Recently,Wirtgen-based synchronous paving process W 380 CR The cold recycling fleet has successfully applied the double-layer joint paving technology of foam asphalt in-situ cold recycling and cement in-situ cold recycling in the restoration project of Tuhe Expressway in Xinjiang Uygur Autonomous Region.。This is after the successful application of Wittgen's double-layer cold in-place recycling technology based on synchronous paving in road maintenance in many countries and provinces.(Click on the link to the previous issueUnderstand Xinjiang G335 Two-layer cold in-place recycling application case),It is the first time that it has been successfully applied to highway maintenance.,It has played a good demonstration benefit for promoting the transformation of green maintenance of expressway.,It has important reference significance.。

In this project,Two sets W 380 CR The cold recycling unit is constructed in sections and steps alternately.,Effectively shorten the construction period、Reduce traffic impact、While reducing construction costs, it also reflects the flexibility of this high-performance green road maintenance technology, which can be applied to a variety of application scenarios.。It also shows that W 380 CR Sustainability of Cold In-Place Reclaimer Construction,It saves a lot of new materials.,It also achieves significant energy saving and emission reduction benefits.,It provides green and low carbon for the repair and maintenance of national highways.、An efficient and economically feasible solution。

Project overview

G3012 Tuhe Expressway is a national expressway network. GOne of the connecting lines of 30,Since Turpan,Via Korla、Kuqa、 Aksu、Kashgar to Hotan,The total length is 1931 kilometers。G3012 Expressway is the east-west corridor in the central part of Xinjiang Uygur Autonomous Region.,It is also the main highway connecting northern and southern Xinjiang at present.。The implementation of this maintenance project will improve the traffic safety of the South Passage.、 Comfortable,It is of great significance to improve the service level of the South Passage.。

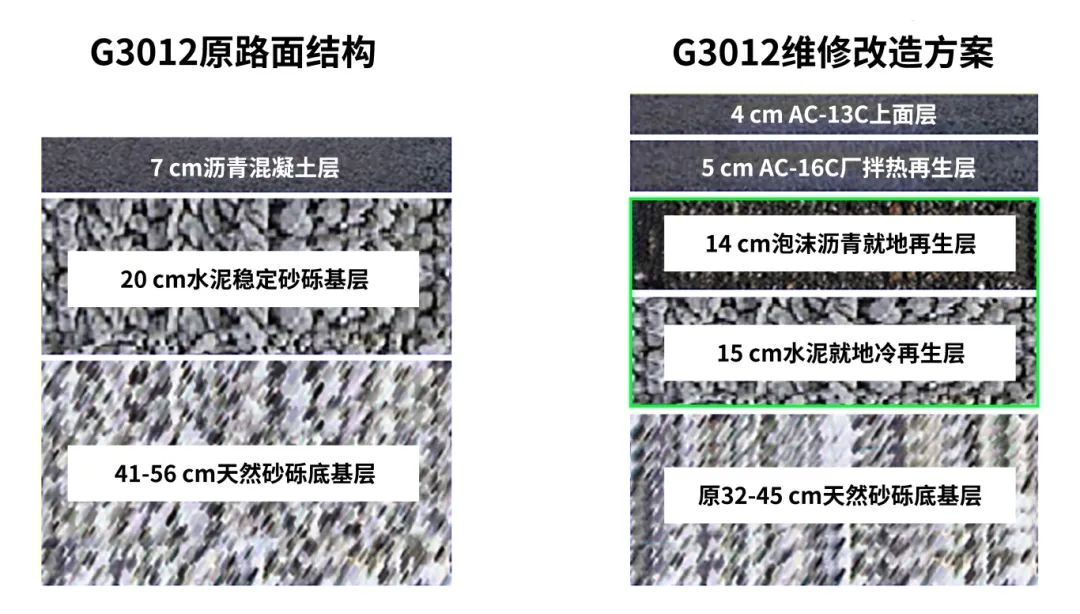

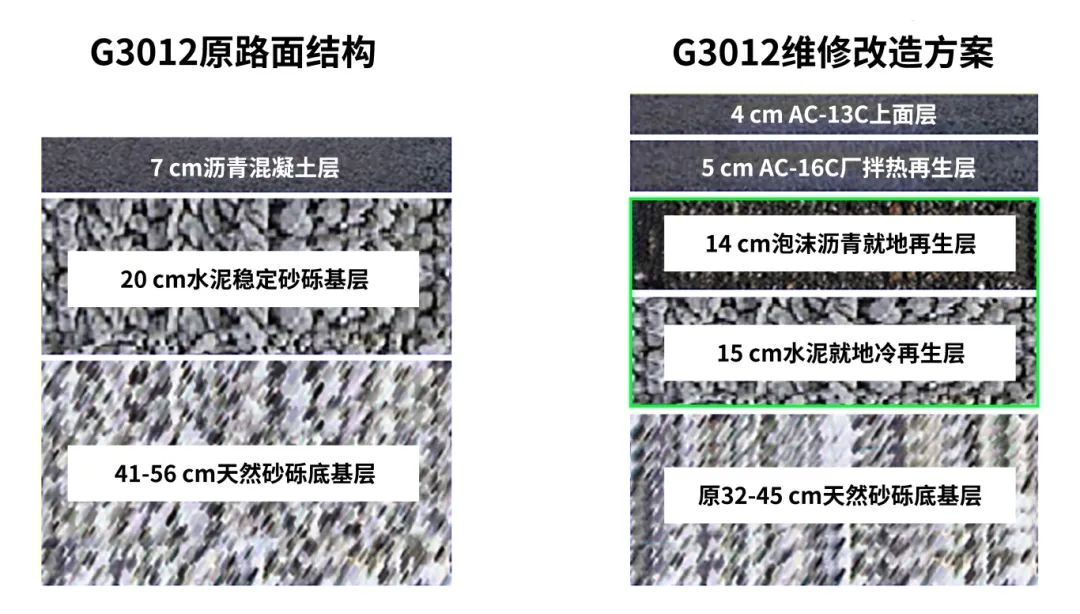

G3012 Uplink K609+000-K628+Section 000 is the utilization of the original G314 transformation section,Original pavement structure 3 cm AC-13Ⅰ+4 cm AC-20Ⅰ+20 cm Cement stabilized gravel base+41~56 cm Natural gravel subbase。It can be seen from the core drilling result,The base is seriously damaged,The apparent disease of the pavement is a large area of cracks.、Cracked and loose,The surface layer has been unable to meet the use requirements.。At the same time, this section is the Kuqa car market section.,It belongs to the open charging range.,The traffic volume is large,High proportion of heavy traffic,Therefore, deep structural maintenance is needed to meet the demand.。

Maintenance plan

Considering the service life、Climate temperature difference、Durable structure、Energy saving and emission reduction and other factors,Combined with the requirements of construction period,After investigation and analysis, it is decided to adopt the double-layer joint paving technology of foam asphalt cold in-place recycling and cement cold in-place recycling based on synchronous paving.,After that, the reconstruction scheme of the upper and lower surface layers is added.。

The specific scheme is as follow:Milling 7 first cm Surface layer,Then proceed to 15 cm Cement cold in-place recycling base course and 14 cm Synchronous double-layer cold recycling construction of foamed asphalt cold recycling layer,Carry out layer seal after curing,Final overlay 5 cm AC-16 C Plant Mix Hot Recycled Asphalt Concrete and 4 cm AC-13 C Upper layer of asphalt concrete。

Figure 1:Upgrading and Reconstruction Scheme of Tuhe Expressway

Before project construction,The construction party selected representative samples.,Relevant units are entrusted to carry out detailed indoor mix design.,Determined by laboratory test results:

The cement consumption of the cement cold in-place recycling mixture is 4.5%;

Optimum moisture content 5.8%;

The unconfined compressive strength of the specimen reaches 4.2 MPA;

The asphalt content of foam asphalt cold in-place recycling mixture is 3.2%;

Amount of foaming water 3.1%;

Cement consumption 1.8%;

Optimum moisture content 7.9%;

The ratio of dry and wet splitting strength is 94.9%;

60 ℃ The dynamic stability reaches 4121 times./mm。

Construction process

Spit and high speed GDouble-layer synchronous joint paving construction technology adopted by 3012,It is carried out by means of sectional and echelon construction.,Divide the 19km road section into 4 parts,This not only meets the needs of reducing the traffic impact of the expressway section reversal, but also meets the needs of the expressway section reversal.,But also can shorten that construction period.,And provide a good working surface for subsequent construction.。

The specific construction steps are as follow:

1.Milling first 7 cm Asphalt layer,Then spread the cement according to the design requirements.,Use a set W 380 CR The cold regeneration unit firstly carries out foam asphalt cold regeneration on the upper bearing layer,And that foam asphalt cold recycle mixture is conveyed to an asphalt Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicle for standby use.。

Figure 2:Construction process of cold in-place recycling of foam asphalt at high speed

2.Then the exposed lower bearing layer shall be evenly sprayed with cement according to the design amount.,Use another set W 380 CR Cement cold recycling construction on the spot by cold recycling unit,The cement cold in-place recycling material can be directly paved by a Paver.,And rolled by a Road Roller,Form a new semi-rigid base structure。

Figure 3:Paving and Compaction of Cement Cold In-place Recycled Materials at Turpan and High Speed

Figure 4:Paving and Compaction of Cement Cold In-place Recycled Materials at Turpan and High Speed

3.After testing and testing,After the compactness and other indicators meet the design requirements,The foamed asphalt mixture previously produced and stored in the Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicle for standby is synchronously paved on the upper part of the cement in-situ cold recycling layer,After compaction by roller,Forming a foam asphalt cold recycled concrete lower surface layer。Ynchronous curing of two regeneration layer,Not only the uniformity and timeliness of the hydration reaction of the cement in the cement stabilized gravel are promoted,,The strength of the structure is enhanced.,The probability of cracking is reduced,But also can obviously improve the continuity between the layers.,Thereby increasing the service life of the road surface.。

Figure 5:Paving and Compaction of Cold In-place Recycled Materials with High-speed Spinning and High-speed Foamed Asphalt

Figure 6:Surface state after spitting and high-speed two-layer cold in-place regeneration

Expected benefits

Double-layer cold in-place recycling technology based on synchronous paving is an effective solution for pavement rehabilitation and upgrading,Especially for the early pavement design standards are not high.,For projects that require upgrading,Have a higher value。Through the green low-carbon process,,GThe upgrade of 3012 high speed can achieve the following ideal expectations.:

98% More than 50% of the original pavement material is recycled.,Save a lot of new materials;

Decrease 90% Milling and round-trip transportation of materials,Significantly reduce transportation costs;

Regeneration speed of 5 meters per minute,Shorten the construction period by more than 50 percent%;

Save more than 70% energy consumption%,Reduce emissions 60% Above,Significant low carbon benefits;

Double-layer regenerative material synchronous curing,Reduce the impact of project construction on traffic by 45 percent%。

In fact,The double-layer cold in-place recycling technology based on synchronous paving has been very mature.,In recent years, the application area on national and provincial trunk roads and municipal roads has exceeded 6 million square meters.,Economic benefits、The social and environmental benefits are very significant.。This time in Xinjiang Uygur Autonomous Region,It is the first time to apply it on the highway.,However, its own advantages can fully meet the needs of highway upgrading and transformation.,It is believed that this technology can provide a more valuable choice for highway maintenance.。