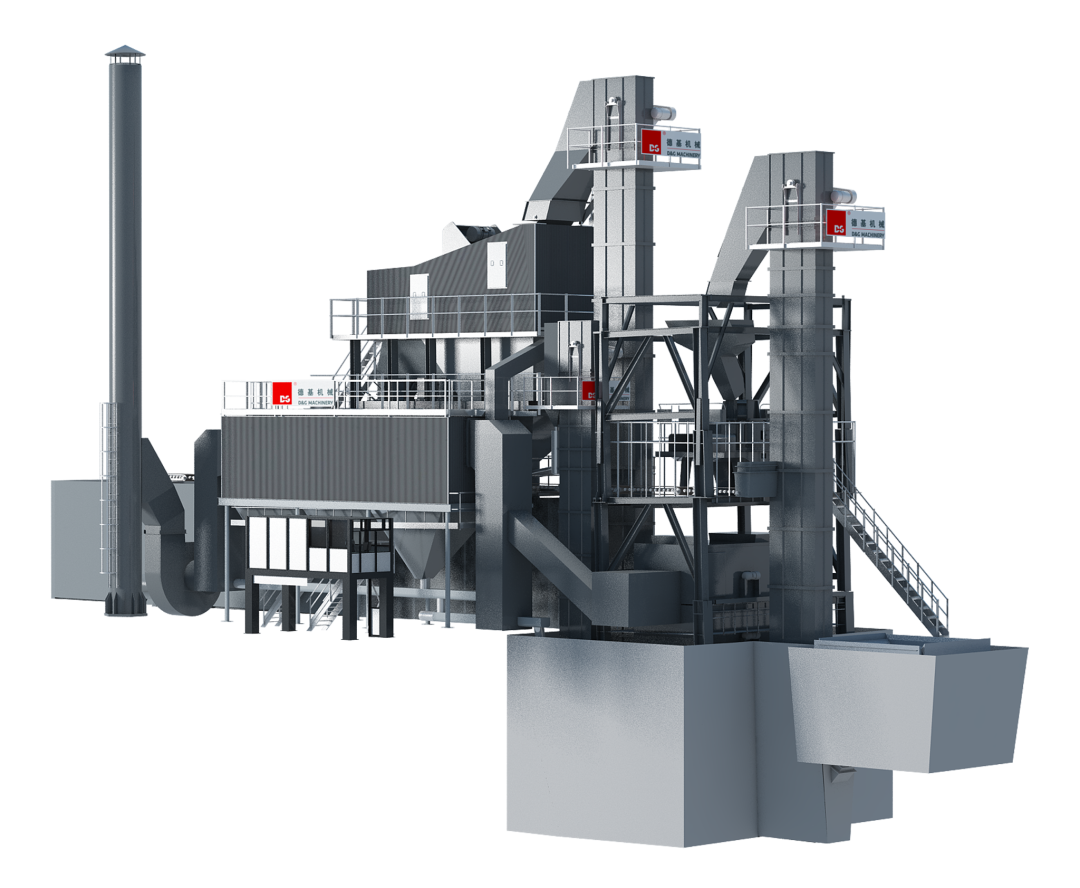

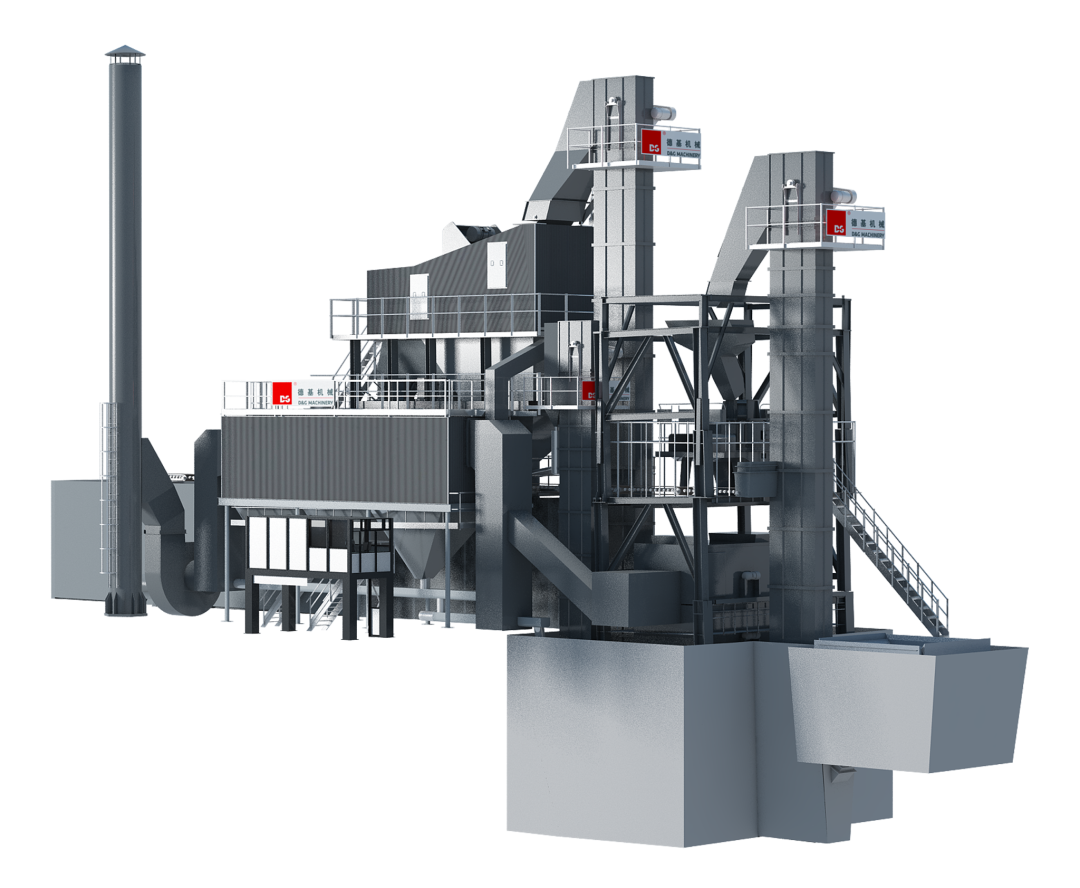

With the rapid development of highway traffic,,Refurbishment of asphalt pavement is increasing,Resulting in milling of the material(Pavement recycling materials)Increasing。In order to save resources、Reduce costs、Reduce environmental pollution、And that construction efficiency is improve、Prolong the service life of pavement。At the same time,In order to improve the performance of the old pavement,,Improve driving safety and comfort。Deji Machinery is based on the original fixed flexible crushing and screening production line for recycled materials.,Launch a new modelMSRSeries of tower-type fine separation and classification equipment for recycled materials,The equipment is highly integrated.、The environmental protection performance is superior。According to production capacity(Throughput) Classification ,Can be divided into:60-80 tons、80-100 tons、100-120 tons、120-150 tons、150-Five models of 200 tons。

During use of the road,Asphalt pavement will be affected by Vehicles.、Damage caused by climate and other factors,Maintenance is required at this time。Take from the road,And use it for the road.,Therefore, the recycling of milling materials is very critical.。Due to the complexity and uncertainty of recycling incoming materials,,Among them, the part of machining classification is particularly important.,The quality of the processing effect,It directly affects the downstream utilization rate of finished materials.。Another horse of Deji Machinery“Dark horse”--MSRSeries of tower-type fine separation and classification equipment for recycled materialsCame into being,Run to the market,It must have its unique advantages.。Some problems of similar products in the market,It is summarized as follows:1.A large amount of fine aggregate will be produced during the operation of the separation machine.,Asphalt Mixing Plant conventional addition can not be fully used,Where 0-5mmMore than 65% of the total-70%。2.The screening efficiency of the vibrating screen is too low,Many manufacturers use two-stage screening treatment.。3.The bag of the dust remover is seriously blocked。

4.Large materials cannot be processed.。

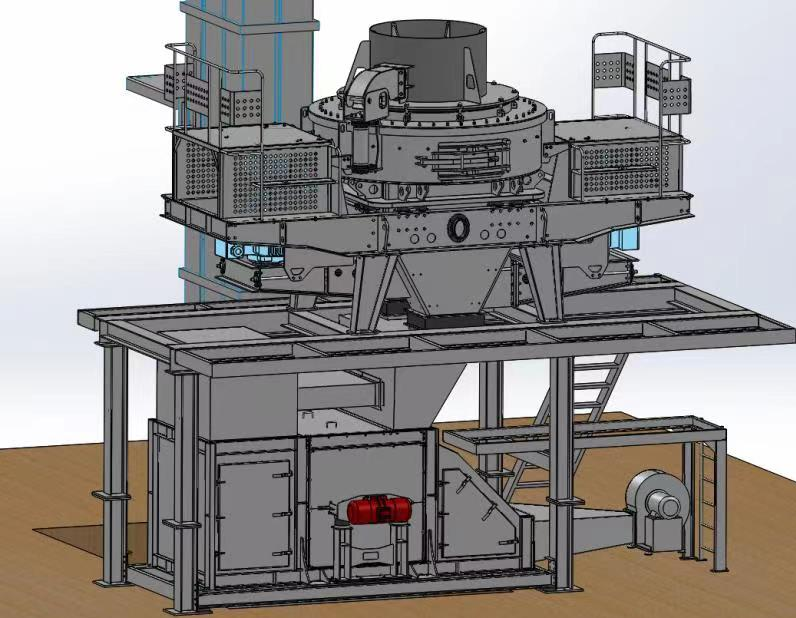

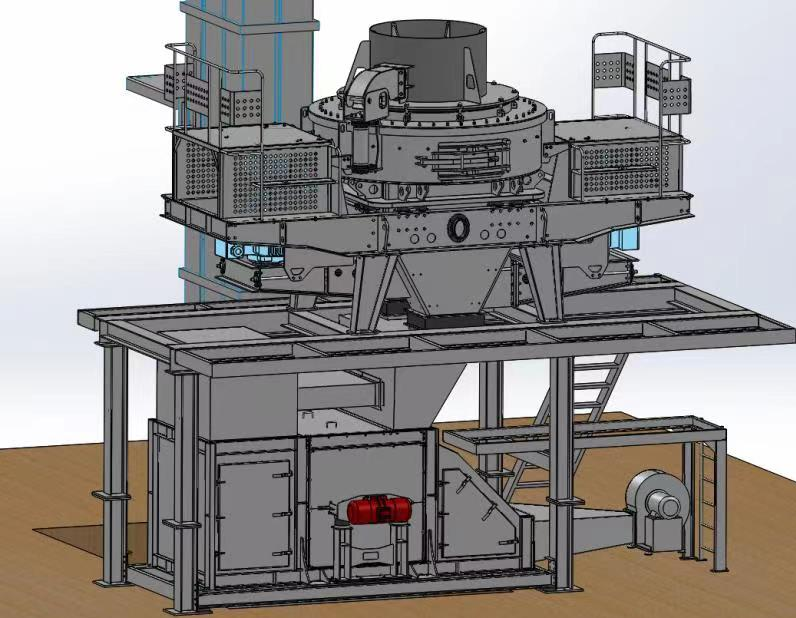

Aiming at the above four difficulties,Durkee mechanical“Dark horse”,Perfect solution to the above problems.。 One、Fine separator:Maximize the utilization of asphalt milling materials for pavement,Double outlet impeller vertical shaft type fine separation main machine specially developed by our company,Utilize the principle that different materials have different crushing values,Pitch adhered to the stones,Separated by certain physical impact, crushing and grinding。Reduce excessive crushing of incoming material,Reduce the dust removal in the downstream、Operation requirements for screening and grading processes。The whole machine adopts thin oil automatic lubrication and sealing system.,Automatic fuel supply system,Equipped with oil temperature detection、Vibration sensor alarm system,Problems can be found in time,Dispose of problems。Two、Digital powder removal device:The device is a patented product developed by our company.,For materials containing soil、Intelligent device with high powder content and specially designed for powder removal。Motor vibration mode is adopted for the whole machine.,Comprising a box body, a vibrating core and a support、Frequency conversion blast, etc.。Evenly spread the cloth from the incoming material,Then pass the air volume of different requirements.,The amount of powder in the material is in accordance with certain finished product requirements.,Collect and control the variable frequency air volume of the matching dust collector。Due to the complexity and uncertainty of pavement milling materials,,In particular, the content of soil, powder and even fine particles in the upper layer accounts for a large proportion.,Digitalized powder removing device matched with fine separation main machine two-in-one,The effect is particularly remarkable.。Three、Optional:The picture above showsFirst break and then screen,We take into account the complexity and uncertainty of incoming materials.,PutSieve first and then breakAs an optional unit。In addition,Option configuration also has a large block.(Non-milling planing material)Material Crusher,Specially handle the leftover materials of the road surface or the broken materials of the breaking hammer,The final realization of the scene“Operation CD-ROM”。Four、High frequency linear environmental protection screen:Allow for incoming mill material and moisture content during storage、Powder content、Effect of temperature and other comprehensive factors on sieving;In addition, the use of finished materials requires grading and refinement.、Asy control of grading and other requirements;And the milling material is a viscous and flexible material。Our company adopts high frequency linear environmental protection screen for screening of milling materials.,On the basis of raw meal screening, the optimization of anti-sticking, anti-blocking and easy moving material was made.。Five、Composite type environmental protection dust-removing and powder-removing system:Dust removal system with dust remover as the core,The dust remover is a box-type pulse bag-type dust remover.,Aiming at stone powder in asphalt milling material、Adhesion of asphalt powder to cloth bag,We have made specific optimization.。From the cloth bag material、Fine separation of incoming materials、The digital powder removal and the screening and classification process of the high-frequency linear environmental protection screen are optimized.,All-round reduction of high requirements for dust remover,Avoid possible problems。

One、Fine separator:Maximize the utilization of asphalt milling materials for pavement,Double outlet impeller vertical shaft type fine separation main machine specially developed by our company,Utilize the principle that different materials have different crushing values,Pitch adhered to the stones,Separated by certain physical impact, crushing and grinding。Reduce excessive crushing of incoming material,Reduce the dust removal in the downstream、Operation requirements for screening and grading processes。The whole machine adopts thin oil automatic lubrication and sealing system.,Automatic fuel supply system,Equipped with oil temperature detection、Vibration sensor alarm system,Problems can be found in time,Dispose of problems。Two、Digital powder removal device:The device is a patented product developed by our company.,For materials containing soil、Intelligent device with high powder content and specially designed for powder removal。Motor vibration mode is adopted for the whole machine.,Comprising a box body, a vibrating core and a support、Frequency conversion blast, etc.。Evenly spread the cloth from the incoming material,Then pass the air volume of different requirements.,The amount of powder in the material is in accordance with certain finished product requirements.,Collect and control the variable frequency air volume of the matching dust collector。Due to the complexity and uncertainty of pavement milling materials,,In particular, the content of soil, powder and even fine particles in the upper layer accounts for a large proportion.,Digitalized powder removing device matched with fine separation main machine two-in-one,The effect is particularly remarkable.。Three、Optional:The picture above showsFirst break and then screen,We take into account the complexity and uncertainty of incoming materials.,PutSieve first and then breakAs an optional unit。In addition,Option configuration also has a large block.(Non-milling planing material)Material Crusher,Specially handle the leftover materials of the road surface or the broken materials of the breaking hammer,The final realization of the scene“Operation CD-ROM”。Four、High frequency linear environmental protection screen:Allow for incoming mill material and moisture content during storage、Powder content、Effect of temperature and other comprehensive factors on sieving;In addition, the use of finished materials requires grading and refinement.、Asy control of grading and other requirements;And the milling material is a viscous and flexible material。Our company adopts high frequency linear environmental protection screen for screening of milling materials.,On the basis of raw meal screening, the optimization of anti-sticking, anti-blocking and easy moving material was made.。Five、Composite type environmental protection dust-removing and powder-removing system:Dust removal system with dust remover as the core,The dust remover is a box-type pulse bag-type dust remover.,Aiming at stone powder in asphalt milling material、Adhesion of asphalt powder to cloth bag,We have made specific optimization.。From the cloth bag material、Fine separation of incoming materials、The digital powder removal and the screening and classification process of the high-frequency linear environmental protection screen are optimized.,All-round reduction of high requirements for dust remover,Avoid possible problems。

16-25MM

11-16MM

5-11MM

0-5MM

In addition to the above functions,The device also has the following design features:

In addition to the above functions,The device also has the following design features:

One、 Compact design,The whole machine consists of the following 6 parts::

1.Incoming material feeding and lifting system

2.Material separation and powder removal system

3.Material lifting and screening system

4.Material grading and output system

5.Environmental protection dust removal system

6.Lectric intelligent control system

Two、All of them adopt modular design:And is convenient to transport,Facilitate the removal and replacement of wearing parts,Convenient installation。

Three、Environmental protection requirements have been considered for the whole machine.,And that seal performance is good,No running, emitting, dripping and leaking,No secondary packaging required。

Four、All parts are bolted together,Field stationary welding。

One、Fine separator:Maximize the utilization of asphalt milling materials for pavement,Double outlet impeller vertical shaft type fine separation main machine specially developed by our company,Utilize the principle that different materials have different crushing values,Pitch adhered to the stones,Separated by certain physical impact, crushing and grinding。Reduce excessive crushing of incoming material,Reduce the dust removal in the downstream、Operation requirements for screening and grading processes。The whole machine adopts thin oil automatic lubrication and sealing system.,Automatic fuel supply system,Equipped with oil temperature detection、Vibration sensor alarm system,Problems can be found in time,Dispose of problems。Two、Digital powder removal device:The device is a patented product developed by our company.,For materials containing soil、Intelligent device with high powder content and specially designed for powder removal。Motor vibration mode is adopted for the whole machine.,Comprising a box body, a vibrating core and a support、Frequency conversion blast, etc.。Evenly spread the cloth from the incoming material,Then pass the air volume of different requirements.,The amount of powder in the material is in accordance with certain finished product requirements.,Collect and control the variable frequency air volume of the matching dust collector。Due to the complexity and uncertainty of pavement milling materials,,In particular, the content of soil, powder and even fine particles in the upper layer accounts for a large proportion.,Digitalized powder removing device matched with fine separation main machine two-in-one,The effect is particularly remarkable.。Three、Optional:The picture above showsFirst break and then screen,We take into account the complexity and uncertainty of incoming materials.,PutSieve first and then breakAs an optional unit。In addition,Option configuration also has a large block.(Non-milling planing material)Material

One、Fine separator:Maximize the utilization of asphalt milling materials for pavement,Double outlet impeller vertical shaft type fine separation main machine specially developed by our company,Utilize the principle that different materials have different crushing values,Pitch adhered to the stones,Separated by certain physical impact, crushing and grinding。Reduce excessive crushing of incoming material,Reduce the dust removal in the downstream、Operation requirements for screening and grading processes。The whole machine adopts thin oil automatic lubrication and sealing system.,Automatic fuel supply system,Equipped with oil temperature detection、Vibration sensor alarm system,Problems can be found in time,Dispose of problems。Two、Digital powder removal device:The device is a patented product developed by our company.,For materials containing soil、Intelligent device with high powder content and specially designed for powder removal。Motor vibration mode is adopted for the whole machine.,Comprising a box body, a vibrating core and a support、Frequency conversion blast, etc.。Evenly spread the cloth from the incoming material,Then pass the air volume of different requirements.,The amount of powder in the material is in accordance with certain finished product requirements.,Collect and control the variable frequency air volume of the matching dust collector。Due to the complexity and uncertainty of pavement milling materials,,In particular, the content of soil, powder and even fine particles in the upper layer accounts for a large proportion.,Digitalized powder removing device matched with fine separation main machine two-in-one,The effect is particularly remarkable.。Three、Optional:The picture above showsFirst break and then screen,We take into account the complexity and uncertainty of incoming materials.,PutSieve first and then breakAs an optional unit。In addition,Option configuration also has a large block.(Non-milling planing material)Material

In addition to the above functions,The device also has the following design features:

In addition to the above functions,The device also has the following design features: