The oldest in Germany A 555 Expressway,A paragraph 2.5 km The long two-way road section has been completely renovated.。The total construction time is expected to exceed 18 Months。The main conTractor for the project selected the advanced Wittgen cold recycling process.,It replaces the traditional construction method.。

To avoid serious traffic congestion in the area.,At least two lanes need to be kept open to traffic。The hard shoulder was converted into a new HGV-only lane.,The maximum load class is BK100。Use traditional paving method,This will involve:Milling of all asphalt layer、Removal and cleaning;Stability of sub-base;Resurfacing asphalt base with sufficient load bearing capacity、A tie lay and a surface layer。

Ideal alternative in terms of saving resources

In traditional asphalt construction,,Spreading of new asphalt layer and transportation of materials by Truck to and from the construction site,Will produce a lot of carbon emissions.。And in A In this construction project of the 555 highway,,Wirtgen's cold recycling process shows great potential in reducing emissions. — KMA 240i Mobile cold in-plant recycling equipment,WithEvery hour High mixing capacity of 240 tons,Continuously produce asphalt stabilized materials for new base paving(BSM),Very little carbon emissions。

Due to the device's high flexibility and relatively small footprint,It can not only move the transition at any time.,Install in place near the construction site,But also that logistic link is better simplify.。In this way,A significant portion of the carbon emissions from the transportation of materials has been slashed.。STRABAG AG(Dylan, Germany (Düren) Division)Technical Manager Stephan Ehlers Express:“The plant-mix cold recycling process of Wirtgen Company is a very advanced operation mode.。”

KMA 240iMobile plant-mix cold recycling equipment can be installed in place near the construction site.,Produce for new BSM Mixture of base course。

KMA 240i Cold plant-mix recycling equipment adds foamed asphalt and cement to the recycled asphalt,Produce a layer for asphalt stabilization(BSM)Cold mix。Such a significant reduction in carbon emissions here.,The main reason is that the mixture is made by Wittgen cold recycling process.。Only the asphalt needs to be heated to 180 degrees.,A small amount of water and compressed air is then sprayed into the asphalt,The foamed asphalt can be produced in the foaming chamber.。That is to say,Energy-intensive heating of aggregate components or asphalt granules is no longer required。

“Use of bituminous stabilised material,Make our construction process more efficient and faster。Consider our commitment to climate neutrality by 2040,We have a great interest in promoting the knowledge learned from this project for future development.,Strive for more profits.。” Stephan Ehlers,STRABAG The technical team manager said.。

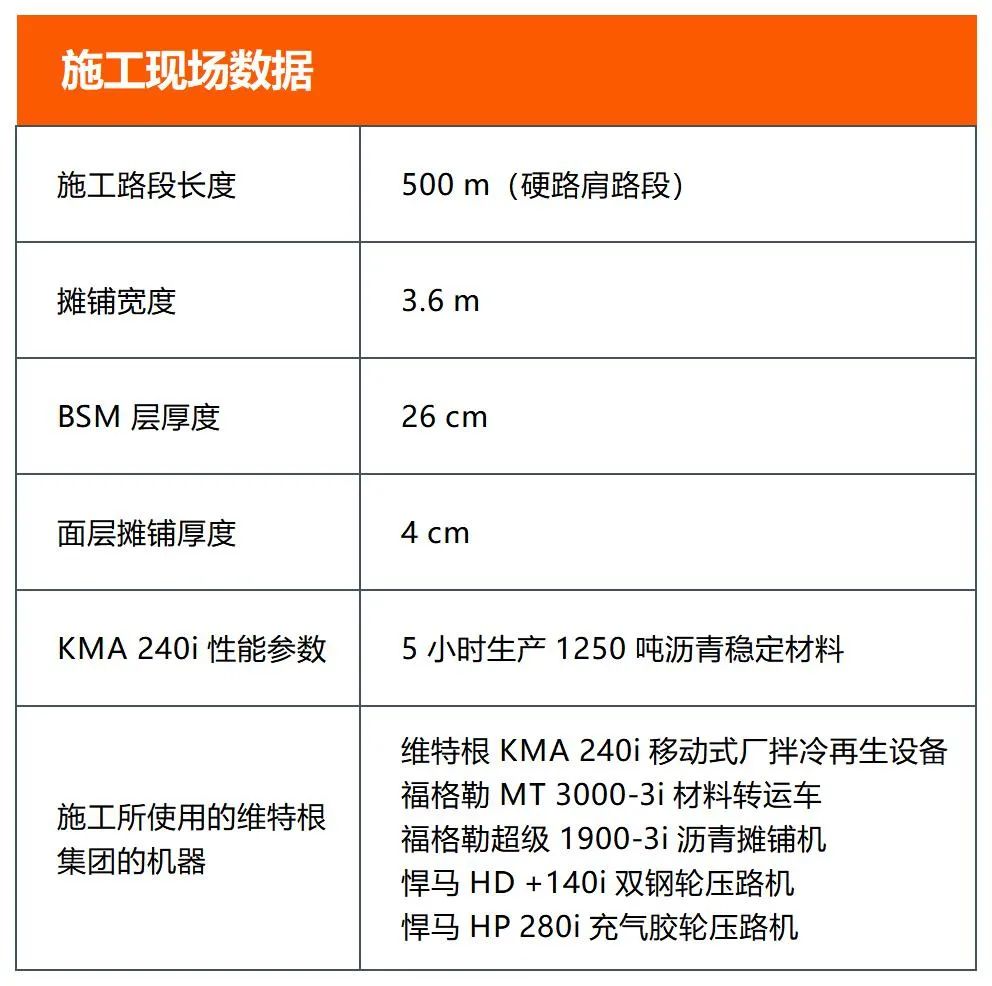

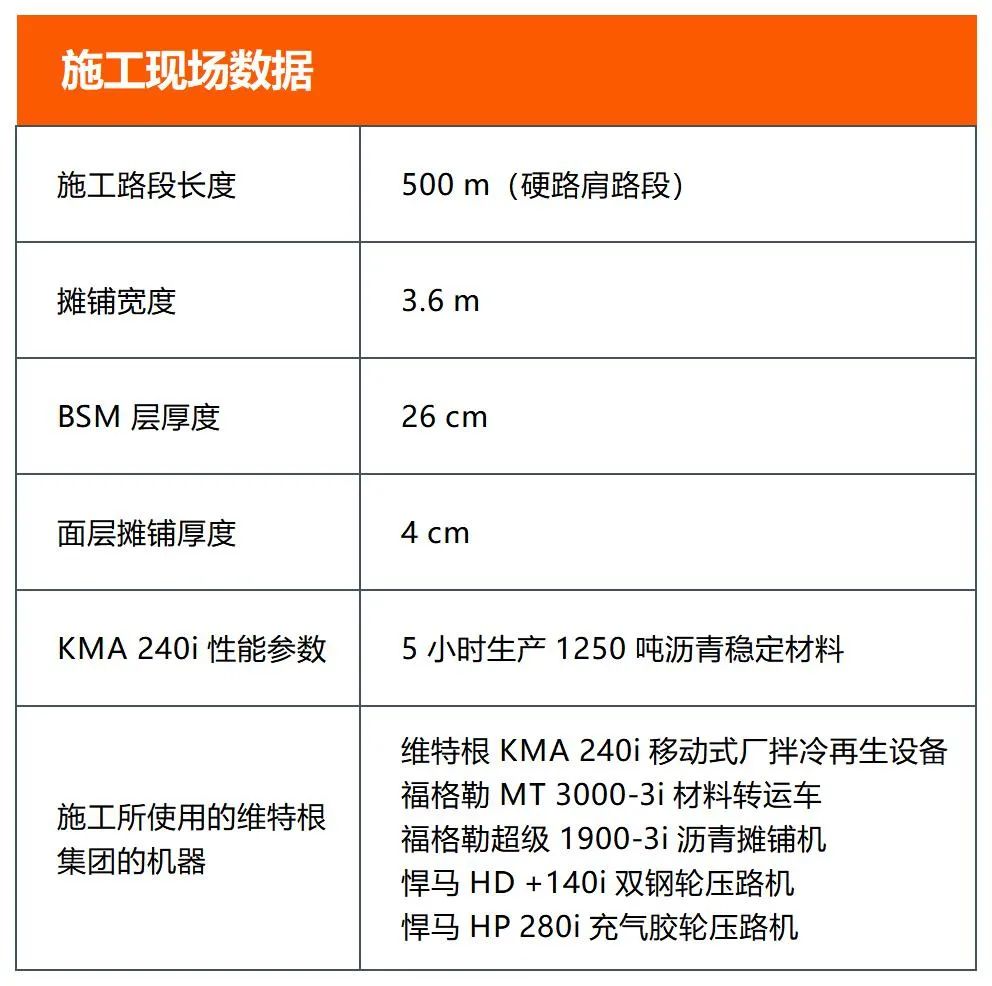

To achieve the desired degree of compaction,BSM The material shall be placed in two layers on top of the prepared sub-base。To ensure uninterrupted spreading,Fogler MT 3000-3i The material transfer Truck delivers the mixture continuously to the Super 1900 at the back-3i In the hopper of the Paver。Then the Paver is responsible for 3..6 m Pave the new base course on the working width。Paved first layer of cold recycled material,The thickness is 16 cm,Pave the second layer on the next day,The thickness is 10 cm。

Pass by ABAfter pre-compaction of the 500 screed,Each layer of cold recycled mixture uses Humvee. HD + 140 Tandem Roller and HP 280i Compaction by pneumatic rubber-tired roller,To obtain a good degree of compaction。This material meets all requirements established during preliminary testing at the job site.。The last process is to pave 4 on the asphalt stabilized layer. cm Thick new bituminous surface course (SMA 11 S)。

A Vogler MT 3000-3i The material transfer Vehicle is transferringBSMThe cold mix is delivered to the Super 1900 behind.-3i Paver

HumveeHD+Series double-drum roller ensures ideal compaction of cold mix,And then by HP280i Pneumatic tire roller for final seal treatment

BSM:Road building material with high quality and low price

BSM The mixture has been tested and verified in many countries and regions.,CanFor all load classes。BSMUsed worldwide on main roads and highway bases,This is nothing new.,It is also getting more and more attention and welcome in Germany.。Strabag AG(Dylan, Germany (Düren) Division)With the assistance of Wirtgen's own road materials testing laboratory,Yeah, near Cologne A The applicability of cold recycling mixture used in the new base of 555 Expressway is tested.。

When the ratio is appropriate,This material can handle all levels of traffic load.。The construction party has determined the addition of binder and aggregate in the preliminary test.。Reclaimed asphalt pavement adopts 25% Machine-made sand filled with fine material、1% Cement、2% Foamed asphalt and water,The components play an ideal synergistic effect,Form a sustainable mix with good performance。

BSM The mixture can also be stored,Make the logistics arrangement on the construction site more flexible:Construction personnel can produce in advance、Short-term storage、Use mix as required。This material is ready for paving,And is different from that traditional mixture.,There is no need to finish paving immediately in a short time.。

Advantages of cold regeneration at a glance:

Reduce material costs by up to 100 percent%

The use of Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicles can be reduced by 90 percent%

Reduce energy consumption by 90 percent%

CO2 emissions can be reduced by 60 percent%

The amount of binder can be reduced by 50 percent%

The total construction cost can be reduced by 50 percent%

Reduce construction time by up to 50 percent%