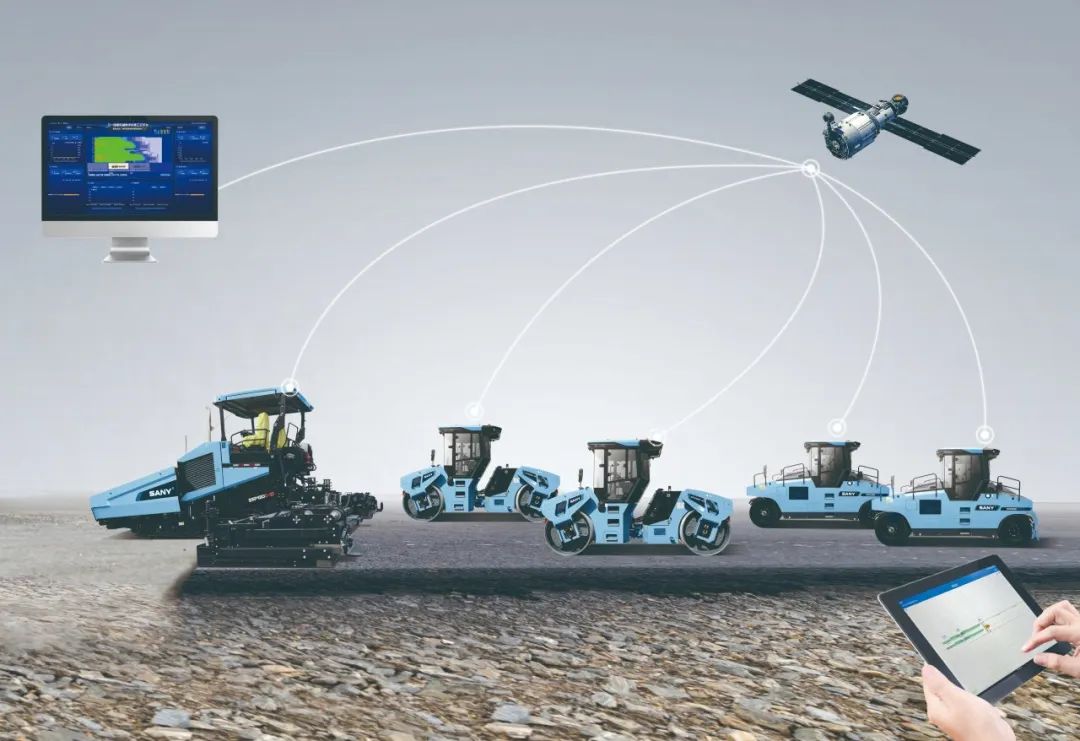

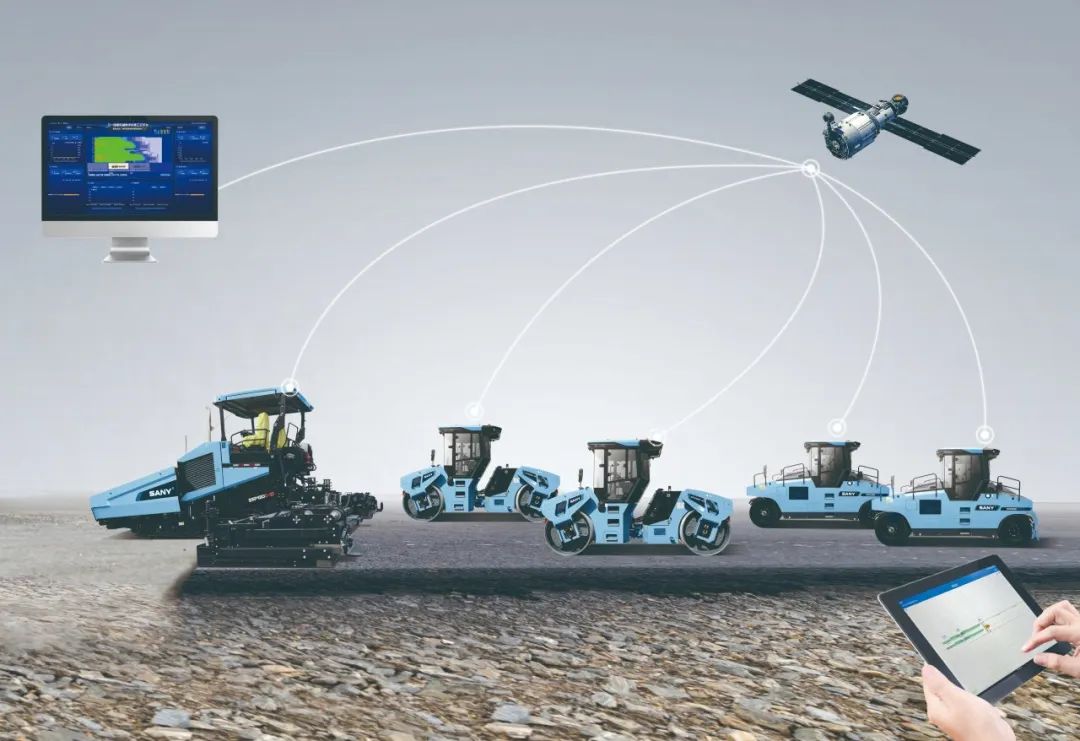

Leader of intelligent pavement construction

Product positioning

The Trinity Road UAV Group isIndustry initiativeComplete set of unmanned Road Machinery products,One-key construction,The quality is reliable,Safe and efficient, Applicable 90%AboveTypical scenario。

Product selling point

1

Unmanned driving saves people's worry.

Reduction of operator staff 60%:The spreading operation can be automatically completed without a driver.,One person, one tablet to control multiple devices,The numb of operators can be reduce by 60%Above。

One-click construction process:Collect road data,One-key automatic modeling,Start the unmanned spreading operation。

2

Strictly abide by the process to ensure quality

Quickly generate standardized jobs:Planning the path of the cluster strictly according to the process specification,Enter process parameters,Generate Standardized Jobs Now。

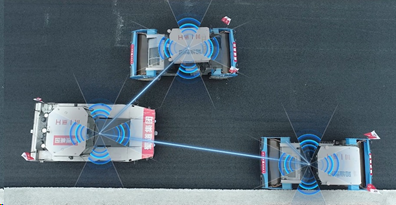

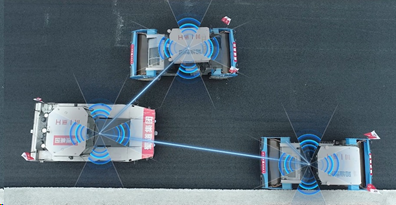

Collaborative scheduling:Based on the generated optimal path、Real-time status and construction schedule of the fleet,Achieve Real-time and Dynamic Cooperative Scheduling of Cluster。

3

Safety redundancy Escort

Triple safety protection:Obstacle avoidance with vision and radar fusion、Electronic fence、Multiple safety protection systems such as safety dispatching,Realize intelligent anti-collision,And that construction safety is ensure。

4

Day and night construction without fear of fatigue

Improve daily productivity 20%:Unmanned fleet,Reduce the number of operators,Can work for a long time,Increases daily productivity by up to 20 percent%。

Coordinated construction of 15 sets of equipment:Through the global co-scheduling technique,Up to 15 UAVs can be used for cooperative construction,And that construction period is shorten。

Technical features

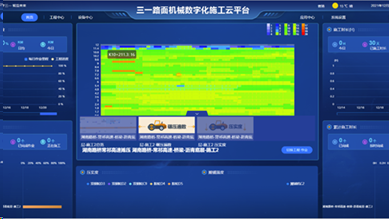

1、Global Cooperative Scheduling Technology

Automatically matching the optimal construction path based on road data,Determine the optimal cluster scheduling model;

Spread the task、Cooperative schedule control of cluster,Ensure high efficiency、Compact construction。

2、High-precision path tracking technology

Combined with Beidou high-precision positioning and precise control algorithm,Centimeter-level path trac of that cluster;

Through laser radar and vision fusion algorithm,High-precision real-time perception and positioning of road boundaries,Really realized“Zero”Welt rolling。

3、Group control security technology

It is equipped with intelligent perception obstacle avoidance system.,Automatic identification of obstacles ahead,Slow down or stop;

Roup path schedule planning of dispatch system,Control the safety coordination scheduling work among the equipment,Avoid mutual collision;

Automatically generate an electronic fence according to a map,Stop alarm if exceeding。

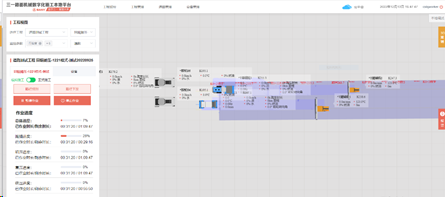

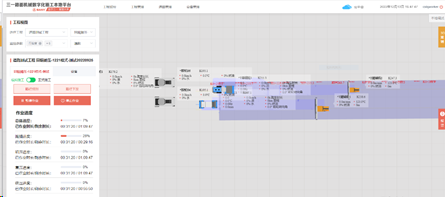

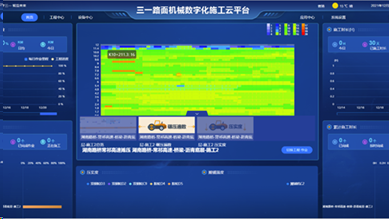

4、Digital management of the whole process

Provide work equipment、Project progress、One-stop management and control capability of construction quality,Realize the digital management of the whole construction process,Make construction management easier。

5、Full coverage of typical scenes

Widely used in highway、Municipal Road、Airport and other construction scenarios,Overcome the technology of unmanned tunnel construction,Achieved 90%The above scenario is covered;

Any combination of equipment operation,Change at any time,Construction process parameters can be adjusted at any time;

Including guided、Asphalt with yoke type、Water stable sectional type、Cross following and other spreading and pressing dispatching modes,Flexible adjustment according to the actual situation。

Economic value

Digital construction

Datamation、Online、Visualization、Easy to trace back。Precise control of millimeter-level leveling、Centimeter-level positioning、Centimeter-scale welt compaction。

Quality Assurance

Construction shall be carried out in strict accordance with process standard,Avoid overpressure、Undervoltage,Realize process control。

Security

Triple safety design,Support personnel、Safety of equipment。

Cost saving

Save people:Reduction of operator staff 60%Above;

Save material:Fuel and materials are saved;

Save time:Day and night construction,Increase daily efficiency by 40 percent%。

Explore the future direction of the industry

Change the construction mode with the help of science and technology,Greatly improve the quality、Efficiency,Leading the development direction of the industry。

Application case

Technical parameters

|

Project

|

Technical indicators

|

|

Positioning accuracy

|

≤2cm

|

|

Straight-path tracking accuracy

|

≤3cm

|

|

Maximum coverage distance of base station wireless communication network

|

3km(Intervisibility unobstructed environment)

|

|

Maximum number of devices for a job

|

15 sets

|

|

Wireless network communication delay

|

≤20ms

|

|

Personnel obstacle avoidance identification and positioning accuracy

|

≤15cm

|

|

Safety protection mode

|

Electronic fence、Active obstacle avoidance、Collaborative scheduling、Remote emergency stop

|

|

Automatic compaction detection

|

Have

|

|

Hand /Automatic switching

|

Have

|

Adapted model

|

Equipment

|

Model

|

|

Paver

|

SSP90、SAP90、SSP130、SAP130

|

|

Single drum roller

|

SSR220、SSR260、SSR330、SSR360

|

|

Rubber-tired roller

|

SPR300

|

|

Double Steel Wheel Roller

|

STR130

|