Celebrate the 75th anniversary of the founding of the People's Republic of China

For 75 years,As the national team of three-dimensional interconnection of transportation infrastructure and the promotion of Chinese standards“Walk out”The leader of the platoon,China Communications Group has always been in mind.“The great of the country”,Give full play to the advantages of integrated service of the whole industry chain,Accelerate the cultivation and development of new quality productive forces,A large number of them were built.“China is the first”“The best in the world”A super project and a heavy weapon of a great power.,Serving the Chinese-style Modernization Construction with the Wisdom and Strength of CCCC。

In order to fully demonstrate the brilliant achievements of CCCC in the field of national transportation infrastructure in the past 75 years.,We have sorted out the key projects in various fields.,This issue is launched“Chinese equipment”Special topic,Let's watch it together.。

Chinese equipment

Equipment industry is a solid support for big country manufacturing。China Communications Group is the world's leading engineering equipment design and manufacturing service provider.,Large offshore construction vessels, including dredging vessels、Port Machinery、Shield Machine、Tower Crane and other fields have technological research and development and manufacturing advantages.。Over the years,China Communications Group closely follows the national development strategy,Insist on independent innovation,Accelerate the cultivation and development of new quality productive forces,Created in the field of equipment manufacturing“China's first”“The world's first”Wait for many records.。

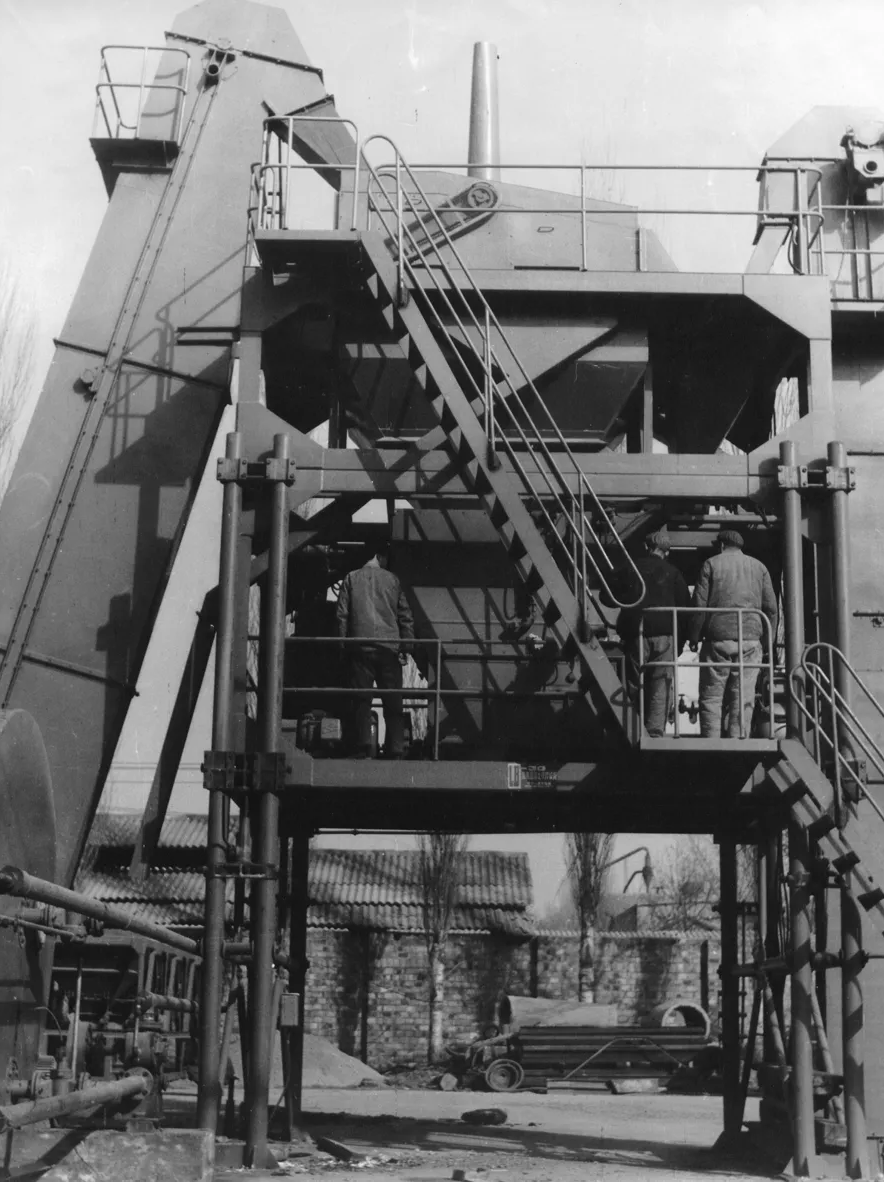

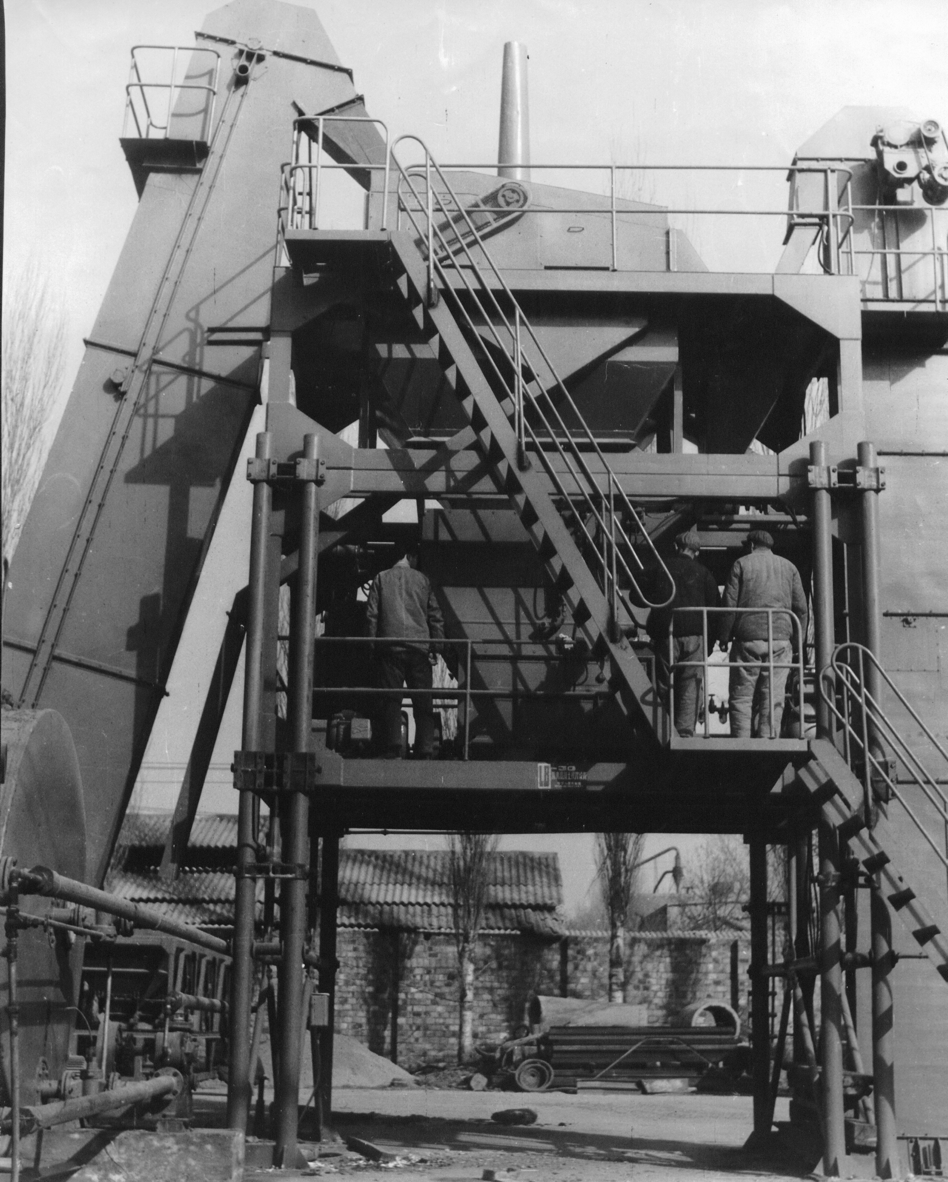

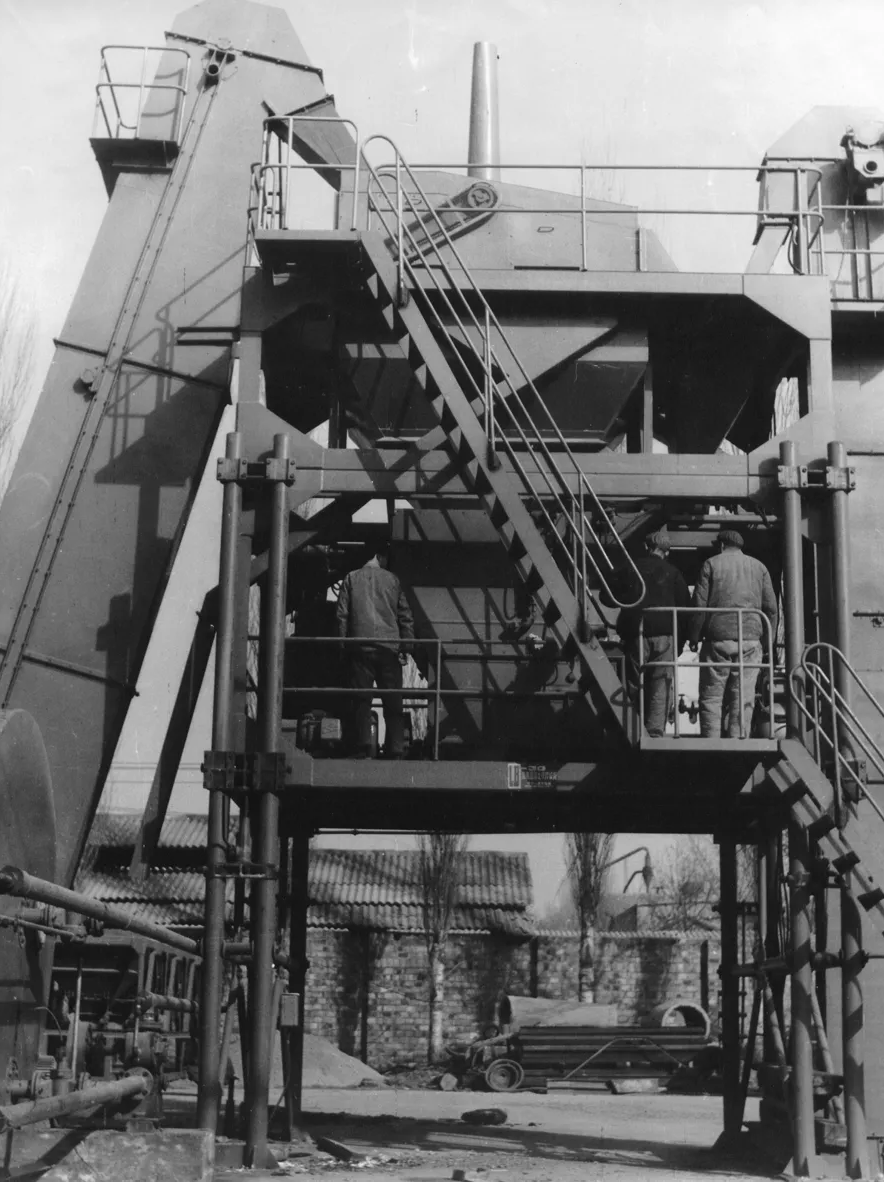

China's first Asphalt Distributor

Asphalt Distributor is a kind of black road maintenance machine.,Spray the asphalt in the molten state evenly on the road surface.。The first Asphalt Distributor in China was designed by Xizhu Company in 1960 based on an old equipment through mapping and improvement.。The 1970s,An Asphalt Distributor was also renovated.,Compared with the original distributor, the material consumption of each distributor is saved by two thirds.,Cost reduced by 300 yuan,At that time, the annual production task was 300 sets.,Save a total of 90000 yuan。

China's first setLB—Type 30

Asphalt Concrete Mixing Plant

1967,The first set of asphalt Concrete Mixing Plant in China was designed by the former Ministry of Transport Research Institute and Xizhu Company with reference to foreign data.,The trial production was successful in 1969。

The world's first to lift three at a time

40-foot containerCrane

The world's first container crane independently developed by Zhenhua Heavy Industries can lift three 40-foot containers at a time.,Put into production in 2006。The crane is in the unloading operation at Mawan Wharf in Shenzhen.,Productivity increased by 20 percent%,It is known as the first choice for upgrading container cranes in the world in the 21st century.。

The crane consists of a single spreader and a set of twin Spreaders.,Three 40-foot containers can be lifted simultaneously on the same trolley,Or two 40-foot containers and two 20-foot containers,Or one 40-foot container and four 20-foot containers,Or six 20-foot containers。The crane can also separate the single spreader and the double spreader to work independently.,Carry out combined loading and unloading of various types of containers,The loading and unloading efficiency of the wharf and the adaptability of the loading and unloading operation are greatly improved.。

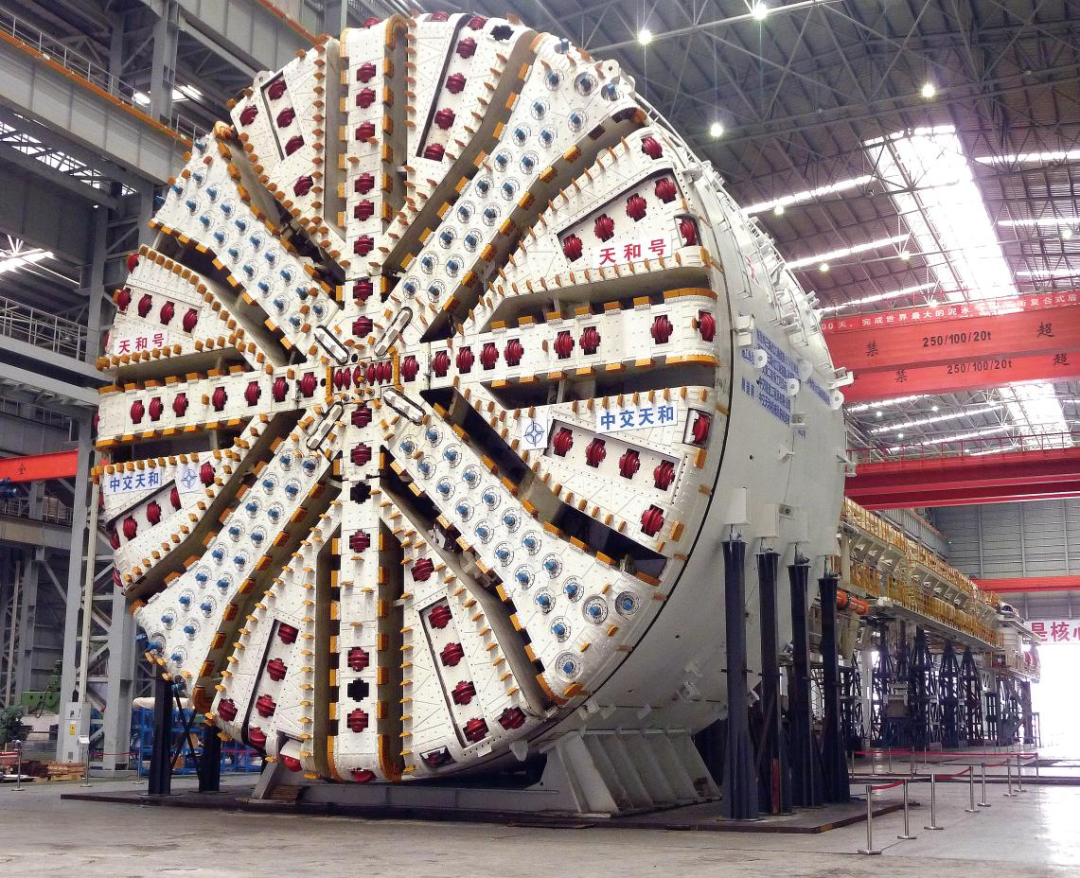

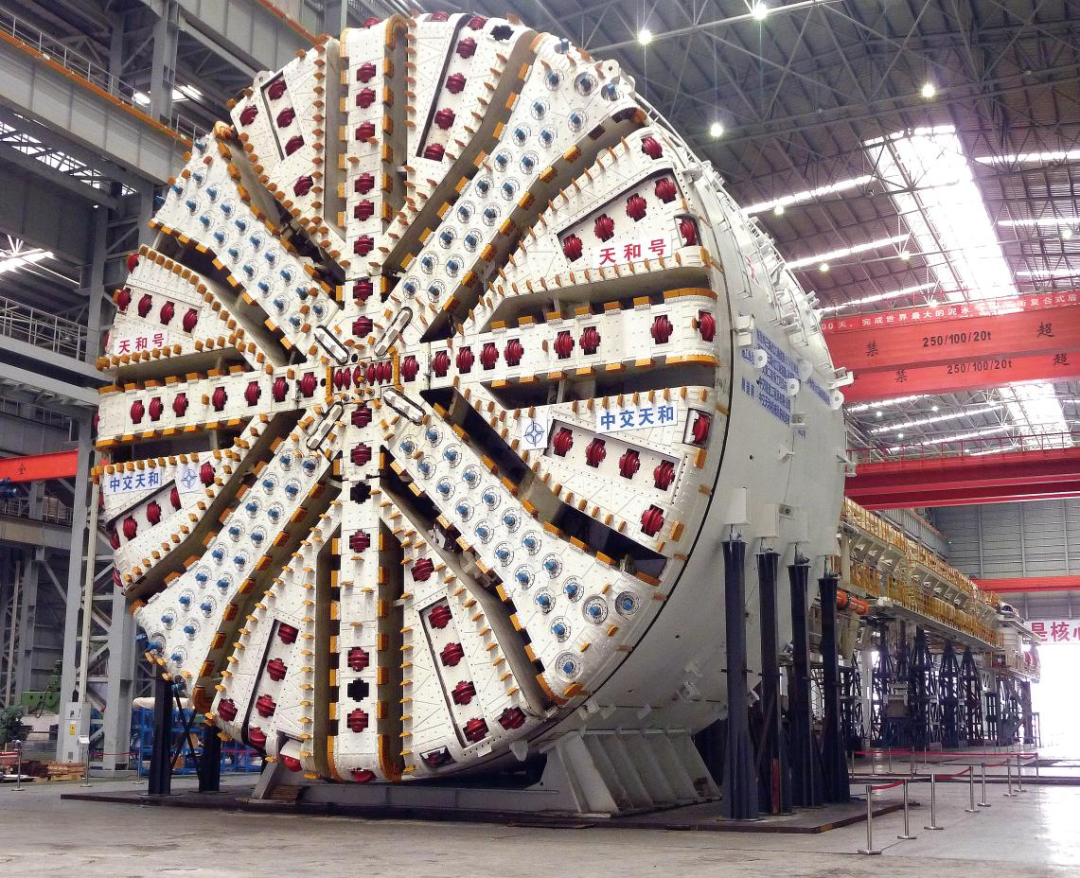

China's first super large diameter Shield Machine

“Tianhe”

“Tianhe”It is the first domestic super-large diameter Shield Machine independently designed and built by China Jiaotong Tianhe.,Break foreign monopolies,It has opened the ice-breaking journey of domestic Shield Machines with a diameter of more than 10 meters.。2016,“Tianhe ”Nanjing Dinghuaimen Tunnel was officially opened to traffic.。

World's first 3EClass 1 quayside container crane

3EClass a super large quayside container crane

3 independently developed by Zhenhua Heavy IndustriesEThe lifting height of Class I super large quayside container crane is 20% higher than that of conventional quayside container crane%Above,It can meet the loading and unloading requirements of ultra-large container ships.,It is the quayside crane with the largest lifting height and forward reach in the world at present.。

2020,Zhenhua Heavy Industries Delivered 4 World's Largest 3 Units to Meishan Wharf, Zhoushan Port, NingboEClass 1 quayside container crane。3EClass III Super Large Quayside Container Crane is aimed at Maersk 3EQuayside container crane developed for class a container ship,Lifting height 48 to 52.5 meters,The extension distance is greater than 70m.,It can load and unload 10 layers of super-high containers on the deck.。3EClass I quayside container crane leads the quayside container crane equipment in major ports around the world to a larger scale.、Faster、Develop in a more efficient direction,After being introduced to the market, it has been widely welcomed by users.。

First in the country with the largest displacement

The most intelligentMultifunctional arrangement ship

“Traffic Construction No.9”

November 2023,Invested and built by Shanghai Navigation Bureau, the first one with the largest displacement in China、The most intelligent multi-functional arrangement ship“Traffic Construction No.9”Go into the water smoothly。The vessel is of single deck、Steel welding and forecastle-type non-motorized multifunctional laying ship,It is suitable for cofferdam land reclamation under different environmental conditions.、Water structure engineering, etc.,Total length 116.6 meters、Profile width: 25m、Depth 6.3 meters、Design draught 3.5 meters。The ship is not only the largest displacement in China at present.、The most intelligent green low-carbon multi-functional arrangement ship,It is also the world's first.,Its equipment and core technology are independently produced and developed in China.。

China's first“Vertical mobile plant”

Integrated intelligent Tower Crane

June 30, 2024,The Shenzhen-Medium Passage was completed and opened to traffic,It has become an important traffic backbone for the construction of Guangdong-Hong Kong-Macao Greater Bay Area.。Among,The tower of Shenzhong Bridge is 270 meters high.,It is the highest bridge tower in the world.,CCCC Construction Team is based on the concept of modern factory construction,Build high altitude“Vertical mobile plant”——The integrated intelligent Tower Crane has a 9-layer functional platform.,Intelligent maintenance integrating concrete distribution and vibration、Functions such as automatic climbing and real-time monitoring are integrated.,Realize automation and personnel reduction、Mechanized replacement、Safety monitoring and protection,At present, it has been in the deep and medium channel.、Changtai Yangtze River Bridge、Application in the construction of Yanji Yangtze River Bridge and other major national projects,Continuously refresh the efficiency of bridge construction。

The world's highest level of intelligence

Heavy-duty self-propelled cutter suction dredger

“Tiankun”

“Tiankun”It is invested and jointly designed by Tianhang Bureau.、China's first independent research and development ship built by Zhenhua Heavy Industries、A green environmental protection with completely independent intellectual property rights、High-efficiency intelligent heavy self-propelled cutter suction dredger。“Tiankun”Successfully launched on November 3, 2017,It was officially put into production on March 12, 2019.。“Tiankun”It is to practice the strategy of marine power.,Respond“The Belt and Road”Initiative,To enhance China's competitiveness in the international high-end dredging market“A great power weighs heavily”,It is to break the technical barriers of one hundred years.,Have completely independent intellectual property rights,Realization“The national ship is made in China”A master of。

The largest in the world、The first ship in China

Dual-fuel power system trailing suction hopper dredger

“New Sea sturgeon”Wheel

It is invested by Shanghai Navigation Bureau、General conTractor of Dredging Technology Research Center、Built by Zhenhua Heavy Industries“New Sea sturgeon”The total length of the wheel is 155.7 meters、Profile width: 32m、Depth 13.5 meters,The maximum capacity of the designed mud tank is about 1.70,000 cubic meters,Configure 1550 cubic metersLNGAmphora。“New Sea sturgeon”The wheel not only has automatic tracking、Dredging control、Whole ship power management and other functions,It also installed the most advanced equipment in China.、The most intelligent“Dredging with one key”And“Dredging and driving in one”System,It is the first time to realize typical working conditions in China.“No one dredges”Function。At the same time,The ship is equipped with an integrated intelligent management platform.,Integrated intelligent cabin、Intelligent navigation、Intelligent energy efficiency management and other systems,Effectively improve the intelligent management level of the whole ship。2024,“New Sea sturgeon”The ship was delivered smoothly,Opened our countryLNGThe prelude to the application of clean energy in dredger,It marks the green development of China's dredging industry.、It is at the forefront of the world in the application of environmental protection and energy saving technologies.。

The world's first integrated vessel for immersed tube transportation and installation

“Yihang Jin'an 1”

“Yihang Jin'an 1”It is the world's first immersed tube transport and installation integrated ship developed and invested by the First Navigation Bureau.,It is also the largest installation capacity in the world、The sinking accuracy is the highest、Most efficient construction operation、The most advanced special ship for the construction of submarine tunnel immersed tube。

The ship is of catamaran design.,Captain 190.8 meters,Width: 75m,Depth 14.7 meters,The deck is the size of two football fields.,Undocking of immersed tube collector、Floating、Installed as a whole,Have“Functional integration、Integrated ship management、The structure is integrated、Power integration”Characteristic,Rapid undock of that immersed tube is realize.、Safe floating、Integration of comprehensive operations such as precise positioning and sinking installation,It further consolidates China's leading technological advantage in the field of immersed tunnel construction in the world.。

The largest in the world、Most advanced

Self-elevating gravel-laying and leveling vessel

“Yihang Jinping 2”

“Yihang Jinping 2”It is developed by the First Navigation Bureau.、Set datum positioning built by Zhenhua Heavy Industry Co., Ltd.、Stone conveying、High-precision laying and leveling、Quality inspection and acceptance functions in one of the world's largest、State-of-the-Art Jack-up Gravel Laying and Leveling Vessel。The ship was launched on 9 April 2019.,Delivery on November 18。

The captain 98.7 meters,Width 66.3 meters,Depth 6.5 meters,Total length of pile leg: 75m。The ship functions as an undersea Paver.,Precise positioning through the riprap tube,Debris is thrown into the seabed and paved,Maximum working water depth: 40m,Gravel laying and leveling range of single ship position is 2500 square meters.,Speed up to 5 meters per minute,The laying accuracy of pipe section foundation bed shall be controlled within plus or minus 4 cm.,It is known as deep-sea leveling operation.“3DPrinter”。

World's Largest 12000 Tons

Fully slewing crane vessel

“Zhenhua 30”

“Zhenhua 30”It is a 12000 ton self-propelled full-rotary crane ship independently developed by Zhenhua Heavy Industries.,It is also the largest single-arm full-slewing crane in the world.。The captain 297.55 meters,58 meters wide,It has a fixed lifting capacity of 12000 tons of single boom and a lifting capacity of 7000 tons of 360-degree full rotation.,It is equivalent to lifting 60 Boeing 747 aircraft at the same time.,Have“Hercules of the sea”Known as。The ship is mainly used for large items at sea.、Module、Hoisting of jacket,Install Large Module Job、Salvage operation、Dismantling the scrapped platform、Subsea Energy Development Operation。

The highest Pile Frame in the world、Maximum pile lifting capacity

140-meter class pile driving ship

“One Hangjin Pile”

“One Hangjin Pile”It is invested and developed by the First Navigation Bureau、Built by Zhenhua Heavy Industries,The highest Pile Frame in the world、Most capable of lifting piles、Maximum pile driving length、Largest pile diameter、Special pile driving vessel with the strongest ability to resist wind and waves。

“One Hangjin Pile”Achieved a number of pioneering innovations:One is the power source for construction operations.——Hydraulic system,Full power for the first time“One button start”Convenient operation,More intelligent and environmentally friendly;Second, it is the first time to adopt all-electric auxiliary propulsion.,It can realize omnibearing flexible ship moving and azimuth adjustment.,It really realizes intelligence.、Number、Green pile sinking operation。Mainly used for large pile foundation、Pile group foundation、Wind power jacket pile、Wind power single pile construction, etc.,At a large port、A bridge across the sea、Offshore wind power、Play a mainstay role in the rapid construction of artificial islands.,It belongs to the field of hydraulic construction in China.“A great power weighs heavily”。

World's Largest Tower Crane

R20000-Model 720 crane

R20000-The 720 crane is the world's largest Tower Crane jointly developed by the Second Navigation Bureau.,It passed the inspection in Changde, Hunan on April 20, 2023.,Officially offline,It is used for the construction of the world's largest span three-tower steel truss cable-stayed bridge, the Maanshan Yangtze River Highway and Railway Bridge on the Chao-Ma Railway.。

The rated lifting moment of the Tower Crane is up to tons of meters 20000.,Maximum lifting capacity is 720 tons.,Maximum lifting height 400m,It took only 8 months from design to offline.,Create a miracle of construction speed of super-large Tower Crane equipment。

The largest in the worldTons 12000/Bucket wheel bulk Stacker

2014,12000 tons independently designed and manufactured by Zhenhua Heavy Industries/Bucket wheel bulk Stacker,Dwarf arc type rotary trolley,Turning radius 50m,Maximum capacity up to tons 14500./Time,It has broken the international monopoly of large Stacker-reclaimer with a production capacity of 10000 tons.。

The bulk Stacker is designed to be large.、Automation is the goal,Several key technologies have been adopted to meet the operation requirements.。The reasonable design of the double-track cart solves the problem of difficult arrangement of the main machine caused by too many monorail wheels of the super-large reclaimer.。Application of the technology of guide chute without buffer bed,It is ensured that in the absence of a buffer bed,,The damage of the material to the ground belt and idler is reduced to the same effect as that of the buffer bed type.。To be safe、Intelligence、The efficient unmanned operating system provides users with an efficient and reliable mode of operation.。The special design of the steel structure section avoids the deformation of the components during transportation.,Further open up the market of large-sized storage yard equipment in mines。

The largest in the world at that time

Jack-up wind pow installation platform

Wind power installation vessel“Longyuan Zhenhua 3”

2000t wind power installation ship“Longyuan Zhenhua 3”It is a large-scale offshore equipment hoisting independently developed, designed and manufactured by Zhenhua Heavy Industries.、Wind power construction platform integrating piling and installation of wind power equipment,It was officially put into production on May 18, 2018.。

The captain is 100.8 meters,Width 43.2 meters,Deep 8.4 meters,Leg length: 85m,It can operate in the sea area with a depth of 50 meters.,Maximum lifting weight of double hook is 2000 tons.,Maximum lifting height 120m,Its lifting weight and lifting height were the first of similar platforms in the world at that time.,It is the key weapon for China's offshore wind power operation to move from shallow sea to offshore.。

The first heavy self-propelled cutter suction dredger in Asia at that time

“Sky Whale”

“Sky Whale”The dredger is invested by Tianhang Bureau.,The first heavy self-propelled cutter suction dredger built by China,When completed, it ranked first in Asia.、Third in the world。Construction commenced on 28 April 2008,Delivery in Shenzhen on January 19, 2010。

“Sky Whale”Total length 127.5 meters,Profile width: 23m,Six meters deep,Design speed 12 knots,Total installed power is kilowatts 20020.,Maximum excavation depth: 30m。The ship was equipped with the most powerful excavation system in Asia at that time.,The power of the cutter reaches 4200 kilowatts.,It was also equipped with the most advanced integrated automatic dredging control system in the world at that time.。Since it was put into production,“Sky Whale”Successively in the major coastal ports in China、Major national projects and“The Belt and Road”Played an important role in the construction.,Be known as“Meritorious ship”。

Largest flagship trailing suction hopper dredger in Asia

“Junyang 1”

“Junyang 1”It is the flagship trailing suction hopper dredger with the largest capacity in Asia invested and built by Guangzhou Navigation Bureau.,It has the most advanced automatic control system in the world and the ability to navigate in the global unlimited navigation area.,It can dredge about 20000 cubic meters of mud per hour.,The maximum excavation depth is 90 meters.,It is well deserved“Sea Big Mac”。The ship was officially put into production in October 2016.。

Since putting into production,“Junyang 1”Participated in the construction of Colombo Port City Project in Sri Lanka、Kuwait Oil CompanyLNGDredging works、Deepwater Channel Widening Project of Guangzhou Port、Zhanjiang Port 300,000-ton Sea-going Channel Project and other key projects,For service“The Belt and Road”Building and promoting the economic and social development of the Guangdong-Hong Kong-Macao Greater Bay Area has contributed wisdom and strength.。

Hydraulic hammer with the largest striking energy in China

“MHU3500S”

Hydraulic Hammer with the Largest Strike Energy in China in 2020MHU3500S,Its unique double-acting hydraulic circuit principle,The application efficiency of the hydraulic energy in the piling operation is greatly improved。MHU3500SIntegral forging type used 7.5 m diameter substitute,First application in China,Structural design improved by the Third Harbor Engineering Bureau,Reduce the energy loss of the whole substitute beating,At that same time, the substitute weight is reduce.。The equipment has successively participated in the construction of Pingtan Dalian Offshore Wind Power Project of CGN.、Three Gorges New Energy Guangdong Yangxi Shaba Offshore Wind Power、Pile foundation construction of offshore wind power projects in Yangjiang, Guangdong。

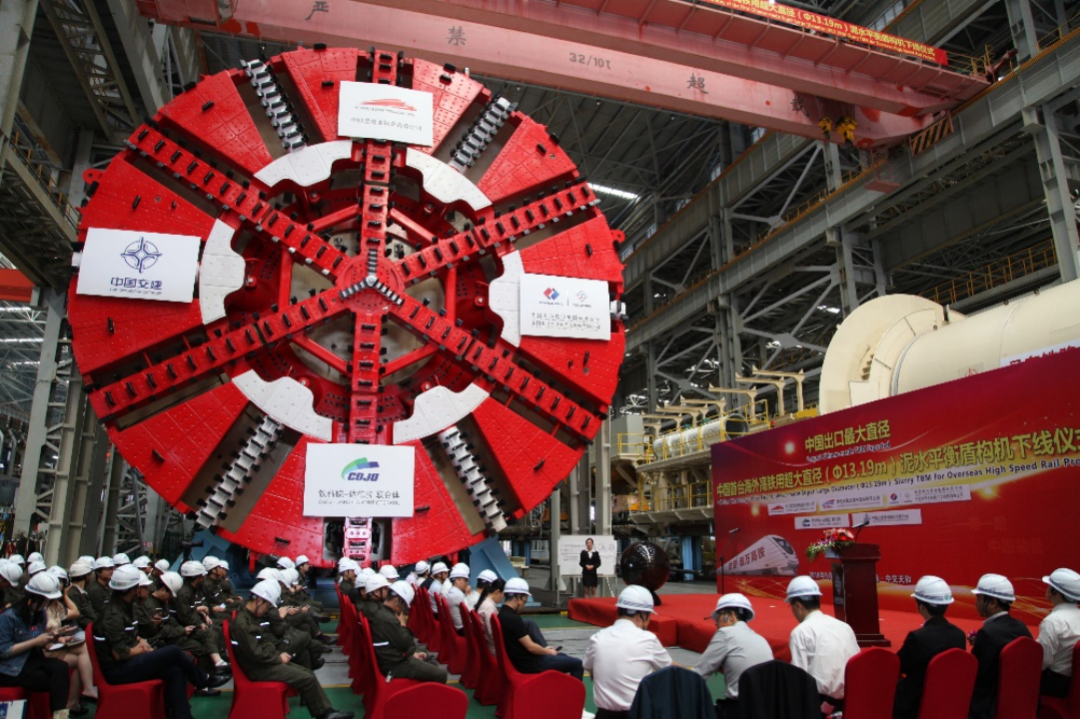

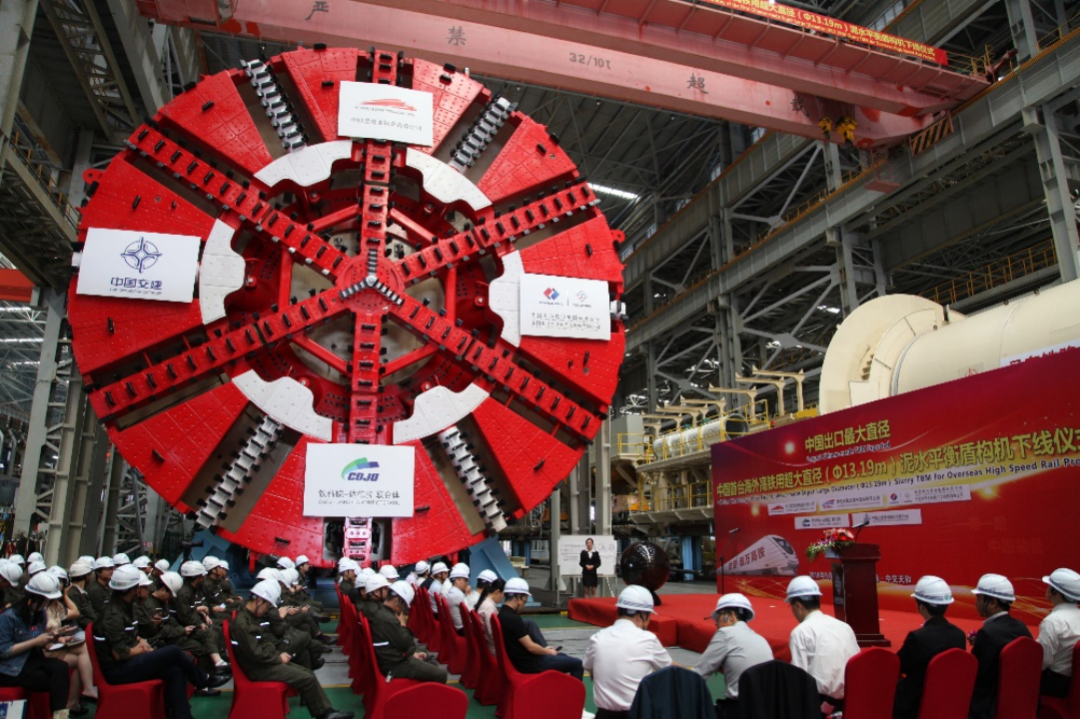

At that time, China exported the largest Shield Machine overseas.

No.1 Tunnel Shield Machine of Jakarta-Bandung High-speed Railway

The No.1 tunnel Shield Machine of Yawan High-speed Railway was the largest diameter Shield Machine exported overseas by China at that time, which was independently developed by China Jiaotong Tianhe.,It was also the largest diameter slurry pressurized balanced Shield Machine in Southeast Asia at that time.。The Shield Machine is used in the construction of No.1 tunnel of the first high-speed railway in Southeast Asia.。

The diameter of the cutter head of the Shield Machine is 13.19 meters、About 101 meters long、It weighs more than 2600 tons.,Application of settlement control、Layered backwash、Ultra-large diameter Shield Machine ultra-long distance tunneling without changing cutter、Tool wear real-time monitoring and many other advanced technologies in the world,Among them, the ultra-large diameter Shield Machine does not change the cutter for ultra-long distance tunneling.、Tool wear real-time monitoring technology is the world's first technology。