August twenty seventh,《Science and Technology Daily》Front Page Headline Special Topic Focuses on Technological Innovation of Railway Construction Heavy Industry:“Add another gold medal for Made in China”——Birth of the Main Bearing of the World's Largest Diameter Shield Machine。The full text is as follows:

“Add another gold medal for Made in China”

——Birth of the Main Bearing of the World's Largest Diameter Shield Machine

【Innovation story】

◎Newspaper reporter Correct Yang Sun Yu

Cross the mountains and rivers,Dig the earth and drill the rock……In the tunnel construction of large projects,,The Shield Machine has become indispensable“A magic weapon”。The Shield Machine is able to“Nibble”Under the hard stone,The cutter head is driven by the main bearing.,This is also the safe and reliable operation of the equipment.“The gate of life”Where。

Shield Machine with a diameter of 18 to 20 meters,Can meet that maximum demand of known project,The matching main bearing diameter specification is 8.61 meters。July 2019,China Railway Construction Heavy Industry Group Co Ltd(Hereinafter referred to as“Railway Construction Heavy Industry”)Establishment of 197 Research and Design Institute,Determined to overcome this difficulty。

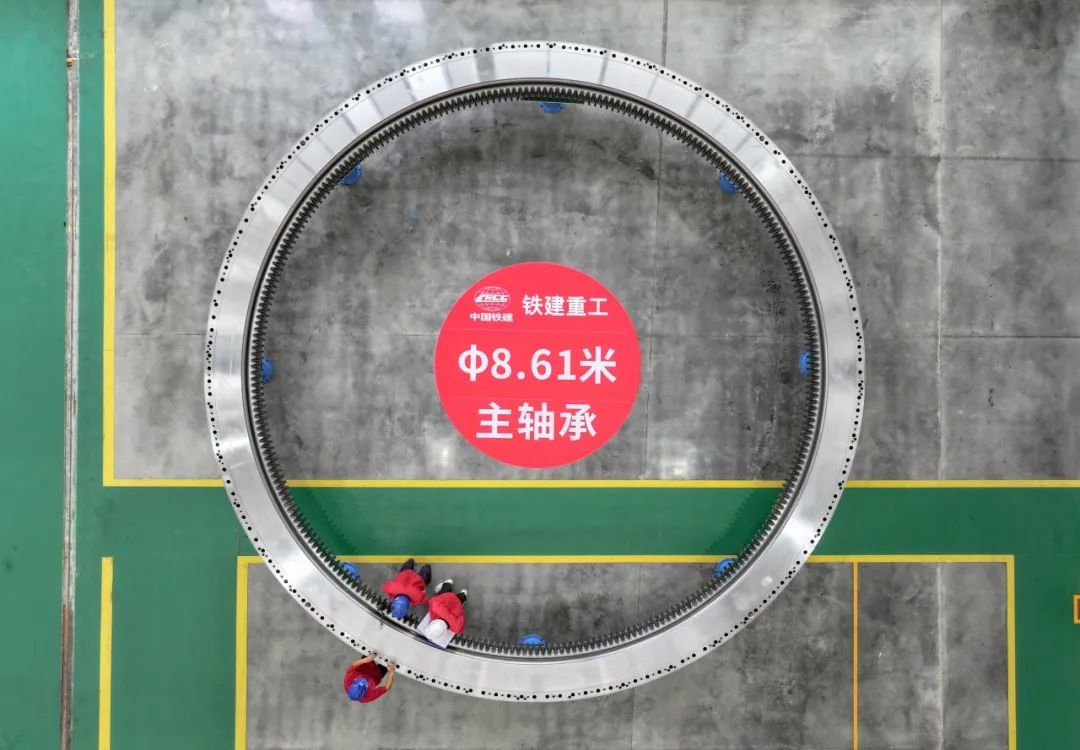

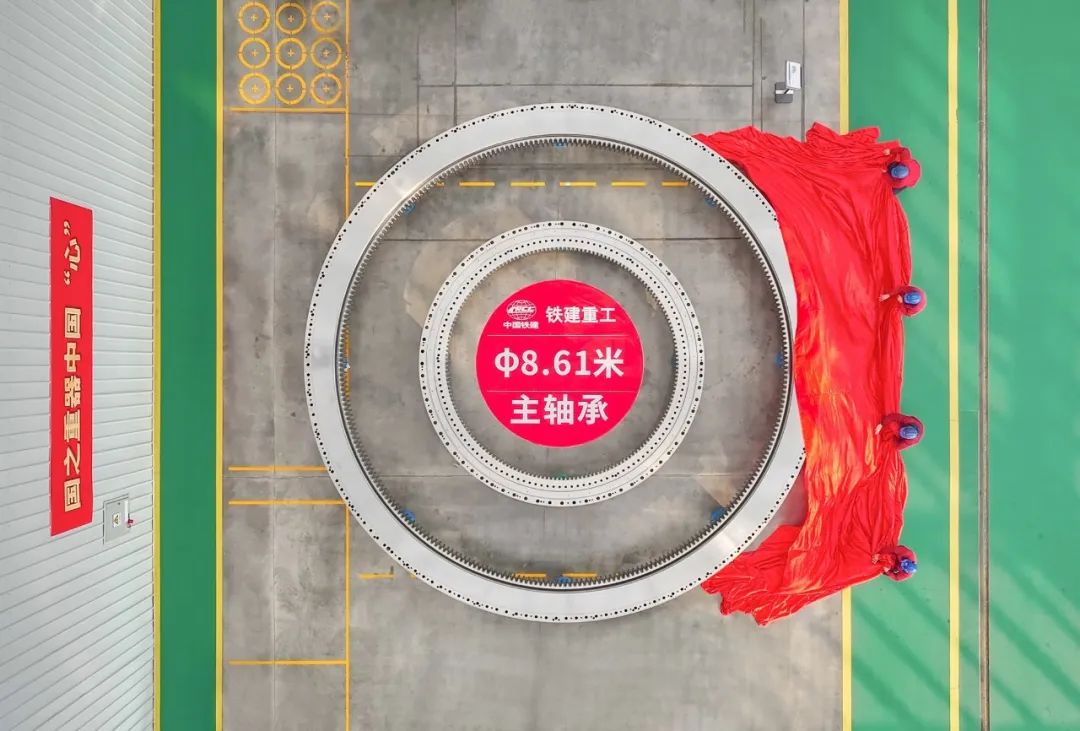

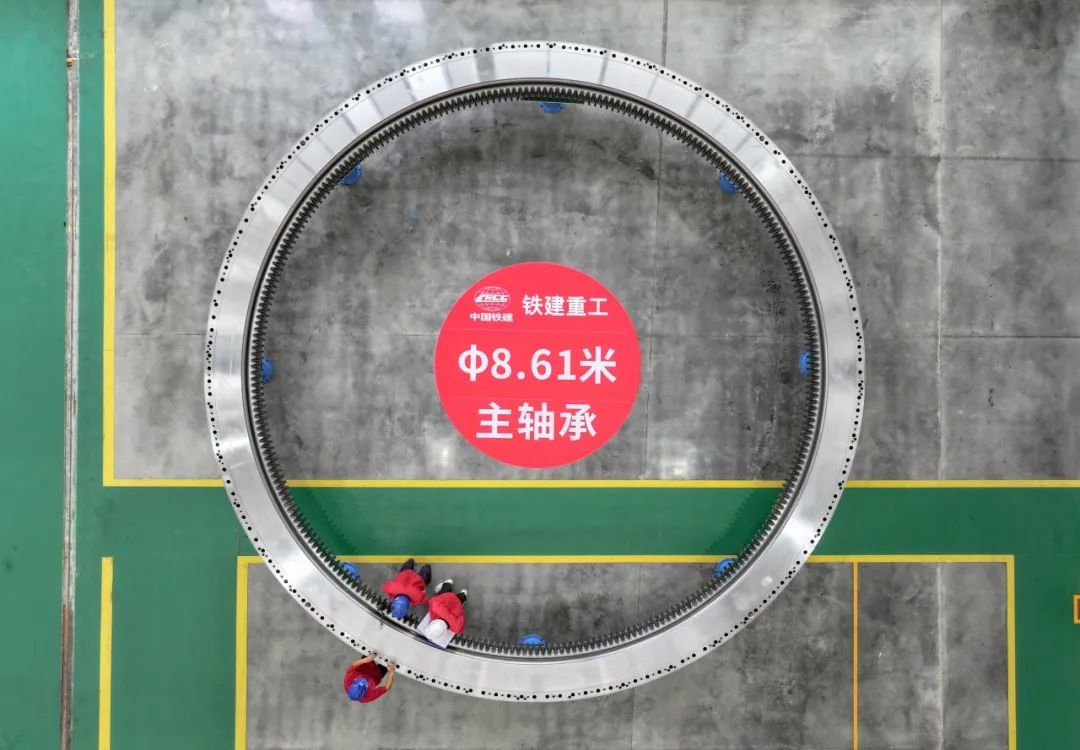

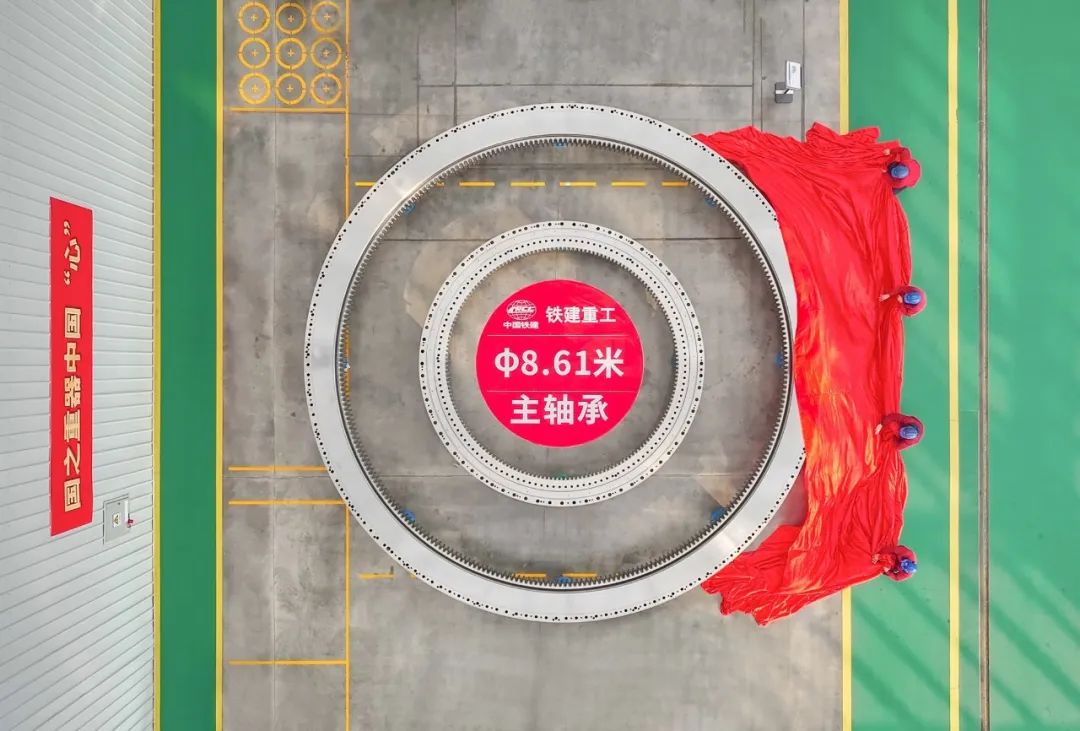

Four years later,Diameter 8.61 meters、It weighs 62 tons,Largest diameter in the world、The monomer is the heaviest、Main bearing of Shield Machine with the highest bearing capacity is launched。The other day,In an interview with a reporter from Science and Technology Daily,Ma Chengbiao, president of 197 Research and Design Institute, said proudly.:“From material to process to design verification,We have realized the independent production of the whole process of the main bearing of the super-large Shield Machine.,Add another gold medal for Made in China!”

“Practice the ancient swordsmanship‘Golden Bell Jar’”

“In the process of shield tunneling,8.The 61m main bearing must withstand the heavy load.、Large partial load、The test of extreme working conditions such as variable frequency load。”Ma Chengbiao said,“So,It has to be enough‘Hard’。”

Materials and processes,It's enough to make“Hard”The first checkpoint of the bearing。

“Take the ring gear of the main bearing as an example.,It requires a Rockwell hardness greater than 58.、Ring layer with thickness not less than 8 mm,In order to withstand the load of more than 10000 tons.。”Xie Jindong, head of manufacturing technology of R & D team, told Sci-tech Daily.。

Main bearing of the world's largest diameter Shield Machine

This 8 mm layer.,Xie Jindong likened it to an internal gear ring.“Golden Bell Jar”,If the main bearing is trained, it will not be crushed.、The key to not grinding kungfu。However,At that time, the conventional quenching process of medium carbon bearing steel in China could only reach Rockwell hardness of 55.、Surface hardening depth 5 mm。

“Hardness and thickness per unit increase, All ‘Difficult to go up to the sky’。”Xie Jindong said,The bearing steel material contains more than 20 formulation elements。These elements interact with each other.,Proportioning needs precise control,Each deployment is on the order of one thousandth.。

R & D Team Joint Iron and Steel Enterprise,After dozens of technical discussions and tests,Finally, a steel standard suitable for the manufacture of large diameter main bearings was found out.。

The material is available,Quenching process must be broken through。

Because of its size,Integral Quenching Process of General Bearing,Cannot be copied to 8.On 61m main bearings,Only surface hardening can be used.。How to ensure quenching hardness、Depth and uniformity,Become a big problem。

R & D personnel constantly adjust their thinking,Local quenching、Multiple quenching……However,Although these methods improve the quenching depth,,But it brings new problems.——Temperature mutual interference in local crossing area。

Go over and over again、Many rounds of tests were fruitless.。

By chance.,Xie Jindong was looking through the relevant materials.,From“Goujian Sword, King of Yue”Manufacturing process——“Cover the soil and burn the blade”Get inspiration from it:Using the soil as a medium,It can perfectly solve the problem of uneven temperature in quenching area.。

“We used the ancient swordsmanship to practice.‘Golden Bell Jar’。”Ma Chengbiao said,The R & D team takes this as inspiration.,A new high temperature resistant medium has been successfully developed.,The problem of temperature interference is solved.。

“Why not the grinding wheel‘Do something’”

The hardness is up to standard,The next step is to precisely control the flatness.。

The floating ring is the core component of the main bearing.,The rollers of the main bearing will constantly crush the high points of its inner wall.。“In the long run,Parts will be crushed, Cause ‘A dike of a thousand miles collapses in an ant hole.’。”Ma Chengbiao explained,The inner wall of the floating ring must be sufficient“Ping”。

Compared with the main bearing with a diameter of 3 meters previously developed by China Railway Construction Heavy Industry,8.61m main bearing weight increased by about 8 times,The circular area of the inner wall is increased by nearly 9 times。“However, the control requirements of flatness cannot be lowered.,Still less than 20 microns.。This is equivalent to no more than one wall undulation.A4 One fifth of the paper thickness。”Ma Chengbiao said。

“Just started,The floating ring we developed can not meet the design requirements all the time.。”Xie Jindong introduced,Due to the thin floating ring、Large area,After a long time of processing and adjusting its flatness,,The big circle with uniform curvature is like a plate.“Throw the noodles”,There is a distortion visible to the naked eye.。

Experts have consulted many times on the spot.,Finally found out“Cause of disease”——Grinding wheel for dressing flatness,Long time with floating ring、Large area contact friction,As a result, the latter is heated too high and deformed.。

We must try to lower the temperature.!Spray water for cooling、Change one-time processing into multiple processing……Many ways have failed.。

“Since the contact surface with the grinding wheel is large,Why not the grinding wheel‘Do something’?”Someone had a sudden idea。

Just do it.!Research and development personnel carefully study the working mechanism and trajectory of the grinding wheel.,Great efforts have been made to adjust the shape of the grinding wheel.。“While reducing the contact area,We need to make sure that the grinding wheel's trajectory covers every part of the inner wall.。”Xie Jindong said。

Adjust the shape again and again、Test verification,The team finally designed a new shape of the grinding wheel.,The floating ring meeting the requirements of flatness was successfully processed.。

Grinding wheel modification is only a part of many manufacturing processes.“The tip of the iceberg”。The R & D team has also conquered cold processing successively.、Tempering、There are more than 20 kinds of manufacturing process problems, such as residual stress balance.,Initiate“Deformation control of super-size thin-walled ring after quenching”“High precision grinding”“High hardened tooth surface hard milling”And other technologies。

“Design method based on data backstepping”

In order to adapt to complex working conditions,Each Shield Machine must meet the requirements of the project.“Tailor-made”。This also means that the main bearings have to be built on demand。

“Before,We can make the main bearings.,But you can't design.。”Chen Haolin, a technician at the 197 Research and Design Institute, told reporters.,Design related to each adjustment of the main bearings,The data need to be sent to foreign manufacturers for verification.,The cycle lasts for more than two months.。

“Don't say for a long time.,Foreign businessmen will raise prices proportionally every year.。”Ma Chengbiao said,Tackling key problems 8.61m main bearing start,The R & D team made up their minds.,“Independent design must be realized.。”

“We're making it、While groping。A component has been built.,The design method is deduced by using the test data.。”Ma Chengbiao introduced。

This is undoubtedly a difficult process.。

The world's largest Shield Machine production base

One time,Process is stuck on a critical calculation formula。“Designers are dizzy with calculation.,Still doesn't match the test data.。”Chen Haolin recalls,Everyone seems to have walked into a road.“A dead end”。

R & D personnel study day and night.,The eyes finally focus on the parameters of the formula.。4 sets of parameters,More than 200 combinations in each group,After more than 800 calculations and adjustments……After determining a series of parameters,,The calculation formula was successfully demonstrated.。

In order to analyze the calculation results,,The team also used a large amount of construction experience and data accumulated by Railway Construction Heavy Industries for many years.,The simulation model is constructed.。

“Through theoretical calculation and simulation analysis,We have successfully developed a special design and simulation software for main bearings.,Realized‘Engineering theoretical calculation+Simulation analysis+Working condition simulation test+Engineering application verification’Closed-loop design verification system。”Chen Haolin said。

On this basis,Tiejian Heavy Industry has also set up the world's largest comprehensive test bed for simulating the working conditions of main bearings.,It solves the worldwide problem that large low-speed and heavy-duty main bearings are difficult to test and verify.。

World's Largest Diameter Shield Machine Main Bearing Offline Site

October 2023,Domestic 8.61m main bearing successfully rolled off the production line,It marks that China Railway Construction Heavy Industry has broken through the material.、Craft、Design、Verification of four major technical problems,Achieve a diameter of 3 meters to 8..61m main bearing product spectrum design and manufacturing full coverage、Nationalization。

“The Third Plenary Session of the 20th CPC Central Committee,‘Strengthen overall planning and tackle key core technologies’And‘Strengthening the dominant position of enterprises in scientific and technological innovation’。This makes everyone more confident.、More power。”Ma Chengbiao said,“Future,We will be based on cracking‘Stuck in the neck’ Problem ,Continue to promote the localization of high-end bearings、Industrialization,Polish up the business cards made in China.!”