It can not only realize functional restoration of old pipelines

And that pipeline doe not need to be connecte,“Disembowel”

It can shuttle flexibly in narrow areas.

But also can save resource and cost.

More Trenchless repair“Stunt”

What I want to introduce to you today is

Underground space“Special Forces”

Thermoplastic repair Vehicle and UV curing Vehicle

XGH5120XJXD6 Thermoplastic repair Vehicle

01 Thermoplastic construction,The operation is convenient

Thermoplastic forming repair process,Will be prefabricatedPVC The resin liner is heated and softened, and is pulled and placed into the pipeline to be repaired.,Take the original pipe as the mold,Continue to heat and pressurize through the steam engine,Make it fit tightly with the original pipeline.,Cooling and solidifying by using a cold drying machine,Form a layer“Tube in tube”,So as to achieve the purpose of pipeline repair.。The liner is prefabricated in the factory.,No curing in place、Grout。

02 Selected materials,Enhanced overcurrent

The liner tube is made of thermoplastic polymer material,Have reversibility,Capable of softening or hardening many times。During pressurization,The liner tube is simultaneously compressed,Decrease in wall thickness,And that Los of the pipe diameter is less。When the repair is complete,Significant increase in pipe flow capacity by 20 percent% Above,And that medium convey efficiency is greatly improved.,100% watertight,The repaired surface is smooth、Wear resistant,Strong corrosion resistance。

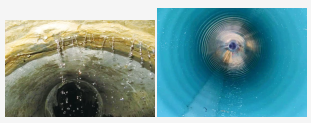

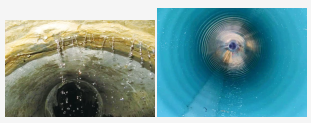

Comparison of thermoplastic repair before and after Trenchless repair

XGH5090XJXD6 UV Curing Vehicle

01 Photochemical reaction,Convenient and efficient

Curing by ultraviolet light,It's a photochemical process.,Curing and hardening of lining hose coating with high intensity UV light,Meet the requirements for normal use,And traditionCIPPCompared with the curing method,Simplify the operation process,Construction is more efficient,Faster,No need for water.,Operation process to traffic、Less impact on society and residents' lives。

02 Selected parts,Flexible and convenient

Large configuration、Small two kinds of lamp holder,Respectively applicableDN600~1600 andDN150~600 Pipeline repair,The maximum power is 5.2kWAnd 12kW,With auxiliary function of bulb opening,Eight light bulbs,The turn-on time is different for each bulb.,After the Bulb On auxiliary function is activated,IBGSet the interval time,The system ignites automatically,Pipe diameter wheel set,Quick Plug and Unplug Settings,Flexible operation on construction site。

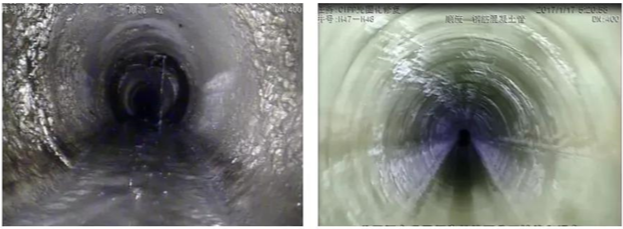

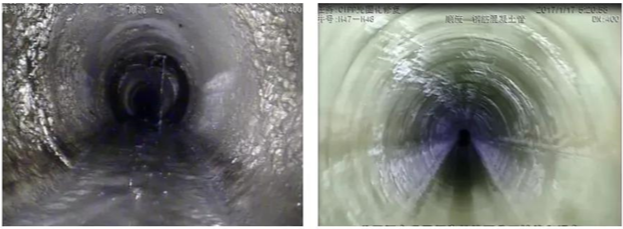

Comparison of UV curing before and after Trenchless restoration

Cast steel and iron

Gallop underground space

Realize Trenchless repair

Protect life with science and technology