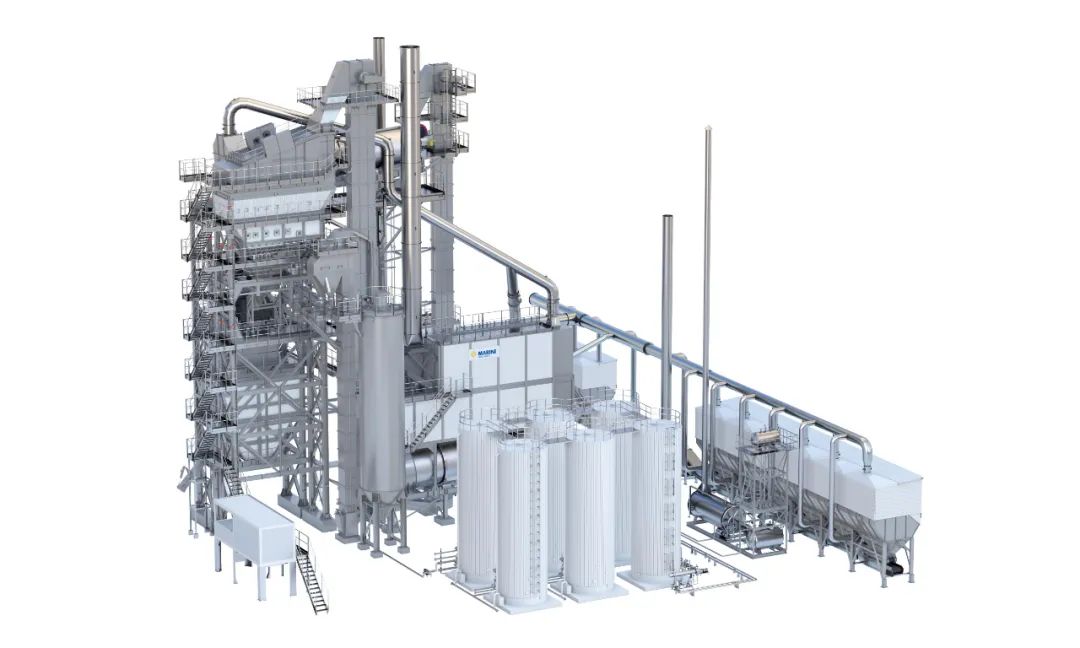

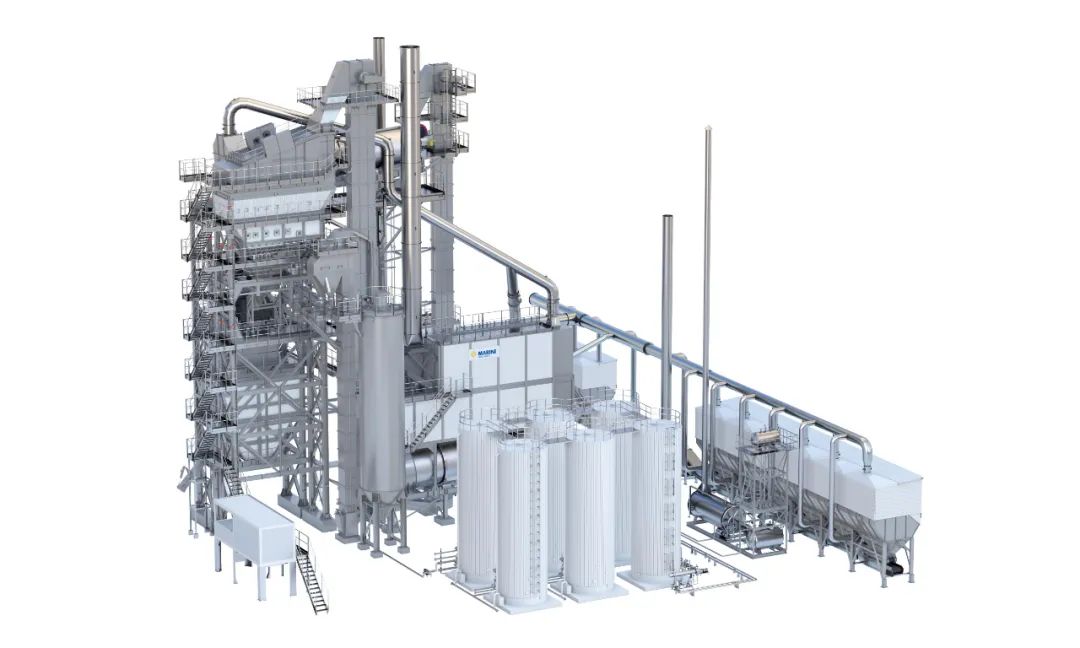

In recent years,Tidy、Environmental protection、Orderly、Intelligence、Efficient,Become ImalenniFRTIt is a true portrayal of the intelligent production base of new material asphalt mixture, which is mainly constructed by the plant-mixing and Recycling Machine.,Changed the past pungent、Clutter、Roar,Traditional asphalt production“Stereotype”。RAP(Old recycled asphalt material)Reuse significantly reduces CO2 emissions、Consumption of asphalt and stone resources,MarleneFRTThe hot selling of products in the Chinese market confirms that Malini's technology is in line with the current concept of low-carbon road in China.。

MarleneFRTPlant mixing and recycling integrated asphalt mixing station,It was Malini who introduced the advanced recycling technology of old asphalt materials from Europe.,Aiming at the special requirements of the plant-mixed hot recycling of the current asphalt mixing fixed station,Specially developed Asphalt Mixing Plant,Lay particular stress on the addition of plant-mix hot recycling of old asphalt。The process of such equipment and the traditional asphalt master station+Same combination of regenerating equipment,But the structure has changed a lot.,Therefore, it is widely called the plant mixing and Recycling Machine in the market.。

01

Ensure production capacity Easy to add

While ensuring the production capacity of raw materials,Is more convenient for the addition and production of the old asphalt material

02

Add vertically Avoid sticky materials

The old asphalt is added vertically into the mixing pot.,Reatly reduce the sticking problem of the old asphalt material

03

Reduce wear and tear Lower the altitude

Effectively reduce the wear and tear of old asphalt on equipment,Reatly reducing the overall height of the plant-mixing regeneration equipment

2016,Maleny launched the first set of recycling all-in-one machine in China(FRT360),Since then, the concept of Recycling Machine has been gradually accepted by the market.。Due to the high market popularity of the product,Therefore, the product and its concept have been imitated by many manufacturers.。In early 2023,Malani has sold more than 60 sets of Recycling Machines in China.,It has become one of the most mature manufacturers of asphalt plant-mixing and Recycling Machines in China.。

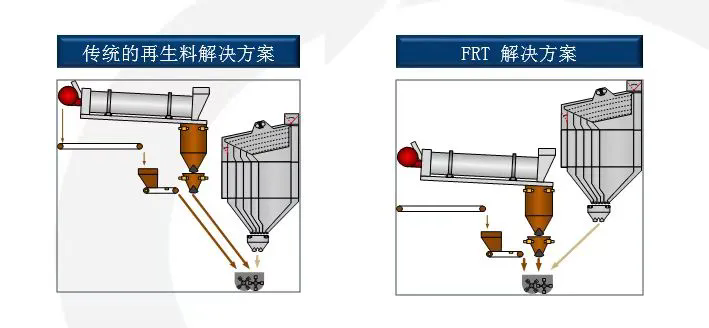

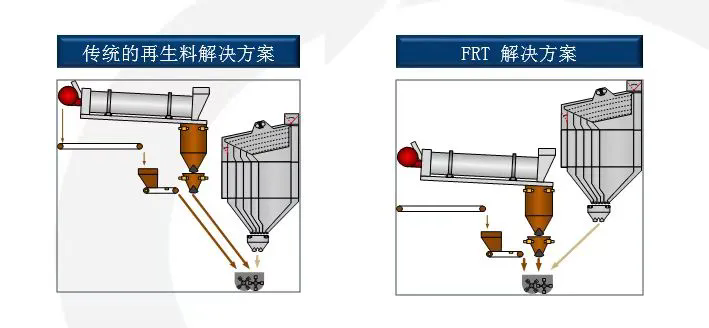

FRTThe biggest feature of the series is to translate the position of the mixing pot to the bottom of the regeneration parallel drum.

The design principle is shown in the figure below.:

FRTThe arrangement form abandons the traditional structure of feeding the boiler through a chute or a belt.,Tructurally avoiding heatedRAPMaterial adhesion problem,Meanwhile, the overall height of the Asphalt Mixing Plant is reduced。

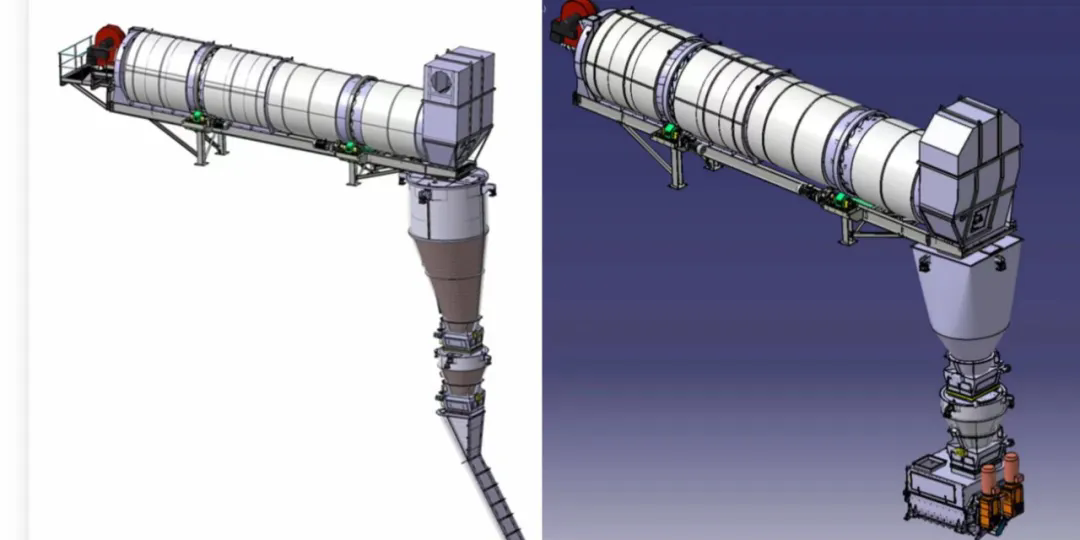

The frame of Asphalt Mixing Plant is designed as a whole.,There is no staggered layer at the overlapping position of each module.,One step in place,The sticky material of the heating recycled material is avoided from the structure.、Blockage and other problems,Measures such as spraying of anti-sticking agent in the chute to prevent sticking and blockage have also been banned.。Improves the metering precision and the adding proportion of the recycled material,Better control of finished material quality。The overall equipment is more environmentally friendly、Energy saving。

In order to better distinguish between the two structures,After 2017, the traditional original is widely used in the market.+Regeneration equipment is called split machine.,And putFRTThe structure is called an all-in-one machine.。Since then, the name of the plant mixing and Recycling Machine has become popular.。

There is no difference between the production functions of the two kinds of Asphalt Mixing Plants with different structural characteristics.。However, the split machine is produced every time.,The regeneration chutes need to be checked and cleaned,Otherwise, it is easy to cause blockage of the chute,Cause the equipment to be unable to be used normally。But also due to the inherent characteristics of recycled materials,,Very easy to stick when heated,After cooling, it is tough enough and not suitable for removal.,Therefore, it must be operated while hot at the end of each production.,Due to the narrow location、The chute is long,Therefore, the operators are laborious.。

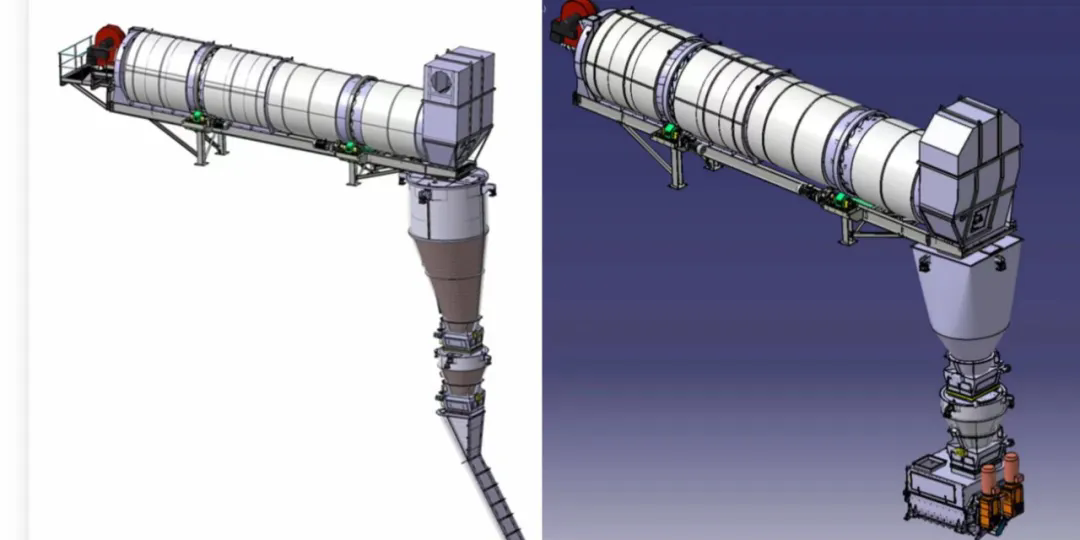

Design drawing of regeneration part of split machine design Design drawing of the regeneration part of the all-in-one machine

Photos of the reproduction part of the split machine Some photos of all-in-one machine regeneration

Obvious,The design of the all-in-one machine is more suitable for the production of plant-mixed hot recycling.。The split machine was designed in the 1990s.,All-in-one machine is the molding design after 2014.,There is a generation difference of nearly 20 years,The all-in-one machine is more advanced than the split machine in design.,It can be called an epoch-making product design in the field of asphalt mixing equipment.。

At present,Marini launched in ChinaFRTSeries plant mixing and regeneration integrated machine equipment,Already ownedFRT400/360/320 and many other models。Future,Malani will introduce more technologically advanced products into China.,Continuous innovation to meet the diverse environmental needs of Chinese customers,And through a comprehensive environmental protection strategy,Continue to unswervingly practice green、Low-carbon development concept,For“The carbon reaches the peak、Carbon neutral”Contribute to the realization of。