Portland Concrete ConTractors Utilize Technology to Upgrade Their Layout Setting Out Process!

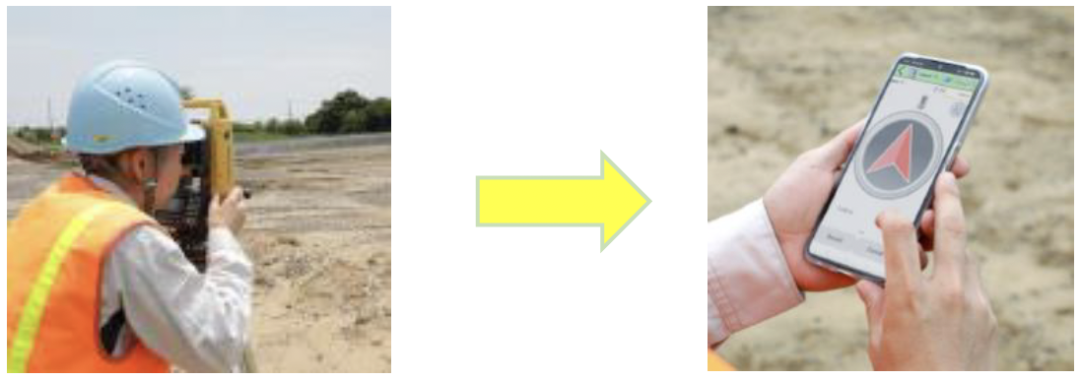

Good leadership can take many forms.。Just Hugo Zavala In terms of,It manifests itself in ensuring that his employees have the best solutions to perform their duties, etc.。As a concrete conTractor based in Portland, Oregon Zavala Corporation President and owner of,He has seen the company become one of the fastest growing private companies in the region.,He also saw inefficiencies caused by the technology his team used in some key parts of their work.、The labor force is dense,An upgrade is urgently needed。He did not turn a blind eye to it and maintain the status quo.,Instead, alternatives to this outdated practice were examined.,He found what he thought was the best way and incorporated it.。So,His staff can now handle the lofted layout of the job more efficiently.,And require only a fraction of the manpower.,This frees up staff to meet other site needs。Effective leadership produces impressive results.。

01

A new discovery on the Internet

Zavala Corporation Founded in 2008,Is a business specializing in the entire Pacific Northwest.、Company providing structural and architectural concrete for heavy civil and industrial construction projects。The company operates all year round.,The core staff is about 40,But it will increase to 60 in the summer.-70 people。According to Zavala The site supervisor Rolando Ruiz Say,The scope of their work is very wide.。

Actually,Zavala Corp.Each aspect of the specific work involves some sort of lofted layout.,Include establishing grid lines and other specific points relevant to the design.。This work is boring.、Laborious and too prone to error。When you're luckyHugo ZavalaBe aware of the problem,And found a solution.。

“I use it a lot LinkedIn,See some of my contacts there.(People who do similar work to us)Something to use at work.,It really caught my attention.。I started doing more research.,And finally made contact. Topcon Solutions Store (TSS),See what they can do for me.。”

02

Enter the alternative

Nowadays,Zavala The staff has another option.,Any of that above risk of error can be eliminated。In Portland TSS At the suggestion of the personnel of the branch,The company purchased a product called Layout Navigator Yes Topcon 3D Robotic solutions,According to Ruiz Say,Since then, he has never returned to the traditional way.。

“This instrument——We currently use twoLN-150 and one of the previous models LN-100——Greatly changed the way we are laying out now,”He said。“What used to be done by two or three people can now be done by one person.,And do it much more accurately.。The setup is very simple,The instrument is self-leveling.,We've been right FCSeries of handbooks and Topcon Satisfied with the use of total station。

He added,Zavala Some of the key staff visited over the weekend. TSS The office conducted a one-day course.,To understand the overall operation of the instrument。Soon after,TSS The representative visited Zavala A work site.,A quick review was given to the staff,And provides more details about the solution。“That's more than enough for us.,”Ruiz Say。

Zavala Corp.The lofting robot design used today is simple in itself.,It is used in conjunction with prisms and handbooks that are fixed to the pole.,Provide them with an accurate 3D Positioning,130 m working radius。Besides Ruiz Mentioned LN-150 simple one-touch self-leveling setting outside,Other advantages include the adoption of MAGNET Software solutions and systems Autodesk And Bentley Seamless cloud-connected workflow。

Zavala Corp.There are currently 4 key staff fully qualified to run LN,Another 10 staff members know how to run them after setting them up.。This has a huge impact on productivity.,This usually means more than just saving personnel.,And reduce the chance of error.。

He added,There are many more benefits.。 Past ,If important information is missing from the initial design,They will be forced to contact the designer or engineer.,This will obviously hinder production.。Now,Knowing that the information in the data collector comes directly from what the engineer used to design the building CAD Paper ,So you can add the missing data yourself and proceed with the construction.,This has saved them more than once.。

03

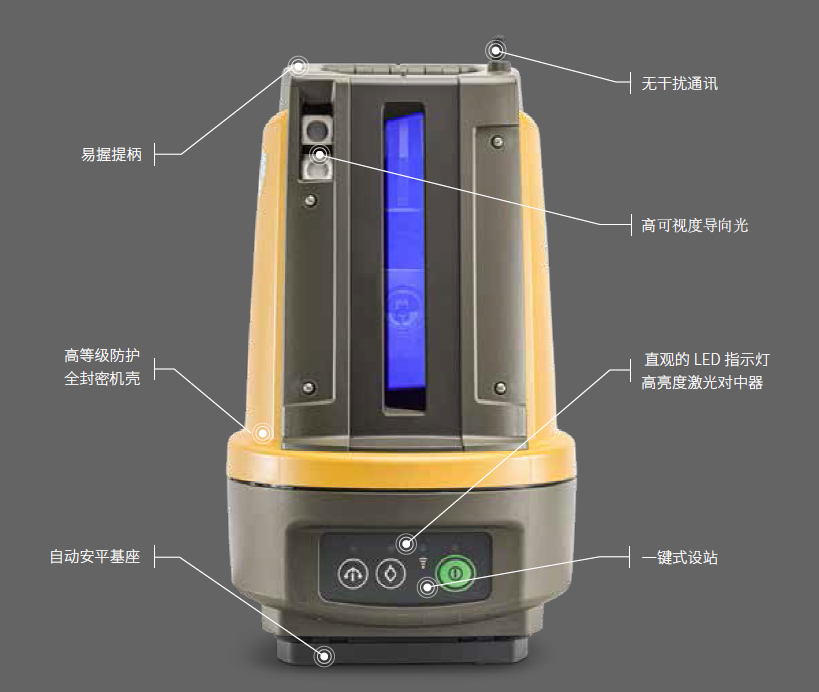

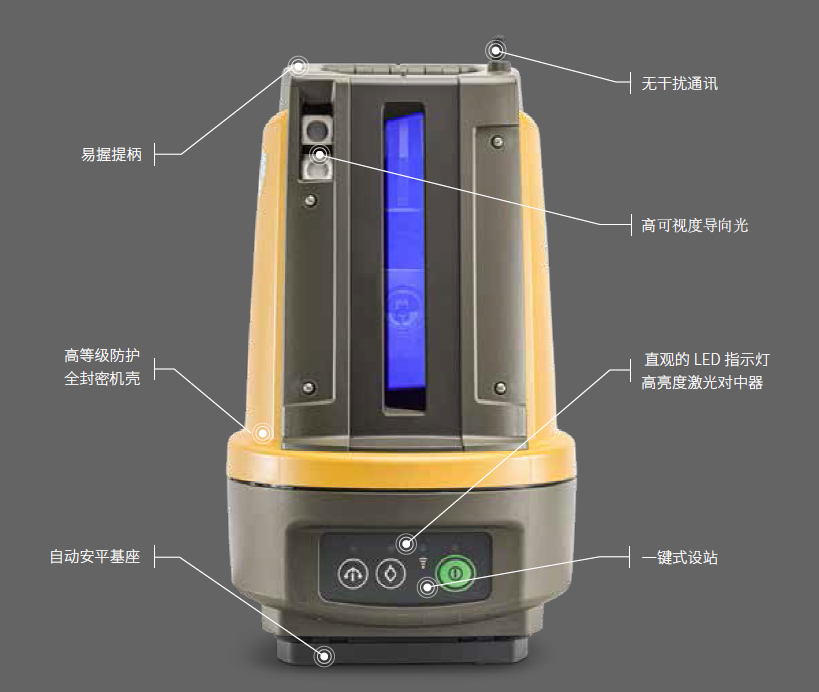

LN-150 Introduction

LN-150 isLAYOUT NAVIGATOR-Abbreviation for 150,It was successfully developed in 2014,The original product isLN-100,LN-150 is the second generation product,It is a professional full-station lofting robot for measuring and lofting functions.,Determine the three-dimensional coordinates of the measured object by means of measurement and ranging。Compared to the first generation product,Its working radius and height range have been greatly improved.。Have a simple stand,Guide light guide,Advantages of automatic tracking measurement。

04

LN-150 features

#1

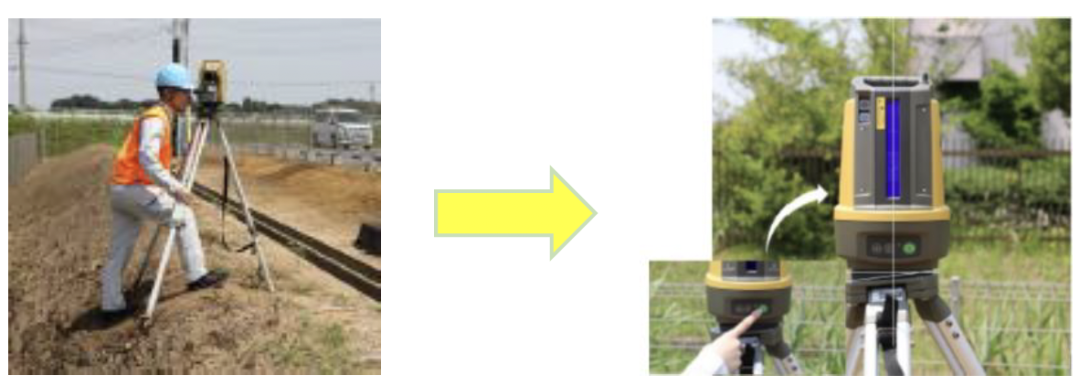

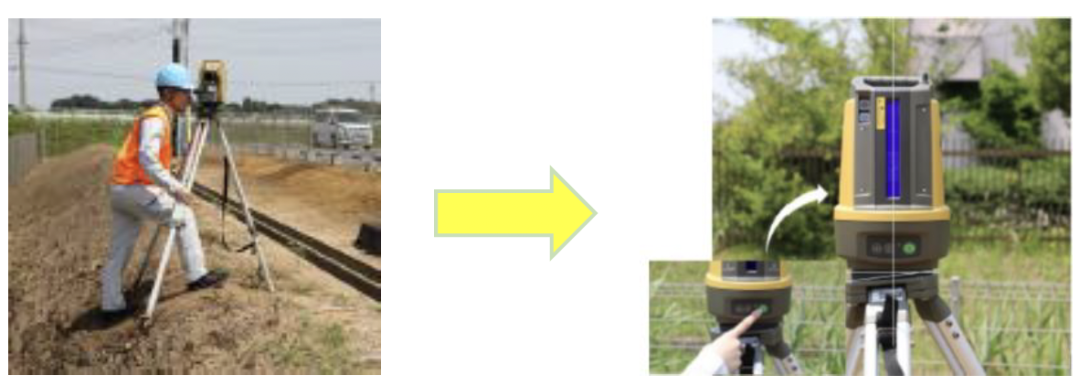

Compared with the traditional total station,3°One-key automatic leveling within the range。

#2

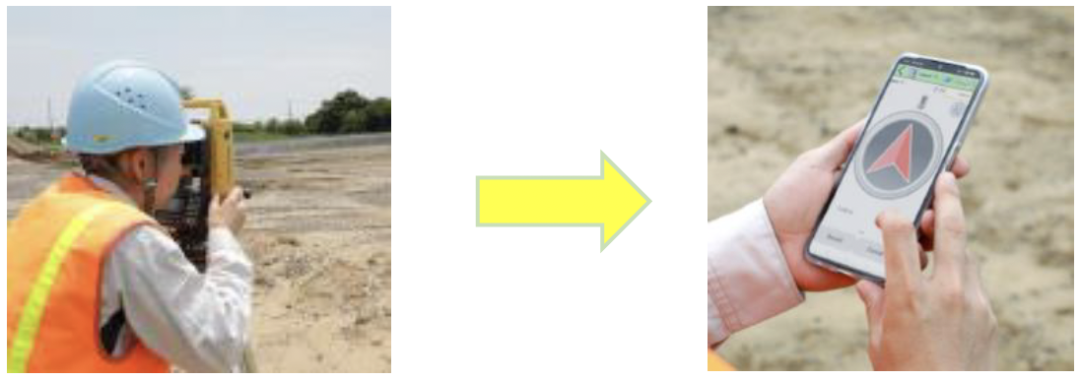

No manual focusing and alignment required,Automatic observation,Red and green light guide to find the target faster。

#3

No need to aim,Automatically aim at the next setting-out point。

05

LN-150 Application value

Reduce professional and technical requirements

Non-professional surveyors can get started quickly,Reduces requirements for operator(Cost per person)

And that labor cost is reduce

One-man operation can complete the work,Reduce labor costs(Number of personnel)

Imple and easy to operate

The instrument is automatically leveled,No need to aim,Setting-out as directed 。

Improve work efficiency

Locking position more quickly,Compared with the traditional total station method,,Time is reduced by 50% 。

06

LN-150 application scenarios

Interior decoration

Municipal Engineering

Engineering installation

Engineering control

Contribution:ICTIntelligent Construction Business Department wtq