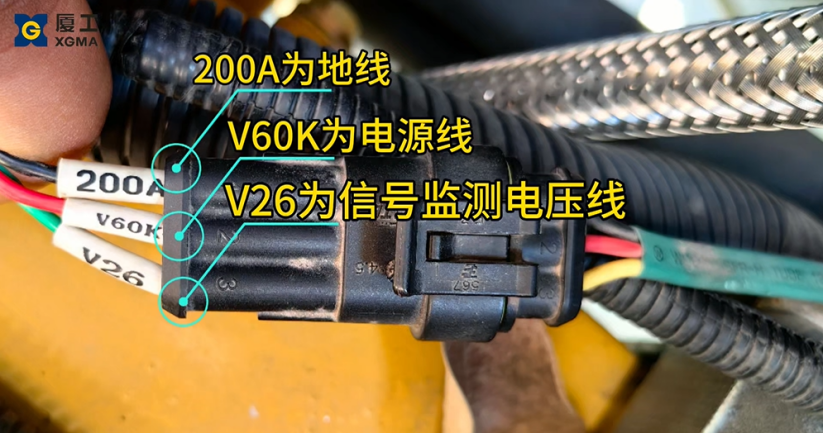

1、Chassis wiring inspection:The oil-water separator connector configured by XGMA has three lines.,Disconnect the multimeter voltage gear detection.,One ground wire 0V,One power cord 24V,One fuel/water separator signal line monitors voltage 22V-23V。

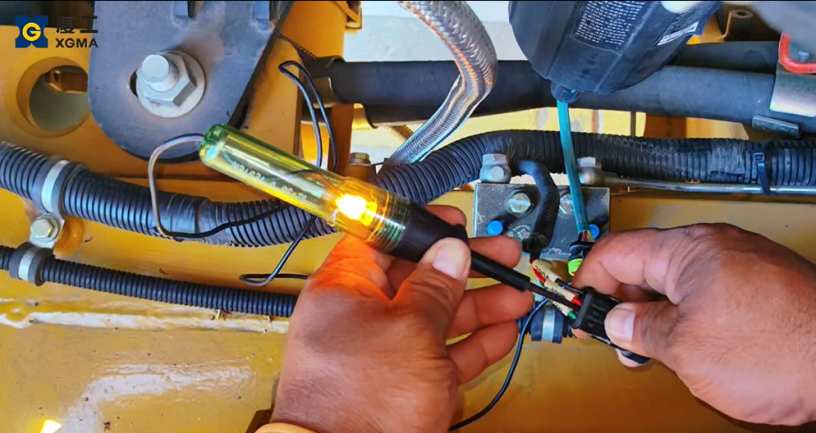

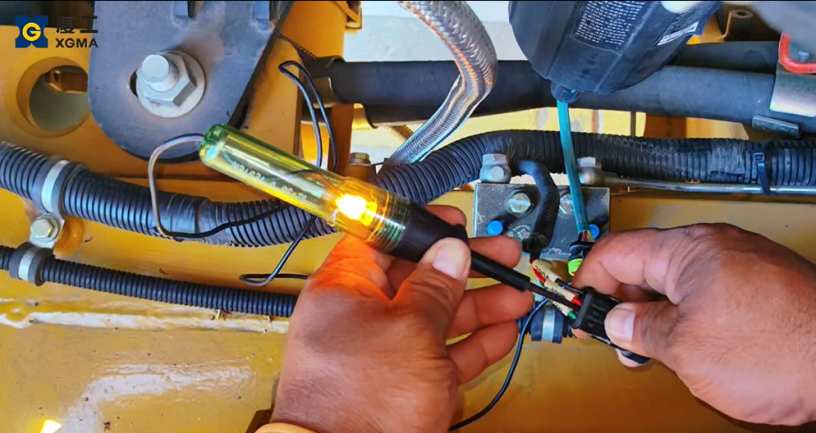

To ensure reliable power supply voltage,Need to use 5WMeasure the power supply and ground wire of the oil-water separator with the test lamp,Prevent virtual electricity,Lead to miscarriage of justice。

2、Oil-water separator test:Detect the oil-water separator signal line without disconnecting,Voltage with water 24V,Voltage without water 0V。

3、Judging whether the circuit and the device are damaged according to the detection result, and repairing or replacing the circuit and the device。

Let's watch a short video of oil-water separator maintenance operation and fault judgment.:

In short,Although the oil-water separator is small,The responsibility is great。Proper use and maintenance can not only ensure its effective operation.,But also prolong that service life.,To provide a solid guarantee for the efficient and stable operation of XGMA loaders in engineering construction。

If you have any questions or need help,Please feel free to contact our after-sales service team。

Welcome to call the official customer service hotline of XGMA

400-6618-668

”Light up,At the same time, the dial appears“If there is water in the oil, please deal with it in time.”And so on have“Water in oil”When prompted by,This filter and the second stage filter need to be checked for water and drained。

”Light up,At the same time, the dial appears“If there is water in the oil, please deal with it in time.”And so on have“Water in oil”When prompted by,This filter and the second stage filter need to be checked for water and drained。